LB11850VA

Single‐phase Full‐wave

Pre‐driver with Speed

Control Function

for Fan Motor

www.onsemi.com

Monolithic Digital IC

Overview

The LB11850VA is a single-phase bipolar fan motor driver with

speed control function that works with a speed feedback signal.

A highly efficient, quiet and low power consumption motor driver

circuit, with a high speed accuracy and large variable speed can be

implemented by adding a small number of external components.

This pre-driver is optimal for driving large scale fan motors (with

large air volume and large current) such as those used in servers and

consumer products.

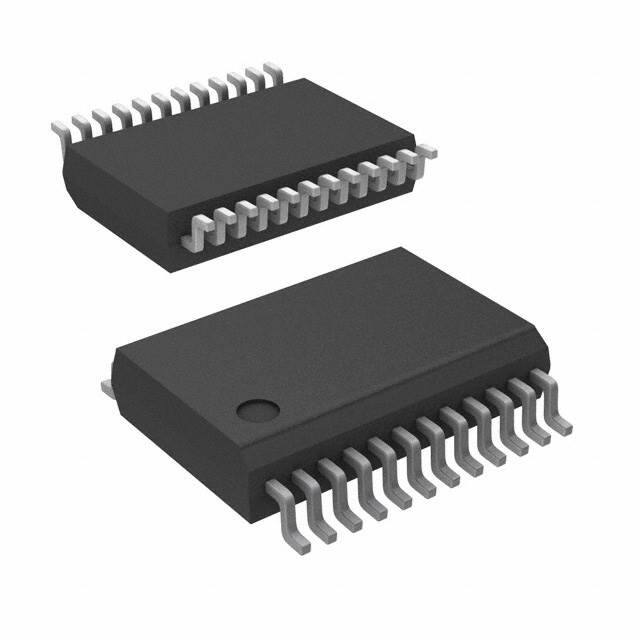

SSOP24

CASE 565AR

MARKING DIAGRAM

Functions and Features

• Pre-driver for Single-phase Full-wave Drive

PMOS-NMOS is Used as an External Power TR, Enabling

High-efficiency and Low-power-consumption Drive by Means

of the Low-saturation Output and Single-phase Full-wave Drive

On-chip Speed Control Circuit

♦ The Speed Control (Closed Loop Control) Using a Speed

Feedback Signal Makes it Possible to Achieve Higher Speed

Accuracy and Lower Speed Fluctuations when Supply Voltage

Fluctuates or Load Fluctuates, Compared with an Open-loop

Control System. Separately Excited Upper Direct PWM Control

Method is Used as the Variable-speed Control System

External PWM Input or Analog Voltage Input Enabling Variable

Speed Control

♦ The Speed Control Input Signal is Compatible with PWM Duty

Ratio or Analog Voltages

On-chip Soft Start Circuit

Lowest Speed Setting Pin

♦ The Lowest Speed can be Set with the External Resistor

Current Limiter Circuit Incorporated

♦ Chopper Type Current Limit at Start or Lock

Reactive Current Cut Circuit Incorporated

♦ Reactive Current before Phase Change is Cut to Enable Silent and

Low-consumption Drive

Constraint Protection and Automatic Reset Functions Incorporated

FG (Speed Detection), RD (Lock Detection) Output

Constant-voltage Output Pin for Hall Bias

XXXXXXXXXX

YMDDD

♦

•

•

•

•

•

•

•

•

•

XXXXX

Y

M

DDD

= Specific Device Code

= Year

= Month

= Additional Traceability Data

PIN ASSIGNMENT

24

1

OUT2P

OUT1P

OUT2N

OUT1N

VCC

SGND

5VREG

SENSE

CVI

C

CVO

EO

CTL

EI

RC

LIM

SOFT

CT

CPWM

IN+

FG

HB

RD

IN−

12

(Top View)

13

ORDERING INFORMATION

See detailed ordering and shipping information on page 14 of

this data sheet.

© Semiconductor Components Industries, LLC, 2013

March, 2018 − Rev. 1

1

Publication Order Number:

LB11850VA/D

�LB11850VA

SPECIFICATIONS

ABSOLUTE MAXIMUM RATINGS (TA = 25°C)

Symbol

VCC max

Parameter

Conditions

Ratings

Unit

VCC Maximum Supply Voltage

18

V

IOUTN max

OUTN Pin Maximum Output Current

20

mA

IOUTP max

OUTP Pin Maximum Sink Current

20

mA

VOUT max

OUT Pin Output Withstand Voltage

18

V

HB

HB Maximum Output Current

10

mA

CTL, C max

CTL, C Pin Withstand Voltage

7

V

CVI, LIM Pin Withstand Voltage

7

V

RD/FD Output Pin Output Withstand

Voltage

19

V

RD/FG Output Current

10

mA

CVI, LIM max

FG max

I5VREG max

Pd max

5VREG Pin Maximum Output Current

Allowable Power Dissipation

Mounted on a specified board (Notes 1, 2)

10

mA

0.9

W

Topr

Operating Temperature Range

−30 to +95

°C

Tstg

Storage Temperature Range

−55 to +150

°C

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. Mounted on a specified board: 114.3 mm × 76.1 mm × 1.6 mm, glass epoxy.

2. Tj max = 150_C. Use the device in a condition that the chip temperature does not exceed Tj = 150_C during operation.

RECOMMENDED OPERATING RANGES (TA = 25°C)

Parameter

Symbol

Conditions

Ratings

Unit

VCC1

VCC Supply Voltage 1

VCC pin

5.5 to 16

V

VCC2

VCC Supply Voltage 2

When VCC − 5VREG shorted

4.5 to 5.5

V

VCTL

CTL Input Voltage Range

0 to 5VREG

V

VLIM

LIM Input Voltage Range

0 to 5VREG

V

VCVI

VCI Input Voltage Range

0 to 5VREG

V

VICM

Hall Input Common Phase Input Voltage

Range

0.2 to 3

V

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

ELECTRICAL CHARACTERISTICS (TA = 25°C, VCC = 12 V, unless otherwise specified)

Parameter

Symbol

ICC1

Circuit Current

ICC2

5VREG

Typ

Max

Unit

During drive

Conditions

Min

12

15

mA

During lock protection

12

15

mA

5VREG Voltage

I5VREG = 5 mA

4.8

5.0

5.2

V

VHB

HB Voltage

IHB = 5 mA

1.05

1.20

1.35

V

VLIM

Current Limiter Voltage

190

210

230

mV

VCRH

CPWM Pin H Level Voltage

2.8

3.0

3.2

V

VCRL

CPWM Pin L level Voltage

0.9

1.1

1.3

V

ICPWM1

CPWM Pin Charge Current

VCPWM = 0.5 V

24

30

36

mA

ICPWM2

CPWM Pin Discharge Current

VCPWM = 3.5 V

21

27

33

mA

FPWM

CPWM Oscillation Frequency

C = 220 pF

30

www.onsemi.com

2

kHz

�LB11850VA

ELECTRICAL CHARACTERISTICS (TA = 25°C, VCC = 12 V, unless otherwise specified) (continued)

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

VCTH

CT Pin H Level Voltage

2.8

3.0

3.2

V

VCTL

CT Pin L Level Voltage

0.9

1.1

1.3

V

ICT1

CT Pin Charge Current

VCT = 2 V

1.6

2.0

2.5

mA

ICT2

CT Pin Discharge Current

VCT = 2 V

0.16

0.20

0.25

mA

RCT

CT Pin Charge/Discharge Current

Ratio

ICT1/ICT2

8

10

12

times

OUTN Pin Output H Voltage

IO = 10 mA

−

VCC−0.85

VCC−1.0

V

VONL

OUTN Pin Output L Voltage

IO = 10 mA

−

0.9

1.0

V

VOPL

OUTP Pin Output L Voltage

IO = 10 mA

−

0.5

0.65

V

VHN

Hall Input Sensitivity

IN+, IN− difference voltage

(including offset and hysteresis)

−

±15

±25

mV

VFGL

FG Output L Voltage

IFG = 5 mA

−

0.15

030

mA

IFGL

FG Pin Leak Current

VFG = 19 V

−

−

30

mA

VRDL

RD Output L Voltage

IRD = 5 mA

−

0.15

0.30

V

IRDL

RD Pin Leak Current

VRD = 19 V

−

−

30

mA

VEOH

EO Pin Output H Voltage

IEO1 = −0.2 mA

VREG−1.2

VREG−0.8

−

V

IEO1 = 0.2 mA

VONH

VEOL

EO Pin Output L Voltage

−

0.8

1.1

V

VRCH

RC Pin Output H Voltage

3.2

3.45

3.7

V

VRCL

RC Pin Output L Voltage

0.7

0.8

1.05

V

RC Pin Clamp Voltage

1.3

1.5

1.7

V

VCTLH

CTL Pin Input H Voltage

2.0

−

VREG

V

VCTLL

CTL Pin Input L Voltage

0

−

1.0

V

VCTLO

CTL Pin Input Open Voltage

VREG−0.5

−

VREG

V

ICTLH

CTL Pin H Input H Current

VFGIN = 5VREG

−10

0

10

mA

ICTLL

CTL Pin L Input L Current

VFGIN = 0 V

−120

−90

−

mA

VRCCLP

VCH

C Pin Output H Voltage

VREG−0.3

VREG−0.1

−

V

VCL

C Pin Output L Voltage

1.8

2.0

2.2

V

IBLIM

LIM Pin Input Bias Current

−1

−

1

mA

VILIM

LIM Pin Common Phase Input

Voltage Range

2.0

−

VREG

V

ICSOFT

SOFT Pin Charge Current

1.0

1.3

1.6

mA

VISOFT

SOFT Pin Operating Voltage

Range

2.0

−

VREG

V

IB(VCI)

CVI Pin Input Bias Current

−1

−

2

mA

CVI Pin Common Phase Input

Voltage Range

2.0

−

VREG

V

−

V

2.2

V

VIVCI

VOH(VCO)

CVO Pin Output H Level Voltage

VOL(VCO)

Output L Level Voltage

VREG−0.35 VREG−0.2

1.8

2.0

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

3. Design target value and si not measured.

www.onsemi.com

3

�LB11850VA

1.2

Mounted on a specified board:

114.3 × 76.1 × 1.6 mm

glass epoxy

Allowable Power Dissipation,

Pd max − W

1.0

0.9

0.8

0.6

0.4

0.2

0.0

−30

0

90 95

60

30

120

Ambient Temperature, TA − 5C

Figure 1. Pd max − TA

TRUTH TABLE − LOCK PROTECTION CPWM = H

IN−

IN+

CT

OUT1P

OUT1N

OUT2P

OUT2N

FG

Mode

H

L

L

L

L

OFF

H

L

OUT1 → 2 drive

L

H

OFF

H

L

L

OFF

OUT2 → 1 drive

OFF

L

OFF

H

L

Lock protection

OFF

H

OFF

L

OFF

OUT1P

OUT1N

OUT2P

OUT2N

Mode

H

L

L

H

H

TRUTH TABLE − SPEED CONTROL CT = L

EO

CPWM

IN−

L

H

H

L

L

L

OFF

H

OUT1 → 2 drive

L

H

OFF

H

L

L

OUT2 → 1 drive

H

L

OFF

L

OFF

H

Regeneration mode

L

H

OFF

H

OFF

L

H

L

IN+

www.onsemi.com

4

�VCC

5

www.onsemi.com

Figure 2. Block Diagram

CTL

signal

CTL

C

CVO

CVI

SOFT

LIM

RC

5VREG

VCC

CTL

VREF

1shot−

multi

VREG

EI

EDEG

Thermal

shut down

FG

EO

FG

RD

IN+

IBL01797

HALL

HB

HallBias

CT

IN−

CPWM

Oscillation

CONTROL

CIRCUIT

SENSE

5VREG

Discharge circuit

GND

OUT2P

OUT2N

OUT1P

OUT1N

LB11850VA

BLOCK DIAGRAM

�LB11850VA

APPLICATION CIRCUIT

*3

1 mF/25 V

Rp = 1 kW

1)

3)

2)

4)

100 W

RF

1 mF/25 V

RFG/RPD =

10 kW to 100 kW

*2

V CC

5VREG

*9

FG

RD

RC

*8

*7

SENSE

LIM

LB11850VA

SOFT

CVI

CVO

OUT1P

1)

OUT1N

2)

OUT2P

3)

OUT2N

4)

HB

IN−

C

CTL signal

*4

IN+

CTL

CT

*5

EI

EO

CPWM

SGND

*1

Figure 3. Sample Application Circuit

www.onsemi.com

6

H

*6

CT = 1 mF

CP = 220 pF

30 kHz

�LB11850VA

DESCRIPTION OF PRE-DRIVER BLOCK

*6:

This is the pin to connect capacitor for lock

detection.

Constant-current charging and constant-current

discharging circuits are incorporated. When the

pin voltage becomes 3.0 V, the safety lock is

applied, and when it lowers to 1.0 V, the lock

protection is reset.

Connect this pin to GND when it is not in use

(when lock protection is not required).

*7:

This is the pin for current limiter detection.

When the pin voltage exceeds 0.21 V, current

limiting is applied, and the low-side regeneration

mode is established.

Connect this pin to GND when it is not in use.

*8:

Lock detection pin.

This is the open collector output, which outputs

“L” during rotation and “H” at stop. This pin is left

open when it is not in use.

*9:

Speed detection pin.

This is the open collector output, which can detect

the rotation speed using the FG output according

to the phase change. This pin is left open when it

is not in use.

*1:

SGND is connected to the control circuit power

supply system.

*2:

For the signal-side power stabilization capacitor,

the capacitance of more than 0.1 mF is used.

Connect the capacitor between VCC and GND with

the thick pattern and along the shortest route.

*3:

For the power-side power stabilization capacitor,

the capacitance of more than 0.1 mF is used.

Connect the capacitor between power-side power

supply and GND with the thick pattern and along

the shortest route.

*4:

Hall signal input pins.

Wiring needs to be short to prevent carrying noise.

If noise is carried, insert a capacitor between IN+

and IN−. The Hall input circuit is a comparator

having a hysteresis of 15 mV.

It has a ±30 mV (input signal difference voltage)

soft switch zone.

It is recommended that the Hall input level is

100 mV (p−p) at the minimum.

*5:

This is the pin to connect capacitor for generating

the PWM basic frequency.

Use of CP = 220 pF produces oscillation at the

frequency of 30 kHz which serves as the PWM

basic frequency.

Since this pin is also used for the current limiter

reset signal, the capacitor must be connected

without fail even when no speed control is

implemented.

www.onsemi.com

7

�LB11850VA

DESCRIPTION OF SPEED CONTROL BLOCK

1. Speed Control Diagram

The speed slope is determined by the constant of the RC pin.

(RPM)

CR time constant large

CR time constant small

Rotation speed

Minimum speed

Determined by LIM pin voltage

Small ← CTL signal (PWMDUTY) → Large

0%

100%

Large ← EO pin voltage (V) → Small

Minimum speed

setting rotation

Variable speed

ON−Duty small

Full speed

ON−Duty large

CTL pin

5VREG

LIM voltage

EO pin

EO voltage

0V

Figure 4. Speed Control Diagram

2. Timing at Startup (Soft Start)

VCC pin

CTL pin

Stop

Full speed

Soft start

The slope changes according to the capacitance of SOFT pin.

(Large → Large of slope)

SOFT pin

Stop

Full speed

Figure 5. Timing at Startup (Soft Start)

www.onsemi.com

8

�LB11850VA

3. Additional Description of Operations:

The LB11850 forms a feedback loop inside the IC so that the FG period (motor speed) corresponding to the control

voltage is established by inputting the duty pulse.

LB11850VA

FG

CTL

signal

CTL

Speed control block

Closed

Feed−back

Loop

Pre−driver block

CONTROL

SIGNAL

Figure 6. Additional Description of Operations

The operation inside the IC is as follows. Pulse signals are created from the edges of the FG signals as shown in the figure

below, and a waveform with a pulse width which is determined by the CR time constants and which uses these edges as

a reference is generated by a one-shot multivibrator.

These pulse waveforms are integrated and the duty ratio of the pre-driver output is controlled as a control voltage.

FG

EDGE pulse

Slope due to

CR time

constant

RC pin

1 shot output

TRC(s) = 1.15RC

Figure 7. Pulse Waveforms

Furthermore, by changing the pulse width as determined by the CR time constant, the VCTL versus speed slope can be

changed as shown in the speed control diagram of the previous section.

However, since the pulses used are determined by the CR time constant, the variations in CR are output as-is as the speed

control error.

www.onsemi.com

9

�LB11850VA

4. Procedure for Calculating Constants:

The slope shown in the speed control diagram is determined by the constant of the RC pin.

(RPM)

Motor

at maximum speed

0%

CTL Duty(%)

100%

Figure 8.

1) Obtain FG signal frequency fFG (Hz) of the maximum speed of the motor.

(With FG2 pulses per rotation)

fFG (Hz) = 2 rpm / 60 ....

2) Obtain the time constant which is connected to the RC pin.

(Have “DUTY” (example: 100% = 1.0, 60% = 0.6) serve as the CTL duty ratio at which the maximum speed is

to be obtained.)

R × C = DUTY / (3.3 × 1.1 × fFG) ....

3) Obtain the resistance and capacitance of the capacitor.

Based on the discharge capacity of the RC pin, the capacitance of the capacitor which can be used is 0.01 to

0.015 mF. Therefore, find the appropriate resistance using equation or below from the result of

above.

R = (R × C) / 0.01 mF ....

R = (R × C) / 0.015 mF ....

The temperature characteristics of the curve are determined by the temperature characteristics of the capacitor of the RC

pin. When temperature-caused fluctuations in the speed are to be minimized, use a capacitor with good temperature

characteristics.

www.onsemi.com

10

�LB11850VA

These pins determine the position of the slope origin. (When the origin point is at (0%, 0 rpm), CVO and CVI are shorted.)

1) Movement along the X-axis (resistance divided between CVO and GND)

(RPM)

Motor

at maximum speed

Move in the direction

of the X−axis

CTL Duty(%)

0%

100%

Figure 9.

(Example)

In the case where the characteristics change from ones with the origin point (0%, 0 rpm) to ones where the speed at a duty

ratio of 30% becomes the speed at 0%:

First, obtain the input voltage of the CVI pin required at 0%.

CVI = 5 − (3 × duty ratio) = 5 − (3 × 0.3) = 5 − 0.9 = 4.1 V

Next, obtain the resistances at which the voltage becomes 4.1 V by dividing the resistance between CVO and GND when

CVO is 5 V. The ratio of CVO−CVI: CVI−GND is 0.9 V : 4.1 V = 1 : 4.5.

Based on the above, the resistance is 20 kW between CVO and CVI and 91 kW between CVI and GND.

Furthermore, the slope changes. (In the case of the example given, since the resistance ratio is 1 : 4.5, the slope is now

4.5/5.5 = 0.8 times what it was originally.)

If necessary, change the resistance of the RC pin, and adjust the slope.

LIM

VREF

SOFT

CVI

R4

CVO

R5

C

CTL

CTL

Figure 10.

www.onsemi.com

11

�LB11850VA

2) Movement along the Y-axis (resistance divided between CVO and VCC)

(RPM)

Motor

at maximum speed

Move in the direction

of the Y−axis

CTL Duty(%)

0%

100%

Figure 11.

(Example)

In the case where the characteristics change from ones with the origin point (0%, 0 rpm) to ones where the speed at a duty

ratio of 25% becomes 0 rpm:

First, obtain the CVO pin voltage required for the CVI voltage to be 5 V at 25%.

CVO = 5 − (3 × duty ratio) = 5 − (3 × 0.25) = 5 − 0.75 = 4.25 V

With CVO = 4.25 V, find the resistances at which CVI = 5 V.

The ratio of CVO−CVI : CVI−GND is 0.75 V : 7 V = 1 : 9.3.

Based on the above, the resistance is 20 kW between CVO and CVI and 180 kW between CVI and VCC.

(Due to the current capacity of the CVO pin, the total resistance must be set to 100 kW or more.)

Furthermore, the slope changes. (In the case of the example given, since the resistance ratio is 1 : 9.3, the slope is now

9.3/10.3 = 0.9 times what it was originally.)

If necessary, change the resistance of the RC pin, and adjust the slope.

VCC

LIM

VREF

SOFT

R4

CVI

CVO

C

CTL

CTL

Figure 12.

www.onsemi.com

12

�LB11850VA

The minimum speed is determined by the voltage of the LIM pin.

(RPM)

Maximum speed

10000

8000

6000

4000

Minimum

speed setup

2000

0%

5V

100%

2V

CTL Duty(%)

CVO pin voltage (V)

Figure 13.

1) Obtain the ratio of the minimum speed required to the maximum speed.

Ra = Minimum speed/maximum speed ....

In the example shown in the figure above, Ra = minimum speed/maximum speed = 3000/10000 = 0.3.

2) Obtain the product of the duty ratio at which the maximum speed is obtained and the value in equation .

Ca = Duty ratio at maximum speed × Ra ....

In this example, Ca = duty ratio at maximum speed × Ra = 0.8 × 0.3 = 0.24.

3) Obtain the required LIM pin voltage.

LIM = 5 − (3 × Ca) ....

In this example, LIM = 5 − (3 × Ca) = 5 − (3 × 0.24) ≈ 4.3 V.

4) Divide the resistance of 5VREG, and generate the LIM voltage.

In this example, the voltage is 4.3 V so the resistance ratio is 1 : 6.

The resistance is 10 kW between 5VREG and LIM and 62 kW between LIM and GND.

5VREG

LIM

VREF

SOFT

CVI

Figure 14.

www.onsemi.com

13

�LB11850VA

In order to connect a capacitor capable of smoothing the pin voltage to the C pin, the correlation given in the following

equation must be satisfied when f (Hz) serves as the input signal frequency of the CTL pin. (R is contained inside the IC,

and is 180 kW (typ.).)

1/f = t < CR

The higher the capacitance of the capacitor is, the slower the response to changes in the input signal is.

5VREG

Connect a capacitor capable of

smoothing the pin voltage

1/f = t < CR

CTL pin input inverted waveform

(same frequency)

C pin

CTL Pin

CTL Circuit

VREF Circuit

180 kW

Figure 15.

ORDERING INFORMATION

Device

Package

Wire Bond

Shipping† (Qty / Packing)

LB11850VA−TLM−E

SSOP24 (225mil)

(Pb−Free)

Au−wire

2,000 / Tape & Reel

LB11850VA−TLM−H

SSOP24 (225mil)

(Pb−Free / Halogen Free)

Au−wire

2,000 / Tape & Reel

LB11850VA−W−AH

SSOP24 (225mil)

(Pb−Free / Halogen Free)

Cu−wire

2,000 / Tape & Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

www.onsemi.com

14

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

SSOP24 (225mil)

CASE 565AR

ISSUE A

DATE 23 OCT 2013

SOLDERING FOOTPRINT*

5.80

1.0

(Unit: mm)

0.32

GENERIC

MARKING DIAGRAM*

XXXXXXXXXX

YMDDD

0.50

NOTE: The measurements are not to guarantee but for reference only.

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

98AON66069E

SSOP24 (225MIL)

XXXXX = Specific Device Code

Y = Year

M = Month

DDD = Additional Traceability Data

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

www.onsemi.com

1

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�