925

FIBER

SENSORS

Thru-beam Type Ultrasonic Sensor

US-N300

Related Information

■■General terms and conditions.............. F-3

■■General precautions....................... P.1595

■■Selection guide...............................P.865~

LASER

SENSORS

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE SENSORS

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

LASER

MARKERS

PLC

HUMAN MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

FA COMPONENTS

panasonic.net/id/pidsx/global

Suitable for detecting transparent films�

or transparent bottles

Reliable detection of transparent objects

Only 16 mm 0.630 in thick

The sensor reliably

detects transparent films

or transparent objects.

Its 16 mm 0.630 in thick compact body allows mounting

in a narrow space.

MACHINE VISION

SYSTEMS

Simple operation mode selection

UV CURING

SYSTEMS

The operation mode can be selected either soundreceived-ON or sound-blocked-ON simply by changing

the connection of the control input wire.

Selection

Guide

Liquid Leak

Detection

Liquid Level

Detection

Water

Detection

Color Mark

Detection

Wafer

Detection

APPLICATIONS

Detecting transparent film or

transparent glass

Detecting transparent bottles

Detecting transparent and

opaque objects

Ultrasonic

Small / Slim

Object Detection

Obstacle

Detection

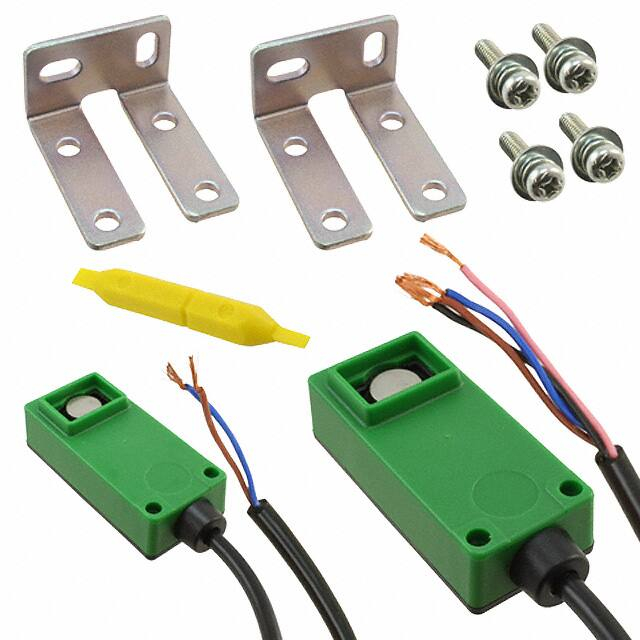

ORDER GUIDE

US-N300

Thru-beam

5 m 16.404 ft 2 m 6.562 ft

cable length cable length

Type

Appearance

Sensing range

Model No.

(Note)

Output

Accessory

・M

� S-N30

(Sensor mounting bracket)

US-N300

300

mm

�

11.811 in

NPN transistor

universal

US-N300-C5

Note: Models whose model name on the product nameplate is followed by “P” are transmitter, while those

whose model name is followed by “D” are receiver.

Two M4

(length 15 mm 0.591 in)

screws with washers

are attached.

�Thru-beam Type Ultrasonic Sensor

US-N300

SPECIFICATIONS

FIBER

SENSORS

Type

Item

926

LASER

SENSORS

Thru-beam

PHOTOELECTRIC

SENSORS

US-N300

Model No.

Sensing range

300 mm 11.811 in

Sensing object

Transparent, translucent or opaque object: 20 × 20 mm 0.787 × 0.787 in or more, Hole: 10 × 10 mm 0.394 × 0.394 in or more

Supply voltage

12 to 24 V DC ±10 % Ripple P-P 10 % or less

AREA

SENSORS

Transmitter: 35 mA or less, Receiver: 35 mA or less

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

Current consumption

NPN transistor universal

• Maximum sink current: 100 mA

• Residual voltage: 1 V or less (at 100 mA sink current)

Output

Output operation

INDUCTIVE

PROXIMITY

SENSORS

Incorporated

Response time

PARTICULAR

USE

SENSORS

5 ms or less

Operation indicator

Red LED (lights up when the output is ON)

Sensitivity adjuster

Continuously variable adjuster

Transmission frequency

Environmental resistance

PRESSURE /

FLOW

SENSORS

Selectable either sound-received-ON or sound-blocked-ON by the control input

Short-circuit protection

SENSOR

OPTIONS

SIMPLE

WIRE-SAVING

UNITS

220 kHz approx.

Protection

IP62 (IEC)

0 to +50 °C +32 to +122 °F (No dew condensation), Storage: -25 to +70 °C -13 to +158 °F

Ambient temperature

Ambient humidity

35 to 85 % RH, Storage: 35 to 85 % RH

Voltage withstandability

1,500 V AC for one min. between all supply terminals connected together and enclosure

Insulation resistance

20 MΩ, or more, with 500 V DC megger between all supply terminals connected together and enclosure

Vibration resistance

10 to 55 Hz frequency, 1.5 mm 0.059 in double amplitude in X, Y and Z directions for two hours each

100 m/s2 acceleration (10 G approx.) in X, Y and Z directions three times each

Shock resistance

Material

Extension up to total 100 m 328.084 ft is possible, for both transmitter and receiver, with 0.2 mm2, or more, cable.

Weight

Transmitter: 80 g approx., Receiver: 85 g approx.

MS-N30 (Sensor mounting bracket): 1 set for transmitter and receiver, Adjusting screwdriver: 1 pc.

Accessories

Note: Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +23 ˚C +73.4 ˚F.

I/O CIRCUIT AND WIRING DIAGRAMS

I/O circuit diagram

Sensor circuit

Tr

Color code

Load

+

(Black) Output

100 mA max.

(Blue) 0 V

(Pink) Control input

Internal circuit

ENERGY

MANAGEMENT

SOLUTIONS

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

Selection

Guide

Brown

D1

ZD

LASER

MARKERS

Wiring diagram

(Brown) + V

4.7 kΩ

STATIC

CONTROL

DEVICES

UV

CURING

SYSTEMS

Color code

D2

MEASUREMENT

SENSORS

HUMAN

MACHINE

INTERFACES

0.2 mm2 4-core (transmitter: 2-core) cabtyre cable, 2 m 6.562 ft long

Cable extension

WIRE-SAVING

SYSTEMS

PLC

Enclosure: Polycarbonate

Cable

MICRO

PHOTOELECTRIC

SENSORS

-

12 to 24 V DC

±10 %

Load

Black

Liquid Leak

Detection

+

-

12 to 24 V DC

±10 %

Blue

*1

Pink

Symbols... D1: Reverse supply polarity protection diode

D2: Reverse current protection diode

ZD: Surge absorption zener diode

Tr : NPN output transistor

Water

Detection

Color Mark

Detection

*1

Wafer

Detection

Ultrasonic

Users’ circuit

Note: The transmitter has only two power supply wires (+V and 0 V).

Liquid Level

Detection

Small / Slim

Object Detection

*1

Non-voltage contact, NPN open-collector transistor or

NPN non-contact transistor

Obstacle

Detection

US-N300

or

or

• Control input

Low (-0.5 to +1.5 V, or connected to 0 V): Sound-received-ON

High (6 V to supply voltage, or open): Sound-blocked-ON

�927

Thru-beam Type Ultrasonic Sensor

SENSING CHARACTERISTICS (TYPICAL)

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

400

15.748

300

11.811

Sensing field

400

15.748

ℓ

200

7.874

L

100

3.937

0

40

1.575

200

7.874

200

7.874

Transmitter

Receiver

Transmitter

100

3.937

20

0

20

40

0.787

0.787

1.575

Left

Center

Right

Operating point ℓ (mm in)

Receiver 50 × 50 mm 1.969 × 1.969 in

Sound insulation board

ℓ

300

11.811 300

11.811

300

11.811

100

3.937

θL

0

40

Receiver

20

0

20

Left

Center

Right

Operating angle θ (°)

L

Transmitter

40

0

20

0.787

10

0

10

20

0.394

0.394

0.787

Left

Center

Right

Operating point ℓ (mm in)

PRECAUTIONS FOR PROPER USE

SIMPLE

WIRE-SAVING

UNITS

• Never use this product as a sensing device

for personnel protection.

• In case of using sensing devices for

personnel protection, use products which

meet laws and standards, such as OSHA,

ANSI or IEC etc., for personnel protection

applicable in each region or country.

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

STATIC

CONTROL

DEVICES

LASER

MARKERS

Angular deviation

400

15.748

Setting distance L (mm in)

MICRO

PHOTOELECTRIC

SENSORS

Parallel deviation

Setting distance L (mm in)

PHOTOELECTRIC

SENSORS

Setting distance L (mm in)

FIBER

SENSORS

LASER

SENSORS

US-N300

Refer to p.1595 for general precautions.

Influence of background objects

• If sensor heads are installed as shown in the figure

below, the operation may become unstable by the

reflected sound wave.

An object, hard and

plain like a glass plate,

reflects the sound

wave.

Background

Mounting

• The tightening torque should be 0.49 N·m or less.

PLC

Transmitter

HUMAN

MACHINE

INTERFACES

ENERGY

MANAGEMENT

SOLUTIONS

Receiver

Placed perpendicular

to the sensing axis.

Sensing object

The receiver should be placed away from the object and at

an angle to it as shown below.

FA

COMPONENTS

MACHINE

VISION

SYSTEMS

M4 (length

15 mm 0.591 in)

screws with

washers

UV

CURING

SYSTEMS

Receiver

Sensor mounting

bracket

MS-N30

(Accessory)

10° approx.

Transmitter

Object

Selection

Guide

Liquid Leak

Detection

Liquid Level

Detection

Water

Detection

Color Mark

Detection

Wafer

Detection

Ultrasonic

Small / Slim

Object Detection

Obstacle

Detection

US-N300

Mutual interference

Sensitivity adjustment

• Normally, use the sensor at the maximum sensitivity.

However, if the sensing is not proper due to surrounding

objects (reflection from surrounding objects, etc.), adjust

the sensitivity.

• When two or more sensors are mounted close together,

the sensors may not enter the “sound-blocked state” due

to mutual interference.

Parallel mounting

Influence of surrounding objects

Influence of an object parallel to the sensing axis

• If there is a wall or a curtain near the sensing axis, the

sound reflection may cause the operation to be unstable.

Face-to-face mounting

①

Receiver Transmitter

Transmitter

Transmitter

Receiver

Transmitter

Receiver

Keep a distance of 10 mm 0.394 in or more

Sensing axis

Receiver

②

Transmitter

Keep a distance of 20 mm 0.787 in or more

Wall or curtain

Receiver

Keep a distance of

100 mm 3.937 in or more

Transmitter

Receiver Receiver Transmitter Transmitter

Back-to-back mounting is possible.

�Thru-beam Type Ultrasonic Sensor

PRECAUTIONS FOR PROPER USE

Traveling speed and minimum sensing object width

• Minimum sensing object width is 20 × 20 mm 0.787 ×

0.787 in in the stationary condition.

The minimum sensing width of a traveling object is

related to the traveling speed and the sensor response

time by the following formula.

W = VT + A (m)

W : Minimum sensing object width (m)

V : Traveling speed of the object (m/sec.)

T : Sensor response time = 0.005 (sec.)

A : M

� inimum sensing object width in the stationary condition

= 0.02 0.066 (m ft)

Example: �If V = 10 m 32.808 ft /sec.

W=

� 10 32.808 × 0.005 0.016 + 0.02 0.066

= 0.07 m 0.230 ft

= 70 mm 2.756 in

US-N300

928

Refer to p.1595 for general precautions.

FIBER

SENSORS

LASER

SENSORS

Others

• Do not use during the initial transient time (50 ms) after the

power supply is switched on.

• The ultrasonic sound propagates through the air.

If the sensor is used at a place where air blows or the

temperature suddenly changes (near a door, an air

conditioner, etc.) the operation may become unstable.

Avoid using US-N300 at such places.

• Take care that the sensor may malfunction due to an

intense extraneous sound, such as, metal impact sound.

• Do not expose the transmitting element or the receiving

element to moisture or dust. It may affect the sensing

operation.

PHOTOELECTRIC

SENSORS

MICRO

PHOTOELECTRIC

SENSORS

AREA

SENSORS

SAFETY LIGHT

CURTAINS /

SAFETY

COMPONENTS

PRESSURE /

FLOW

SENSORS

INDUCTIVE

PROXIMITY

SENSORS

PARTICULAR

USE

SENSORS

SENSOR

OPTIONS

DIMENSIONS (Unit: mm in)

The CAD data can be downloaded from our website.

US-N300

Sensor

SIMPLE

WIRE-SAVING

UNITS

WIRE-SAVING

SYSTEMS

MEASUREMENT

SENSORS

12.1 0.476

12.6 0.496

STATIC

CONTROL

DEVICES

8.3 7.4

Sensitivity adjuster (receiver only)

0.327 0.291

Operation indicator (Red) (Receiver only)

20

0.787

(2)

28

16

(0.079)

1.102

0.630

LASER

MARKERS

PLC

13 0.512

HUMAN

MACHINE

INTERFACES

60

2.63243

1.693

ENERGY

MANAGEMENT

SOLUTIONS

FA

COMPONENTS

7.5 0.295

2-M4 × 0.7 0.028

thru-hole threads

4

0.157

MACHINE

VISION

SYSTEMS

ø4.8 ø0.189 cable, 2 m 6.562 ft long

ø13

ø0.512

20

0.787

UV

CURING

SYSTEMS

MS-N30

Sensor mounting bracket (Accessory)

Assembly dimensions

12 4

0.472 0.157

4.3

0.169

19

0.748

4.3

0.169

37

32

1.457 1.260

20

0.787

30

1.181

20

0.787

4

0.157

t2

t 0.079

20

0.787

4.3

0.169

Selection

Guide

Liquid Leak

Detection

4

32 39

0.157 1.260 1.535

4.3

0.169

Liquid Level

Detection

Water

Detection

(2)

(0.079)

Color Mark

Detection

28

Wafer

Detection

Ultrasonic

8 0.315

Small / Slim

Object Detection

88

3.465 75

2.953

20 0.787

12 0.472

Mounting drawing

with the receiver

4

0.157

4-ø4.3

ø0.169 holes

Material: Cold rolled carbon steel (SPCC)

Two M4 (length 15 mm 0.591 in) screws with washers are attached.

32 28

1.260 1.102 12

0.472

5

0.197

Obstacle

Detection

20

0.787

30

1.181

4-ø4.3 ø0.169

holes

5

0.197

t2

t 0.079

19

0.748

35

1.378

39

1.535

US-N300

�

很抱歉,暂时无法提供与“US-N300-P”相匹配的价格&库存,您可以联系我们找货

免费人工找货