Smart LiB Gauge

Battery Fuel Gauge LSI

For 1‐Cell Lithium‐ion/

Polymer (Li+)

LC709203F

www.onsemi.com

Overview

LC709203F is a Fuel Gauge for a single lithium ion/polymer

battery. It is part of our Smart LiB Gauge family of Fuel Gauges

which measure the battery RSOC (Relative State Of Charge) using its

unique algorithm called HG−CVR. The HG−CVR algorithm

eliminates the use of a sense resistor and provides accurate RSOC

information even under unstable conditions (e.g. changes of battery;

temperature, loading, aging and self-discharge). An accurate RSOC

contributes to the operating time of portable devices.

LC709203F is available in two small packages realizing the

industries smallest PCB footprint for the complete solution. It has

minimal parameters to be set by the user enabling simple, quick setup

and operation.

1

WDFN8

CASE 509AF

MARKING DIAGRAMS

WDFN8

9203F

**

ASWLYW

G

Features

• HG−CVR Algorithm Technology

No External Sense Resistor

♦ 2.8% Accuracy of RSOC

♦ Accurate RSOC of Aging Battery

♦ Automatic Convergence of Error

♦ Adjustment for the Parasitic Impedance around the Battery

♦ Simple and Quick Setup

Low Power Consumption

♦ 3 �A Operational Mode

Precision Voltage Measurement

♦ ±7.5 mV

Precision Timer

♦ ±3.5%

Alerts for Low RSOC and/or Low Voltage

Temperature Compensation

♦ Sense Thermistor Input

♦ Via I2C

Detect Battery Insertion

I2C Interface (up to 400 kHz Supported)

These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

♦

•

•

•

•

•

•

•

•

Applications

•

•

•

•

•

•

Wireless Handsets

Smartphones/PDA Devices

MP3 Players

Digital Cameras

Portable Game Players

USB-related Devices

© Semiconductor Components Industries, LLC, 2015

November, 2020 − Rev. 17

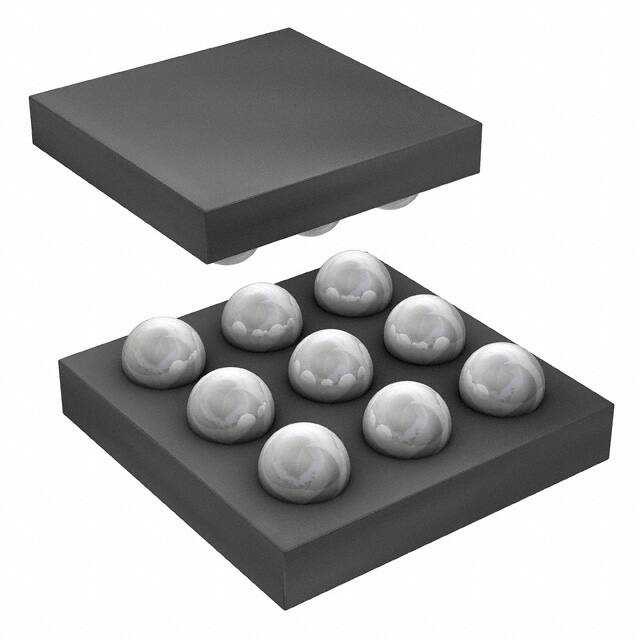

WLCSP9

CASE 567JH

9203F** = Specific Device Code

**

= 01 (LC709203FQH−01TWG)

02 (LC709203FQH−02TWG)

03 (LC709203FQH−03TWG)

04 (LC709203FQH−04TWG)

AS

= Assembly Location

WL

= Lot Number

YW

= Work Week

G

= Pb−Free Package

(Note: Microdot may be in either location)

WLCSP9

203**

YMXXX

203**

**

Y

M

XXX

= Specific Device Code

= 01 (LC709203FXE−01MH)

02 (LC709203FXE−02MH)

03 (LC709203FXE−03MH)

04 (LC709203FXE−04MH)

05 (LC709203FXE−05MH)

= Year

= Month Code

= Lot Number

ORDERING INFORMATION

See detailed ordering and shipping information on page 19 of

this data sheet.

1

Publication Order Number:

LC709203F/D

�LC709203F

Application Circuit Example

System VDD

10 k�

10 k�

I2C Bus VDD

Master

TSW

TSENSE

Battery

Pack

SDA

SCL

T

ASIC

ALARMB

VDD

VSS

10 k�

Interrupt Input

PACK+

PACK−

TEST

LC709203F

1 �F

VSS

System

System VSS

Figure 1. Example of an Application Schematic using LC709203F

(Temperature Input via I2C)

System VDD

10 k�

10 k�

I2C Bus VDD

Battery

Pack

Master

10 k� (same as Thermistor

Resistance Value)

TSW

SDA

SCL

10 k�

Thermistor

TSENSE

100 �

T

ASIC

PACK+

PACK−

ALARMB

VDD

VSS

TEST

LC709203F

10 k�

Interrupt Input

1 �F

VSS

System

System VSS

Figure 2. Example of an Application Schematic using LC709203F

(The Temperature is Measured Directly by a Thermistor)

www.onsemi.com

2

�LC709203F

SDA

ALARMB

I2C

Interface

SCL

TEST

VDD

Drv

TSW

Look Up

Table for

Internal

Battery

Impedance

& OCV

Processing

Unit

ADC

TSENSE

VDD

Voltage

Sense

VSS

Reference

Voltage

Timer

Power On

Reset

Figure 3. Simplified Block Diagram

ALARMB

(Bottom View)

VDD

(Bottom View)

VSS

WLCSP9 1.60x1.76

“Pb-Free, Halogen Free Type”

TEST

WDFN8 3x4, 065P

“Pb-Free, Halogen Free Type”

1

2

3

4

9

C1

C2

C3

SDA

SCL

TSENSE

B1

B2

B3

TEST

NC

TSW

A2

A3

8

7

6

5

SCL

SDA

TSENSE

TSW

A1

VSS

Figure 4. Pin Assignment

www.onsemi.com

3

ALARMB VDD

�LC709203F

Table 1. PIN FUNCTION

WDFN8

WLP9

Pin Name

I/O

1

B1

TEST

I

Connect this pin to VSS.

Description

2

A1

VSS

−

Connect this pin to the battery’s negative (−) pin.

3

A3

VDD

−

Connect this pin to the battery’s positive (+) pin.

4

A2

ALARMB

O

This pin indicates alarm by low output(open drain). Pull-up must be done externally.

Alarm conditions are specified by registers (0x13 or 0x14).

Connect this pin to VSS when not in use.

5

B3

TSW

O

Power supply output for thermistor. This pin goes HIGH during temperature read

operation. Resistance value of TSW (for thermistor pull-up) must be the same value

as the thermistor. (Note 1)

6

C3

TSENSE

I

Thermistor sense input. If you connect this pin to thermistor, insert 100 � resistance

between them for ESD. (Note 1)

7

C1

SDA

I/O

I2C Data pin (open drain). Pull-up must be done externally.

8

C2

SCL

I/O

I2C Clock pin (open drain). Pull-up must be done externally.

−

B2

NC

−

Don’t care.

9

−

Exposed

PAD

−

Don’t care.

1. TSW and TSENSE must be disconnected as Figure 1 when not in use.

Table 2. ABSOLUTE MAXIMUM RATINGS (TA = 25°C, VSS = 0 V)

Specification

Parameter

Symbol

Maximum Supply Voltage

Pin/Remarks

Conditions

VDD (V)

Min

Typ

Max

Unit

V

VDD max

VDD

−

−0.3

−

+6.5

Input Voltage

VI (1)

TSENSE

−

−0.3

−

VDD + 0.3

Output Voltage

Vo (1)

TSW

−

−0.3

−

VDD + 0.3

Vo (2)

ALARMB

−

−0.3

−

Input/Output Voltage

VIO (1)

SDA, SCL

−

−0.3

−

+5.5

Allowable Power Dissipation

Pd max

WDFN8

−

−

−

480

WLP9

TA = −40 to

+85_C

−

−

−

210

Operating Ambient Temperature

Topr

−

−40

−

+85

Storage Ambient Temperature

Tstg

−

−55

−

+125

mW

_C

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

Table 3. ALLOWABLE OPERATING CONDITIONS (TA = −40 to +85°C, VSS = 0 V)

Specification

VDD (V)

Min

Typ

Max

Unit

VDD

−

2.5

−

4.5

V

VIH (1)

TSENSE

2.5 to 4.5

0.7 VDD

−

VDD

VIH (2)

ALARMB, SDA, SCL

2.5 to 4.5

1.4

−

−

VIL (1)

TSENSE

2.5 to 4.5

VSS

−

0.25 VDD

VIL (2)

ALARMB, SDA, SCL

2.5 to 4.5

−

−

0.5

Parameter

Symbol

Pin/Remarks

Operating Supply Voltage

VDD (1)

High Level Input Voltage

Low Level Input Voltage

Conditions

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

www.onsemi.com

4

�LC709203F

Table 4. ELECTRICAL CHARACTERISTICS (TA = −40 to +85°C, VSS = 0 V)

Specification

Symbol

Pin/Remarks

Conditions

VDD (V)

Min

High Level Input Current

IIH (1)

SDA, SCL

VIN = VDD

(including output

transistor off leakage

current)

2.5 to 4.5

−

−

1

Low Level Input Current

IIL (1)

SDA, SCL

VIN = VSS

(including output

transistor off leakage

current)

2.5 to 4.5

−1

−

−

VOH (1)

TSW

IOH = −0.4 mA

3.0 to 4.5

VDD − 0.4

−

−

IOH = −0.2 mA

2.5 to 4.5

VDD − 0.4

−

−

IOL = 3.0 mA

3.0 to 4.5

−

−

0.4

IOL = 1.3 mA

2.5 to 4.5

−

−

0.4

2.5 to 4.5

−

0.1 VDD

−

2.5 to 4.5

−

10

−

pF

−

−

2.4

V

−

−

90

ms

Parameter

High Level Output Voltage

VOH (2)

Low Level Output Voltage

Hysteresis Voltage

VOL (2)

TSW,

ALARMB,

SDA, SCL

VOL (1)

VHYS(1)

SDA, SCL

Pin Capacitance

CP

All pins

Reset Release Voltage

(Note 2)

VRR

VDD

Initialization Time after

Reset Release (Note 2)

TINIT

Auto Sleep Set Time

TATS

Time Measurement

Accuracy

TME

Consumption Current

(Note 3)

IDD (1)

Voltage Measurement

Accuracy

VME (1)

2.4 to 4.5

VDD

IDD (2)

VME (2)

Pins other than

the pin under test

VIN = VSS

TA = 25_C

VDD

Typ

Max

Unit

�A

V

2.4 to 4.5

−

1

1.2

s

TA = −20_C to +70_C

2.5 to 4.5

−3.5

−

+3.5

%

Operational mode

2.5 to 4.5

−

3

4.5

�A

Sleep mode

2.5 to 4.5

−

1

2

TA = +25_C

3.6

−7.5

−

+7.5

TA = −20_C to +70_C

2.5 to 4.5

−20

−

+20

mV/cell

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

2. Once VDD voltage exceeds over the VRR, this LSI will release RESET status. And the LSI goes into Sleep mode TINIT after it.

3. Consumption current is a value in the range of −20_C to +70_C.

www.onsemi.com

5

�LC709203F

Table 5. I2C SLAVE CHARACTERISTICS (TA = −40 to +85°C, VSS = 0 V)

Specification

Min

Max

Unit

−

400

kHz

(See Figure 5)

1.3

−

�s

SCL, SDA

(See Figure 5)

1.1

−

�s

THD:RSTA

SCL, SDA

(See Figure 5)

0.6

−

�s

Repeated START Condition Setup Time

TSU:STA

SCL, SDA

(See Figure 5)

0.6

−

�s

STOP Condition Setup Time

TSU:STO

SCL, SDA

(See Figure 5)

0.6

−

�s

Data Hold Time

THD:DAT

SCL, SDA

(See Figure 5)

0

0.9

�s

Data Setup Time

TSU:DAT

SCL, SDA

(See Figure 5)

100

−

ns

Clock Low Period

TLOW

SCL

(See Figure 5)

1.3

−

�s

Clock High Period

(See Figure 5)

Parameter

Symbol

Pin/Remarks

Clock Frequency

TSCL

SCL

Bus Free Time between STOP Condition

and START Condition

TBUF

SCL, SDA

Hold Time START Condition.

First clock pulse is generated after this

interval

THD:STA

Hold Time Repeated START Condition

Conditions

VDD (V)

2.5 to 4.5

THIGH

SCL

0.6

−

�s

Clock/Data Fall Time

TF

SCL, SDA

20 + 0.1CB

300

ns

Clock/Data Rise Time

TR

SCL, SDA

20 + 0.1CB

300

ns

Time-out Interval (Notes 4, 5)

TTMO

SCL, SDA

(See Figure 6)

9

11

s

Wake Up Time from Sleep Mode

TWU

SDA

(See Figure 7)

−

400

�s

SDA Low Pulse Width to Wake Up

TSP

SDA

(See Figure 7)

0.6

−

�s

Wake Up Retention Time from the Falling

Edge of SDA

TWR1

SDA

(See Figure 7)

500

−

ms

Wake Up Retention Time from STOP

Condition

TWR2

SCL, SDA

(See Figure 7)

500

−

ms

4. This LSI resets I2C communication if the communication takes more than TTMO. It initializes an internal timer to measure the interval when

it detects ninth clock pulse. It can receive a new START condition after the reset.

5. This LSI may lose I2C communication at this reset operation. Then if a master can’t receive a response it must restart transaction from START

condition.

TBUF

SDA

THD:STA

TLOW

TR THD:DAT

THIGH

TF

TSU:DAT

TSU:STA

THD:RSTA

TSU:STO

SCL

P

S

Sr

Figure 5. I2C Timing Diagram

P

SDA

TTMO

SCL

1

S

2

8

1

9

ACK

Figure 6. I2C Time-out Interval

www.onsemi.com

6

2

8

9

ACK

�LC709203F

I2C Communication Protocol

Communication protocol type: I2C

Frequency: Supported up to 400 kHz

Slave Address: 0001011 (The first 8−bits after the Strat Condition is 0x16 (WRITE) or 0x17 (READ).)

This LSI will stretch the clock.

Bus Protocols

S

Sr

Rd

Wr

A

N

P

CRC−8

…

Read Word Protocol

S

:

:

:

:

:

:

:

:

:

:

:

Start Condition

Repeated Start Condition

Read (bit value of 1)

Write (bit value of 0)

ACK (bit value of 0)

NACK (bit value of 1)

Stop Condition

Slave Address to Last Data (CRC−8−ATM : ex.3778 mV : 0x16, 0x09, 0x17, 0xC2, 0x0E → 0x86)

Master-to-Slave

Slave-to-Master

Continuation of protocol

Slave Address

Wr

A

Command Code

A

Sr

Slave Address

Rd

A

Data Byte Low

A

A

CRC−8

N

P

…

Data Byte High

* When you do not read CRC−8, LSI data is not reliable. CRC−8−ATM ex: (5 bytes) 0x16, 0x09, 0x17, 0xC2,

0x0E → 0x86

Write Word Protocol

S

Data Byte Low

Slave Address

Wr

A

A

Command Code

Data Byte High

A

A

CRC−8

* When you do not add CRC−8, the Written data (Data byte Low/High) become invalid.

CRC−8−ATM ex: (4 bytes) 0x16, 0x09, 0x55, 0xAA → 0x3B

www.onsemi.com

7

…

A

P

…

�LC709203F

Wake Up from Sleep Mode

Sleep Mode

Enable I2C

Communication

Disable I2C Communication

Disable I2C

Communication

TSP

SDA

TWU

TWR1

(Not to Scale)

Sleep Mode

Enable I2C Communication

SCL

Disable I2C Communication

TWR2

SDA

(Not to Scale)

STOP Condition

Figure 7. I2C Wake up Timing Diagram

To wake up from Sleep mode, and to start I2C

communication, Host side must set SDA low prior to the I2C

communication. The Fuel Gauge LSI enables I2C

communication after the TWU time period which is

measured from the falling edge of SDA, as above timing

chart. This “Wake up condition” is invalid for the following

two cases:

1. After TWR1 timing following the falling edge of

SDA, the Fuel Gauge LSI “Wake up condition”

goes into autonomous disable. Once I2C

communication is started, the operation doesn’t go

into disable until the TWR2 timing has elapsed

after STOP condition (below case).

2. After TWR2 timing following I2C Bus STOP

condition, the Fuel gauge LSI “Wake up

condition” goes into autonomous disable.

If the “Wake up condition” goes into disable, set SDA low

to once again wake up from the Sleep mode prior to the I2C

communication. If Operational mode is set, it is possible to

start I2C communication without this “Wake up operation”.

Notice for I2C Communication Shared with Another

Device

When the I2C Bust (on which the Fuel Gauge LSI is

connected) is shared with another device the Fuel Gauge LSI

must be in its operation mode before the other Device starts

I2C communication.

www.onsemi.com

8

�LC709203F

Table 6. FUNCTION OF REGISTERS

Command

Code

Register Name

R/W

Range

0x04

Before RSOC

W

0xAA55: Initialize RSOC

0x06

Thermistor B

R/W

0x0000 to 0xFFFF

0x07

Initial RSOC

W

0xAA55: Initialize RSOC

0x08

Cell Temperature

R

0x0000 to 0xFFFF

Unit

W

0x09E4 to 0x0D04

(I2C mode)

Initial

Value

Description

Executes RSOC initialization with sampled

maximum voltage when 0xAA55 is set.

1K

Sets B−constant of the

thermistor to be measured.

Executes RSOC initialization when 0xAA55

is set.

0.1K

(0.0°C =

0x0AAC)

Displays Cell Temperature

Sets Cell Temperature in

mode

1 mV

I2C

Displays Cell Voltage

−

0x0D34

−

0x0BA6

(25°C)

0x09

Cell Voltage

R

0x0000 to 0xFFFF

−

0x0A

Current Direction

R/W

0x0000: Auto mode

0x0001: Charge mode

0xFFFF: Discharge mode

Selects Auto/Charge/Discharge mode

0x0000

0x0B

APA

(Adjustment Pack

Application)

R/W

0x0000 to 0x00FF

Sets Adjustment parameter

−

0x0C

APT

(Adjustment Pack

Thermistor)

R/W

0x0000 to 0xFFFF

Sets a value to adjust temperature

measurement delay timing

0x001E

0x0D

RSOC

R/W

0x0000 to 0x0064

1%

Displays RSOC value based

on a 0−100 scale

−

0x0F

ITE (Indicator to

Empty)

R

0x0000 to 0x03E8

0.1%

Displays RSOC value based

on a 0−1000 scale

−

0x11

IC Version

R

0x0000 to 0xFFFF

Displays an ID number of an IC

−

0x12

Change Of The

Parameter

R/W

0x0000 or 0x0001

Selects a battery profile

0x0000

0x13

Alarm Low RSOC

R/W

0x0000: Disable

0x0001to0x0064: Threshold

1%

Sets RSOC threshold to

generate Alarm signal

0x0008

0x14

Alarm Low Cell

Voltage

R/W

0x0000: Disable

0x0001to0xFFFF: Threshold

1 mV

Sets Voltage threshold to

generate Alarm signal

0x0000

0x15

IC Power Mode

R/W

0x0001: Operational mode

0x0002: Sleep mode

Selects Power mode

(Note 6)

0x16

Status Bit

R/W

0x0000: I2C mode

0x0001: Thermistor mode

Selects Temperature obtaining method

0x0000

0x1A

Number of The

Parameter

R

0x0301 or 0x0504

Displays Battery profile code

−

NOTE: 0xXXXX = Hexadecimal notation

6. See “Power-on Reset/Battery Insertion Detection” and Figure 17.

Before RSOC (0x04)

“Before RSOC” command can obtain historical voltage

data in-between Release reset and “Before RSOC”

command timing. And this command initializes RSOC with

the maximum battery voltage which was obtained. (See

Figure 9) Don’t use this command if battery is charged in the

term.

This LSI will get initial RSOC by Open Circuit Voltage

(OCV) of a battery. It is desirable for battery current to be

less than 0.025C to get expected OCV. (i.e. less than 75 mA

for 3000 mAh design capacity battery.) This LSI initializes

RSOC by measured battery voltage in initial sequence. (See

Figure 8) But if reported RSOC after reset release is not

expected value, “Before RSOC” command (0x04 = AA55)

or “Initial RSOC” command (0x07 = AA55) can initialize

RSOC again.

Thermistor B (0x06)

Sets B-constant of the thermistor to be measured. Refer to

the specification sheet of the thermistor for the set value to

use.

www.onsemi.com

9

�LC709203F

Initial RSOC (0x07)

Cell Voltage (0x09)

The LSI can be forced to initialize RSOC by sending the

Before RSOC Command (0×04 = AA55) or the Initial

RSOC Command (0×07 = AA55).

This register contains the voltage on VDD 1 mV units.

Current Direction (0x0A)

This register is used to control the reporting of RSOC. In

Auto mode the RSOC is reported as it increases or decreases.

In Charge mode the RSOC is not permitted to decrease. In

Discharge mode the RSOC is not permitted to increase.

With consideration of capacity influence by temperature,

we recommend operating in Auto because RSOC is affected

by the cell temperature. A warm cell has more capacity than

a cold cell. Be sure not to charge in the Discharge mode and

discharge in the Charge mode; it will create an error.

An example of RSOC reporting is shown in Figures 11

and 12.

Figure 8. RSOC Automatic Initialization

Figure 10. Initial RSOC Command

Figure 9. Before RSOC Command

The LSI initializes RSOC by the measured voltage at that

time when the Initial RSOC command is written. (See

Figure 10). The maximum time to initialize RSOC after the

command is written is 1.5 ms.

Cell Temperature (0x08)

This register contains the cell temperature from −20_C

(0×09E4) to +60_C (0×0D04) measured in 0.1_C units.

In the Thermistor mode (0×16 = 01) the LSI measures the

attached thermistor and loads the temperature into the Cell

Temperature register. In the Thermistor mode, the

thermistor shall be connected to the LSI as shown in

Figure 2. The temperature is measured by having TSW pin

to provide power into the thermistor and TSENSE pin to

sense the output voltage from the thermistor. Temperature

measurement timing is controlled by the LSI, and the power

to the thermistor is not supplied for other reasons except to

measure the temperature.

In the I2C mode (0×16 = 00) the temperature is provided

by the host processor. During discharge/charge the register

should be updates when the temperature changes more than

1_C

Figure 11. Discharge Mode

(An example with increasing in temperature. A warm

cell has more capacity than a cold cell. Therefore

RSOC increases without charging in Auto mode)

www.onsemi.com

10

�LC709203F

Table 7. TYPICAL APA

Figure 12. Charge Mode

(An example with decreasing in temperature. A cold

cell has less capacity than a warm cell. Therefore

RSOC decreases without discharging in Auto mode)

APA(0x0B)

Design

Capacity

of Battery

Type−01,

Type−03

Type−06

Type−07

100 mAh

0x08

0x0D

0x07

200 mAh

0x0B

0x15

0x0C

500 mAh

0x10

0x20

0x18

1000 mAh

0x19

−

0x28

2000 mAh

0x2D

−

0x40

3000 mAh

0x36

−

0x4D

Design

Capacity

of Battery

Type−04

Type−05

2600 mAh

0x1A

0x0D

APA(0x0B)

Adjustment Pack Application (0x0B)

This register contains the adjustment value for a battery

type to improve the RSOC precision. Figure 13 and Table 7

show typical values of APA according to the design

capacities per 1 cell and battery type. When some batteries

are connected in parallel, the design capacity per 1 cell is

applied to the table. The APA values of Type−04 and

Type−05 are used for battery type that is specified in Table 8.

Please contact ON Semiconductor if you don’t satisfy the

RSOC precision. The deeper adjustment of APA may

improve the accuracy.

Figure 14. An Example of a Capacitor Across

the Thermistor

RSOC (0x0D)

RSOC is reported in 1% units over the range 0% to 100%.

When this register is written in operational mode the data

may be updated to close it to actual RSOC of a battery. Set

Sleep mode to keep the data. Writing to this register is not

necessary in normal operation. ITE (0x0F) will be updated

with the writing too.

Figure 13. Typical APA

Indicator to Empty (0x0F)

This is the same as RSOC with a resolution of 0.1% over

the range 0.0% to 100.0%.

Adjustment Pack Thermistor (0x0C)

This is used to compensate for the delay of the thermistor

measurement caused by a capacitor across the thermistor.

The default value has been found to meet most of circuits

where a capacitor like showing in Figure 14 is not put.

Please contact ON Semiconductor if you have an unusual

circuit implementation.

IC Version (0x11)

This is an ID number of an LSI.

Change of the Parameter (0x12)

The LSI contains a data file comprised of two battery

profiles. This register is used to select the battery profile to

be used. See Table 8. Register Number of the Parameter

(0x1A) contains identity of the data file.

www.onsemi.com

11

�LC709203F

is counted continuously to measure the RSOC in

Operational mode. If battery is discharged or charged in the

Sleep mode, the count breaks off.

When it is switched from Sleep mode to Operational

mode, RSOC calculation is continued by using the data

which was measured in the previous Operational mode.

The Data file is loaded during final test depending on the

part number ordered.

Most of the time, battery nominal/rated voltage or

charging voltage values are used to determine which profile

data shall be used. Please contact ON Semiconductor if you

cannot identify which profile to select.

Alarm Low RSOC (0x13)

The ALARMB pin will be set low when the RSOC value

falls below this value, will be released from low when RSOC

value rises than this value. Set to Zero to disable. Figure 15.

Figure 16. Alarm Low Cell Voltage

Status Bit (0x16)

This selects the Thermistor mode. Thermistor mode

(0x16 = 01) the LSI measures the attached thermistor and

loads the temperature into the Cell Temperature register.

I2C mode (0x16 = 00) the temperature is provided by the

host processor.

Figure 15. Alarm Low RSOC

Alarm Low Cell Voltage (0x14)

The ALARMB pin will be set low if VDD falls below this

value, will be released from low if VDD rises than this value.

Set to Zero to disable. Figure 16.

Number of the Parameter (0x1A)

The LSI contains a data file comprised of two battery

profiles. This register contains identity of the data file.

Please see register Change of the Parameter (0x12) to select

the battery profile to be used. See Table 8.

The Data file is loaded during final test depending on the

part number ordered. This file can be loaded in the field if

required.

Please contact ON Semiconductor if you cannot identify

which profile to select.

IC Power Mode (0x15)

The LSI has two power modes. Sleep (0x15 = 02) or

Operational mode (0x15 = 01). In the Sleep mode only I2C

communication functions. In the Operational mode all

functions operate with full calculation and tracking of

RSOC during charge and discharge.

If the battery is significantly charged or discharged during

sleep mode, the RSOC will not be accurate. Moved charge

www.onsemi.com

12

�LC709203F

Table 8. BATTERY PROFILE VS. REGISTER

IC Type

LC709203Fxx−01xx

LC709203Fxx−03xx

LC709203Fxx−04xx

Battery

Type

Nominal/Rated

Voltage

Charging

Voltage

Design

Capacity

Number of

the Parameter

(0x1A)

Change of

the Parameter

(0x12)

03

3.8 V

4.35 V

≥ 500 mAh

0x0301

0x0000

01

3.7 V

4.2 V

−

06

3.8 V

4.35 V

< 500 mAh

01

3.7 V

4.2 V

−

05

0x0601

0x0001

0x0001

3.85 V

4.4 V

−

06

3.8 V

4.35 V

< 500 mAh

0x0706

Hybrid Gauging by Current-Voltage Tracking with

Internal Resistance

V(VARIED)

RM

FCC

100%

(eq. 3)

Then the decreased FCC must be preliminarily measured

with learning cycle. But HG−CVR can measure the RSOC

of deteriorated battery without learning cycle. The internal

battery impedance that HG−CVR uses to calculate the

current correlates highly with FCC. The correlation is based

on battery chemistry. The RSOC that this LSI reports using

the correlation is not affected by aging.

Figures 24−26 show RSOC measurement result of

a battery with decreased FCC due to its aging. The shown

RSOC is based on the decreased FCC even with a battery

with 80% FCC after executing 300 times of discharge/

charge.

HG−CVR is ON Semiconductor’s unique method which

is used to calculate accurate RSOC. HG−CVR first

measures battery voltage and temperature. Precise reference

voltage is essential for accurate voltage measurement.

LC709203F has accurate internal reference voltage circuit

with little temperature dependency.

It also uses the measured battery voltage and internal

impedance and Open Circuit Voltage (OCV) of a battery for

the current measurement. OCV is battery voltage without

load current. The measured battery voltage is separated into

OCV and varied voltage by load current. The varied voltage

is the product of load current and internal impedance. Then

the current is determined by the following formulas.

V(VARIED) + V(MEASURED) * OCV

0x0000

0x0001

RSOC +

R(INTERNAL)

0x0000

UR18650ZY (Panasonic)

07

HG−CVR

I+

0x0000

0x0504

ICR18650−26H (SAMSUNG)

04

LC709203Fxx−05xx

0x0001

Automatic Convergence of the Error

A problem of coulomb counting method is the fact that the

error is accumulated over time − This error must be

corrected. The general gauges using coulomb counting

method must find an opportunity to correct it.

This LSI with HG−CVR has the feature that the error of

RSOC converges autonomously, and doesn’t require

calibration opportunities. The error constantly converges in

the value estimated from the Open Circuit Voltage.

Figure 27 shows the convergent characteristic example

from the initialize error.

Also, coulomb counting method cannot detect accurate

residual change because the amount of the current from

self-discharge is too small but HG−CVR is capable to deal

with such detection by using the voltage information.

(eq. 1)

(eq. 2)

Where V(VARIED) is varied voltage by load current,

V(MEASURED) is measured voltage, R(INTERNAL) is

internal impedance of a battery. Detailed information about

the internal impedance and OCV is installed in the LSI. The

internal impedance is affected by remaining capacity,

load-current, temperature, and more. Then the LSI has the

information as look up table. HG−CVR accumulates battery

coulomb using the information of the current and a steady

period by a high accuracy internal timer. The remaining

capacity of a battery is calculated with the accumulated

coulomb.

Simple and Quick Setup

In general, it is necessary to obtain multiple parameters for

a fuel gauge and it takes a lot of resource and additional

development time of the users. One of the unique features of

LC709203F is very small number of parameters to be

prepared by the beginning of battery measurement – the

minimum amount of parameter which users may make is

one because Adjustment pack application register has to

How to Identify Aging

By repeating discharge/charge, internal impedance of

a battery will gradually increase, and the Full Charge

Capacity (FCC) will decrease. In coulomb counting method

RSOC is generally calculated using the FCC and the

Remaining Capacity (RM).

www.onsemi.com

13

�LC709203F

have one. Such simple and quick start-up is realized by

having multiple profile data in the LSI to support various

types of batteries. Please contact your local sales office to

learn more information on how to measure a battery that

cannot use already-prepared profile data.

into Sleep mode. LC709203FQH−0xTWG doesn’t set itself

into Sleep mode automatically. Figure 17.

This LSI will also execute system reset automatically if

a battery voltage exceeds under the VRR during operation.

Furthermore after Change of the Parameter (0x12)

command input it will execute LSI initialization like battery

insertion. Figure 18.

Low Power Consumption

Low power consumption of 3 �A is realized in the

Operation mode. This LSI monitors charge/discharge

condition of a battery and changes the sampling rate

according to its change of current. Power consumption

reduction without deteriorating its RSOC accuracy was

enabled by utilizing this method.

Parasitic Resistance

The LSI measures RSOC by using internal impedance of

a battery. Therefore, the parasitic resistance which exists in

VDD/VSS Lines between measured Battery or Battery Pack

to the LSI can become an error factor. But the resistance of

Lines which is not connected other than the LSI is not

included. Figure 19.

The lower resistance may improve the RSOC precision.

Please see LC709203F Application note for information

about layout method of VDD/VSS Lines to reduce it.

Power-on Reset/Battery Insertion Detection

When this LSI detects battery insertion, it starts Power-on

reset automatically. Once the battery voltage exceeds over

the VRR, it will release RESET status and will complete LSI

initialization within TINIT to enter into Operational mode.

All registers are initialized after Power-on reset. Then I2C

communication can be started.

LC709203FXE−0xMH sets itself into Sleep mode

automatically after TATS from the end of initialization.

Therefore set to operational mode manually after it enters

Measurement Starting Flow

After Reset release, users can start battery measurement

by writing appropriate value into the registers by following

the flow shown in Figures 20−21. Please refer to Register

function section for more information about each register.

LC709203FQH−0xTWG

Reset

Initialization

Operation Mode

VDD

VRR

TINT

LC709203FXE−0xMH

Reset

Initialization

Operation Mode

TINT

TATS

VDD

VRR

(Not to Scale)

Figure 17. Power On Timing Diagram

www.onsemi.com

14

Sleep Mode

�LC709203F

LC709203FQH−0xTWG

0x12

Command

Initialization

Operation Mode

SCL

TINIT

SDA

Stop Condition

LC709203FXE−0xMH

0x12

Command

Initialization

Operation Mode

Sleep Mode

SCL

TINIT

TATS

SDA

Stop Condition

(Not to Scale)

Figure 18. Timing Diagram after 0x12 Command

VDD

Application

LC709203F

VSS

Application

Processor

The components that the resistance must be measured.

Figure 19. An Example of Parasitic Resistance

www.onsemi.com

15

Battery

or

Battery Pack

�LC709203F

STARTING FLOW

Power On

Input SDA Pulse

(Note 7)

Wake Up from

Sleep Mode

Set 0x0001

to Register 0x15

(Note 7)

Set Operational

Mode

Set 0xZZZZ

to Register 0x0B

Set APA

Set 0x000Z

to Register 0x12

Initial RSOC

Set 0xAA55

to Register 0x04 or 0x07

(Note 8)

Set Thermistor

Mode

Set 0x0001

to Register 0x16

Set B-constant

of Thermistor

Set 0xZZZZ

to Register 0x06

Initialization End

7. It’s unnecessary if initial power mode is

Operational mode.

SDA pulse can be substituted in some kind of

commands.

Ex: Input “Set Operational mode” twice.

8. It’s unnecessary if OCV can be get at automatic

initialization.

Set Battery Profile

Figure 20. Starting Flow at Thermistor Mode

Power On

Input SDA Pulse

(Note 9)

Wake Up from

Sleep Mode

Set 0x0001

to Register 0x15

(Note 9)

Set 0xZZZZ

to Register 0x0B

Set 0x000Z

to Register 0x12

Initial RSOC

Set 0xAA55

to Register 0x04 or 0x07

(Note 10)

Set via I2C

Mode

Set 0x0000

to Register 0x16

Set Operational

Mode

Set Temperature

Set 0xZZZZ

to Register 0x08

Set APA

Initialization End

9. It’s unnecessary if initial power mode is

Operational mode.

SDA pulse can be substituted in some kind of

commands.

Ex: Input “Set Operational mode” twice.

10. It’s unnecessary if OCV can be get at automatic

initialization.

Set Battery Profile

Figure 21. Starting Flow at I2C Mode

www.onsemi.com

16

�LC709203F

TYPICAL CHARACTERISTICS

Figure 22. Discharge Characteristics by Temperature Change

Figure 23. Discharge Characteristics by Load Change

www.onsemi.com

17

�LC709203F

TYPICAL CHARACTERISTICS

Figure 24. Discharge/Charge Cycle

Figure 25. Battery Capacity Deterioration

Figure 26. Discharge Characteristics of Deterioration Battery

www.onsemi.com

18

�LC709203F

TYPICAL CHARACTERISTICS

Figure 27. Convergent Characteristic from the Initialize Error

This Graph is the Example for Starting Point 48% (Includes 52% Error Case) Instead of 100% (No Error)

Table 9. ORDERING INFORMATION

Package

Shipping†

LC709203FQH−01TWG

WDFN8 3x4, 0.65P

(Pb-Free / Halogen Free)

2,000 / Tape & Reel

LC709203FQH−02TWG

WDFN8 3x4, 0.65P

(Pb-Free / Halogen Free)

2,000 / Tape & Reel

LC709203FQH−03TWG

WDFN8 3x4, 0.65P

(Pb-Free / Halogen Free)

2,000 / Tape & Reel

LC709203FQH−04TWG

WDFN8 3x4, 0.65P

(Pb-Free / Halogen Free)

2,000 / Tape & Reel

LC709203FXE−01MH

WLCSP9, 1.60x1.76

(Pb-Free / Halogen Free)

5,000 / Tape & Reel

LC709203FXE−02MH

WLCSP9, 1.60x1.76

(Pb-Free / Halogen Free)

5,000 / Tape & Reel

LC709203FXE−03MH

WLCSP9, 1.60x1.76

(Pb-Free / Halogen Free)

5,000 / Tape & Reel

LC709203FXE−04MH

WLCSP9, 1.60x1.76

(Pb-Free / Halogen Free)

5,000 / Tape & Reel

LC709203FXE−05MH

WLCSP9, 1.60x1.76

(Pb-Free / Halogen Free)

5,000 / Tape & Reel

Device

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

NOTE: IC performance may vary depend on the types of battery to be in use. Contact your local sales office for

assistance in choosing the correct model.

ON Semiconductor is licensed by the Philips Corporation to carry the I2C bus protocol. All other brand names and product names

appearing in this document are registered trademarks or trademarks of their respective holders.

www.onsemi.com

19

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

WDFN8 3x4, 0.65P

CASE 509AF

ISSUE C

1

SCALE 2:1

L

A

B

D

DATE 06 MAY 2014

L

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED TERMINAL

AND IS MEASURED BETWEEN 0.15 AND

0.30mm FROM THE TERMINAL TIP.

4. PROFILE TOLERANCE APPLIES TO THE

EXPOSED PAD AS WELL AS THE LEADS.

L1

DETAIL A

PIN ONE

REFERENCE

2X

0.10 C

2X

ALTERNATE

CONSTRUCTIONS

ÉÉÉÉ

ÉÉÉÉ

ÉÉÉÉ

ÉÉÉÉ

0.10 C

E

ÉÉ

ÉÉ

ÇÇ

EXPOSED Cu

MOLD CMPD

DETAIL B

ALTERNATE

CONSTRUCTIONS

TOP VIEW

A

(A3)

DETAIL B

0.10 C

DIM

A

A1

A3

b

D

D2

E

E2

e

L

L1

GENERIC

MARKING DIAGRAM*

XXXXX

XXXXX

AYWWG

G

0.08 C

NOTE 4

SIDE VIEW

1

C

SEATING

PLANE

0.10 C A B

D2

DETAIL A

A1

4

0.10 C A B

8X

MILLIMETERS

MIN

MAX

−−−

0.80

0.00

0.05

0.20 REF

0.20

0.30

3.00 BSC

1.70

1.90

4.00 BSC

2.30

2.50

0.65 BSC

0.45

0.55

−−−

0.10

L

A

Y

WW

G

= Assembly Location

= Year

= Work Week

= Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

E2

8

5

e/2

8X

RECOMMENDED

SOLDERING FOOTPRINT*

b

1.96

ÇÇÇ

ÇÇÇ

ÇÇÇ

ÇÇÇ

0.10 C A B

e

BOTTOM VIEW

0.05 C

NOTE 3

8X

0.70

2.56 4.30

ÇÇÇ

ÇÇÇ

ÇÇÇ

ÇÇÇ

1

0.65

PITCH

8X

0.35

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

98AON80983E

WDFN8 3X4, 0.65P

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

WLCSP9, 1.60x1.76

CASE 567JH

ISSUE B

SCALE 4:1

ÈÈ

ÈÈ

PIN A1

REFERENCE

2X

E

A B

DATE 23 JAN 2014

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. COPLANARITY APPLIES TO THE SPHERICAL

CROWNS OF THE SOLDER BALLS.

D

DIM

A

A1

b

D

E

e

0.05 C

2X

0.05 C

TOP VIEW

BACKCOAT

A

0.10 C

0.08 C

9X

C

SIDE VIEW

PACKAGE

OUTLINE

SEATING

PLANE

e

b

0.05 C A B

RECOMMENDED

SOLDERING FOOTPRINT*

A1

A1

NOTE 3

MILLIMETERS

MIN

MAX

0.51

−−−

0.09

0.19

0.20

0.30

1.60 BSC

1.76 BSC

0.50 BSC

e

C

0.03 C

B

0.50

PITCH

9X

0.25

0.50

PITCH

DIMENSIONS: MILLIMETERS

A

1

2

3

BOTTOM VIEW

DOCUMENT NUMBER:

DESCRIPTION:

98AON79525F

WLCSP9, 1.60X1.76

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

www.onsemi.com

1

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�