NCP1086

1.5 A Adjustable and 3.3 V

Fixed Output Linear

Regulator

The NCP1086 linear regulator provides 1.5 A at 3.3 V or adjustable

output voltage. The adjustable output voltage device uses two external

resistors to set the output voltage within a 1.25 V to 5.5 V range.

The regulators is intended for use as post regulator and

microprocessor supply. The fast loop response and low dropout

voltage make this regulator ideal for applications where low voltage

operation and good transient response are important.

The circuit is designed to operate with dropout voltages less than

1.4 V at 1.5 A output current. Device protection includes overcurrent

and thermal shutdown.

This device is pin compatible with LT1086 family of linear

regulators and has lower dropout voltage.

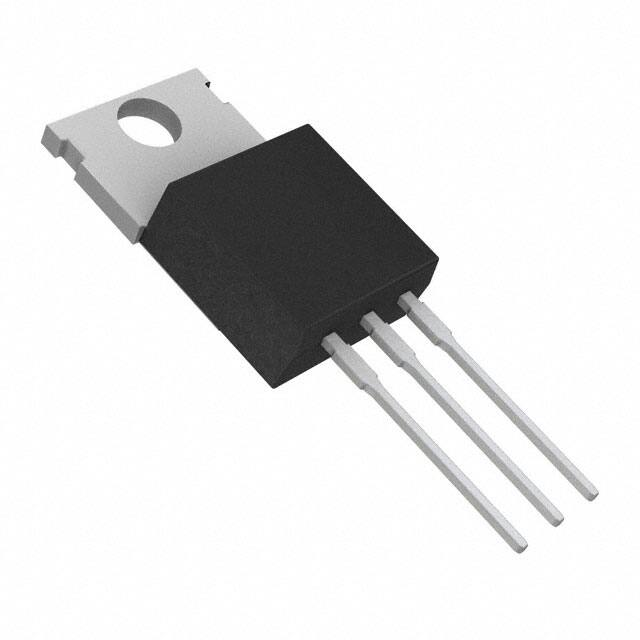

The regulators are available in TO−220−3, surface mount

D2PAK−3, and SOT−223 packages.

http://onsemi.com

TO−220−3

T SUFFIX

CASE 221A

1

2

3

D2PAK−3

DP SUFFIX

CASE 418AB

Features

•

•

•

•

•

•

Output Current to 1.5 A

Output Accuracy to ±1% Over Temperature

Dropout Voltage (Typical) 1.05 V @ 1.5 A

Fast Transient Response

Fault Protection Circuitry

♦ Current Limit

♦ Thermal Shutdown

Pb−Free Packages are Available

12

3

1

SOT−223

ST SUFFIX

CASE 318E

23

Adjustable

Output

Tab = VOUT

Pin 1. Adj

2. VOUT

3. VIN

3.3 V Fixed

Output

Tab = VOUT

Pin 1. GND

2. VOUT

3. VIN

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 9 of this data sheet.

DEVICE MARKING INFORMATION

See general marking information in the device marking

section on page 10 of this data sheet.

5.0 V

VIN

NCP1086

3.3 V

@ 1.5 A

VOUT

Adj

10 mF

5.0 V

VIN

124 W

1.0%

December, 2009 − Rev. 9

VOUT

GND

22 mF

5.0 V

10 mF

5.0 V

200 W

1.0%

Figure 1. Application Diagram, Adjustable Output

© Semiconductor Components Industries, LLC, 2009

NCP1086

3.3 V

@ 1.5 A

22 mF

5.0 V

Figure 2. Application Diagram, 3.3 V Fixed Output

1

Publication Order Number:

NCP1086/D

�NCP1086

MAXIMUM RATINGS*

Parameter

Supply Voltage, VCC

Operating Temperature Range

Junction Temperature

Storage Temperature Range

Lead Temperature Soldering:

Wave Solder (through hole styles only) Note 1

Reflow (SMD styles only) Note 2

ESD Damage Threshold

Value

Unit

7.0

V

−40 to +70

°C

150

°C

−60 to +150

°C

260 Peak

230 Peak

°C

2.0

kV

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. 10 second maximum.

2. 60 second maximum above 183°C.

ELECTRICAL CHARACTERISTICS (CIN = 10 mF, COUT = 22 mF Tantalum, VOUT + VDROPOUT < VIN < 7.0 V, 0°C ≤ TA ≤ 70°C,

TJ ≤ +150°C, unless otherwise specified, Ifull load = 1.5 A.)

Test Conditions

Characteristic

Min

Typ

Max

Unit

1.241

(−1%)

1.254

1.266

(+1%)

V

ADJUSTABLE OUTPUT VOLTAGE

Reference Voltage (Notes 3 and 4)

VIN − VOUT = 1.5 V; VAdj = 0 V,

10 mA ≤ IOUT ≤ 1.5 A

Line Regulation

1.5 V ≤ VIN − VOUT ≤ 5.75 V; IOUT = 10 mA

−

0.02

0.2

%

Load Regulation (Notes 3 and 4)

VIN − VOUT = 1.5 V; 10 mA ≤ IOUT ≤ 1.5 A

−

0.04

0.4

%

Dropout Voltage (Note 5)

IOUT = 1.5 A

−

1.05

1.4

V

Current Limit

VIN − VOUT = 3.0 V; TJ ≥ 25°C

1.6

3.1

−

A

Minimum Load Current (Note 6)

VIN = 7.0 V; VAdj = 0

−

0.6

2.0

mA

Adjust Pin Current

VIN − VOUT = 3.0 V; IOUT = 10 mA

−

50

100

mA

Thermal Regulation (Note 7)

30 ms pulse; TA = 25°C

−

0.002

0.02

%/W

Ripple Rejection (Note 7)

f = 120 Hz; IOUT = 1.5 A; VIN − VOUT = 3.0 V;

VRIPPLE = 1.0 VP−P

−

80

−

dB

Thermal Shutdown (Note 8)

−

150

180

210

°C

Thermal Shutdown Hysteresis (Note 8)

−

−

25

−

°C

3.25

(−1.5%)

3.3

3.35

(+1.5%)

V

FIXED OUTPUT VOLTAGE

Output Voltage (Notes 3 and 4)

VIN − VOUT = 1.5 V, 0 ≤ IOUT ≤ 1.5 A

Line Regulation

2.0 V ≤ VIN − VOUT ≤ 3.7 V; IOUT = 10 mA

−

0.02

0.2

%

Load Regulation (Notes 3 and 4)

VIN − VOUT = 2.0 V; 10 mA ≤ IOUT ≤ 1.5 A

−

0.04

0.4

%

Dropout Voltage (Note 5)

IOUT = 1.5 A

−

1.05

1.4

V

Current Limit

VIN − VOUT = 3.0 V

1.6

3.1

−

A

Quiescent Current

IOUT = 10 mA

−

5.0

10

mA

Thermal Regulation (Note 7)

30 ms pulse; TA = 25°C

−

0.002

0.02

%/W

3. Load regulation and output voltage are measured at a constant junction temperature by low duty cycle pulse testing. Changes in output

voltage due to thermal gradients or temperature changes must be taken into account separately.

4. Specifications apply for an external Kelvin sense connection at a point on the output pin 1/4” from the bottom of the package.

5. Dropout voltage is a measurement of the minimum input/output differential at full load.

6. The minimum load current is the minimum current required to maintain regulation. Normally the current in the resistor divider used to set the

output voltage is selected to meet the minimum requirement.

7. Guaranteed by design, not 100% tested in production.

8. Thermal shutdown is 100% functionally tested in production.

http://onsemi.com

2

�NCP1086

ELECTRICAL CHARACTERISTICS (continued) (CIN = 10 mF, COUT = 22 mF Tantalum, VOUT + VDROPOUT < VIN < 7.0 V,

0°C ≤ TA ≤ 70°C, TJ ≤ +150°C, unless otherwise specified, Ifull load = 1.5 A.)

Test Conditions

Characteristic

Min

Typ

Max

Unit

−

80

−

dB

FIXED OUTPUT VOLTAGE (continued)

f = 120 Hz; IOUT = 1.5 A; VIN − VOUT = 3.0 V;

VRIPPLE = 1.0 VP−P

Ripple Rejection (Note 9)

Thermal Shutdown (Note 10)

−

150

180

210

°C

Thermal Shutdown Hysteresis

(Note 10)

−

−

25

−

°C

9. Guaranteed by design, not 100% tested in production.

10. Thermal shutdown is 100% functionally tested in production.

PACKAGE PIN DESCRIPTION, ADJUSTABLE OUTPUT

Package Pin Number

D2PAK−3

TO−220−3

SOT−223

Pin Symbol

1

1

1

Adj

2

2

2

VOUT

3

3

3

VIN

Function

Adjust pin (low side of the internal reference).

Regulated output voltage (case).

Input voltage.

PACKAGE PIN DESCRIPTION, 3.3 V FIXED OUTPUT

Package Pin Number

D2PAK−3

TO−220−3

SOT−223

Pin Symbol

1

1

1

GND

Ground connection.

2

2

2

VOUT

Regulated output voltage (case).

3

3

3

VIN

Function

Input voltage.

VOUT

VIN

VOUT

VIN

Output

Current

Limit

Thermal

Shutdown

− +

Output

Current

Limit

Thermal

Shutdown

Error

Amplifier

Bandgap

− +

Error

Amplifier

Bandgap

Adj

GND

Figure 3. Block Diagram, Adjustable Output

Figure 4. Block Diagram, 3.3 V Fixed Output

http://onsemi.com

3

�NCP1086

TYPICAL PERFORMANCE CHARACTERISTICS

1.05

0.10

TCASE = 0°C

0.08

Output Voltage Deviation (%)

1.00

V Drop Out (V)

0.95

0.90

TCASE = 25°C

0.85

0.80

TCASE = 125°C

0.75

0

300

600

900

IOUT (mA)

1200

0.04

0.00

−0.04

−0.08

−0.12

0

1500

TJ (°C)

Figure 5. Dropout Voltage vs. Output Current

Figure 6. Reference Voltage vs. Temperature

3.5

65

3.1

IO = 10mA

60

ISC (A)

Adjust Pin Current (mA)

70

55

50

40

0

2.7

2.3

1.9

45

20

40

60

80

Temperature (°C)

100

1.5

1.0

120

Voltage Deviation (mV)

200

100

0

VOUT = 3.3 V

COUT = CIN = 22 mF Tantalum

−120

0

−200

1500

750

0

0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

2.0

3.0

4.0

5.0

VIN − VOUT (V)

7.0

6.0

Figure 8. Short Circuit Current vs VIN − VOUT

Load Step (mA)

Voltage Deviation (mV)

Figure 7. Adjust Pin Current vs. Temperature

(Adjustable Output)

Load Step (mA)

10 20 30 40 50 60 70 80 90 100 110 120 130

9.0

10

Time, ms

Figure 9. Transient Response (Adjustable Output)

200

100

0

−120

0

−200

COUT = CIN = 22 mF Tantalum

1500

750

0

0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10

Time, ms

Figure 10. Transient Response (3.3 V Fixed Output)

http://onsemi.com

4

�85

85

75

75

Ripple Rejection (dB)

Ripple Rejection (dB)

NCP1086

65

55

45

TCASE = 25°C

IOUT = 6A

(VIN − VOUT = 3V)

VRIPPLE = 1.6VPP

CAdj = 0.1 mF

35

25

15

101

102

65

55

45

TCASE = 25°C

IOUT = 6A

(VIN − VOUT = 3V)

VRIPPLE = 1.6VPP

35

25

103

104

Frequency (Hz)

105

15

101

106

Figure 11. Ripple Rejection vs. Frequency

(Adjustable Output)

Minimum Load Current (mA)

Output Voltage Deviation, (%)

105

106

0.65

0.075

0.050

TCASE = 125°C

0

0

103

104

Frequency (Hz)

Figure 12. Ripple Rejection vs. Frequency

(3.3 V Fixed Output)

0.100

0.025

102

TCASE = 25°C

TCASE = 0°C

0.55

TCASE = 125°C

TCASE = 25°C

0.50

0.45

CIN = COUt = 22 mF Tantalum

TCASE = 0°C

1.0

0.60

2.0

Output Current (A)

0.40

1.0

2.0

3.0

4.0

5.0

6.0

7.0

VIN − VOUT (V)

Figure 13. Load Regulation vs. Output Current

(Adjustable Output)

Figure 14. Minimum Load Current vs VIN − VOUT

(Adjustable Output)

APPLICATIONS INFORMATION

A resistor divider network R1 and R2 causes a fixed

current to flow to ground. This current creates a voltage

across R2 that adds to the 1.25 V across R1 and sets the

overall output voltage. The adjust pin current (typically

50 mA) also flows through R2 and adds a small error that

should be taken into account if precise adjustment of VOUT

is necessary.

The output voltage is set according to the formula:

The NCP1086 voltage regulator series provides

adjustable and 3.3 V output voltages at currents up to 1.5 A.

The regulator is protected against overcurrent conditions

and includes thermal shutdown.

The NCP1086 series has a composite PNP−NPN output

transistor and requires an output capacitor for stability. A

detailed procedure for selecting this capacitor is included in

the Stability Considerations section.

VOUT + VREF

Adjustable Operation

The adjustable output device has an output voltage range

of 1.25 V to 5.5 V. An external resistor divider sets the

output voltage as shown in Figure 15. The regulator

maintains a fixed 1.25 V (typical) reference between the

output pin and the adjust pin.

) R2Ǔ ) I

ǒR1 R1

Adj

R2

The term IAdj × R2 represents the error added by the adjust

pin current.

http://onsemi.com

5

�NCP1086

R1 is chosen so that the minimum load current is at least

2.0 mA. R1 and R2 should be the same type, e.g. metal film

for best tracking over temperature.

must be able to withstand the short circuit condition

indefinitely while protecting the IC.

EXTERNAL

VIN

VOUT

VIN

C1

SUPPLY

VOUT

NCP1086

VREF

Adj

R1

C2

VIN

NCP1086

VOUT

Adj

IAdj

R2

VOUT

Figure 15. Resistor Divider Scheme

Figure 16. Short Circuit Protection Circuit for High

Voltage Application

The adjustable output linear regulator has an absolute

maximum specification of 7.0 V for the voltage difference

between VIN and VOUT. However, the IC may be used to

regulate voltages in excess of 7.0 V. The main

considerations in such a design are powerup and short circuit

capability.

In most applications, ramp−up of the power supply to VIN

is fairly slow, typically on the order of several tens of

milliseconds, while the regulator responds in less than one

microsecond. In this case, the linear regulator begins

charging the load as soon as the VIN to VOUT differential is

large enough that the pass transistor conducts current. The

load at this point is essentially at ground, and the supply

voltage is on the order of several hundred mV, with the result

that the pass transistor is in dropout. As the supply to VIN

increases, the pass transistor will remain in dropout, and

current is passed to the load until VOUT reaches the point at

which the IC is in regulation. Further increase in the supply

voltage brings the pass transistor out of dropout. The result

is that the output voltage follows the power supply ramp−up,

staying in dropout until the regulation point is reached. In

this manner, any output voltage may be regulated. There is

no theoretical limit to the regulated voltage as long as the

VIN to VOUT differential of 7.0 V is not exceeded.

However, the possibility of destroying the IC in a short

circuit condition is very real for this type of design. Short

circuit conditions will result in the immediate operation of

the pass transistor outside of its safe operating area.

Overvoltage stresses will then cause destruction of the pass

transistor before overcurrent or thermal shutdown circuitry

can become active. Additional circuitry may be required to

clamp the VIN to VOUT differential to less than 7.0 V if

fail−safe operation is required. One possible clamp circuit is

illustrated in Figure 16; however, the design of clamp

circuitry must be done on an application by application

basis. Care must be taken to ensure the clamp actually

protects the design. Components used in the clamp design

Stability Considerations

The output or compensation capacitor helps determine

three main characteristics of a linear regulator: startup delay,

load transient response and loop stability.

The capacitor value and type is based on cost, availability,

size and temperature constraints. A tantalum or aluminum

electrolytic capacitor is best, since a film or ceramic

capacitor with almost zero ESR can cause instability. The

aluminum electrolytic capacitor is the least expensive

solution. However, when the circuit operates at low

temperatures, both the value and ESR of the capacitor will

vary considerably. The capacitor manufacturers’ data sheet

provides this information.

A 22 mF tantalum capacitor will work for most

applications, but with high current regulators such as the

NCP1086 series the transient response and stability improve

with higher values of capacitance. The majority of

applications for this regulator involve large changes in load

current, so the output capacitor must supply the

instantaneous load current. The ESR of the output capacitor

causes an immediate drop in output voltage given by:

DV + DI

ESR

For microprocessor applications it is customary to use an

output capacitor network consisting of several tantalum and

ceramic capacitors in parallel. This reduces the overall ESR

and reduces the instantaneous output voltage drop under

load transient conditions. The output capacitor network

should be as close as possible to the load for the best results.

http://onsemi.com

6

�NCP1086

Protection Diodes

When large external capacitors are used with a linear

regulator it is sometimes necessary to add protection diodes.

If the input voltage of the regulator gets shorted, the output

capacitor will discharge into the output of the regulator. The

discharge current depends on the value of the capacitor, the

output voltage and the rate at which VIN drops. In the

NCP1086 series linear regulator, the discharge path is

through a large junction and protection diodes are not

usually needed. If the regulator is used with large values of

output capacitance and the input voltage is instantaneously

shorted to ground, damage can occur. In this case, a diode

connected as shown in Figure 17 or Figure 18 is

recommended.

VIN

VIN

C1

NCP1086

VOUT

Adj

RLOAD

Figure 19. Conductor Parasitic Resistance Effects

Can Be Minimized with the Above Grounding

Scheme for Fixed Output Regulators

For the adjustable regulator, the best load regulation

occurs when R1 is connected directly to the output pin of the

regulator as shown in Figure 20. If R1 is connected to the

load, RC is multiplied by the divider ratio and the effective

resistance between the regulator and the load becomes

VOUT

R1

RC

VOUT

NCP1086

IN4002 (optional)

VIN

VIN

Conductor Parasitic

Resistance

RC

C2

) R2Ǔ

ǒR1 R1

where RC = conductor parasitic resistance.

R2

VIN

Figure 17. Protection Diode Scheme for Large Output

Capacitors (Adjustable Output)

VIN

RC

VOUT

NCP1086

Conductor Parasitic

Resistance

R1

Adj

RLOAD

IN4002 (optional)

VIN

VIN

C1

NCP1086

GND

VOUT

R2

VOUT

C2

Figure 20. Grounding Scheme for the

Adjustable Output Regulator to Minimize

Parasitic Resistance Effects

Figure 18. Protection Diode Scheme for Large Output

Capacitors (3.3 V Fixed Output)

Calculating Power Dissipation and

Heatsink Requirements

Output Voltage Sensing

The NCP1086 linear regulator includes thermal shutdown

and current limit circuitry to protect the device. High power

regulators such as these usually operate at high junction

temperatures so it is important to calculate the power

dissipation and junction temperatures accurately to ensure

that an adequate heatsink is used.

Since the NCP1086 is a three terminal regulator, it is not

possible to provide true remote load sensing. Load

regulation is limited by the resistance of the conductors

connecting the regulator to the load.

For best results the fixed output regulator should be

connected as shown in Figure 19.

http://onsemi.com

7

�NCP1086

The case is connected to VOUT, and electrical isolation

may be required for some applications. Thermal compound

should always be used with high current regulators such as

these.

The thermal characteristics of an IC depend on the

following four factors:

1.

2.

3.

4.

Each material in the heat flow path between the IC and the

outside environment has a thermal resistance. Like series

electrical resistances, these resistances are summed to

determine RqJA, the total thermal resistance between the

junction and the surrounding air.

1. Thermal Resistance of the junction to case, RqJC

(°C/W)

2. Thermal Resistance of the case to Heatsink, RqCS

(°C/W)

3. Thermal Resistance of the Heatsink to the ambient

air, RqSA (°C/W)

These are connected by the equation:

Maximum Ambient Temperature TA (°C)

Power dissipation PD (W)

Maximum junction temperature TJ (°C)

Thermal resistance junction to ambient RqJA (°C/W)

These four are related by the equation

TJ + TA ) PD

RqJA

RqJA + RqJC ) RqCS ) RqSA

(eq. 1)

(eq. 3)

The value for RqJA is calculated using Equation 3 and the

result can be substituted in Equation 1.

The value for RqJC is 3.5°C/W. For a high current

regulator such as the NCP1086 the majority of the heat is

generated in the power transistor section. The value for

RqSA depends on the heatsink type, while RqCS depends on

factors such as package type, heatsink interface (is an

insulator and thermal grease used?), and the contact area

between the heatsink and the package. Once these

calculations are complete, the maximum permissible value

of RqJA can be calculated and the proper heatsink selected.

For further discussion on heatsink selection, see application

note “Thermal Management,” document number

AND8036/D via our website at www.onsemi.com.

The maximum ambient temperature and the power

dissipation are determined by the design while the

maximum junction temperature and the thermal resistance

depend on the manufacturer and the package type.

The maximum power dissipation for a regulator is:

PD(max) + {VIN(max) * VOUT(min)}IOUT(max) ) VIN(max)IQ

(eq. 2)

where:

VIN(max) is the maximum input voltage,

VOUT(min) is the minimum output voltage,

IOUT(max) is the maximum output current, for the application

IQ is the maximum quiescent current at IOUT(max).

A heatsink effectively increases the surface area of the

package to improve the flow of heat away from the IC and

into the surrounding air.

http://onsemi.com

8

�NCP1086

ORDERING INFORMATION

Package

Shipping†

NCP1086D2T−ADJ

D2PAK

50 Units/Rail

NCP1086D2T−ADJG

D2PAK

50 Units/Rail

Device

Type

(Pb−Free)

NCP1086D2T−ADJR4

D2PAK

NCP1086D2TADJR4G

D2PAK

(Pb−Free)

NCP1086ST−ADJT3

Adjustable

750 Tape & Reel

SOT−223

NCP1086ST−ADJT3G

SOT−223

(Pb−Free)

NCP1086T−ADJ

2500 Tape & Reel

TO220

NCP1086T−ADJG

TO220

(Pb−Free)

50 Units/Rail

NCP1086D2T−033

D2PAK

50 Units/Rail

NCP1086D2T−33R4

D2PAK

D2PAK

(Pb−Free)

NCP1086D2T−33R4G

NCP1086ST−33T3

NCP1086ST−33T3G

750 Tape & Reel

SOT−223

3.3 V

SOT−223

(Pb−Free)

NCP1086T−033

2500 Tape & Reel

TO220

NCP1086T−033G

TO220

(Pb−Free)

50 Units/Rail

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

http://onsemi.com

9

�NCP1086

MARKING DIAGRAMS

Adjustable Output

TO−220−3

T SUFFIX

CASE 221A

D2PAK−3

D2T SUFFIX

CASE 418AB

3.3 V Fixed Output

SOT−223

ST SUFFIX

CASE 318E

AYW

086−AG

NCP1086−A

AWLYWWG

NCP1086−A

AWLYWWG

TO−220−3

T SUFFIX

CASE 221A

D2PAK−3

D2T SUFFIX

CASE 418AB

SOT−223

ST SUFFIX

CASE 318E

AYW

08633G

1086−33

AWLYWWG

G

1086−33

AWLYWWG

1

1

1

1

1

1

A

WL, L

YY, Y

WW, W

G or G

= Assembly Location

= Wafer Lot

= Year

= Work Week

= Pb−Free Package

http://onsemi.com

10

G

�NCP1086

PACKAGE DIMENSIONS

TO−220 3−LEAD

T SUFFIX

CASE 221AF−01

ISSUE A

SEATING

PLANE

−T−

E

Q

P

A

H1

A1

4

D

D1

1 2 3

L

L1

A2

b2

c

e

b

http://onsemi.com

11

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: INCHES.

3. DIMENSIONS D AND E DO NOT INCLUDE MOLD FLASH

AND GATE PROTRUSIONS. MOLD FLASH AND GATE

PROTRUSIONS NOT TO EXCEED 0.005 PER SIDE. THESE

DIMENSIONS ARE TO BE MEASURED AT OUTERMOST

EXTREME OF THE PLASTIC BODY.

3. DIMENSION b2 DOES NOT INCLUDE DAMBAR

PROTRUSION. LEAD WIDTH INCLUDING PROTRUSION

SHALL NOT EXCEED 0.080.

DIM

A

A1

A2

b

b2

c

D

D1

E

e

H1

L

L1

P

Q

INCHES

MIN

MAX

0.140

0.190

0.045

0.055

0.080

0.115

0.025

0.040

0.045

0.070

0.014

0.025

0.560

0.625

0.320

0.390

0.380

0.420

0.100 BSC

0.235

0.255

0.500

0.580

--0.280

0.139

0.161

0.100

0.135

MILLIMETERS

MIN

MAX

3.56

4.83

1.14

1.40

2.03

2.92

0.64

1.02

1.14

1.78

0.36

0.64

14.22

15.88

8.13

9.91

9.65

10.67

2.54 BSC

5.97

6.48

12.70

14.73

--7.11

3.53

4.09

2.54

3.43

�NCP1086

PACKAGE DIMENSIONS

D2PAK−3

CASE 418AB−01

ISSUE A

A

SEATING

PLANE

B

A

E

L1

0.10

A

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: INCHES.

3. DIMENSIONS D AND E DO NOT INCLUDE MOLD

FLASH AND GATE PROTRUSIONS. MOLD FLASH

AND GATE PROTRUSIONS NOT TO EXCEED

0.005 MAXIMUM PER SIDE. THESE DIMENSIONS

TO BE MEASURED AT DATUM H.

4. THERMAL PAD CONTOUR OPTIONAL WITHIN

DIMENSIONS E, L1, D1, AND E1. DIMENSIONS

D1 AND E1 ESTABLISH A MINIMUM MOUNTING

SURFACE FOR THE THERMAL PAD.

M

E1

c2

E/2

B A

D1

D

DETAIL C

H

c

A

e

3X

b

0.13

M

B A

VIEW A−A

B

M

H

RECOMMENDED

MOUNTING FOOTPRINT*

SEATING

PLANE

A1

L3

0.424

GAUGE

PLANE

DIM

A

A1

b

c

c2

D

D1

E

E1

e

H

L

L1

L3

M

INCHES

MIN

MAX

0.170

0.180

0.000

0.010

0.026

0.036

0.017

0.026

0.045

0.055

0.325

0.368

0.270

−−−

0.380

0.420

0.245

−−−

0.100 BSC

0.580

0.620

0.090

0.110

−−−

0.066

0.010 BSC

0°

8°

L

0.310

M

DETAIL C

0.631

0.180

3X

0.100

PITCH

0.040

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

PACKAGE THERMAL DATA

Parameter

D2PAK−3

TO−220−3

SOT−223

Unit

RqJC

Typical

3.5

3.5

15

°C/W

RqJA

Typical

50

10−50*

156

°C/W

* Depending on thermal properties of substrate. RqJA = RqJC + RqCA

http://onsemi.com

12

MILLIMETERS

MIN

MAX

4.32

4.57

0.00

0.25

0.66

0.91

0.43

0.66

1.14

1.40

8.25

9.53

6.86

−−−

9.65

10.67

6.22

−−−

2.54 BSC

14.73

15.75

2.29

2.79

−−−

1.68

0.25 BSC

0°

8°

�NCP1086

PACKAGE DIMENSIONS

SOT−223 (TO−261)

ST SUFFIX

CASE 318E−04

ISSUE N

D

b1

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: INCH.

4

HE

1

2

3

b

e1

e

A1

C

q

A

0.08 (0003)

DIM

A

A1

b

b1

c

D

E

e

e1

L

L1

HE

E

q

L

MIN

1.50

0.02

0.60

2.90

0.24

6.30

3.30

2.20

0.85

0.20

1.50

6.70

0°

MILLIMETERS

NOM

MAX

1.63

1.75

0.06

0.10

0.75

0.89

3.06

3.20

0.29

0.35

6.50

6.70

3.50

3.70

2.30

2.40

0.94

1.05

−−−

−−−

1.75

2.00

7.00

7.30

10°

−

MIN

0.060

0.001

0.024

0.115

0.009

0.249

0.130

0.087

0.033

0.008

0.060

0.264

0°

INCHES

NOM

0.064

0.002

0.030

0.121

0.012

0.256

0.138

0.091

0.037

−−−

0.069

0.276

−

MAX

0.068

0.004

0.035

0.126

0.014

0.263

0.145

0.094

0.041

−−−

0.078

0.287

10°

L1

SOLDERING FOOTPRINT

3.8

0.15

2.0

0.079

2.3

0.091

2.3

0.091

6.3

0.248

2.0

0.079

1.5

0.059

SCALE 6:1

mm Ǔ

ǒinches

ON Semiconductor and

are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5773−3850

http://onsemi.com

13

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

NCP1086/D

�