Is Now Part of

To learn more about ON Semiconductor, please visit our website at

www.onsemi.com

Please note: As part of the Fairchild Semiconductor integration, some of the Fairchild orderable part numbers

will need to change in order to meet ON Semiconductor’s system requirements. Since the ON Semiconductor

product management systems do not have the ability to manage part nomenclature that utilizes an underscore

(_), the underscore (_) in the Fairchild part numbers will be changed to a dash (-). This document may contain

device numbers with an underscore (_). Please check the ON Semiconductor website to verify the updated

device numbers. The most current and up-to-date ordering information can be found at www.onsemi.com. Please

email any questions regarding the system integration to Fairchild_questions@onsemi.com.

ON Semiconductor and the ON Semiconductor logo are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries. ON Semiconductor owns the rights to a number

of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent-Marking.pdf. ON Semiconductor reserves the right

to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products and applications using ON

Semiconductor products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON

Semiconductor data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s

technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not designed, intended, or authorized for use as a critical component in life support systems or any FDA

Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended

or unauthorized application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out

of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor

is an Equal Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

�FPF2200-FPF2202

Integrated Load Switch with 500mA High Precision Current Limit

Features

General Description

1.8 to 5.5V Input Voltage Range

Typical RDS(ON) = 140m

@ VIN = 5.5V

Typical RDS(ON) = 160m

@ VIN = 3.3V

The FPF2200-FPF2202 are low RDS(ON) P-Channel MOSFET

load switches with high precision current limit value. The input

voltage range operates from 1.8V to 5.5V to fulfill today's Ultra

Portable Device's supply requirement. Switch control is by a

logic input (ON) capable of interfacing directly with low voltage

control signal. On-chip pull-down is available for output quick

discharge when switch is turned off.

Fixed 500mA Current Limit (min)

5% Accurate Current Limit

72

(typ) Output Discharge Resistance

ESD Protected, above 8kV HBM and 2kV CDM

For the FPF2201, if the constant current condition still persists

after 30ms, these parts will shut off the switch and pull the fault

signal pin (FLAGB) low. The FPF2200 has an auto-restart

feature which will turn the switch on again after 450ms if the ON

pin is still active. The FPF2201 do not have this auto-restart

feature so the switch will remain off until the ON pin is cycled.

For the FPF2202, a current limit condition will immediately pull

the fault signal pin low and the part will remain in the constantcurrent mode until the switch current falls below the current

limit. For the FPF2200 through FPF2202, the minimum current

limit is 500mA with 5% accuracy.

Applications

PDAs

Cell Phones

GPS Devices

MP3 Players

Digital Cameras

Peripheral Ports

Notebook Computer

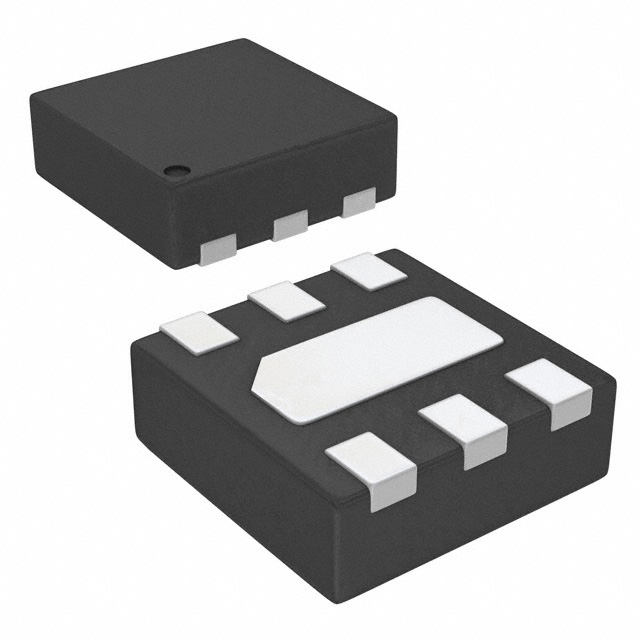

Pin 1

BOTTOM

TOP

Ordering Information

Part

Current Limit

(mA)

Current Limit

Blanking Time

(mS)

Auto-Restart Time

(mS)

ON Pin

Activity

FPF2200

500

30

450

Active HI

FPF2201

500

30

NA

Active HI

FPF2202

500

NA

NA

Active HI

©2008 Fairchild Semiconductor Corporation

FPF2200-FPF2202 Rev. B

1

www.fairchildsemi.com

FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

June 2008

�TO LOAD

VOUT

VIN

FPF2200/1/2

OFF ON

FLAGB

ON

GND

Functional Block Diagram

VIN

UVLO

THERMAL

SHUTDOWN

CONTROL

LOGIC

ON

CURRENT

LIMIT

VOUT

Output Discharge

FLAGB

GND

FPF2200-FPF2202 Rev. B

2

www.fairchildsemi.com

FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

Typical Application Circuit

�FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

Pin Configuration

ON 6

1 N/C

GND 5

2 VIN

FLAGB 4

3 VOUT

MicroFET 2x2 6L

(BOTTOMVIEW)

Pin Description

Pin

Name

1

N/C

No Connection

Function

2

VIN

Supply Input: Input to the power switch and the supply voltage for the IC

3

VOUT

4

FLAGB

5

GND

6

ON

Switch Output: Output of the power switch

Fault Output: Active LO, open drain output which indicates an over current, supply

under voltage or over temperature state

Ground

ON/OFF Control Input

Absolute Maximum Ratings

Parameter

VIN, VOUT, ON, FLAGB TO GND

Min.

Max.

Unit

-0.3

6

V

1.2

W

-65

125

°C

86

°C/W

Power Dissipation @ TA = 25°C

Operating and Storage Junction Temperature

Thermal Resistance, Junction to Ambient

Electrostatic Discharge Protection

HBM

8000

V

MM

400

V

CDM

2000

V

Recommended Operating Range

Parameter

Min.

Max.

Unit

VIN

1.8

5.5

V

Ambient Operating Temperature, TA

-40

85

°C

Electrical Characteristics

VIN = 1.8 to 5.5V, TA = -40 to +85°C unless otherwise noted. Typical values are at VIN = 3.3V and TA = 25°C.

Parameter

Symbol

Conditions

Min.

Typ.

Max.

Units

5.5

V

Basic Operation

Operating Voltage

Quiescent Current

VIN Shutdown Current

FPF2200-FPF2202 Rev. B

VIN

IQ

1.8

IOUT=0mA, VIN=VON=1.8V

40

65

IOUT=0mA, VIN=VON=3.3V

45

75

IOUT=0mA, VIN=VON=5.5V

55

85

VON=0V, VIN=5.5V, VOUT=short to

GND

3

2.5

A

A

www.fairchildsemi.com

�Symbol

Min.

Typ.

VON=0V, VOUT=5.5V, VIN=short to

GND

VOUT Shutdown Current

On-Resistance

Conditions

RON

VIH

ON Input Logic Low Voltage (OFF)

VIL

On Input Leakage

FLAGB Output High Leakage Current

A

140

185

160

210

VIN=1.8V, IOUT=200mA, TA=25°C

230

300

90

VIN=1.8V

0.8

1.4

m

265

72

VIN=5.5V

105

V

VIN=1.8V

0.5

VIN=5.5V

1.0

VON = VIN or GND

FLAGB Output Logic Low Voltage

1

VIN=3.3V, IOUT=200mA, TA=25°C

VIN=3.3V, VON=0V, IOUT=10mA

ON Input Logic High Voltage (ON)

Units

VIN=5.5V, IOUT=200mA, TA=25°C

VIN=3.3V, IOUT=200mA,

TA=-40°C to 85°C

Output Discharge Resistance

Max.

-1

1

VIN=5.5V, ISINK=100 A

0.05

0.1

VIN=1.8V, ISINK=100 A

0.12

0.25

VIN=5.5V, Switch on

1

V

A

V

A

Protections

Current Limit

ILIM

Thermal Shutdown

Under Voltage Shutdown

UVLO

VIN=3.3V, VOUT = 3.0V, TA=25°C

504

530

Shutdown Threshold

140

Return from Shutdown

130

Hysteresis

10

VIN increasing

1.55

Under Voltage Shutdown Hysteresis

1.65

557

mA

°C

1.75

V

50

mV

Dynamic

Turn On Time

tON

RL=500 , CL=0.001uF

70

S

Turn Off Time

tOFF

RL=500 , CL=0.001uF

600

nS

VOUT Rise Time

tRISE

RL=500 , CL=0.001uF

40

S

VOUT Fall Time

tFALL

RL=500 , CL=0.001uF

Over Current Blanking Time

tBLANK

FPF2200, FPF2201

15

30

60

mS

Auto-Restart Time

tRSTRT

FPF2200

225

450

900

mS

Current Limit Response Time

FPF2200-FPF2202 Rev. B

VIN = VON = 3.3V. Over-Current

Condition: RLOAD=1.55

4

100

5

nS

S

www.fairchildsemi.com

FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

Parameter

�80

70

V ON = VIN

50

SUPPLY CURRENT (uA)

SUPPLY CURRENT (uA)

VON=VIN

70

60

o

85 C

o

25 C

40

o

-40 C

30

20

VIN=3.3V

60

VIN=5.5V

50

VIN=1.8V

40

30

20

10

-40

10

1

2

3

4

5

6

-15

SUPPLY VOLTAGE (V)

60

85

Figure 2. Quiescent Current vs. Temperature

1.30

1.6

1.15

VIH

VON SUPPLY VOLTAGE (V)

VON SUPPLY VOLTAGE (V)

35

o

Figure 1. Quiescent Current vs. Input Voltage

VIL

1.00

0.85

0.70

0.55

0.40

1.4

VIN=5.5V

1.2

1.0

VIN=3.3V

0.8

VIN=1.8V

0.6

0.4

1

2

3

4

5

6

-40

-15

VIN, SUPPLY VOLTAGE (V)

10

35

60

85

o

TJ, JUNCTION TEMPERATURE ( C)

Figure 3. VON vs. Input Voltage

Figure 4. VON High Voltage vs. Temperature

1.4

0.04

1.2

0.03

VIN=5.5V

1.0

ON PIN CURRENT (uA)

VON SUPPLY VOLTAGE (V)

10

TJ, JUNCTION TEMPERATURE ( C)

VIN=3.3V

0.8

VIN=1.8V

0.6

0.4

0.02

VON = 5.5V

0.01

0.00

VON = 0V

-0.01

-0.02

-0.03

0.2

-40

-15

10

35

60

-40

85

10

35

60

85

TJ, JUNCTION TEMPERATURE ( C)

Figure 5. VON Low Voltage vs. Temperature

FPF2200-FPF2202 Rev. B

-15

o

o

TJ, JUNCTION TEMPERATURE ( C)

Figure 6. On Pin Current vs. Temperature

5

www.fairchildsemi.com

FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

Typical Characteristics

�600

590

500

OUTPUT CURRENT (mA)

OUTPUT CURRENT (mA)

600

400

300

200

580

VIN = 3.3V

570

VIN = 1.8V

560

550

VIN = 5.5V

540

100

530

-40

0

0

1

2

3

4

5

6

-15

VIN-VOUT (V)

Figure 7. Current Limit vs. Output Voltage

300

270

270

240

RON(mOhms)

RON (mOhms)

240

210

o

85 C

150

25oC

120

VIN=1.8V

210

180

VIN=3.3V

VIN=5.5V

90

-40

60

3.5

4.5

5.5

-15

10

35

60

85

o

VIN, SUPPLY VOLTAGE (V)

TJ, JUNCTION TEMPERATURE ( C)

Figure 9. RON vs. Input Voltage

Figure 10. RON vs. Temperature

1000

100

TFALL

RISE / FALL TIMES (uS)

TURN-ON/OFF TIMES (uS)

85

120

90

2.5

60

150

-40oC

1.5

35

Figure 8. Current Limit vs. Temperature

300

180

10

TJ, JUNCTION TEMPERATURE (oC)

100

TOFF

10

TON

VIN = 3.3V

RL = 500 Ohms

COUT = 0.11uF

1

0.1

-40

-15

10

35

60

-15

10

35

60

85

o

o

TJ, JUNCTION TEMPERATURE ( C)

TJ, JUNCTION TEMPERATURE ( C)

Figure 11. TON / TOFF vs. Temperature

FPF2200-FPF2202 Rev. B

TRISE

1

0.1

-40

85

VIN = 3.3V

RL = 500 Ohms

COUT = 0.11uF

10

Figure 12. TRISE / TFALL vs. Temperature

6

www.fairchildsemi.com

FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

Typical Characteristics

�BLANKING TIME (mS)

40

VIN

2V/DIV

38

36

IOUT

10mA/DIV

34

VON

2V/DIV

32

30

28

-40

VIN=3.3V,

RL=500 ,

CIN=10 F

VOUT

2V/DIV

-15

10

35

60

85

TJ, JUNCTION TEMPERATURE ( C)

100 s/DIV

Figure 13. TBLANK vs Temperature

VIN

2V/DIV

Figure 14. TON Response

VON

5V/DIV

VIN=3.3V,

RL=500 ,

CIN=10 F

VIN=3.3V,

RL=5 ,

CIN=10 F

IOUT

500mA/DIV

IOUT

10mA/DIV

VFLAGB

2V/DIV

VON

2V/DIV

TBLANK

VOUT

2V/DIV

VOUT

2V/DIV

500ns/DIV

10ms/DIV

Figure 15. TOFF Response

Figure 16. TBLANK Response

VIN=3.3V,

RL=1.2 ,

CIN=10 F

COUT=10 F

VON

2V/DIV

IOUT

500mA/DIV

IOUT

500mA/DIV

VIN

2V/DIV

VIN

2V/DIV

VOUT

2V/DIV

VOUT

2V/DIV

100 s/DIV

500 s/DIV

Figure 17. Current Limit Response

(Output is loaded with 1.2 resistor and COUT=10 F)

FPF2200-FPF2202 Rev. B

VIN=5V,

RL=1.2 ,

CIN=10 F

COUT=10 F

VON

2V/DIV

Figure 18. Current Limit Response

(Output is loaded with 1.2 resistor and COUT=100 F)

7

www.fairchildsemi.com

FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

Typical Characteristics

�IOUT

500mA/DIV

IOUT

5A/DIV

VIN=VON=,3.

3V, RL=1.2 ,

CIN=10 F

COUT=1 F

VOUT

2V/DIV

VOUT

2V/DIV

100 s/DIV

20 s/DIV

Figure 19. Current Limit Response

(Switch is powered into a short - Input and

enable pins are tied together)

FPF2200-FPF2202 Rev. B

VIN=3.3V,

RL=100 ,

CIN=10 F

COUT=1 F

VON

2V/DIV

VON

2V/DIV

Figure 20. Current Limit Response

(Output shorted to GND while the switch is in normal operation)

8

www.fairchildsemi.com

FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

Typical Characteristics

�Undervoltage Lockout (UVLO)

The FPF2200, FPF2201, and FPF2202 are state of the art High

Precision Current Limit switches designed to meet USB OTG

(On-The-Go) applications with optimum current for a safe

design practice. The core of each device is a 0.16 P-channel

MOSFET and a controller capable of functioning over an input

operating range of 1.8- 5.5V. The controller protects or offers

current limiting, UVLO(undervoltage lockout) and thermal

shutdown protection. The minimum current limit value is set to

500mA allowing to draw as much as 500mA from the USB port.

The undervoltage lockout turns-off the switch if the input voltage

drops below the undervoltage lockout threshold. With the ON

pin active the input voltage rising above the undervoltage

lockout threshold will cause a controlled turn-on of the switch

which limits current over-shoots.

Output Discharge Resistor

The FPF2200/1/2 family contains an 80 on-chip load resistor

for quick output discharge when the switch is turned off. This

features become more attractive when application requires

large output capacitor to be discharged when switch turns-off.

However, VOUT pin should not be connected directly to the

battery source due to the discharge mechanism of the load

switch.

On/Off Control

The ON pin is active high, and controls the state of the switch.

Applying a continuous high signal will hold the switch in the ON

state. The switch will move into the OFF state when the active

high is removed, or if a fault is encountered. For all versions, an

undervoltage on VIN or a junction temperature in excess of

140°C overrides the ON control to turn off the switch.

In addition, excessive currents will cause the switch to turn off in

the FPF2200 and FPF2201. The FPF2200 has an Auto-Restart

feature which will automatically turn the switch ON again after

450ms. For the FPF2201, the ON pin must be toggled to turn-on

the switch again. The FPF2202 does not turn off in response to

an over current condition but instead remains operating in a

constant current mode so long as ON is active and the thermal

shutdown or UVLO have not activated.

Thermal Shutdown

The thermal shutdown protects the die from internally or

externally generated excessive temperatures. During an overtemperature condition the FLAGB is activated and the switch is

turned-off. The switch automatically turns-on again if

temperature of the die drops below the threshold temperature.

Fault Reporting

Upon the detection of an over-current condition, an input UVLO,

or an over-temperature condition, the FLAGB signals the fault

mode by activating LO. In the event of an over-current condition

for the FPF2200 and FPF2201, the FLAGB goes LO at the end

of the blanking time while FLAGB goes LO immediately for the

FPF2202. If the over-current condition lasts longer than

blanking time, FLAGB remains LO through the Auto-Restart

Time for the FPF2200 while for the FPF2201, FLAGB is latched

LO and ON must be toggled to release it. With the FPF2202,

FLAGB is LO during the faults and immediately returns HI at the

end of the fault condition. FLAGB is an open-drain MOSFET

which requires a pull-up resistor between VIN and FLAGB.

During shutdown, the pull-down on FLAGB is disabled to reduce

current draw from the supply. A 100K pull up resistor is

recommended to be used in the application.

Current Limiting

The current limit ensures that the current through the switch

doesn't exceed a maximum value while not limiting at less than

a minimum value. The minimum current at which the parts will

limit is set to 500mA. The FPF2200 and FPF2201 have a

blanking time of 30ms (nominal) during which the switch will act

as a constant current source. At the end of the blanking time,

the switch will be turned-off. The FPF2202 has no current limit

blanking period so it will remain in a constant current state until

the ON pin is deactivated or the thermal shutdown turns-off the

switch.

FPF2200-FPF2202 Rev. B

9

www.fairchildsemi.com

FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

Description of Operation

�PCB Layout Recommendations

Input Capacitor

For best performance, all traces should be as short as possible.

To be more effective, the input and output capacitors should be

placed close to the device to minimize the effects that parasitic

trace inductances may have on normal and short-circuit

operation. Using wide traces for VIN, VOUT and GND will help

minimize parasitic electrical effects along with minimizing the

case to ambient thermal impedance.

To limit the voltage drop on the input supply caused by transient

in-rush currents when the switch is turned on into a discharged

load capacitor or a short-circuit, a capacitor is recommended to

be placed between VIN and GND. A 1uF ceramic capacitor, CIN,

placed close to the pins is usually sufficient. Higher values of

CIN can be used to further reduce the voltage drop.

Output Capacitor

Improving Thermal Performance

A 0.1uF capacitor COUT, should be placed between VOUT and

GND. This capacitor will prevent parasitic board inductances

from forcing VOUT below GND when the switch turns-off. For the

FPF2200 and FPF2201, the total output capacitance needs to

be kept below a maximum value, COUT(max), to prevent the

part from registering an over-current condition and turning-off

the switch. The maximum output capacitance can be

determined from the following formula:

An improper layout could result in higher junction temperature

and triggering the thermal shutdown protection feature. This

concern applies when the switch is set at higher current limit

value and an over-current condition occurs. In this case, the

power dissipation of the switch, from the formula below, could

exceed the maximum absolute power dissipation of 1.2W.

PD = (VIN - VOUT) x ILIM (Max)

ILIM (Max) X tBLANK (Min)

COUT (Max) =

The following techniques have been identified to improve the

thermal performance of this family of devices.

These

techniques are listed in order of the significance of their impact.

VIN

Power Dissipation

1. Thermal performance of the load switch can be improved by

connecting pin7 of the DAP (Die Attach Pad) to the GND plane

of the PCB.

During normal on-state operation, the power dissipated in the

device will depend upon the level at which the current limit is

set. The maximum allowed setting for the current limit is 500mA

and will result in a power dissipation of:

2. Embedding two exposed through-hole vias into the DAP

(pin7) provides a path for heat to transfer to the back GND

plane of the PCB. A drill size of Round, 14 mils (0.35mm) with

1-ounce copper plating is recommended to result in appropriate

solder reflow. A smaller size hole prevents the solder from

penetrating into the via, resulting in device lift-up. Similarly, a

larger via-hole consumes excessive solder, and may result in

voiding of the DAP.

P = (ILIM)2 * RON = (0.5)2 * 0.16 = 40mW

If the part goes into current limit, the maximum power

dissipation will occur when the output is shorted to ground. For

the FPF2200, the power dissipation will scale by the AutoRestart Time, tRSTRT, and the Over Current Blanking Time,

tBLANK, so that the maximum power dissipated is:

P (Max) =

=

tBLANK

tBLANK + tRSTRT

30

30 + 450

* VIN (Max) * ILIM (Max)

* 5.5 * 0.5 = 0.17W

Note this is below the maximum package power dissipation, and

the thermal shutdown feature will act as additional safety to

protect the part from damage due to excessive heating. The

junction temperature is only able to increase to the thermal

shutdown threshold. Once this temperature has been reached,

toggling ON will not turn-on the switch until the junction

temperature drops. For the FPF2202, a short on the output will

cause the part to operate in a constant current state dissipating

a worst case power of:

Figure 21: Two through hole open vias embedded in DAP

3. The VIN, VOUT and GND pins will dissipate most of the heat

generated during a high load current condition. The layout

suggested in Figure 23 provides each pin with adequate copper

so that heat may be transferred as efficiently as possible out of

the device. The low-power FLAGB and ON pin traces may be

laid-out diagonally from the device to maximize the area

available to the ground pad. Placing the input and output

capacitors as close to the device as possible also contributes to

heat dissipation, particularly during high load currents.

P (Max) = VIN (MAX) * ILIM (MAX) = 5.5 * 0.557 = 3.064W

This large amount of power will activate the thermal shutdown

and the part will cycle in and out of thermal shutdown so long as

the ON pin is active and the short is present.

FPF2200-FPF2202 Rev. B

10

www.fairchildsemi.com

FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

Application Information

�FPF2200-FPF2202 Integrated Load Switch with 500mA High Precision Current Limit

Figure 22: X-Ray result (bottom view with 45o angle)

Figure 25: Bottom and ASB Layers

Figure 26: Zoom in to Top layer

Figure 23: Proper layout of output and ground copper area

FPF22XX Demo Board

FPF22XX Demo board has components and circuitry to

demonstrate FPF2223/4/5 load switches functions and features.

R4 resistor with 0 value is used for measuring the output

current. Load current can be scoped by removing the R4

resistor and soldering a current loop to the R4 footprint. Thermal

performance of the board is improved using a few techniques

recommended in the layout recommendations section of

datasheet. R3 resistor should be left open for FPF220X family.

Figure 24: Top, SST, and AST Layers

FPF2200-FPF2202 Rev. B

11

www.fairchildsemi.com

�2.0

0.05 C

A

1.72

1.68

B

2X

6

4

0.15

2.0

1.21

2.25

0.90

0.52(6X)

0.05 C

PIN#1 IDENT

TOP VIEW

1

2X

3

0.65

0.42(6X)

RECOMMENDED

LAND PATTERN

0.10 C

NOTES:

0.08 C

SIDE VIEW

C

A. PACKAGE DOES NOT FULLY CONFORM

TO JEDEC MO-229 REGISTRATION

SEATING

PLANE

B. DIMENSIONS ARE IN MILLIMETERS.

C. DIMENSIONS AND TOLERANCES PER

ASME Y14.5M, 2009.

D. LAND PATTERN RECOMMENDATION IS

EXISTING INDUSTRY LAND PATTERN.

(0.70)

(0.20)4X

PIN #1 IDENT

1

E. DRAWING FILENAME: MKT-MLP06Krev5.

3

(0.40)

(6X)

(0.60)

6

4

(6X)

0.65

1.30

BOTTOM VIEW

0.10

0.05

C A B

C

�ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

19521 E. 32nd Pkwy, Aurora, Colorado 80011 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

© Semiconductor Components Industries, LLC

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

www.onsemi.com

1

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

www.onsemi.com

�