ON Semiconductor

Is Now

To learn more about onsemi™, please visit our website at

www.onsemi.com

onsemi and and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates and/or

subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of onsemi

product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent-Marking.pdf. onsemi reserves the right to make changes at any time to any products or information herein, without

notice. The information herein is provided “as-is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the information, product features, availability, functionality,

or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all

liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products and applications using onsemi products, including compliance with all laws,

regulations and safety requirements or standards, regardless of any support or applications information provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/

or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application

by customer’s technical experts. onsemi does not convey any license under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized

for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for

implantation in the human body. Should Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees,

subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal Opportunity/Affirmative

Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner. Other names and brands may be claimed as the property of others.

�Is Now Part of

To learn more about ON Semiconductor, please visit our website at

www.onsemi.com

Please note: As part of the Fairchild Semiconductor integration, some of the Fairchild orderable part numbers

will need to change in order to meet ON Semiconductor’s system requirements. Since the ON Semiconductor

product management systems do not have the ability to manage part nomenclature that utilizes an underscore

(_), the underscore (_) in the Fairchild part numbers will be changed to a dash (-). This document may contain

device numbers with an underscore (_). Please check the ON Semiconductor website to verify the updated

device numbers. The most current and up-to-date ordering information can be found at www.onsemi.com. Please

email any questions regarding the system integration to Fairchild_questions@onsemi.com.

ON Semiconductor and the ON Semiconductor logo are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries. ON Semiconductor owns the rights to a number

of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent-Marking.pdf. ON Semiconductor reserves the right

to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products and applications using ON

Semiconductor products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON

Semiconductor data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s

technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not designed, intended, or authorized for use as a critical component in life support systems or any FDA

Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended

or unauthorized application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out

of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor

is an Equal Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

�FAN2012

1.5 A Low-Voltage, Current-Mode Synchronous PWM

Buck Regulator

Features

Description

The FAN2012 is a high-efficiency, low-noise,

synchronous Pulse Width Modulated (PWM) currentmode DC-DC converter designed for low-voltage

applications. It provides up to 1.5 A continuous-load

current from the 4.5 V to 5.5 V input. The output voltage

is adjustable over a wide range of 0.8 V to 3.5 V by

means of an external voltage divider.

95% Efficiency, Synchronous Operation

Adjustable Output Voltage from 0.8 V to 3.5 V

4.5 V to 5.5 V Input Voltage Range

Up to 1.5 A Output Current

Fixed-Frequency 1.3 MHz PWM Operation

Soft Start

Excellent Load Transient Response

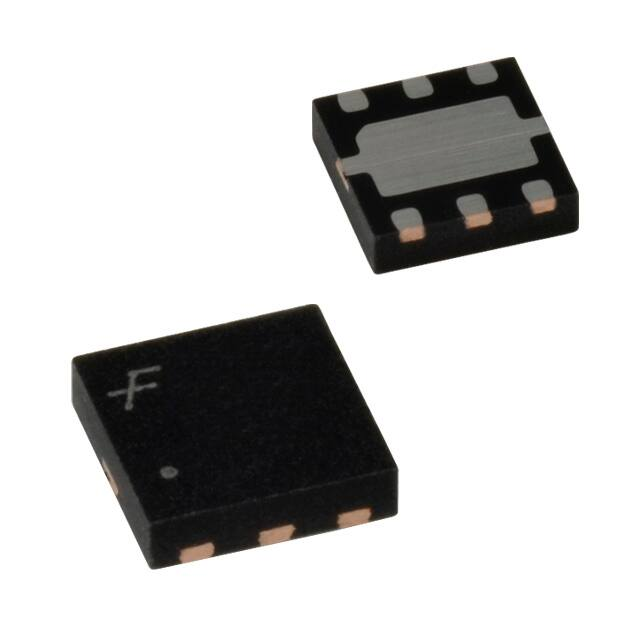

3 x 3 mm, 6-Lead, MLP

A current-mode control loop with a fast transient

response ensures excellent line and load regulation.

The fixed 1.3 MHz switching frequency enables

designers to choose a small, inexpensive external

inductor and capacitor. Filtering is easily accomplished

with very small components.

Applications

The FAN2012 has an “Enable Input” and the device can

be put in shutdown mode, in which the ground current

falls below 1 µA.

Hard Disk Drive

Set-Top Box

Protection features include input under-voltage lockout,

short-circuit protection, and thermal shutdown. Softstart limits inrush current during start-up conditions.

Point-of-Load Power

Notebook Computer

Communications Equipment

The device is available in a 3x3 mm 6-lead molded

leadless package (MLP), making it possible to build a

1.5 A complete DC-DC converter in limited space on the

printed circuit board (PCB).

Ordering Information

Part Number

Output Voltage

Operating Temperature Range

FAN2012MPX

Adjustable

0°C to 85°C

3x3 mm 6-Lead MLP

FAN2012EMPX

Adjustable

-40°C to 85°C

3x3 mm 6-Lead MLP

© 2004 Fairchild Semiconductor Corporation

FAN2012 • Rev. 1.0.5

Package

www.fairchildsemi.com

FAN 2012 — 1.5 A Low-Voltage, Current-Mode Synchronous PWM Buck Regulator

October 2013

�FB

R2

EN

1

6

10K

PGND

R1

L1

VOUT

SW

P1

(AGND)

2

3

5

4

3.3H

VIN

+5V

PVIN

10F

4 x 10F

Figure 1.

Typical Application

Pin Configuration

Figure 2.

Pin Assignments

Pin Definitions

Pin #

Name

Description

P1

AGND

1

FB

2

PGND

3

SW

4

PVIN

5

VIN

Supply Voltage Input.

6

EN

Enable Input. Logic HIGH enables the chip and logic LOW disables the chip, reducing the

supply current to less than 1 µA. Do not float this pin.

Analog Ground. P1 must be soldered to the PCB ground.

FAN 2012 — 1.5 A Low-Voltage, Current-Mode Synchronous PWM Buck Regulator

Typical Application

Feedback Input. Adjustable voltage option; connect this pin to the resistor divider.

Power Ground. This pin is connected to the internal MOSFET switches. This pin must be

externally connected to AGND.

Switching Node. This pin is connected to the internal MOSFET switches.

Supply Voltage Input. This pin is connected to the internal MOSFET switches.

© 2004 Fairchild Semiconductor Corporation

FAN2012 • Rev. 1.0.5

www.fairchildsemi.com

2

�Stresses exceeding the absolute maximum ratings may damage the device. The device may not function or be

operable above the recommended operating conditions and stressing the parts to these levels is not recommended.

In addition, extended exposure to stresses above the recommended operating conditions may affect device

reliability. The absolute maximum ratings are stress ratings only.

Symbol

Parameter

VIN

Input Voltage

VIN

Input Voltage on PVIN and Any Other Pin

Thermal Resistance-Junction to Tab

TL

Lead Soldering Temperature (10 Seconds)

Storage Temperature

TJ

Junction Temperature

ESD

Max.

Unit

-0.3

6.5

V

-0.3

VIN

V

(1)

JC

TSTG

Min.

Electrostatic Discharge Protection Level

(2)

8

°C/W

260

°C

-65

150

°C

-40

150

°C

HBM

4

CDM

2

kV

Notes:

1. Junction-to-ambient thermal resistance, JA, is a strong function of PCB material, board thickness, thickness and

number of copper planes, number of via used, diameter of via used, available copper surface, and attached heat

sink characteristics.

2. Using Mil Std. 883E, method 3015.7 (Human Body Model) and EIA/JESD22C101-A (Charged Device Model).

Recommended Operating Conditions

The Recommended Operating Conditions table defines the conditions for actual device operation. Recommended

operating conditions are specified to ensure optimal performance to the datasheet specifications. Fairchild does not

recommend exceeding them or designing to Absolute Maximum Ratings.

Symbols

VIN

Parameter

Min.

Typ.

Max.

Unit

Supply Voltage Range

4.5

5.5

V

VOUT

Output Voltage Range, Adjustable Version

0.8

3.5

V

IOUT

Output Current

1.5

A

L

CIN

COUT

TA

Inductor

(3)

Input Capacitor

(3)

Output Capacitor

(3)

Operating Ambient

Temperature Range

FAN2012MPX

FAN2012EMPX

3.3

µH

10

µF

4 x 10

µF

0

+85

°C

-40

+85

°C

FAN 2012 — 1.5 A Low-Voltage, Current-Mode Synchronous PWM Buck Regulator

Absolute Maximum Ratings

Notes:

3. Refer to the Applications section for details.

© 2004 Fairchild Semiconductor Corporation

FAN2012 • Rev. 1.0.5

www.fairchildsemi.com

3

�VIN = 4.5 V to 5.5 V, VOUT = 1.2 V, IOUT = 200 mA, CIN = 10 µF, COUT = 4 x 10 µF, L = 3.3 µH, TA = 0°C to +85°C,

unless otherwise noted. Typical values are at TA = 25°C.

Symbol

Parameter

VIN

Input Voltage

IQ

Quiescent Current

VUVLO

Conditions

Min.

Typ.

Max.

Units

5.5

V

7

10

mA

3.7

4.0

V

4.5

IOUT = 0 mA

VIN Rising

UVLO Threshold

3.4

Hysteresis

150

mV

RON_PMOS

PMOS On Resistance

VIN = VGS = 5 V

150

290

RON_NMOS

NMOS On Resistance

VIN = VGS = 5 V

150

290

ILIMIT

P-Channel Current Limit

4.5 V < VIN < 5.5 V

2.6

3.5

TOVP

Over-Temperature

Protection

Rising Temperature

150

°C

Hysteresis

20

°C

fSW

2.2

Switching Frequency

1000

1300

RLINE

Line Regulation

VIN = 4.5 to 5.5 V, IOUT = 100 mA

0.16

RLOAD

Load Regulation

0 mA ≤ IOUT ≤ 1500 mA

0.2

VOUT

Output Voltage During

(4)

Load Transition

IOUT from 700 mA to 100 mA

ILEAK

Reverse Leakage Current

VIN = Open, EN = GND, VSW = 5.5 V

into Pin SW

0.1

VREF

Reference Voltage

0.8

VOUT

Output Voltage Accuracy

VIN = 4.5 to 5.5 V,

0 mA ≤ IOUT ≤

1500 mA

ISD

Shutdown Mode Supply

Current

VEN = 0 V

IBIAS

EN Bias Current

VENH

EN HIGH Voltage

VENL

EN LOW Voltage

IOUT from 100 mA to 700 mA

kHz

0.5

%

5

%

%

1.0

µA

V

FAN2012MPX

-2

2

%

FAN2012EMPX

-3

3

%

1.0

µA

0.1

µA

0.1

1.3

V

0.4

Figure 3.

A

%/V

-5

Notes:

4. Please refer to the load transient response test waveform shown in Figure 3.

© 2004 Fairchild Semiconductor Corporation

FAN2012 • Rev. 1.0.5

1600

M

V

FAN 2012 — 1.5 A Low-Voltage, Current-Mode Synchronous PWM Buck Regulator

Electrical Characteristics

Load Transient Response Test Waveform

www.fairchildsemi.com

4

�TA = 25°C, CIN = 10 µF, COUT = 40 µF, L = 3.3 µH, VIN = 5 V; unless otherwise noted.

1.214

T em p

T em p

T em p

T em p

T em p

Outp ut V o ltag e (V)

1.212

1.210

1.208

(

(

(

(

(

C ) vs . V OUT @ 0 m A

C ) vs . V OUT @ 100m A

C ) vs . V OUT @ 500 m A

C ) vs . V OUT @ 1000 m A

C ) vs . V OUT@ 1500 m A

1.206

1.204

1.202

1.200

1.198

1.196

1.194

-40

-20

0

20

40

60

80

100

120

A m b ien t Tem p eratu re (°C)

Figure 4.

Output Voltage vs. Ambient Temperature

Sw itch in g Freq ue nc y ( KHz)

1260

1255

1250

1245

1240

1235

1230

0

20

40

60

80

100

120

A m b ien t Tem p eratu re (°C)

Figure 5.

Switching Frequency vs. Ambient Temperature

FAN 2012 — 1.5 A Low-Voltage, Current-Mode Synchronous PWM Buck Regulator

Typical Performance Characteristics

Po wer Eff iciency ( % )

100

V O U T = 3 .3 V

90

80

V O U T = 1 .2 V

70

V I N = 4 .5 V

60

V IN = 5 V

50

40

V I N = 5 .5 V

30

10

100

1000

1000 0

Loa d C u rren t ( mA )

Figure 6.

© 2004 Fairchild Semiconductor Corporation

FAN2012 • Rev. 1.0.5

Efficiency vs. Load Current

www.fairchildsemi.com

5

�(Continued)

TA = 25°C, CIN = 10 µF, COUT = 40 µF, L = 3.3 µH, VIN = 5 V; unless otherwise noted.

Star t-up Res ponse

Star t- up Resp on se

In put

Vo lt ag e

(5V/div)

Inp ut

Vo lt ag e

(5V/div )

SW No d e

Vo lt ag e

(5V/div )

SW N od e

Vo lt age

(5V/div)

In du cto r

Current

(200m A /di v )

In duc tor

Cu rren t

(200mA /div )

Out put

Vo ltag e

(500m V/d iv )

Ou tpu t

Vo lt age

(1V/di v)

V O UT = 1 .2 V

IO UT = 1 0 0 m A

V O UT = 3 .3 V

IO UT = 1 0 0 m A

Ti m e (50 µs/div)

Figure 7.

Ti m e (100 µs/div)

Startup Response

Figure 8.

Start-up Re spo n s e

Star t- up Response

In put

Vo lt ag e

(5V/div)

In pu t

Vo ltag e

(5V/di v )

SW No d e

Vo lt ag e

(5V/div )

SW N ode

Vo lt ag e

(5V/div )

In du cto r

Current

(500m A /di v )

Indu cto r

Cur rent

(500m A/d iv)

Out put

Vo ltag e

(500m V/d iv )

Startup Response

Ou tpu t

Vo lt ag e

(1V/di v)

V O UT = 1 .2 V

IO UT = 1 5 0 0 m A

V O U T = 3 .3 V

IO UT = 1 5 0 0 m A

Ti m e (100 µs/div)

Ti m e (100 µs/div)

Figure 9.

Startup Response

Figure 10.

Tran sien t Re spon se

Startup Response

Tr an sie n t Re spons e

FAN 2012 — 1.5 A Low-Voltage, Current-Mode Synchronous PWM Buck Regulator

Typical Performance Characteristics

700mA

Lo ad

Current

Lo ad

Cu rrent

100mA

SW No d e

Vo lt ag e

(5V/div )

SW N ode

Vo lt ag e

(5V/div )

Out put

Vo ltag e

(20m V/d iv)

Ou tpu t

Vo lt age

(20m V/div )

In du cto r

Current

(200m A /di v )

Ind u ct or

Curr ent

(200m A/d iv)

700mA

100mA

V O U T = 1 .2 V

V O U T = 1 .2 V

Ti m e (5 µs/div)

Ti m e (5µs/div)

Figure 11.

Transient Response

© 2004 Fairchild Semiconductor Corporation

FAN2012 • Rev. 1.0.5

Figure 12.

Transient Response

www.fairchildsemi.com

6

�Figure 13.

Block Diagram

Detailed Operation Description

possible voltage drops of the input voltage and

eliminates the output voltage overshoot. The soft-start

is implemented as a digital circuit, increasing the switch

current in four steps to the P-channel current limit

(2600 mA). Typical start-up time for a 40 µF output

capacitor and a load current of 1500 mA is 800 µs.

The FAN2012 is a step-down pulse width modulated

(PWM) current mode converter with a typical switching

frequency of 1.3 MHz. At the beginning of each clock

cycle, the P-channel transistor is turned on. The

inductor current ramps up and is monitored via an

internal circuit. The P-channel switch is turned off when

the sensed current causes the PWM comparator to trip

when the output voltage is in regulation or when the

inductor current reaches the current limit (set internally,

typically 2600 mA). After a minimum dead time, the Nchannel transistor is turned on and the inductor current

ramps down. As the clock cycle is completed, the Nchannel switch is turned off and the next clock cycle

starts. The duty cycle is solely given by the ratio of

output voltage and input voltage. Therefore, the

converter runs with a minimum duty cycle when output

voltage is at minimum and input voltage is at maximum.

FAN 2012 — 1.5 A Low-Voltage, Current-Mode Synchronous PWM Buck Regulator

Block Diagram

Short-Circuit Protection

The switch peak current is limited cycle by cycle to a

typical value of 2600 mA. In the event of an output

voltage short circuit, the device operates with a

frequency of 400 kHz and minimum-duty cycle,

therefore the average input current is typically 350 mA.

Thermal Shutdown

When the die temperature exceeds 150°C, a reset

occurs and remains in effect until the die cools to

130°C, at which point, the circuit restarts.

UVLO and Soft Start

The reference and the circuit remain reset until the V IN

crosses its UVLO threshold.

The FAN2012 has an internal soft-start circuit that limits

the in-rush current during start-up. This prevents

© 2004 Fairchild Semiconductor Corporation

FAN2012 • Rev. 1.0.5

www.fairchildsemi.com

7

�Setting the Output Voltage

PCB Layout Recommendations

The internal voltage reference is 0.8 V. The output is

divided down by a voltage divider, R1 and R2 to the FB

pin. The output voltage is:

The inherently high peak currents and switching

frequency of power supplies require a careful PCB

layout design. For best results, use wide traces for highcurrent paths and place the input capacitor, the

inductor, and the output capacitor as close as possible

to the integrated circuit terminals. To minimize voltage

stress to the device resulting from ever-present

switching spikes, use an input bypass capacitor with low

ESR. Use of an external Schottky diode, with its anode

connected to SW node and cathode connected to

PVIN, further reduces switching spikes. Note that the

peak amplitude of the switching spikes depends upon

the load current; the higher the load current, the higher

the switching spikes.

V

O UT

= V

REF

R

1 + -----1R

EQ. 2

2

According to this equation, and assuming desired

output voltage of 1.5096 V, and given R2 = 10 k, the

calculated value of R1 is 8.87 k.

Inductor Selection

The inductor parameters directly related to device

performance are saturation current and DC resistance.

The FAN2012 operates with a typical inductor value of

3.3 µH. The lower the DC resistance, the higher the

efficiency. For saturation current, the inductor should be

rated higher than the maximum load current, plus half of

the inductor ripple current calculated as follows:

1 – ( VO U T ⁄ VIN)

∆ IL = VO U T × ------------------------------------------L×f

The resistor divider that sets the output voltage should

be routed away from the inductor to avoid RF coupling.

The ground plane at the bottom side of the PCB acts as

an electromagnetic shield to reduce EMI. The

recommended PCB layout is shown below in Figure 14.

EQ. 3

where:

IL = Inductor Ripple Current

f = Switching Frequency

L = Inductor Value

Some recommended inductors are suggested in the

table below:

Table 1. Recommended Inductors

Inductor Value

Vendor

Part Number

3.3 µH

Panasonic

ELL6PM3R3N

3.3 µH

Murata

LQS66C3R3M04

3.3 µH

Coiltronics

SD-3R3-R

Figure 14.

Capacitors Selection

For best performances, a low-ESR input capacitor is

required. A ceramic capacitor of at least 10 µF, placed

as close to the VIN and AGND pins of the device is

recommended. The output capacitor determines the

output ripple and the transient response.

Recommended PCB Layout

FAN 2012 — 1.5 A Low-Voltage, Current-Mode Synchronous PWM Buck Regulator

Applications Information

Table 2. Recommended Capacitors

Capacitor

Value

Vendor

Taiyo Yuden

10 µF

TDK

Murata

© 2004 Fairchild Semiconductor Corporation

FAN2012 • Rev. 1.0.5

Part Number

JMK212BJ106MG

JMK316BJ106KL

C2012X5ROJ106K

C3216X5ROJ106M

GRM32ER61C106K

www.fairchildsemi.com

8

�3.0

0.15 C

3.50

2.45

A

2X

B

3.50

1.65

0.45

2.10

3.0

(0.70)

0.15 C

PIN #1 IDENT

0.95 TYP

0.45 TYP

2X

TOP VIEW

RECOMMENDED LAND PATTERN

0.8 MAX

0.10 C

(0.20)

0.08 C

0.05

0.00

C

SIDE VIEW

SEATING

PLANE

2.25

PIN #1 IDENT

3

1

0.45

0.20

0.40

0.2 MIN

1.65

4

6

0.30~0.45

0.95

1.90

0.10

0.05

C A B

C

BOTTOM VIEW

A. CONFORMS TO JEDEC REGISTRATION MO-229,

VARIATION WEEA, DATED 11/2001

EXCEPT FOR DAP EXTENSION TABS

FAN 2012 — 1.5 A Low-Voltage, Current-Mode Synchronous PWM Buck Regulator

Physical Dimensions

B. DIMENSIONS ARE IN MILLIMETERS.

C. DIMENSIONS AND TOLERANCES PER

ASME Y14.5M, 1994

Figure 15.

3x3 mm, 6-Lead, Molded Leadless Package (MLP)

Package drawings are provided as a service to customers considering Fairchild components. Drawings may change in any manner

without notice. Please note the revision and/or date on the drawing and contact a Fairchild Semiconductor representative to verify

or obtain the most recent revision. Package specifications do not expand the terms of Fairchild’s worldwide terms and conditions,

specifically the warranty therein, which covers Fairchild products.

Always visit Fairchild Semiconductor’s online packaging area for the most recent package drawings:

http://www.fairchildsemi.com/dwg/ML/MLP06F.pdf.

© 2004 Fairchild Semiconductor Corporation

FAN2012 • Rev. 1.0.5

www.fairchildsemi.com

9

�FAN 2012 — 1.5 A Low-Voltage, Current-Mode Synchronous PWM Buck Regulator

© 2004 Fairchild Semiconductor Corporation

FAN2012 • Rev. 1.0.5

www.fairchildsemi.com

10

�ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

19521 E. 32nd Pkwy, Aurora, Colorado 80011 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

© Semiconductor Components Industries, LLC

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

www.onsemi.com

1

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

www.onsemi.com

�