ON Semiconductor

Is Now

To learn more about onsemi™, please visit our website at

www.onsemi.com

onsemi and and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates and/or

subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of onsemi

product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent-Marking.pdf. onsemi reserves the right to make changes at any time to any products or information herein, without

notice. The information herein is provided “as-is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the information, product features, availability, functionality,

or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all

liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products and applications using onsemi products, including compliance with all laws,

regulations and safety requirements or standards, regardless of any support or applications information provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/

or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application

by customer’s technical experts. onsemi does not convey any license under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized

for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for

implantation in the human body. Should Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees,

subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal Opportunity/Affirmative

Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner. Other names and brands may be claimed as the property of others.

�CAT93C46R

EEPROM Serial 1-Kb

Microwire

Description

The CAT93C46R is a 1−Kb Microwire Serial EEPROM device

which is organized as either 64 registers of 16 bits or 128 registers of 8

bits, as determined by the state of the ORG pin. The CAT93C46R

features sequential read and self−timed internal write with auto−clear.

On−chip Power−On Reset circuitry protects the internal logic against

powering up in the wrong state.

In contrast to the CAT93C46, the CAT93C46R features an internal

instruction clock counter which provides improved noise immunity

for Write/Erase commands.

Features

•

•

•

•

•

•

•

•

•

•

•

•

High Speed Operation: 4 MHz @ 5 V, 2 MHz @ 1.8 V

1.8 V to 5.5 V Supply Voltage Range

Selectable x8 or x16 Memory Organization

Sequential Read

Software Write Protection

Power−up Inadvertant Write Protection

Low Power CMOS Technology

1,000,000 Program/Erase Cycles

100 Year Data Retention

Industrial Temperature Range

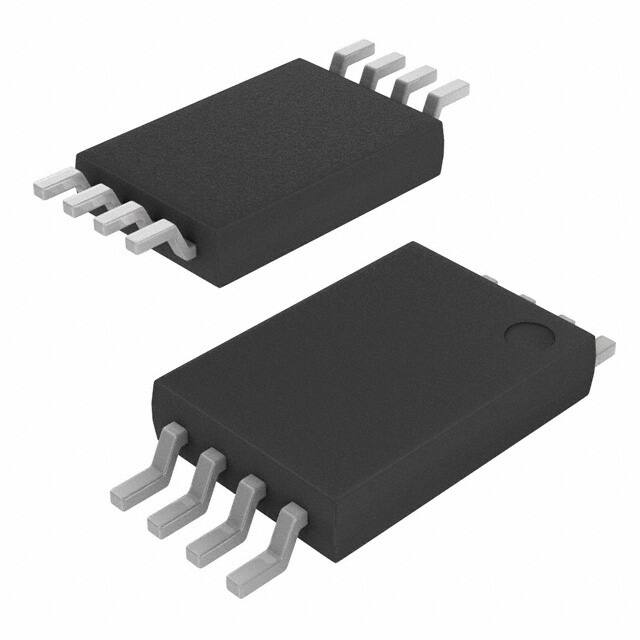

8−pin PDIP, SOIC, TSSOP and 8−pad TDFN Packages

This Device is Pb−Free, Halogen Free/BFR Free and RoHS

Compliant*

www.onsemi.com

PDIP−8

L SUFFIX

CASE 646AA

TSSOP−8

Y SUFFIX

CASE 948AL

SOIC−8

V SUFFIX

CASE 751BD

TDFN−8**

VP2 SUFFIX

CASE 511AK

PIN CONFIGURATION

CS

SK

DI

DO

VCC

NC

ORG

GND

1

PDIP (L), SOIC (V),

TSSOP (Y), TDFN (VP2)**

(Top View)

** Not recommended for new designs

VCC

PIN FUNCTION

Pin Name

ORG

CS

SK

CAT93C46R

DO

DI

GND

Figure 1. Functional Symbol

Chip Select

SK

Clock Input

DI

Serial Data Input

DO

Serial Data Output

VCC

Power Supply

GND

Ground

ORG

Memory Organization

NC

*For additional information on our Pb−Free strategy and soldering details, please

download the ON Semiconductor Soldering and Mounting Techniques

Reference Manual, SOLDERRM/D.

Function

CS

No Connection

Note: When the ORG pin is connected to VCC, the

x16 organization is selected. When it is connected

to ground, the x8 pin is selected. If the ORG pin is

left unconnected, then an internal pull−up device will

select the x16 organization.

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 8 of this data sheet.

© Semiconductor Components Industries, LLC, 2013

May, 2018 − Rev.10

1

Publication Order Number:

CAT93C46R/D

�CAT93C46R

Table 1. ABSOLUTE MAXIMUM RATINGS

Parameter

Value

Units

Storage Temperature

−65 to +150

°C

Voltage on Any Pin with Respect to Ground (Note 1)

−0.5 to +6.5

V

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. The DC input voltage on any pin should not be lower than −0.5 V or higher than VCC + 0.5 V. During transitions, the voltage on any pin may

undershoot to no less than −1.5 V or overshoot to no more than VCC + 1.5 V, for periods of less than 20 ns.

Table 2. RELIABILITY CHARACTERISTICS (Note 2)

Symbol

NEND (Note 3)

TDR

Parameter

Endurance

Min

Units

1,000,000

Program / Erase Cycles

100

Years

Data Retention

2. These parameters are tested initially and after a design or process change that affects the parameter according to appropriate AEC−Q100

and JEDEC test methods.

3. Block Mode, VCC = 5 V, TA = 25°C

Table 3. D.C. OPERATING CHARACTERISTICS (VCC = +1.8 V to +5.5 V, unless otherwise specified.)

Symbol

Parameter

Test Conditions

Min

Max

Units

ICC1

Power Supply Current (Write)

fSK = 1 MHz

VCC = 5.0 V

1

mA

ICC2

Power Supply Current (Read)

fSK = 1 MHz

VCC = 5.0 V

500

mA

ISB1

Power Supply Current (Standby) (x8 Mode)

CS = 0 V

ORG = GND

10

mA

ISB2

Power Supply Current (Standby) (x16 Mode)

CS = 0 V

ORG = Float or VCC

10

mA

VIN = 0 V to VCC

2

mA

VOUT = 0 V to VCC,

CS = 0 V

2

mA

0.8

V

ILI

Input Leakage Current

ILO

Output Leakage Current (Including ORG pin)

VIL1

Input Low Voltage

4.5 V v VCC < 5.5 V

−0.1

VIH1

Input High Voltage

4.5 V v VCC < 5.5 V

2

VCC + 1

V

VIL2

Input Low Voltage

1.8 V v VCC < 4.5 V

0

VCC x 0.2

V

VIH2

Input High Voltage

1.8 V v VCC < 4.5 V

VCC x 0.7

VCC + 1

V

VOL1

Output Low Voltage

4.5 V v VCC < 5.5 V

IOL = 2.1 mA

0.4

V

VOH1

Output High Voltage

4.5 V v VCC < 5.5 V

IOH = −400 mA

VOL2

Output Low Voltage

1.8 V v VCC < 4.5 V

IOL = 1 mA

VOH2

Output High Voltage

1.8 V v VCC < 4.5 V

IOH = −100 mA

www.onsemi.com

2

2.4

V

0.2

VCC − 0.2

V

V

�CAT93C46R

Table 4. PIN CAPACITANCE

Symbol

COUT (Note 4)

CIN (Note 4)

Test

Conditions

Output Capacitance (DO)

Input Capacitance (CS, SK, DI, ORG)

Min

Typ

Max

Units

VOUT = 0 V

5

pF

VIN = 0 V

5

pF

4. These parameters are tested initially and after a design or process change that affects the parameter according to appropriate AEC−Q100

and JEDEC test methods.

Table 5. A.C. CHARACTERISTICS (Note 5)

Parameter

Symbol

VCC = 1.8 V − 5.5 V

VCC = 4.5 V − 5.5 V

Min

Min

Max

Max

Units

tCSS

CS Setup Time

50

50

ns

tCSH

CS Hold Time

0

0

ns

tDIS

DI Setup Time

100

50

ns

tDIH

DI Hold Time

100

50

ns

tPD1

Output Delay to 1

0.25

tPD0

Output Delay to 0

0.25

0.1

ms

Output Delay to High−Z

100

100

ns

5

5

ms

tHZ (Note 6)

tEW

Program/Erase Pulse Width

0.1

ms

tCSMIN

Minimum CS Low Time

0.25

0.1

ms

tSKHI

Minimum SK High Time

0.25

0.1

ms

tSKLOW

Minimum SK Low Time

0.25

0.1

ms

tSV

Output Delay to Status Valid

SKMAX

Maximum Clock Frequency

0.25

DC

2

DC

0.1

ms

4

MHz

5. Test conditions according to “A.C. Test Conditions” table.

6. These parameters are tested initially and after a design or process change that affects the parameter according to appropriate AEC−Q100

and JEDEC test methods.

Table 6. POWER−UP TIMING (Notes 4 and 7)

Symbol

Max

Units

tPUR

Power−up to Read Operation

Parameter

1

ms

tPUW

Power−up to Write Operation

1

ms

7. tPUR and tPUW are the delays required from the time VCC is stable until the specified operation can be initiated.

Table 7. A.C. TEST CONDITIONS

Input Rise and Fall Times

v 50 ns

Input Pulse Voltages

0.4 V to 2.4 V

4.5 V v VCC v 5.5 V

0.8 V, 2.0 V

4.5 V v VCC v 5.5 V

0.2 VCC to 0.7 VCC

1.8 V v VCC v 4.5 V

Timing Reference Voltages

0.5 VCC

1.8 V v VCC v 4.5 V

Output Load

Current Source IOLmax/IOHmax; CL = 100 pF

Timing Reference Voltages

Input Pulse Voltages

www.onsemi.com

3

�CAT93C46R

Table 8. INSTRUCTION SET

Address

Data

Instruction

Start Bit

Opcode

x8

x16

x8

READ

1

10

A6−A0

A5−A0

Read Address AN–A0

ERASE

1

11

A6−A0

A5−A0

Clear Address AN–A0

WRITE

1

01

A6−A0

A5−A0

EWEN

1

00

11XXXXX

11XXXX

Write Enable

EWDS

1

00

00XXXXX

00XXXX

Write Disable

ERAL

1

00

10XXXXX

10XXXX

Clear All Addresses

WRAL

1

00

01XXXXX

01XXXX

Device Operation

The CAT93C46R is a 1024−bit nonvolatile memory

intended for use with industry standard microprocessors.

The CAT93C46R can be organized as either registers of 16

bits or 8 bits. When organized as X16, seven 9−bit

instructions control the reading, writing and erase

operations of the device. When organized as X8, seven

10−bit instructions control the reading, writing and erase

operations of the device. The CAT93C46R operates on a

single power supply and will generate on chip the high

voltage required during any write operation.

Instructions, addresses, and write data are clocked into the

DI pin on the rising edge of the clock (SK). The DO pin is

normally in a high impedance state except when reading data

from the device, or when checking the ready/busy status

after a write operation.

The ready/busy status can be determined after the start of

a write operation by selecting the device (CS high) and

polling the DO pin; DO low indicates that the write

operation is not completed, while DO high indicates that the

device is ready for the next instruction. If necessary, the DO

pin may be placed back into a high impedance state during

chip select by shifting a dummy “1” into the DI pin. The DO

pin will enter the high impedance state on the rising edge of

the clock (SK). Placing the DO pin into the high impedance

state is recommended in applications where the DI pin and

the DO pin are to be tied together to form a common DI/O

pin. The Ready/Busy flag can be disabled only in Ready

state; no change is allowed in Busy state.

The format for all instructions sent to the device is a

logical “1” start bit, a 2−bit (or 4−bit) opcode, 6−bit address

(an additional bit when organized X8) and for write

operations a 16−bit data field (8−bit for X8 organization).

D7−D0

D7−D0

x16

D15−D0

D15−D0

Comments

Write Address AN–A0

Write All Addresses

Read

Upon receiving a READ command and an address

(clocked into the DI pin), the DO pin of the CAT93C46R will

come out of the high impedance state and, after sending an

initial dummy zero bit, will begin shifting out the data

addressed (MSB first). The output data bits will toggle on

the rising edge of the SK clock and are stable after the

specified time delay (tPD0 or tPD1).

Sequential Read

After the 1st data word has been shifted out and CS

remains asserted with the SK clock continuing to toggle, the

CAT93C46R will automatically increment to the next

address and shift out the next data word. As long as CS is

continuously asserted and SK continues to toggle, the device

will keep incrementing to the next address automatically

until it reaches the end of the address space, then loops back

to address 0. In the sequential Read mode, only the initial

data word is preceeded by a dummy zero bit; all subsequent

data words will follow without a dummy zero bit.

Erase/Write Enable and Disable

The CAT93C46R powers up in the write disable state.

Any writing after power−up or after an EWDS (write

disable) instruction must first be preceded by the EWEN

(write enable) instruction. Once the write instruction is

enabled, it will remain enabled until power to the device is

removed, or the EWDS instruction is sent. The EWDS

instruction can be used to disable all CAT93C46R write and

erase instructions, and will prevent any accidental writing or

clearing of the device. Data can be read normally from the

device regardless of the write enable/disable status.

www.onsemi.com

4

�CAT93C46R

tSKHI

tSKLOW

tCSH

SK

tDIS

tDIH

VALID

DI

VALID

tCSS

CS

tDIS

tPD0, tPD1

DO

tCSMIN

DATA VALID

Figure 2. Synchronous Data Timing

SK

tCSMIN

CS

AN

DI

1

1

AN−1

STANDBY

A0

0

DO

tHZ

tPD0

HIGH−Z

HIGH−Z

0

DN

DN−1

D1

D0

Figure 3. Read Instruction Timing

SK

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

CS

AN

DI

DO

1

1

AN−1

Don’t Care

A0

0

HIGH−Z

Dummy 0

D15...D0

or

D7...D0

Address + 1

D15...D0

or

D7...D0

Figure 4. Sequential Read Instruction Timing

www.onsemi.com

5

Address + 2

D15...D0

or

D7...D0

Address + n

D15...

or

D7...

�CAT93C46R

SK

CS

STANDBY

DI

1

0

0

*

* ENABLE = 11

DISABLE = 00

Figure 5. EWEN/EWDS Instruction Timing

Write

edge of CS will start the self clocking clear cycle of all

memory locations in the device. The clocking of the SK pin

is not necessary after the device has entered the self clocking

mode. The ready/busy status of the CAT93C46R can be

determined by selecting the device and polling the DO pin.

Once cleared, the contents of all memory bits return to a

logical “1” state.

After receiving a WRITE command, address and the data,

the CS (Chip Select) pin must be deselected for a minimum

of tCSMIN (See Design Note for details). The falling edge of

CS will start the self clocking clear and data store cycle of

the memory location specified in the instruction. The

clocking of the SK pin is not necessary after the device has

entered the self clocking mode. The ready/busy status of the

CAT93C46R can be determined by selecting the device and

polling the DO pin. Since this device features Auto−Clear

before write, it is NOT necessary to erase a memory location

before it is written into.

Write All

Upon receiving a WRAL command and data, the CS

(Chip Select) pin must be deselected for a minimum of

tCSMIN. The falling edge of CS will start the self clocking

data write to all memory locations in the device. The

clocking of the SK pin is not necessary after the device has

entered the self clocking mode. The ready/busy status of the

CAT93C46R can be determined by selecting the device and

polling the DO pin. It is not necessary for all memory

locations to be cleared before the WRAL command is

executed.

Erase

Upon receiving an ERASE command and address, the CS

(Chip Select) pin must be deasserted for a minimum of

tCSMIN after the proper number of clock pulses (See Design

Note). The falling edge of CS will start the self clocking

clear cycle of the selected memory location. The clocking of

the SK pin is not necessary after the device has entered the

self clocking mode. The ready/busy status of the

CAT93C46R can be determined by selecting the device and

polling the DO pin. Once cleared, the content of a cleared

location returns to a logical “1” state.

Design Note

With CAT93C46R, after the last data bit has been

sampled, Chip Select (CS) must be brought Low before the

next rising edge of the clock (SK) in order to start the

self−timed high voltage cycle. This is important because if

the CS is brought low before or after this specific frame

window, the addressed location will not be programmed or

erased.

Erase All

Upon receiving an ERAL command, the CS (Chip Select)

pin must be deselected for a minimum of tCSMIN. The falling

SK

tCS MIN

CS

STATUS

VERIFY

AN

DI

1

0

AN−1

A0

DN

D0

1

tSV

DO

STANDBY

tHZ

BUSY

HIGH−Z

READY

tEW

Figure 6. Write Instruction Timing

www.onsemi.com

6

HIGH−Z

�CAT93C46R

SK

CS

STANDBY

STATUS VERIFY

AN−1

AN

1

DI

tCS MIN

A0

1

1

tSV

tHZ

HIGH−Z

DO

BUSY

READY

HIGH−Z

tEW

Figure 7. Erase Instruction Timing

SK

CS

STATUS VERIFY

STANDBY

tCS MIN

DI

1

0

0

1

0

tSV

tHZ

HIGH−Z

DO

BUSY

READY

HIGH−Z

tEW

Figure 8. ERAL Instruction Timing

SK

CS

STATUS VERIFY

STANDBY

tCS MIN

DI

1

0

0

0

DN

1

D0

tSV

tHZ

BUSY

DO

tEW

Figure 9. WRAL Instruction Timing

www.onsemi.com

7

READY

HIGH−Z

�CAT93C46R

Ordering Information

Specific

Device

Marking

Pkg Type

Temperature Range

CAT93C46RLI−G

93C46RL

PDIP−8

CAT93C46RVI−G

93C46RV

CAT93C46RVI−GT3

Lead

Finish

Shipping

I = Industrial

(−40°C to +85°C)

NiPdAu

Tube, 50 Units / Tube

SOIC−8, JEDEC

I = Industrial

(−40°C to +85°C)

NiPdAu

Tube, 100 Units / Tube

93C46RV

SOIC−8, JEDEC

I = Industrial

(−40°C to +85°C)

NiPdAu

Tape & Reel,

3000 Units / Reel

EL

TDFN−8

I = Industrial

(−40°C to +85°C)

NiPdAu

Tape & Reel,

3000 Units / Reel

CAT93C46RYI−G

46R

TSSOP−8

I = Industrial

(−40°C to +85°C)

NiPdAu

Tube, 100 Units / Tube

CAT93C46RYI−GT3

46R

TSSOP−8

I = Industrial

(−40°C to +85°C)

NiPdAu

Tape & Reel,

3000 Units / Reel

OPN

CAT93C46RVP2IGT3

(Note 8)

8. Not recommended for new designs.

9. All packages are RoHS−compliant (Lead−free, Halogen−free).

10. The standard lead finish is NiPdAu.

11. For additional package and temperature options, please contact your nearest ON Semiconductor Sales office.

12. For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

www.onsemi.com

8

�CAT93C46R

PACKAGE DIMENSIONS

PDIP−8, 300 mils

CASE 646AA−01

ISSUE A

SYMBOL

MIN

NOM

A

E1

5.33

A1

0.38

A2

2.92

3.30

4.95

b

0.36

0.46

0.56

b2

1.14

1.52

1.78

c

0.20

0.25

0.36

D

9.02

9.27

10.16

E

7.62

7.87

8.25

E1

6.10

6.35

7.11

e

PIN # 1

IDENTIFICATION

MAX

2.54 BSC

eB

7.87

L

2.92

10.92

3.30

3.80

D

TOP VIEW

E

A2

A

A1

c

b2

L

e

eB

b

SIDE VIEW

END VIEW

Notes:

(1) All dimensions are in millimeters.

(2) Complies with JEDEC MS-001.

www.onsemi.com

9

�CAT93C46R

PACKAGE DIMENSIONS

SOIC 8, 150 mils

CASE 751BD−01

ISSUE O

E1

E

SYMBOL

MIN

A

1.35

1.75

A1

0.10

0.25

b

0.33

0.51

c

0.19

0.25

D

4.80

5.00

E

5.80

6.20

E1

3.80

4.00

MAX

1.27 BSC

e

PIN # 1

IDENTIFICATION

NOM

h

0.25

0.50

L

0.40

1.27

θ

0º

8º

TOP VIEW

D

h

A1

θ

A

c

e

b

L

SIDE VIEW

END VIEW

Notes:

(1) All dimensions are in millimeters. Angles in degrees.

(2) Complies with JEDEC MS-012.

www.onsemi.com

10

�CAT93C46R

PACKAGE DIMENSIONS

TSSOP8, 4.4x3

CASE 948AL−01

ISSUE O

b

SYMBOL

MIN

NOM

E1

E

MAX

1.20

A

A1

0.05

0.15

A2

0.80

b

0.19

0.30

c

0.09

0.20

D

2.90

3.00

3.10

E

6.30

6.40

6.50

E1

4.30

4.40

4.50

0.90

e

0.65 BSC

L

1.00 REF

L1

0.50

θ

0º

0.60

1.05

0.75

8º

e

TOP VIEW

D

A2

c

q1

A

A1

L1

SIDE VIEW

L

END VIEW

Notes:

(1) All dimensions are in millimeters. Angles in degrees.

(2) Complies with JEDEC MO-153.

www.onsemi.com

11

�CAT93C46R

PACKAGE DIMENSIONS

TDFN8, 2x3

CASE 511AK−01

ISSUE A

D

e

A

b

E2

E

PIN#1

IDENTIFICATION

A1

PIN#1 INDEX AREA

D2

TOP VIEW

SIDE VIEW

SYMBOL

MIN

NOM

MAX

A

0.70

0.75

0.80

A1

0.00

0.02

0.05

A2

0.45

0.55

0.65

A3

A2

A3

0.20

0.25

0.30

D

1.90

2.00

2.10

D2

1.30

1.40

1.50

E

2.90

3.00

3.10

E2

1.20

1.30

1.40

L

BOTTOM VIEW

0.20 REF

b

e

FRONT VIEW

0.50 TYP

0.20

0.30

L

0.40

Notes:

(1) All dimensions are in millimeters.

(2) Complies with JEDEC MO-229.

www.onsemi.com

12

�CAT93C46R

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

19521 E. 32nd Pkwy, Aurora, Colorado 80011 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

◊

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

www.onsemi.com

13

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

CAT93C46R/D

�