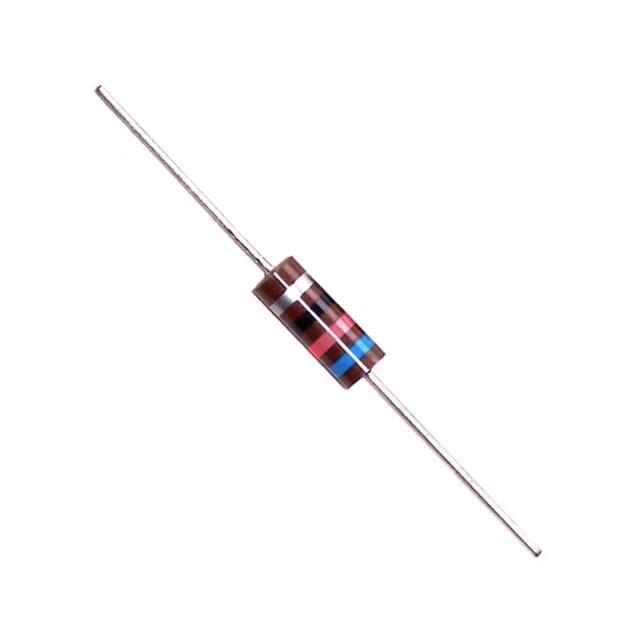

1 WATT CARBON COMPOSITION

Features:

Low inductance / High Frequency Performance

High Surge / High Pulse Capability

Rugged Construction

Carbon Composition resistors are commonly used in high frequency, fusing, or pulse applications including:

Snubbers

Lightening Surge Protection Circuits

Grounding Resistors

RFI Suppression

Value in

Ohms

10

15

22

33

47

68

100

NTE

Stock

Number

1WCC010

1WCC015

1WCC022

1WCC033

1WCC047

1WCC068

1WCC110

NTE

Stock

Number

Value in

Ohms

150

220

330

470

680

1K

1.5K

1WCC115

1WCC122

1WCC133

1WCC147

1WCC168

1WCC210

1WCC215

NTE

Stock

Number

Value in

Ohms

2.2K

3.3K

4.7K

6.8K

10K

15K

22K

Value in

Ohms

1WCC222

1WCC233

1WCC247

1WCC268

1WCC310

1WCC315

1WCC322

33K

47K

68K

100K

150K

220K

330K

NTE

Stock

Number

NTE

Stock

Number

Value in

Ohms

1WCC333

1WCC347

1WCC368

1WCC410

1WCC415

1WCC422

1WCC433

470K

680K

1M

1WCC447

1WCC468

1WCC510

SPECIFICATIONS

Electrical Characteristics @ 70 C

NTE Number

Resistance Range

(Ohms)

Tolerance

(%)

Voltage

(Volts)

Operating Temperature

(Topr)

1WCC010 thru 1WCC510

10 to 1M

10

500

−55 to +150 C

Temperature Coefficient

(PPM/ C)

0.15%

Mechanical* (Typical, inches/mm)

NTE Number

Body Length

(L)

Body Diameter

(D)

1WCC010 thru 1WCC115

0.562 (14.27)

0.225 (5.72)

1WCC122

0.591 (15.0)

0.236 (6.0)

1WCC133 thru 1WCC268

0.562 (14.27)

0.225 (5.72)

1WCC310

0.591 (15.0)

0.236 (6.0)

1WCC315 thru 1WCC333

0.562 (14.27)

0.225 (5.72)

1WCC347

0.591 (15.0)

0.236 (6.0)

1WCC368 thru 1WCC510

0.562 (14.27)

0.225 (5.72)

* These dimensions are for reference only, please consult the factory for actual size.

Lead Diameter

(d)

Lead Length

(LL)

0.036 (0.91)

0.032 (0.80)

0.036 (0.91)

0.032 (0.80)

0.036 (0.91)

0.032 (0.80)

0.036 (0.91)

1.000 (25.4)

1.102 (28.0)

1.000 (25.4)

1.102 (28.0)

1.000 (25.4)

1.102 (28.0)

1.000 (25.4)

D

d

LL

L

GENERAL INFORMATION

Pros and Cons of Carbon Composition Resistors

Carbon Composition resistors offer excellent surge and high−frequency performance due to the bulk nature of the resistance element. Unlike wirewound

and film resistors, there are no windings of resistance wire, nor any film depositions to open under overload pulses. Since the resistance element is a hot−

molded solid core comprised of resin and a carbon slug, without helical turns of resistance wire or film, the inductance is extremely low, essentially the same

as a straight piece of wire. The trade−off for the excellent surge and high−frequency capability is a rather unstable environmental performance, particularly

in humid environments, a condition well known by most circuit designers. Carbon composition resistors therefore should not be utilized in precision applications, which are generally better suited by other resistor families such as NTE’s standard Metal Film types.

There is no single resistor family, however, that offers the unique specialty performance levels of the composition construction, but depending on circuit

requirements, other models will often provide a suitable replacement.

18

NTE Electronics, Inc.

Voice (973) 748−5089

FAX (973) 748−6224

http://www.nteinc.com

�1 WATT CARBON COMPOSITION

GENERAL INFORMATION (Cont’d)

Moisture / Humidity Considerations

Carbon Composition resistors are not as stable as other types of resistors, especially in higher humidity conditions and therefore not suitable for precision

applications. For example, carbon comps may shift up to 10% during endurance testing. Most general purpose chip resistors have a maximum shift under

the same conditions of less than 3%.

Carbon comps are also highly susceptible to moisture penetration. Damp heat testing may cause carbon comps to shift up to 10%. For that reason, carbon

comps are recommended to be used soon after purchase, especially once the bag is opened. However, even in a sealed poly−bag, carbon comps may

shift up to 5% in a year. Resistance changes due to humidity/ moisture can be positive or negative (mostly positive) and is usually reversible by conditioning

the resistors at 100 −105 C or by dry storage.

Before being considered failures, out−of−tolerance resistors should be conditioned in a dry oven at a temperature of 100 C +5 C for 96 4 hours prior to

conducting resistance measurements, although some customers have had satisfactory results by baking 12−24 hrs at 110 −120 C. Regardless of the

amount of baking, some units may not return to the original value.

Typical levels of shift due to the absorption of moisture is generally less than 10% after 10 days of cycled humidity at 80−100% RH levels. Low and medium−

value composition resistors typically exhibit less change due to humidity than high−value resistors. Parts should be stored in low humidity conditions (45%

RH max). Conditioned (dry) resistors are the most sensitive to humidity.

In operation, moisture absorption is minimized by operating the resistors with as little as 1/8th rated wattage load (the self−heating effect causes parts to

dehumidify).

NTE Electronics, Inc.

Voice (973) 748−5089

FAX (973) 748−6224 http://www.nteinc.com

19

�

很抱歉,暂时无法提供与“1WCC047”相匹配的价格&库存,您可以联系我们找货

免费人工找货