NZ2520SH-24MHZ-ERG5007B 数据手册

Document No. EKS11B-01799C 1/9

REFERENCE SPECIFICATION

Customer: JUDE

Item:

Simple Packaged Crystal Oscillator

(SPXO)

Type:

NZ2520SH

Nominal Frequency:

For your reference we submit

this specification.

Please study and keep in your

related document file.

24 MHz

Customer’s Spec. No.:

---

NDK Spec. No.:

ERG5007B

Revision Record

Rev.

Date

---

24.Sep.2015

A

9.Oct.2015

B

24.Oct.2018

C

8.Oct.2019

Items

Contents

Approved

Checked

Issue

---

Y.Akasaka

---

T.Wada

3.Type

Change

Y.Akasaka

---

C.Sakurai

Y.Akasaka

H.Okajima

C.Sakurai

Y.Akasaka

---

R.Saito

5.7 Operating Temperature Range

-40 to +85 °C-40 to +105 °C

5.8 Overall Frequency Tolerance

8.1 Dimension drawing

8.2 Marking drawing

8.3 Reliability assurance Item

5.7 Operating Temperature Range

5.8 Overall Frequency Tolerance

Add (+/-50ppm at -40 to +105 °C)

EKD14B-00027(Rev. CRev. E)

EKH11B-00052(Rev. HRev. K)

EKS30B-00060(Rev. CRev. E)

-40 to +105 °C -40 to +125 °C

Add (+/-80ppm at -40 to +125°C)

8.1 Dimension drawing

EKD14B-00027(Rev. ERev. F)

NIHON DEMPA KOGYO CO., LTD.

Drawn

Form P-4E

�Document No. EKS11B-01799C 2/9

1. Customer’s Spec. No.

: ----------

2. NDK Spec. No.

: ERG5007B

3. Type

: NZ2520SH

4. Maximum Ratings

Ratings

Item

1 Supply Voltage

2 Storage Temperature Range

min

max

Units

-0.3

-55

4.0

+125

V

C

Notes

5. Electrical Specifications

(Unless otherwise noted, TA=-40 to +125 C, VCC=1.8 V, Load=15 pF)

Parameters

1

2

3

4

5

6

7

SYM

Nominal Frequency

Supply Voltage

Current Consumption (Operating)

Current Consumption (Stand-by)

Output Level

Load Capacitance

Operating Temperature Range

8 Overall Frequency Tolerance

fnom

VCC

ICC

IST

CL

Topr

f/fnom

VOL

VOH

tr/tf

SYM

tsu

-

9 Output Voltage

10

11

12

13

Electrical Spec.

min

typ

1.62

24

1.8

-40

-20

-30

-50

-80

0.9 VCC

max

1.98

4.0

20

C-MOS

15

+125

+20

+30

+50

+80

0.1 VCC

Units

MHz

V

mA

A

pF

C

ppm

ppm

ppm

ppm

V

V

ns

%

ms

Notes

at 25C

at 25C

at -30 to +75 C*1

at -40 to +85 C*1

at -40 to +105 C*1

at -40 to +125 C*1

Rise Time(tr), Fall Time(tf)

6

0.1 VCC to 0.9 VCC

Symmetry

45

55

at 1/2 VCC

Start-up Time

4

Output Wave Form

Rectangular

Stand-by Function

#1 PAD input

# 3 PAD output

14

H level (0.7 VCC to VCC) or open

Operating

L level (0.3 VCC max)

High impedance

*1 Inclusive of Freq. tolerance (at 25 C), frequency/temperature characteristics, frequency/voltage coefficient.

tr

tf

VOH

0.9VCC

1/2 VCC

0.1VCC

0V

VO L

t

T

Symmetry

t / T 100 ( % )

NIHON DEMPA KOGYO CO., LTD.

Form P-3E

�Document No. EKS11B-01799C 3/9

6. Measuring circuits

VCC

A

Cby

OS

4

3

X

1

FC

2

CL

V

CL ; 15pF MAX including input capacity of oscilloscope

Cby ; Bypass capacitor (0.01uF)

7. Test data will not be submitted.

8. Application drawing

8.1 Dimension drawing

EKD14B-00027

8.2 Marking drawing

EKH11B-00052

8.3 Reliability assurance Item

EKS30B-00060

8.4 Taping & Reel drawing

EKK17B-00032

EEK17B-00015

9. Instruction Notice

9.1 Noise

When the NZ2520 series are used, the 0.01 F capacitor should be connected between VCC and GND line.

(Closer to the product terminal is desirable.)

9.2 Resistance to dropping

The NZ2520 series is designed to be impactproof so that no damage occurs when dropped a height(75 cm)

three times. However, if dropped from a desk etc., it is advisable to check their performance or contact us to

check it.

9.3 Electrostatic protection

The NZ2520 series employ C-MOS ICs for the active element. Please use them in static-free environments.

9.4 High temperature

Normal operation cannot be guaranteed for the NZ2520 series at +125 C (for 24 hours). Be sure that the units

are kept within the specified temperature range.

9.5 Cleaning

Basically, the NZ2520 series are applicable for ultrasonic wave cleaning. However, in some case, during

ultrasonic wave cleanings, internal design may get damage. Please check condition carefully beforehand.

9.6 Other

The NZ2520 series are C-MOS applied products. And careful handling(same as with C-MOS IC) are needed

to avoid electrostatic problems.

Incorrect PAD connection is cause of trouble. Please make sure to connect correctly as below.

#2 terminal GND

#4 terminal VCC

10. Order items are manufactured according to specification. As to conditions, which are not indicated in

this specification and unpredictable such as applied condition and oscillation margin, please check them

beforehand.

NIHON DEMPA KOGYO CO., LTD.

Form P-3E

�Document No. EKS11B-01799C 4/9

*Example For Soldering Conditions (The below graph corresponds to Pb free solder)

300

Peak 260 ± 5 degC / 10sec. Max

250

Temperature(degC)

4.5degC/s Max

4.5degC/s Max

200

150

150-180degC

90 ± 30 sec.

230degC over

30 ± 10sec.

100

4.5degC/s Max

50

0

Time

NIHON DEMPA KOGYO CO., LTD.

Form P-3E

�Document No. EKS11B-01799C 5/9

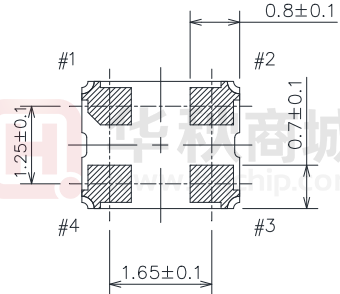

Terminal land connections

#1 STAND-BY

#2 GND

#3 OUTPUT

#4 VCC

Land pattern (Recommended)

F

Date of Revise

19.Sep.2019

Charge

C.Sakurai

Date

Name

Drawn

23.Oct.2003

M.Yamaguchi

Designed

Checked

27.Jun.2003

M.Yamaguchi

Approved

23.Oct.2003

-----

----H.Omata

Approved

Reason

Add Land pattern (Recommended)

Y.Akasaka

Third Angle Projection

Tolerance

Dimension : mm

------Title

NZ2520S

Dimension of External

Drawing No.

EKD14B-00027

Scale

-------Rev.

F

NIHON DEMPA KOGYO CO., LTD.

Form M-1

�Document No. EKS11B-01799C 6/9

2

1

DOT MARK

#1 PIN LOCATION

4

MANUFACTURES LOGO

3

1 [FREQUENCY]

Digits are five and 6TH digit will be omitted.

MHz unit sign is not marked.

ex, ) 28.63636MHz 28.636 [Unit sign not marked]

2 [MODEL MARK]

A last digit of model is marked.

[MODEL MARK]

NZ2520SA Space

NZ2520SB

B

NZ2520SC

C

NZ2520SD

D

NZ2520SDA

D

NZ2520SEA

E

NZ2520SEB

E

NZ2520SF

F

NZ2520SG

G

NZ2520SH

H

NZ2520SHA

H

NZ2520SHB

H

NZ2520SHC

H

NZ2520SJ

J

3 [WEEK CODE (Digit are three)]

ex1,) In case of 7TH week of 2006

6 0 7

Week No. (Digit are two)

Lower one digit of year

ex2,) In case of 31TH week of 2006

6 3 1

4 [Trace code]

Trace code consists of four digits number or letter.

This code indicates production date and production line number.

K

Date of Revise

12.Apr.2018

Date

Charge

Y.Okajima

Approved

S.Murase

Name

Drawn

27.Jan.2006

Y.Oishi

Designed

Checked

Approved

27.Jan.2006

27.Jan.2006

27.Jan.2006

Y.Okajima

C.Ishimaru

H.Omata

Reason

Model mark addition.(NZ2520SHB,SHC)

Third Angle Projection

mm

Title

Tolerance

Scale

-------

-------

Drawing No.

NZ2520S Marking

NIHON DEMPA KOGYO CO., LTD.

EKH11B-00052

Rev.

K

Form M-1

�Document No. EKS11B-01799C 7/9

Environmental Test Conditions

Specification

1.Thermal Shock Test

1 cycle -40C (30 minutes) +85C(30 minutes)

1

Number of cycle: 100 cycle.

2.High Temperature High Humidity Test

Temperature +85C, Humidity 80 85%,

1

Time 250 hours.

3.+85C Aging (Non Operating)

1

Temperature +85C, Time 500 Hours.

4.Vibration Test

MIL-STD-202F test method:204D

Test condition D

1

10 2000Hz, 1.52mmp-p, or 196m/s2

20 minutes/cycle, XYZ 3 directions 4 times.

5.Shock Test

MIL-STD-202F test method 213B

1

Test condition Half sinusoidal wave

29400m/s2, 0.3ms, 3 directions, 3 times each.

6. Drop Test (JIG attachment )

Dummy load : 200g, Height : 1.5m,

Fall conditions : On concrete

1

The number of times of fall : Six directions and 1 time each are

made into 1 cycle, and it is

10 cycle.

7.Soldering Test (Reflow )

More than 90% of

should be covered

Pre heat : 15010C, 60120sec.

by solder.

Main heat : 301 seconds after amounting to 215 C.

Peak temperature : 240C

8.Soldering Resistance ( Reflow )

Pre heat 18010C, 120 sec min,

Main heat : 225C min, 70sec max.

1

Peak temperature : 260C .

Reflow time : 3 times.

1 After the test mentioned above, the electrical specifications are satisfied.

Also frequency deviation before and after test should be

F/F 1010-6

The electrical specifications are ICC, Tr/Tf, VOL/VOH, duty cycle,

stand-by current consumption.

Reliability assurance item: EKS30B-00060E

NIHON DEMPA KOGYO CO., LTD.

Form M-3

�Document No. EKS11B-01799C 8/9

1.75 0.1

P U LL D IR EC TIO N

TO P TA P E m aterial:

polyethylene terephthalate

40.0 0.15(4×10P )

4.0 0.1

1.55

0.05

2.0 0.05

1.1

3 m ax

8.0 0.2

2.8 0.1

3.5 0.05

0.25 0.05

2.3

0.1

0.1

4.0 0.1

1.1 0.1

N Z2520 H O LD ER

TA P IN G m aterial:C onductive P S

DIRECTION OF UNIT

2.0 0.5

13.0 0.2

60 0

0

+1

180 -1.5

21.0 0.8

+0.3

9.00

LA B EL

11.4 1.0

R eelm aterial:C onductive P S

EIAJ standard reel

Start

Begin

Close

End

3000pcs M A X-P roduct Tape

C

Date of Revise

5.Sep.2012

Date

Drawn

7.Oct.2003

Designed

Checked

7.Oct.2003

Approved

7.Oct.2003

Charge

Y.Oishi

Name

Y.Okajima

Y.Okajima

H.Omata

Approved

C.Ishimaru

Reason

3000pcs-Product Tape3000pcs MAX-Product Tape.

Third Angle Projection

Dimension:mm

Title

NZ2520

Taping and Reel Spec.

Tolerance

Drawing No.

EKK17B-00032

NIHON DEMPA KOGYO CO., LTD.

Scale

/

Rev.

C

Form M-1

�Document No. EKS11B-01799C 9/9

Spacer

M aterial:P aper

φ180 reel

P asteboard

M aterial:C orrugated paper

A sleeve is inserted when reels are 1 to 4.

Shock pad

M aterial:C orrugated paper

154

Sleeve

M aterial:C orrugated paper

Label

21

0

C

Date of Revise

4 Jul. 2012

Date

0

O uter box

M aterial:C orrugated paper

21

Charge

H.Ohkubo

Name

Drawn

26 Feb. 2010

Designed

Checked

26 Feb. 2010

26 Feb. 2010

H. Ohkubo

K.Oguri

K.Oguri

Approved

26 Feb. 2010

J. Nakamura

Approved

K.Oguri

Reason

Addition of condition when reels are 1 to 4.

Third Angle Projection

Dimension:mm

Title

180 dia. Reel package

Tolerance

---------

Drawing No.

EEK17B-00015

Scale

--------Rev.

C

NIHON DEMPA KOGYO CO., LTD.

Form M-1

�