NCN6000

Compact Smart Card

Interface IC

The NCN6000 is an integrated circuit dedicated to the smart card

interface applications. The device handles any type of smart card

through a simple and flexible microcontroller interface. On top of that,

due to the built−in chip select pin, several couplers can be connected in

parallel. The device is particularly suited for low cost, low power

applications, with high extended battery life coming from extremely

low quiescent current.

http://onsemi.com

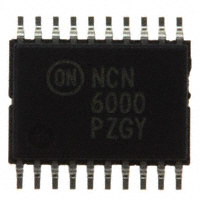

MARKING

DIAGRAM

Features

20

• 100% Compatible with ISO7816−3 and EMV Standard

• Wide Battery Supply Voltage Range: 2.7 v Vbat v 6.0 V

• Programmable CRD_VCC Supply to Cope with either 3.0 V or 5.0 V

Card Operation

• Built−in DC−DC Converter Generates the CRD_VCC Supply with a

•

•

•

•

•

•

•

•

Single External Low Cost Inductor only, providing a High Efficiency

Power Conversion

Full Control of the Power Up/Down Sequence Yields High Signal

Integrity on both the Card I/O and the Signal Lines

Programmable Card Clock Generator

Built−in Chip Select Logic allows Parallel Coupling Operation

ESD Protection on Card Pins (8.0 kV, Human Body Model)

Fault Monitoring includes Vbatlow and Vcclow, providing Logic

Feedback to External CPU

Card Detection Programmable to Handle Positive or Negative

Going Input

Built−in Programmable CRD_CLK Stop Function Handles both

High or Low State

These are Pb−Free Devices**

Typical Application

• E−Commerce Interface

• ATM Smart Card

• Pay TV System

1

A = Assembly Location

L

= Wafer Lot

Y = Year

W = Work Week

G

= Pb−Free Package

(Note: Microdot may be in either location)

PIN CONNECTIONS

A0 1

20 Vbat

A1 2

19 Lout_H

PGM 3

18 Lout_L

PWR_ON 4

17 PWR_GND

STATUS 5

16 GROUND

CS 6

15 CRD_VCC

RESET 7

14 CRD_IO

I/O 8

13 CRD_CLK

INT 9

12 CRD_RST

CLOCK_IN 10

11 CRD_DET

(Top View)

ORDERING INFORMATION

ISO/EMV

MICRO

CONTROLLER

NCN

6000

ALYWG

G

TSSOP−20

DTB SUFFIX

CASE 948E

1

NCN6000

SMART CARD

INTERFACE

Device

Package

Shipping †

NCN6000DTB

TSSOP−20*

75 Units / Rail

NCN6000DTBG

TSSOP−20*

75 Units / Rail

NCN6000DTBR2

TSSOP−20* 2500/Tape & Reel

NCN6000DTBR2G TSSOP−20* 2500/Tape & Reel

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specifications

Brochure, BRD8011/D.

*This package is inherently Pb−Free.

Figure 1. Simplified Application

**For additional information on our Pb−Free strategy and soldering details, please download the ON Semiconductor Soldering and Mounting

Techniques Reference Manual, SOLDERRM/D.

© Semiconductor Components Industries, LLC, 2006

March, 2006 − Rev. 4

1

Publication Order Number:

NCN6000/D

�NCN6000

+5 V

PB7

2

PB6

3

PB5

PB4

PB3

PB2

PB1

PB0

4

5

6

7

8

9

IRQ

10

MCU

20

A0

Vbat

A1

Lout_H

PGM

Lout_L

PWR_ON PWR_GND

STATUS

GROUND

CS

CRD_VCC

RESET

10 �F

C1

U1

1

CRD_IO

I/O

CRD_CLK

INT

CRD_RST

XTAL

CLOCK_IN CRD_DET

GND

NCN6000

GND

19

L1

18

22 �H

17

16

GND

15

C2

10 �F

C3

100 nF

14

13

GND

17

18

12

8

11

4

3

2

1

GND

GND

5

7

Swb

C8

C4

CLK

RST

VCC

GND

I/O

VPP

J1

SMARTCARD

Figure 2. Typical Application

http://onsemi.com

2

GND

GND

Swa

ISO7816

VCC

�NCN6000

+Vbat

+

−

Vbat_OK

20 Vbat

2.0 V

50 k

INT

9

500 k

Vbat

GND

11

Q

R

GND

+Vbat

CARD DETECTION

POLARITY

PROGRAMMABLE

50 k

CS

CRD_DET

50 �s

Delay

S

STATUS INT

6

CLK STOP

PGM

3

A1

2

A0

1

Fout

DC−DC CONVERTER

DATA

SELECT

DECODER

1:16

VCC

CLOCK

15 CRD_VCC

19 Lout_H

3V/5V

Set_VCC

Power Down

Active Pwr_Down

1/1

1/2

1/4

1/8

CLOCK_IN 10

CLOCK

DIVIDER

18 Lout_L

GND

FAULT

17 PWR_GND

ON/OFF

STATUS INT

DC−DC STATUS

ENABLE VCC

CARD STATUS

PWR_ON

4

16 GROUND

LOGIC & CARD PINS SEQUENCER

SEQ 3

50 k

SEQ 2

SEQ 1

Vbat

STATUS

GND

5

Vbat

VCC

Vbat_OK

CLOCK

CLK_STOP

CLOCK

13 CRD_CLK

SEQ 2

2

A

GND

Vbat

1

20 k

Vbat_OK

I/O

20 k

SEQ 1

8

I/O

DATA

DATA

14 CRD_IO

I/O

1

RESET

7

2

Vbat

3

SEQ 3

PWR_ON

Figure 3. Block Diagram

http://onsemi.com

3

RESET

12 CRD_RST

�L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

H

H

H

H

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

−

H/L

H/L

L/H

H/L

2

3

4

5

6

7

4

8

9

10

11

http://onsemi.com

12

13

14

15

16

17

18

19

20

Z

Z

Z

Z

H

H

H

H

H

H

H

H

L

L

L

L

L

L

L

L

H

H

L

L

H

H

H

H

L

L

L

L

H

H

H

H

L

L

L

L

STATUS PGM RESET A1

1

H

L

H

L

H

H

L

L

H

H

L

L

H

H

L

L

H

H

L

L

A0

Z

Z

Z

Z

H

L

H

L

H

L

L

H

H

L

H

L

H

L

H

L

I/O

Program Chip

Normal Chip Operation

CARD PRESENT NO CARD DC−DC OK DC−DC OVERLOADED

Figure 4. Programming and Normal Operation Basic Timing

Read CRD_VCC status−> Low = CRD_VCC Low Voltage

Read STATUS = 1−>DC−DCOK/ = 0−> DC−DC Overloaded

Read Vbat status−> Low = Battery OK

CRD_DET = Normally Close

Read STATUS = 1−> Card Present/ = 0−> No Card

CRD_DET = Normally Close

CRD_DET = Normally Close

CRD_DET = Normally Open

Reserved

STOP CRD_CLKLow

STOP CRD_CLKHigh

5 V CLOCK_IN 1/8

ENABLE CRD_CLK

5 V CLOCK_IN 1/2

5 V CLOCK_IN 1/4

3 V CLOCK_IN 1/8

5 V CLOCK_IN 1/1

3 V CLOCK_IN 1/2

3 V CLOCK_IN 1/4

3 V CLOCK_IN 1/1

CS

I/O

A0

A1

RESET

PGM

STATUS

NCN6000

�NCN6000

The programming can be achieved with the card powered

ON or OFF. The identification of the interrupt is carried out

by polling the STATUS pin, the Vbat voltage and the

DC−DC results being provided on the same pin as depicted

INTERRUPT

ACKNOWLEDGE

by the table in Figure 4. During the programming mode, the

PGM pin can be released to High since the mode is internally

latched by the Negative going transition presents on the Chip

Select pin.

CARD IDENTIFICATION

POLLING

50 �s

CARD EXTRACTED

50 �s

CRD_DET

INT

CS

PGM

High

A0

Low

A1

Low

STATUS

S1 CLEAR INTERRUPT

S2 CARD PRESENT: STATUS = 1

S3 CLEAR INTERRUPT

S4 CARD PRESENT: STATUS = 0

Figure 5. Interrupt Servicing and Card Polling

otherwise a Low is presented pin 5. The 50 �s digital filter

is activated during both Insertion and Extraction of the card.

The MPU shall clear the INT line when the card has been

extracted, making the interrupt function available for other

purposes. However, neither the NCN6000 operation nor the

smart card I/O line or commands are affected by the state of

the INT pin.

On the other hand, clearing the INT and reading the

STATUS register can be performed by a single read by the

MPU: states S1 and S2 can be combined in a single

instruction, the same for S3 and S4.

When a card is either inserted or extracted, the CRD_DET

pin signal is debounced internally prior to pull the INT pin

to Low. The built−in logic circuit automatically

accommodates positive or negative input signal slope, on

both insertion and extraction state, depending upon the

polarity defined during the initialization sequence. The

default condition is Normally Open switch, negative going

card detection. The external CPU shall acknowledge the

request by forcing CS = L which, in turn, releases the INT

pin to High upon positive going of Chip Select (Table 4).

Polling the STATUS pin as depicted in Table 3 identifies the

active card. If a card is present, the STATUS returns High,

http://onsemi.com

5

�NCN6000

ABBREVIATIONS

Lout_H

DC−DC External Inductor

Lout_L

DC−DC External Inductor

Cout

Output Capacitor

VCC

Card Power Supply Input

Icc

Current at CRD_VCC Pin

Class A

5.0 V Smart Card

Class B

3.0 V Smart Card

CS

Chip Select (from MPU)

Z

High Impedance Logic State

(according to ISO7816)

CRD_VCC

Interface IC Card Power Supply Output

CRD_CLK

Interface IC Card Clock Output

CRD_RST

Interface IC Card Reset Output

CRD_IO

Interface IC Card I/O Signal Line

CRD_DET

Interface IC Card Detection

ATR

Answer to Reset

PGM

Select Programming or Normal Operation

INT

Interrupt (to MPU)

tr

Rise Time

tf

Fall Time

td

Delay Time

ts

Storage Time

PIN FUNCTIONS AND DESCRIPTION

Pin

Name

Type

Description

1

A0

INPUT

This pin is combined with A1, PGM, RESET and I/O to program the chip mode of operation

and to read the data provided by STATUS. (Figures 4 and 5 and Tables 2 and 3)

2

A1

INPUT

This pin is combined with A0, PGM, RESET and I/O to program the chip mode of operation

and to read the data provided by STATUS. (Figures 4 and 5 and Tables 2 and 3)

3

PGM

INPUT

This pin is combined with A0, A1, RESET and I/O to program the chip mode of operation

and to read the data provided by STATUS. (Figures 4 and 5 and Tables 2 and 3)

4

PWR_ON

INPUT

Pull Down

This pin validates the operation of the internal DC−DC converter:

CS = L + PWR_ON = Negative going: DC−DC is OFF

CS = L + PWR_ON = Positive going: DC−DC is ON

Note: The PWR_ON bit must be combined with a Low state CS signal to activate

the function. (Table 2)

5

STATUS

OUTPUT

This pin provides logic state related to the card and NCN6000 status. According to the A0,

A1 and PGM logic state, this pin carries either the Card present status or the Vbat or the

DC−DC operation state. When PGM = L, STATUS is not affected, see Table 2.

6

CS

INPUT

Pull Up

This pin provides the NCN6000 chip select function. The PWR_ON, RESET, I/O, A0, A1 and

PGM signals are disabled when CS = H. When PGM = L and CS = L, the device jumps to

the programming mode (Figure 4 and Tables 1, 2 and 3). The Chip Select pin must be a

unique physical address when more than one card are controlled by a single MPU. The data

presented by the MPU are latched upon positive going edge of the Chip Select pin.

7

RESET

INPUT

Pull Down

This pin provides two modes of operation depending upon the logic state of PGM pin 3:

PGM = 1: The signal present at this pin is translated to pin 12 (card reset

signal) when CS = L and PWR_ON = H. It is latched when CS = H.

PGM = 0: The signal present on this pin is used as a logic input to program the

internal functions (Figure 5 and Tables 2 and 3).

http://onsemi.com

6

�NCN6000

PIN FUNCTIONS AND DESCRIPTION (continued)

Pin

Name

Type

Description

8

I/O

Input/Output

Pull Up

This pin is connected to an external microcontroller interface. A bidirectional level translator

adapts the serial I/O signal between the smart card and the microcontroller. The level

translator is enabled when CS = L. The signal present on this pin is latched when CS = H.

This pin is also used in programming mode (Tables 1, 2 and 3, Figures 4 and 5).

9

INT

OUTPUT

Pull Down

This pin is activated LOW when a card has been inserted and detected by the interface or

when the NCN6000 reports Vbat or CRD_VCC status (See Table 6). The signal is reset to

a logic 1 on the rising edge of either CS or PWR_ON. The Collector open mode makes

possible the wired AND/OR external logic. When two or more interfaces share the INT

function with a single microcontroller, the software must poll the STATUS pin to identify the

origin of the interrupt (Figure 5).

10

CLOCK_IN

CLOCK INPUT

High Impedance

This pin can be connected to either the microcontroller master clock, or to any clock signal,

to drive the external smart cards. The signal is fed to internal clock selector circuit and

translated to the CRD_CLK pin at either the same frequency, or divided by 2 or 4 or 8,

depending upon the programming mode (Tables 1, 2 and 3).

Care must be observed, at PCB level, to minimize the pick−up noise coming from the

CLOCK_IN line. It is recommended to put a shield, built with a 10 mil copper track, around

this line and terminated to the GND.

11

CRD_DET

INPUT

The signal coming from the external card connector is used to detect the presence of the

card. A built−in pull up low current source makes this pin active LOW or HIGH, assuming

one side of the external switch is connected to ground. At Vbat start up, the default

condition is Normally Open switch, negative going insertion detection. The Normally

Closed switch, positive going insertion detection, can be defined by programming the

NCN6000 accordingly. In this case, the polarity must be set up during the first cycles of the

system initialization, otherwise an already inserted card will not be detected by the chip.

12

CRD_RST

OUTPUT

This pin is connected to the RESET pin of the card connector. A level translator adapts the

RESET signal from the microcontroller to the external card. The output current is internally

limited to 15 mA. The CRD_RST is validated when PWR_ON = H and PGM = H and hard

wired to Ground when the card is deactivated.

13

CRD_CLK

OUTPUT

This pin is connected to the CLK pin of the card connector. The CRD_CLK signal comes

from the clock selector circuit output. Combining A0, A1, PGM and I/O, as depicted in

Table 3 and Figure 3, programs the clock selection. This signal can be forced into a

standby mode with CRD_CLK either High or Low, depending upon the mode defined by

the programming sequence (Tables 1, 2 and 3 and Figure 4).

Care must be observed, at PCB level, to minimize the pick−up noise coming from the

CRD_CLK line. It is recommended to put a shield, built with a 10mil copper track, around

this line and terminated to the GND.

14

CRD_IO

I/O

This pin handles the connection to the serial I/O pin of the card connector. A bidirectional

level translator adapts the serial I/O signal between the card and the microcontroller. The

CRD_IO pin current is internally limited to 15 mA. A built−in register holds the previous

state presents on the I/O input pin.

15

CRD_VCC

POWER

This pin provides the power to the external card. It is the logic level “1” for CRD_IO,

CRD_RST and CRD_CLK signals. The energy stored by the DC−DC external inductor

Lout must be smoothed by a 10 �F capacitor, associated with a 100 nF ceramic in parallel,

connected across CRD_VCC and GND. In the event of a CRD_VCC UVLOW voltage, the

NCN6000 detects the situation and feedback the information in the STATUS bit. The device

does not take any further action, particularly the DC−DC converter is neither stopped nor

reprogrammed by the NCN6000. It is up to the external MPU to handle the situation.

However, when the CRD_VCC is overloaded, the NCN6000 shut off the DC−DC converter,

pulls the INT pin Low and reports the fault in the STATUS register.

16

GROUND

SIGNAL

The logic and low level analog signals shall be connected to this ground pin. This pin must

be externally connected to the PWR_GND pin 17. The designer must make sure no high

current transients are shared with the low signal currents flowing into this pin.

17

PWR_GND

POWER

This pin is the Power Ground associated with the built−in DC−DC converter and must be

connected to the system ground together with GROUND pin 11. Using good quality ground

plane is recommended to avoid spikes on the logic signal lines.

18

Lout_L

POWER

The High Side of the external inductor is connected between this pin and Lout_H to provide

the DC−DC function. The built−in MOS devices provide the switching function together with

the CRD_VCC voltage rectification.

http://onsemi.com

7

�NCN6000

PIN FUNCTIONS AND DESCRIPTION (continued)

Pin

Name

Type

Description

19

Lout_H

POWER

The High Side of the external inductor is connected between this pin and Lout_L to provide

the DC−DC function. The current flowing into this inductor is limited by a sense resistor

internally connected from Vbat/pin 20 and pin 19. Typically, Lout = 22��H, with ESR

< 2.0 �, for a nominal 55 mA output load.

20

Vbat

POWER

This pin is connected to the supply voltage and monitored by the NCN6000. The operation

is inhibited when Vbat is below the minimum 2.70 V value, followed by a PWR_DOWN

sequence and a Low STATUS state.

MAXIMUM RATINGS (Note 1)

Rating

Symbol

Value

Unit

Battery Supply Voltage

Vbat

7.0

V

Battery Supply Current (Note 2)

Ibat

300

mA

Power Supply Voltage

Vcc

6.0

V

Power Supply Current

Icc

"100

mA

Digital Input Pins

Vin

−0.5 V < Vin < Vbat +0.5 V,

but < 7.0 V

V

Iin

"5.0

mA

Digital Output Pins

Vout

−0.5 V < Vin < Vbat +0.5 V,

but < 7.0 V

V

Digital Output Pins

Iout

"10

mA

Card Interface Pins

Vcard

−0.5 V < Vcard < CRD_VCC +0.5 V

V

Card Interface Pins, except CRD_CLK

Icard

"15

mA

Inductor Current

ILout

300

mA

ESD Capability (Note 3)

Standard Pins

Card Interface Pins and CRD_DET

VESD

Digital Input Pins

kV

2.0

8.0

TSSOP−20 Package

Power Dissipation @ Tamb = +85°C

Thermal Resistance Junction to Air (R�ja)

PDS

R�ja

320

125

mW

°C/W

Operating Ambient Temperature Range

TA

−25 to +85

°C

Operating Junction Temperature Range

TJ

−25 to +125

°C

TJmax

+150

°C

Tsg

−65 to +150

°C

Maximum Junction Temperature (Note 4)

Storage Temperature Range

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. Maximum electrical ratings are defined as those values beyond which damage to the device may occur at TA = +25°C.

2. This current represents the maximum peak current the pin can sustain, not the NCN6000 consumption (see Ibatop).

3. Human Body Model, R = 1500 �, C = 100 pF.

4. Absolute Maximum Rating beyond which damage to the device may occur.

http://onsemi.com

8

�NCN6000

POWER SUPPLY SECTION (−25°C to +85°C ambient temperature, unless otherwise noted.)

Rating

Symbol

Pin

Min

Typ

Max

Unit

Power Supply

Vbat

20

2.7

−

6.0

V

Standby Supply Current Conditions:

PWR_ON = L, STATUS = H, CLOCK_IN = H,

CS = H. All other logic inputs and outputs are open:

Vbat = 3.0 V

Vbat = 5.0 V

Ibatsb

20

DC Operating Current (Figure 19)

PWR_ON = H, CLOCK_IN = 0, CS = H, all CRD pins

unloaded

@ Vbat = 6.0 V, CRD_VCC = 5.0 V

@ Vbat = 3.6 V, CRD_VCC = 5.0 V

Ibatop

Vbat Undervoltage DetectionHigh

Vbat Undervoltage DetectionLow

Vbat Undervoltage DetectionHysteresis

VbatLH

VbatLL

VbatHY

20

Vcc

15

Output Card Supply Voltage @ Icc = 55 mA

@ 2.70 V vVbat v6.0 V

CRD_VCC = 3.0 V

CRD_VCC = 5.0 V

@ VbatLL < Vbat < 2.70 V

CRD_VCC = 5.0 V

Output Card Supply Peak Current @ Vcc = 5.0 V

@ CRD_VCC = 5.0 V

@ CRD_VCC = 3.0 V

@ Vbat = 3.6 V, CRD_VCC = 5.0 V, Tamb < 65°C

�A

−

−

3.0

−

8.0

15

20

mA

−

−

7.0

2.0

−

5.0

2.1

2.0

−

−

−

100

2.7

2.6

−

V

VC3H

VC5H

2.75

4.75

−

−

3.25

5.25

VC5H

4.50

−

−

55

55

65

−

−

−

−

−

−

Iccp

V

V

mV

15

mA

Output Current Limit Time Out

tdoff

15

−

4.0

−

ms

Output Over Current Limit

Iccov

15

−

−

100

mA

Output Dynamic Peak Current @ CRD_VCC = 3.0 V

or 5.0 V, Cout = 10 �F Ceramic XR7, Pulse Width

400 ns (Notes 5 and 6)

Iccd

15

100

−

−

mA

Battery Start−Up Current

@ CRD_VCC = 3.0 V, −25°C v TA v+ 85°C

@ CRD_VCC = 5.0 V, −25°CvTAv+ 85°C

Iccst

20

−

−

140

300

−

−

Output Card Supply Voltage Ripple @ Lout = 22 �H,

Cout 1 = 10 �F, Cout 2 = 100 nF, Vbat = 3.6 V

Iout = 55 mA

CRD_VCC = 5.0 V

(Note 5)

CRD_VCC = 3.0V

Vccrip

Output Card Supply Turn On Time @ Lout = 22 �F,

Cout1 = 10 �F, Cout2 = 100 nF, Vbat = 2.7 V,

CRD_VCC = 5.0 V

VccTON

Output Card Supply Shut Off Time @ Cout1 = 10 �F,

Ceramic, Vbat = 2.7 V, CRD_VCC = 5.0 V,

VccOFF < 0.4 V

mA

15

mV

−

−

−

−

50

50

15

−

−

2.0

ms

VccTOFF

15

−

−

250

�s

Fsw

18

−

600

−

kHz

Power Switch Drain/Source Resistor

RONS

18

−

1.9

2.2

�

Output Rectifier ON Resistor

ROND

15

−

2.8

3.4

�

DC−DC Converter Operating Frequency

5. Ceramic X7R, SMD types capacitors are mandatory to achieve the CRD_VCC specifications. When electrolytic capacitor is used, the

external filter must include a 100 nF, max 50 m� ESR capacitor in parallel, to reduce both the high frequency noise and ripple to a minimum.

Depending upon the PCB layout, it might be necessary is to use two 6.8 �F/10 V/ceramic/X7R//SMD1206 in parallel, yielding an improved

CRD_VCC ripple over the temperature range.

6. According to ISO7816−3, paragraph 4.3.2.

http://onsemi.com

9

�NCN6000

DIGITAL PARAMETERS SECTION @ 2.70 VvVbatv6.0 V, NORMAL OPERATING MODE (−25°C to +85°C ambient

temperature, unless otherwise noted.) Note: Digital inputs undershoot < −0.30 V to ground, Digital inputs overshoot