MJD122, NJVMJD122

(NPN), MJD127,

NJVMJD127 (PNP)

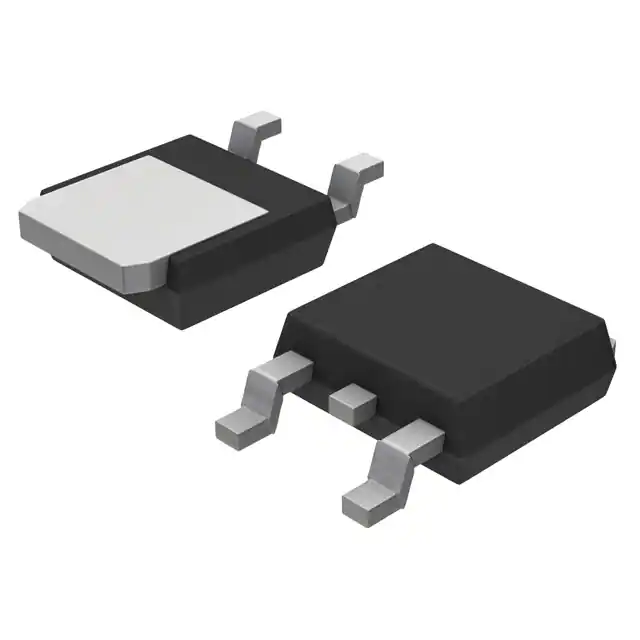

Complementary Darlington

Power Transistor

DPAK For Surface Mount Applications

Designed for general purpose amplifier and low speed switching

applications.

Features

www.onsemi.com

SILICON

POWER TRANSISTOR

8 AMPERES

100 VOLTS, 20 WATTS

• Lead Formed for Surface Mount Applications in Plastic Sleeves

• Surface Mount Replacements for 2N6040−2N6045 Series,

•

•

•

•

•

•

TIP120−TIP122 Series, and TIP125−TIP127 Series

Monolithic Construction With Built−in Base−Emitter Shunt Resistors

High DC Current Gain: hFE = 2500 (Typ) @ IC = 4.0 Adc

Epoxy Meets UL 94 V−0 @ 0.125 in

ESD Ratings:

♦ Human Body Model, 3B > 8000 V

♦ Machine Model, C > 400 V

NJV Prefix for Automotive and Other Applications Requiring

Unique Site and Control Change Requirements; AEC−Q101

Qualified and PPAP Capable

These Devices are Pb−Free, Halogen Free/BFR Free and are RoHS

Compliant

DPAK

CASE 369C

STYLE 1

COLLECTOR 2, 4

BASE

1

EMITTER 3

MARKING DIAGRAM

AYWW

J12xG

A

Y

WW

x

G

= Assembly Location

= Year

= Work Week

= 2 or 7

= Pb−Free Package

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 7 of this data sheet.

© Semiconductor Components Industries, LLC, 2013

September, 2016 − Rev. 15

1

Publication Order Number:

MJD122/D

�MJD122, NJVMJD122 (NPN), MJD127, NJVMJD127 (PNP)

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

VCEO

100

Vdc

Collector−Base Voltage

VCB

100

Vdc

Emitter−Base Voltage

VEB

5

Vdc

Collector−Emitter Voltage

Collector Current

Continuous

Peak

IC

Base Current

IB

Total Power Dissipation

@ TC = 25°C

Derate above 25°C

PD

Total Power Dissipation (Note 1)

@ TA = 25°C

Derate above 25°C

PD

Adc

8

16

120

20

0.16

Operating and Storage Junction Temperature Range

TJ, Tstg

mAdc

W

W/°C

1.75

0.014

W

W/°C

−65 to +150

°C

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

THERMAL CHARACTERISTICS

Symbol

Max

Unit

Thermal Resistance, Junction−to−Case

Characteristic

RqJC

6.25

°C/W

Thermal Resistance, Junction−to−Ambient (Note1)

RqJA

71.4

°C/W

1. These ratings are applicable when surface mounted on the minimum pad sizes recommended.

www.onsemi.com

2

�MJD122, NJVMJD122 (NPN), MJD127, NJVMJD127 (PNP)

ELECTRICAL CHARACTERISTICS (TC = 25_C unless otherwise noted)

Symbol

Characteristic

Min

Max

100

−

−

10

−

10

−

2

1000

100

12,000

−

−

−

2

4

−

4.5

−

2.8

4

−

Unit

OFF CHARACTERISTICS

VCEO(sus)

Collector−Emitter Sustaining Voltage

(IC = 30 mAdc, IB = 0)

Collector Cutoff Current

(VCE = 50 Vdc, IB = 0)

ICEO

Collector Cutoff Current

(VCB = 100 Vdc, IE = 0)

ICBO

Emitter Cutoff Current

(VBE = 5 Vdc, IC = 0)

IEBO

Vdc

mAdc

mAdc

mAdc

ON CHARACTERISTICS

hFE

DC Current Gain

(IC = 4 Adc, VCE = 4 Vdc)

(IC = 8 Adc, VCE = 4 Vdc)

Collector−Emitter Saturation Voltage

(IC = 4 Adc, IB = 16 mAdc)

(IC = 8 Adc, IB = 80 mAdc)

VCE(sat)

Base−Emitter Saturation Voltage (Note 2)

(IC = 8 Adc, IB = 80 mAdc)

VBE(sat)

Base−Emitter On Voltage

(IC = 4 Adc, VCE = 4 Vdc)

VBE(on)

−

Vdc

Vdc

Vdc

DYNAMIC CHARACTERISTICS

Current−Gain−Bandwidth Product

(IC = 3 Adc, VCE = 4 Vdc, f = 1 MHz)

|hfe|

Output Capacitance

(VCB = 10 Vdc, IE = 0, f = 0.1 MHz)

MJD127, NJVMJD127

MJD122, NJVMJD122

Cob

Small−Signal Current Gain

(IC = 3 Adc, VCE = 4 Vdc, f = 1 kHz)

hfe

MHz

pF

−

−

300

200

300

−

−

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

2. Pulse Test: Pulse Width v 300 ms, Duty Cycle v 2%.

PD, POWER DISSIPATION (WATTS)

TA TC

2.5 25

2 20

TC

1.5 15

TA

SURFACE

MOUNT

1 10

0.5

5

0

0

25

50

75

100

T, TEMPERATURE (°C)

Figure 1. Power Derating

www.onsemi.com

3

125

150

�MJD122, NJVMJD122 (NPN), MJD127, NJVMJD127 (PNP)

TYPICAL ELECTRICAL CHARACTERISTICS

PNP MJD127

NPN MJD122

20,000

20,000

VCE = 4 V

VCE = 4 V

10,000

hFE , DC CURRENT GAIN

hFE , DC CURRENT GAIN

10,000

7000

5000

TJ = 150°C

3000

2000

25°C

1000

700

500

300

200

0.1

-�55°C

0.2

5000

TJ = 150°C

3000

2000

25°C

1000

-�55°C

500

0.3

0.5 0.7

1

2

3

7

5

300

200

0.1

10

0.2

0.5 0.7

0.3

IC, COLLECTOR CURRENT (AMP)

1

2

3

5

7

10

IC, COLLECTOR CURRENT (AMP)

3

VCE , COLLECTOR-EMITTER VOLTAGE (VOLTS)

VCE , COLLECTOR-EMITTER VOLTAGE (VOLTS)

Figure 2. DC Current Gain

TJ = 25°C

2.6

IC = 2 A

4A

6A

2.2

1.8

1.4

1

0.3

0.5 0.7

1

2

3

5

7

10

20

30

3

TJ = 25°C

2.6

IC = 2 A

4A

6A

2.2

1.8

1.4

1

0.3

0.5 0.7

1

IB, BASE CURRENT (mA)

2

3

5

7

10

20 30

IB, BASE CURRENT (mA)

Figure 3. Collector Saturation Region

3

3

TJ = 25°C

TJ = 25°C

2.5

V, VOLTAGE (VOLTS)

V, VOLTAGE (VOLTS)

2.5

2

1.5

1

VBE @ VCE = 4 V

VBE(sat) @ IC/IB = 250

2

1.5

VBE @ VCE = 4 V

1

VCE(sat) @ IC/IB = 250

VCE(sat) @ IC/IB = 250

0.5

0.1

0.2 0.3

0.5 0.7

VBE(sat) @ IC/IB = 250

1

2

3

5

7

0.5

0.1

10

IC, COLLECTOR CURRENT (AMP)

0.2 0.3

0.5 0.7

1

2

3

IC, COLLECTOR CURRENT (AMP)

Figure 4. “On” Voltages

www.onsemi.com

4

5

7

10

�MJD122, NJVMJD122 (NPN), MJD127, NJVMJD127 (PNP)

TYPICAL ELECTRICAL CHARACTERISTICS

NPN MJD122

+�5

θV, TEMPERATURE COEFFICIENTS (mV/°C)

θV, TEMPERATURE COEFFICIENTS (mV/°C)

PNP MJD127

*IC/IB ≤ hFE/3

+�4

+�3

+�2

+�1

0

25°C to 150°C

qVC for VCE(sat)

-�1

-�2

-�3

-�55°C to 25°C

25°C to 150°C

qVB for VBE

-�55°C to 25°C

-�4

-�5

0.1

0.2 0.3

1

2 3

0.5

IC, COLLECTOR CURRENT (AMP)

5

7

+�5

+�4

*IC/IB ≤ hFE/3

+�3

25°C to 150°C

+�2

-�55°C to 25°C

+�1

0

*qVC for VCE(sat)

-�1

-�2

-�3

-�4

-�5

0.1

10

25°C to 150°C

qVB for VBE

-�55°C to 25°C

0.2 0.3

0.5 0.7 1

2 3

IC, COLLECTOR CURRENT (AMP)

5

7

10

Figure 5. Temperature Coefficients

105

105

REVERSE

FORWARD

IC, COLLECTOR CURRENT (��A)

μ

IC, COLLECTOR CURRENT (��A)

μ

REVERSE

104

VCE = 30 V

103

102

TJ = 150°C

101

100°C

100

25°C

10-1

+�0.6 +�0.4 +�0.2

0 -�0.2 -�0.4 -�0.6 -�0.8 -�1

VBE, BASE-EMITTER VOLTAGE (VOLTS)

FORWARD

104

VCE = 30 V

103

102

TJ = 150°C

101

100

100°C

25°C

10-1

-�0.6 -�0.4 -�0.2

0 +�0.2 +�0.4 +�0.6 +�0.8 +�1

VBE, BASE-EMITTER VOLTAGE (VOLTS)

-�1.2 -�1.4

+�1.2 +�1.4

Figure 6. Collector Cut−Off Region

300

5000

3000

2000

200

TJ = 25°C

C, CAPACITANCE (pF)

hfe , SMALL-SIGNAL CURRENT GAIN

10,000

1000

500

300

200

TC = 25°C

VCE = 4 Vdc

IC = 3 Adc

100

50

30

20

10

2

5

100

70

Cib

50

PNP

NPN

1

Cob

10

20

50 100

f, FREQUENCY (kHz)

200

500 1000

30

0.1

PNP

NPN

0.2

0.5

1

2

5

10

VR, REVERSE VOLTAGE (VOLTS)

Figure 8. Capacitance

Figure 7. Small−Signal Current Gain

www.onsemi.com

5

20

50

100

�MJD122, NJVMJD122 (NPN), MJD127, NJVMJD127 (PNP)

5

RB & RC VARIED TO OBTAIN DESIRED CURRENT LEVELS

�D1, MUST BE FAST RECOVERY TYPE, e.g.:

��1N5825 USED ABOVE IB ≈ 100 mA

��MSD6100 USED BELOW IB ≈ 100 mA

VCC

-�30 V

RC SCOPE

RB

51

≈ 8 k ≈ 120

D1

+4V

25 ms

tf

0.7

0.5

0.3

0.2

0.1

0.07

0.05

0.1

FOR td AND tr, D1 IS DISCONNECTED

AND V2 = 0

tr, tf ≤ 10 ns

DUTY CYCLE = 1%

PNP

NPN

ts

1

t, TIME (��s)

μ

TUT

V2

APPROX

+�8 V

0

V1

APPROX

-12 V

3

2

0.2

FOR NPN TEST CIRCUIT REVERSE ALL POLARITIES.

r(t), EFFECTIVE TRANSIENT

THERMAL RESISTANCE (NORMALIZED)

Figure 9. Switching Times Test Circuit

1

0.7

0.5

tr

VCC = 30 V

IC/IB = 250

IB1 = IB2

TJ = 25°C

td @ VBE(off) = 0 V

0.3

0.5 0.7 1

3

2

IC, COLLECTOR CURRENT (AMP)

5

7

10

Figure 10. Switching Times

D = 0.5

0.3

0.2

0.2

0.1

0.1

0.07

0.05

0.05

0.03

SINGLE PULSE

RqJC(t) = r(t) RqJC

RqJC = 6.25°C/W

D CURVES APPLY FOR POWER

PULSE TRAIN SHOWN

READ TIME AT t1

TJ(pk) - TC = P(pk) qJC(t)

0.01

0.02

0.01

0.01

0.02 0.03

0.05

0.1

0.2 0.3

0.5

1

2

3

5

10

t, TIME OR PULSE WIDTH (ms)

20

30

P(pk)

t1

t2

DUTY CYCLE, D = t1/t2

50

100

200 300

500

1000

IC, COLLECTOR CURRENT (AMP)

Figure 11. Thermal Response

20

15

10

500�m

σ

5

3

2

0.5

0.3

0.2

5�ms

BONDING WIRE LIMIT

THERMAL LIMIT

TC = 25°C (SINGLE PULSE)

SECOND BREAKDOWN LIMIT

CURVES APPLY BELOW RATED VCEO

0.1

0.05

0.03

0.02

100�m

σ

1�ms

TJ = 150°C

1

1

2

There are two limitations on the power handling ability of

a transistor: average junction temperature and second

breakdown. Safe operating area curves indicate IC − VCE

limits of the transistor that must be observed for reliable

operation; i.e., the transistor must not be subjected to greater

dissipation than the curves indicate.

The data of Figure 12 is based on TJ(pk) = 150_C; TC is

variable depending on conditions. Second breakdown pulse

limits are valid for duty cycles to 10% provided TJ(pk)

< 150_C. TJ(pk) may be calculated from the data in

Figure 11. At high case temperatures, thermal limitations

will reduce the power that can be handled to values less than

the limitations imposed by second breakdown.

3

5

7

10

20

dc

30

50 70 100

VCE, COLLECTOR-EMITTER VOLTAGE (VOLTS)

Figure 12. Maximum Forward Bias

Safe Operating rea

www.onsemi.com

6

�MJD122, NJVMJD122 (NPN), MJD127, NJVMJD127 (PNP)

COLLECTOR

PNP

COLLECTOR

NPN

BASE

BASE

≈8k

≈ 120

≈8k

EMITTER

≈ 120

EMITTER

Figure 13. Darlington Schematic

ORDERING INFORMATION

Package Type

Shipping†

MJD122G

DPAK

(Pb−Free)

75 Units / Rail

MJD122T4G

DPAK

(Pb−Free)

2,500 / Tape & Reel

NJVMJD122T4G*

DPAK

(Pb−Free)

2,500 / Tape & Reel

MJD127G

DPAK

(Pb−Free)

75 Units / Rail

MJD127T4G

DPAK

(Pb−Free)

2,500 / Tape & Reel

NJVMJD127T4G*

DPAK

(Pb−Free)

2,500 / Tape & Reel

Device

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

*NJV Prefix for Automotive and Other Applications Requiring Unique Site and Control Change Requirements; AEC−Q101 Qualified and PPAP

Capable

www.onsemi.com

7

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

DPAK (SINGLE GAUGE)

CASE 369C

ISSUE F

4

1 2

DATE 21 JUL 2015

3

SCALE 1:1

A

E

b3

C

A

B

c2

4

L3

Z

D

1

L4

2

3

NOTE 7

b2

e

c

SIDE VIEW

b

0.005 (0.13)

TOP VIEW

H

DETAIL A

M

BOTTOM VIEW

C

Z

H

L2

GAUGE

PLANE

C

L

L1

DETAIL A

Z

SEATING

PLANE

BOTTOM VIEW

A1

ALTERNATE

CONSTRUCTIONS

ROTATED 905 CW

STYLE 1:

PIN 1. BASE

2. COLLECTOR

3. EMITTER

4. COLLECTOR

STYLE 6:

PIN 1. MT1

2. MT2

3. GATE

4. MT2

STYLE 2:

PIN 1. GATE

2. DRAIN

3. SOURCE

4. DRAIN

STYLE 7:

PIN 1. GATE

2. COLLECTOR

3. EMITTER

4. COLLECTOR

STYLE 3:

PIN 1. ANODE

2. CATHODE

3. ANODE

4. CATHODE

STYLE 8:

PIN 1. N/C

2. CATHODE

3. ANODE

4. CATHODE

STYLE 4:

PIN 1. CATHODE

2. ANODE

3. GATE

4. ANODE

STYLE 9:

STYLE 10:

PIN 1. ANODE

PIN 1. CATHODE

2. CATHODE

2. ANODE

3. RESISTOR ADJUST

3. CATHODE

4. CATHODE

4. ANODE

SOLDERING FOOTPRINT*

6.20

0.244

2.58

0.102

5.80

0.228

INCHES

MIN

MAX

0.086 0.094

0.000 0.005

0.025 0.035

0.028 0.045

0.180 0.215

0.018 0.024

0.018 0.024

0.235 0.245

0.250 0.265

0.090 BSC

0.370 0.410

0.055 0.070

0.114 REF

0.020 BSC

0.035 0.050

−−− 0.040

0.155

−−−

MILLIMETERS

MIN

MAX

2.18

2.38

0.00

0.13

0.63

0.89

0.72

1.14

4.57

5.46

0.46

0.61

0.46

0.61

5.97

6.22

6.35

6.73

2.29 BSC

9.40 10.41

1.40

1.78

2.90 REF

0.51 BSC

0.89

1.27

−−−

1.01

3.93

−−−

GENERIC

MARKING DIAGRAM*

XXXXXXG

ALYWW

AYWW

XXX

XXXXXG

IC

Discrete

= Device Code

= Assembly Location

= Wafer Lot

= Year

= Work Week

= Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

6.17

0.243

SCALE 3:1

DIM

A

A1

b

b2

b3

c

c2

D

E

e

H

L

L1

L2

L3

L4

Z

XXXXXX

A

L

Y

WW

G

3.00

0.118

1.60

0.063

STYLE 5:

PIN 1. GATE

2. ANODE

3. CATHODE

4. ANODE

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: INCHES.

3. THERMAL PAD CONTOUR OPTIONAL WITHIN DIMENSIONS b3, L3 and Z.

4. DIMENSIONS D AND E DO NOT INCLUDE MOLD

FLASH, PROTRUSIONS, OR BURRS. MOLD

FLASH, PROTRUSIONS, OR GATE BURRS SHALL

NOT EXCEED 0.006 INCHES PER SIDE.

5. DIMENSIONS D AND E ARE DETERMINED AT THE

OUTERMOST EXTREMES OF THE PLASTIC BODY.

6. DATUMS A AND B ARE DETERMINED AT DATUM

PLANE H.

7. OPTIONAL MOLD FEATURE.

mm Ǔ

ǒinches

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

98AON10527D

DPAK (SINGLE GAUGE)

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

onsemi and

are trademarks of Semiconductor Components Industries, LLC dba onsemi or its subsidiaries in the United States and/or other countries. onsemi reserves

the right to make changes without further notice to any products herein. onsemi makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does onsemi assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation

special, consequential or incidental damages. onsemi does not convey any license under its patent rights nor the rights of others.

© Semiconductor Components Industries, LLC, 2018

www.onsemi.com

�onsemi,

, and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates

and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property.

A listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi reserves the right to make changes at any time to any

products or information herein, without notice. The information herein is provided “as−is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the

information, product features, availability, functionality, or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use

of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products

and applications using onsemi products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information

provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/or specifications can and do vary in different applications and actual performance may

vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. onsemi does not convey any license

under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized for use as a critical component in life support systems

or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should

Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

onsemi Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�