NX3215SA-32.768KHZ-EXS00A-MU00746 数据手册

Document No. EXS11B-06127 1 / 10

REFERENCE SPECIFICATION

Customer:

Item:

CRYSTAL UNIT

Type:

NX3215SA

Nominal Frequency:

32.768kHz

Customer’s Spec. No.:

For your reference we submit this

specification.

Please study and keep in your

related document file.

---

NDK Spec. No.:

EXS00A-MU00746

Charge:

Sales

Engineer

Revision Record

Rev.

Date

Items

Contents

Approved

Checked

Drawn

---

17.Jun.2015

Issue

---

S.Sunaba

S.Kawanishi

Y.Hasuike

NIHON DEMPA KOGYO CO., LTD.

Form P-1E (2014.2.2)

�Document No. EXS11B-06127 2 / 10

1. Customer’s Spec. No.

: ---

2. NDK Spec. No.

: EXS00A-MU00746

3. Type

: NX3215SA

4. Electrical Specifications

Parameters

4.1 Nominal Frequency

SYM.

Electrical Spec.

MIN

TYP

MAX

Notes

UNITS

Fnom

32.768

kHz

-

-

Fundamental

-

-

CL

7.0

pF

Network Analyzer

(CNA-LF made in Transat corp.)

4.4 Frequency Tolerance

-

+/-20

ppm

at +25 +/-3C ,Not include aging

4.5 Turning Point

-

+25 +/-5

C

4.6 Temperature coefficient

-

-

-

-0.04 ppm/ C2 -

4.7 Operating Temperature range

-

-40

~

+85

4.8 Aging

-

4.2 Oscillation Mode

4.3 Load Capacitance

+/-3

C

-

-

ppm

1st year (at +25C)

4.9 Drive level

DL

-

0.1

1.0

uW

-

4.10 Equivalent Resistance

Rr

-

-

70

kΩ

Network Analyzer

(CNA-LF made in Transat corp.)

4.11 Shunt Capacitance

C0

0.5

1.0

1.5

pF

-

4.12 Insulation Resistance

-

500

-

-

MΩ

Terminal to terminal insulation

resistance must be 500MΩ (Min.)

when DC100V 15V is applied.

4.13 Storage Temperature range

-

-40

~

+85

C

-

C1

2.0

4.0

6.0

fF

Network Analyzer

(CNA-LF made in Transat corp.)

4.14 Motional Capacitance

5. Examination results document

Since a performance is guaranteed, an examination results document does not submit.

6. Application drawing

6.1 Dimension drawing

6.2 Taping and reel figure

6.3 Holder marking

6.4 Reel Packing

6.5 Reliability assurance Item

: EXD14B-00462

: EXK17B-00303

: EXH11B-00422

: EEK17B-00015

: EXS30B-00952

NIHON DEMPA KOGYO CO., LTD.

Form P-5E

�Document No. EXS11B-06127 3 / 10

7. Notice

7.1 Order items are manufactured according to specification. As to conditions, which are not indicated in

this specification and unpredictable such as applied condition and oscillation margin, please check

them beforehand.

7.2 Unless we receive request for modification within 3 weeks from the issue date of this NDK

specification sheet, we will supply products according to this specification. Also, if you’d like to modify

specification of order, which has been placed with delivery request within 3 weeks from the issue data

of this specification sheet, we would like to discuss with you separately.

7.3 In no event shall the company be liable for any product failure resulting from an inappropriate handling

or operation of the product beyond the scope of its guarantee.

7.4 Where any change to the process condition is made due to the change(s) in the production line, inform

personnel of the specifications.

7.5 Should this specification data give rise to any disputes relating to any intellectual property rights or any

other rights of a third person, the company shall not indemnify anyone for any damage. Their disclosure

must not be construed as the grant of a license to use any of the intellectual property rights owned by

the company.

7.6 If you intend to use products listed on this specification for applications that may result in loss of life or

assets (controls relating to safety, medical equipment, aeronautical equipment, space equipment, etc.),

please do not fail to advise us of your intention beforehand.

7.7 In the company’s production process whatever amount of ozone depleting substances (ODS) as

specified in the Montreal protocol is not used.

7.8 Information contained in this specification must not be quoted, reproduced or used for other purposes

including processing either in part or in full without obtaining prior approval from the company.

7.9 The appearance color and so on have a different case by purchasing it more than 2 suppliers of the

component, but characteristic and reliability are guaranteed.

7.10 Crystal units will be damaged by ultrasonic welding process due to resonance of crystal wafer itself.

NDK does not recommend using ultrasonic welding. If Ultra Sonic welding used, NDK strongly

recommend verifying crystal unit damage by ultrasonic weld.

8. Prohibited items

Be sure to use the product under the following conditions. Otherwise, the characteristics deterioration or

destruction of the product may result.

(1)Reflow soldering heat resistance

Peak temperature

: 265C, 10 sec

Heating

: 230C or higher, 30 sec

Preheating

: 150C to 180C, 120 sec

Reflow passage times : twice

(2)Manual soldering heat resistance

Pressing a soldering iron of 400C on the terminal electrode for four seconds (twice) .

NIHON DEMPA KOGYO CO., LTD.

Form P-5E

�Document No. EXS11B-06127 4 / 10

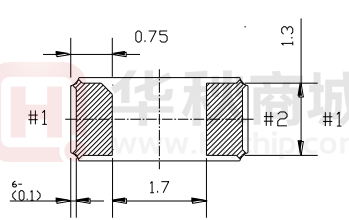

Cover:Metal

Base:Ceramics

INTERNAL CONNECTION

(TOP VIEW)

Recommended soldering pattern

Date of Revise

B

10.May.2012

Charge

Hasuike

Approved

Matsudo

Reason

Add bilingual

Date

Name

Third Angle Projection

Tolerance

Drawn

30.Aug.2009

Dimension:mm

±0.2

Designed

Checked

30.Aug.2009

Approved

30.Aug.2009

Miyahara

Miyahara

--K. Ueki

---

Title

Drawing No.

NX3215SA

EXD14B-00462

External Dimension

NIHON DEMPA KOGYO CO., LTD.

Scale

10 / 1

Rev.

B

Form M-1

�Document No. EXS11B-06127 5 / 10

40.0 0.15(4×10P)

TOP TAPE material :

polyethylene terephthalate

4.0 0.1

+0.1

1.5 0

2.0 0.1

1.7 0.1

1.0 0.1

4.0 0.1

3 max

12.0 0.3

0.3 0.05

3.4 0.1

5.5 0.05

1.75 0.1

PULL DIRECTION

1.0 0.1

DIRECTION OF UNIT

3215 TYPE HOLDER

NA

NA

NA

TAPING material: Conductive PS

Pull direction

MIN.250mm

MIN. 160mm

Cover tape

(End)

B

Products

Empty pockets

MIN. 150mm

MIN. 250mm

Empty pockets

Cover tape

(Start)

MAX. 3000 pcs

Date of Revise

24.Apr.2013

Charge

Sato

Date

Name

Drawn

9.Jul.2009

Designed

Checked

9.Jul.2009

Approved

9.Jul.2009

N.Yamamoto

N.Yamamoto

--K.Ueki

---

Approved

Matsudo

Reason

Added English

Third Angle Projection

Tolerance

mm

Title

3215 TYPE Taping and Reel Spec.

Scale

/

Drawing No.

EXK17B-00303 1/2

Rev.

B

NIHON DEMPA KOGYO CO., LTD.

Form M-1

�Document No. EXS11B-06127 6 / 10

2.0±0.2

φ180

φ60

+0

-3

+1

-0

10.5±0.4

φ13.0±0.2

LABEL

13.0±0.3

QTY.

15.4±1.0

Reel material: Conductive PS

3,000 PCS

EIAJ standard reel

START

BEGIN

CLOSE

1

2

4

4

2

END

3

B

Date of Revise

24.Apr.2013

Charge

Sato

Date

Name

Drawn

9.Jul.2009

Designed

Checked

9.Jul.2009

Approved

9.Jul.2009

N.Yamamoto

N.Yamamoto

--K.Ueki

---

Approved

Matsudo

Reason

Added English

Third Angle Projection

Tolerance

mm

Title

3215 TYPE Taping and Reel Spec.

Scale

/

Drawing No.

EXK17B-00303 2/2

Rev.

B

NIHON DEMPA KOGYO CO., LTD.

Form M-1

�Document No. EXS11B-06127 7 / 10

Trace code(Product data and Line number)

#2

#1

Month Code (See Table)

Year Code (Last One Digit)

Frequency Code

Manufacture's Symbol

#2

#1

NOTE

1. Month Code

Month

Month Code

1

Jan.

2

3

Feb. Mar.

1

2

3

4

Apr.

5

6

May June

4

5

6

7

July

7

8

9

Aug. Sep.

8

9

10

Oct.

11

12

Nov. Dec.

X

Y

Z

2. Frequency Code

A : 32.768kHz

3. Marking Method

Marking Method is Laser Triming.

Date of Revise

Date

Drawn

28.OCt.2009

Designed

Checked

28.OCt.2009

Approved

28.OCt.2009

--

Charge

Name

Miyahara

Miyahara

-Ueki

Approved

Reason

Third Angle Projection

Dimension:mm

Title

Tolerance

Drawing No.

NX3215SA

Marking Drawing

Scale

/

Rev.

EXH11B-00422

NIHON DEMPA KOGYO CO., LTD.

Form M-1

�Document No. EXS11B-06127 8 / 10

Spacer

Material: Paper

φ180 reel

Pasteboard

Material: Corrugated paper

A sleeve is inserted when reels are 1 to 4.

Shock pad

Material:Corrugated paper

154

Sleeve

Material:Corrugated paper

Label

21

0

C

Date of Revise

4 Jul. 2012

0

21

Charge

H.Ohkubo

Date

Name

Drawn

26 Feb. 2010

Designed

Checked

26 Feb. 2010

26 Feb. 2010

H. Ohkubo

K.Oguri

K.Oguri

Approved

26 Feb. 2010

J. Nakamura

Approved

K.Oguri

Outer box

Material: Corrugated paper

Reason

Addition of condition when reels are 1 to 4.

Third Angle Projection

Dimension:mm

Title

180 dia. Reel package

Tolerance

--------Drawing No.

EEK17B-00015

Scale

--------Rev.

C

NIHON DEMPA KOGYO CO., LTD.

Form M-1

�Document No. EXS11B-06127 9 / 10

Reliability assurance item

(page: 1/2)

Specification

Code

No.

Test Item

Test Methods

1

AGING

1 year at 25 C +/- 3C

A

2

HEAT RESISTANCE

at 85 C for 500 hours.

B

3

COLD RESISTANCE

at –40 C for 500 hours.

B

4

HUMIDITY

at +85 C with 80 to 85 % RH for 500 hours.

B

Temperature cycle as shown in (Fig.1) for 100 cycle.

30 minutes

+85±3℃

5

THERMAL SHOCK

-40±3℃

30 minutes

B

ONE CYCLE (Fig.1)

6

VIBRATION

7

SHOCK 1

Frequency Range

Amplitude or Acceleration

1 cycle

Test time

Shock

Test time

: 10 to 2000Hz

: 1.52 mm or 20 G

: 20 minutes

: Three mutually perpendicular

axes each 12 times.

: 3000 Gs 0.3 msec.

: Six mutually perpendicular axes each 1 times.

B

Shock

8

SHOCK 2

9

SOLDERABILITY

10

REFLOW

RESISTANCE

: Device are put on the weight of 200 g and

dropped on concrete board.

Height

: 1.5 m

Drop times : Six mutually perpendicular axes each 10 times.

Residual heat temperature : 150 C

Residual heat time

: 60 to 120 sec

Peak temperature

: 240C

(more than 215 C 10 to 30 sec)

B

Temperature cycle as shown in (Fig2.) for 3 cycle.

Specification code

A

B

C

D

C

D

B

Specification

dF/F +/- 3ppm

dF/F +/- 5ppm

dCI +/- 5 kohm

dF/F +/- 15ppm

dCI +/- 5 kohm

The electrodes shall acquire a new solder coat over at least 90 % of immersed

area.

Reliability assurance item: EXS30B-00952A

NIHON DEMPA KOGYO CO., LTD.

Form M-3

�Document No. EXS11B-06127 10 / 10

(page: 2/2)

C

260 C

230 C

B

100 C

A

0

50

100

150

200

sec.

Fig.2 REFLOW

A: 150 to 180 C ( 60 to 120 sec. )

B: 230 C min. ( 30 sec. max. )

C: PEAK-TEMP. 260 C +/- 5 C ( 10sec. max. )

Reliability assurance item: EXS30B-00952A

NIHON DEMPA KOGYO CO., LTD.

Form M-3

�

NX3215SA-32.768KHZ-EXS00A-MU00746 价格&库存

很抱歉,暂时无法提供与“NX3215SA-32.768KHZ-EXS00A-MU00746”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 5+2.32384

- 50+1.84475

- 150+1.63955

- 500+1.38338

- 3000+1.26933