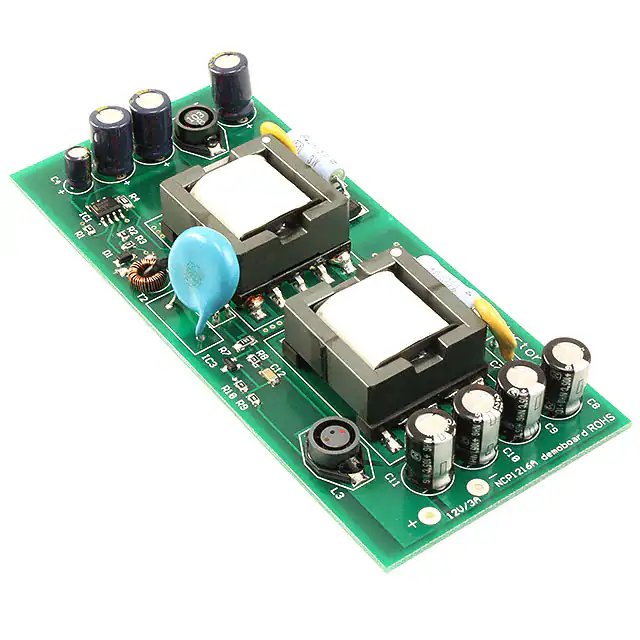

NCP1216AFORWGEVB

Implementing a DC/DC

Single‐ended Forward

Converter with the

NCP1216A Evaluation

Board User's Manual

http://onsemi.com

EVAL BOARD USER’S MANUAL

• Current-mode Operation

Introduction

This document describes how the NCP1216A controller

can be used to design a DC/DC single-ended forward

converter suitable for telecommunication applications. The

requirements for the converter are as follows:

• Input Voltage Range from 36 V to 72 VDC

• Continuous Output Power Greater than 30 W for a 12 V

Output Voltage

• Small PCB Dimensions

• Efficiency Greater then 85%

• Input to Output Isolation Voltage of 1500 V

•

•

The NCP1216A controller is an attractive solution for this

application, due to the following features:

•

• 50% Maximum Duty Cycle Operation

•

•

Forward converters usually limit the maximum duty

cycle to 50%. Since the voltage reset is constrained to

be equal to the input voltage (1:1 reset ratio), it is not

desirable to exceed 50% DC to avoid saturating the

transformer core.

No Auxiliary Winding Operation

The DSS (Dynamic Self-supply) function allows

the NCP1216A derive power directly from the HV

line without having to supply VCC either from the

secondary output inductance (creepage distance and

isolation issues) or via an auxiliary winding delivering

a variable voltage of N × Vin.

500 mA Peak Current Capability

The NCP1216A can drive a MOSFET directly without

any additional driver stage. If the selected MOSFET

gate charge would overload the DSS capability, then an

auxiliary winding could be used solely to supply the

driver pulses.

© Semiconductor Components Industries, LLC, 2012

August, 2012 − Rev. 1

Cycle-by-cycle primary current monitoring eliminates

any overcurrent situations, e.g. resulting from a

secondary short-circuit.

Direct Optocoupler Connection

In applications where the input to output isolation is

required, a direct connection eases the design stage,

saving external components.

Extremely Low No-load Power Consumption

Extremely low consumption in no-load operation is a

great advantage of the NCP1216A controller. Today’s

maximum stand-by consumption standards can be

easily met if this function is used.

Short-circuit Protection

By monitoring the activity on the feedback line,

the NCP1216A simplifies the task of secondary side

short-circuit protection. Coupling problems are

eliminated thanks to this feature and the DSS

implementation.

The 35 W DC/DC Converter Board Specifications

The schematic of the proposed converter is shown in

Figure 1. This converter has the following specifications:

Minimum Input Voltage

36 VDC

Maximum Input Voltage

72 VDC

Output Voltage

12 VDC

Continued Output Current

100 kHz

No-load Consumption at 48 V

1.8 mA

Maximum Ambient Temperature

1

3.0 A

Operating Frequency

70°C

Publication Order Number:

EVBUM2133/D

�R1

12 k

+

36−

72 V

C1

22 m/

100 V

2

http://onsemi.com

Figure 1. Schematic Diagram

NCP1216A

C4

22 m

DRV

GND

HV

VCC

IC1

CS

FB

ADJ

10 mH

L1

C2

22 m/

100 V

+

R5

8k2

1N4148

1k8

R3

10 R

D1

0R

C5

1.5 n

T2

Q1

FQD18N20

D3

MURA240T3

R4

+

R2

C3

22 m/

100 V

MURA240T3

D2

T1

4n7/Y2

C6

MURB1620CT

D4B

D4A

C9

220 m/

25 V

C10

220 m/

25 V

+

C8

220 m/

25 V

IC3

TLV431

PC817

IC2

18 k

R8

R7

560 R

33 n

C12

1.0 mH

+

100 mH

+

L3

2n2

C7

L2

100 R

R6

R10

4k3

R9

39 k

C11

220 m/

25 V

+12 V

NCP1216AFORWGEVB

�NCP1216AFORWGEVB

Description of Converter Connection

The primary magnetization current does not directly

participate in the energy transfer and cause additive losses

on the power switch and the primary winding. When the

switch is off, the transformer core must be reset in order to

let the internal flux return to zero. This is done via a

dedicated reset circuit. Consequently the magnetizing

current Imag must be kept smaller than the productive

component of the primary current.

The core flux density excursion DB has to be chosen with

respect to the characteristics of the core material: the

saturation flux density Bmax or Bsat, the residual flux

density Br, hysteretic losses and the core temperature

behavior. With respect to these characteristics, the flux

density excursion in high frequency converters should be

between 0.15 T and 0.2 T. If a higher value is chosen, greater

losses will be generated. The primary turn count Np can be

calculated by rearranging equation 4:

Capacitors C1, C2, C3 and inductor L1 form the input

filter. Diode D3, capacitor C5 and resistor R5 provide the

primary clamping network which combats leakage

inductance between the reset winding and the primary

winding. The link between both windings occurs via D2

when the switch is off. Transformer T2 with diode D1 and

resistors R2, R3 serve as the primary current sensing circuit.

Thanks to low insertion losses, the final efficiency of the

converter benefits greatly from this configuration. IC1 is the

main driving circuit of the power converter. The secondary

circuitry has D4A as the forward diode and D4B as the

freewheeling diode. Capacitor C6 offers a path for

common-mode (CM) currents circulating via the various

transformer stray capacitances during switching events.

Resistors R7, R8, R9, and R10 together with capacitor C12,

shunt regulator IC3, and optocoupler IC2 form an isolated

feedback circuit for output voltage regulation. A snubber

network (R6, C7) is connected across inductor L2 in order

to damp high frequency oscillations. L2, C8, C9 and C10

form the basic LC output filter. L3 and C11 form an

additional output filter to reduce high frequency noise.

Design considerations for various sections of the

converter are described below.

Np +

In a forward converter, the core magnetization is ensured

by applying a voltage Vin on the primary side. This action

creates the core flux f which links both primary and

secondary windings. Using Faraday’s law, we can write that

E = N.df/dt, where E is the voltage generated by a winding

of N turns, energized by a flux f. By integrating this formula,

and rearranging it in terms of the input voltage Vin and the

on time ton, we can see that the internal flux depends on the

volt-second product:

(eq. 1)

where:

Ae is the total core area

B is the core flux density

Thus, the maximum core flux density DBMAX and the peak

primary magnetization current IPKMAG of the transformer

are given by the primary inductance value L1 and the

maximum input voltage according to equations (2) and (3):

I PKMAG +

V in max

DB MAX +

where:

Vin max

L1

fop

ądmax

Np

L1

@ 1 @ d max

f op

V in max @ d max

N p @ f op @ A e

(eq. 4)

For an EFD25 core with a total core area of 58 mm2

(DBmax = 0.2 T, Vin max = 80 V, fop = 100 kHz and

maximum duty cycle dmax = 0.5) then the number of

primary turns Np = 35.

The number of reset winding turns depends on design

tradeoffs. When the number of turns of the reset winding is

lower than the that of the primary winding, the reflected

voltage on the power switch drain will be lower than

2 × Vin max. However, this limits the maximum duty cycle

excursion to less than 50%. Conversely, if the reset turns are

larger than the primary turns, the maximum allowed duty

cycle will increase but the MOSFET voltage stress will

exceed 2 × Vin max. Due to these issues, the practical number

of turns for the reset winding is usually chosen to be the same

as the primary winding, or a 1:1 ratio. It is important to

provide a very good coupling between these two windings.

A high leakage inductance between these windings would

require a hard voltage clamp that would hurt the converter

efficiency.

The number of turns on the secondary winding Ns can be

obtained from equation 5:

Transformer Design

V in @ t on + N @ f + N @ A e @ B

V in max @ d max

DB MAX @ f op @ A e

Ns + Np @

where:

Vout

Vf

Vin min

(eq. 2)

(eq. 3)

V out

d max

) Vf

V in min

(eq. 5)

is the desired output voltage

is the voltage drop of the output rectifier

is the minimum input voltage

In the example using the EFD 25, equation (5) gives

Ns = 25 turns.

The primary and the secondary windings must be wound

to limit the skin effect. This can be done by using several

wires wound in parallel. The maximum diameter Dmax

(in mm) of each single wire in the winding is given by

equation 6:

is the maximum input voltage

is the primary winding inductance

is the operating frequency

is the maximum duty cycle

is the count of the primary turns

http://onsemi.com

3

�NCP1216AFORWGEVB

D max + 2 @ 75

Ǹfop

would be about 3.0 W. When the current sense transformer

is used, power losses are about 50 mW. The disadvantage of

this solution lies in the current error brought by the

magnetization current of current sense transformer. This

error is additive so it should accounted for and reduced.

A toroidal core with 38 turns of the secondary winding

was used in NCP1216A demo board. The primary winding

is created by one turn of isolated wire. The peak current I2pk

of the current sense resistor can be obtained from equation 8:

(eq. 6)

The total area of the selected wire for primary and

secondary windings is a tradeoff between the desired output

power, allowable conduction losses in the windings and

thermal considerations. The current density in the

transformer winding can generally range from 2 to

3.5 A/mm2. If a cooling fan is used, the current density can

be increased.

The reset winding can be made with a single wire

technique, given the low magnetization current flowing

into it.

In some cases, a small air gap can be inserted into the

magnetic circuit of the forward transformer. This solution

brings the residual flux density Br to a lower value than

without a gap. The main drawback lies in the primary

inductance decrease which forces a higher magnetizing

current.

I 2pk + I 1pk @ 1 * I magpk

Ns

where:

I1pk

Ns

Imagpk

I magpk +

The value of the output inductor selected depends on the

acceptable level of ripple current. For a small ripple current,

a large inductance is needed. On the other hand, when the

current ripple is high, large output capacitors must be used

to reduce the voltage ripple. In practice, it is usual to limit the

current ripple to about 10−20% of the average current of the

inductor. The maximum current ripple DImax in a forward

converter occurs at 50% duty cycle. Its value can be found

via equation (7):

V sec max

4 @ f op @ L 2

is the peak current of the power switch

is the count of secondary turns

is the peak value of the magnetization current

Figure 2 shows the current sense transformer circuit. The

peak value of the magnetization current is given by

equation 9:

Output Inductor Design

DI max +

(eq. 8)

V csth max @ d max

(eq. 9)

L s @ f op

where:

Vcsth max is the maximum threshold voltage of the

current sense input

Ls

is the inductance of the secondary winding

Q1

(eq. 7)

I1/Ns

D1

where:

Vsec max is the maximum secondary voltage

L2

is the inductance of inductor L2

I2

T2

Imag

I1

RSENSE

In the NCP1216A demo board, where a 100 mH inductor

is used, the maximum output ripple will be DImax = 2.0 A.

This is rather high, but the allowable dimensions of the

inductor limit a higher inductance value selection.

The values and types of output capacitors must be chosen

with respect to the maximum allowable output voltage

excursion as well as the RMS current that will flow in them.

Ns

Np

Figure 2. Implementation of the Current Sense

Transformer

The value of the current sense resistor Rsense can be

calculated by using equation 10:

Current Sense Transformer Design

R sense +

The current sense transformer is used to reduce power

losses traditionally found in the standard current sense

resistor configuration. If a classical current sense resistor

were used in this application, the associated power loss

V csth max

I 2pk

(eq. 10)

The NCP1216A Leading Edge Blanking circuit (LEB)

allows the designer to avoid using a RC network to suppress

voltage spikes during the switch turn-on event.

http://onsemi.com

4

�NCP1216AFORWGEVB

Primary RCD Clamp and Inductor Snubber Network

Design

C clamp +

Because of manufacturing constraints, the leakage

inductance between primary and secondary windings is

never equal to zero. The energy stored in this leakage

inductance during ton will cause large voltage spikes when

the switch is turning off. To protect the power switch from

a catastrophic voltage spike, a RCD clamping network must

be used. The values of these components depend not only on

the leakage inductance value but also on the reflected

voltage, the parasitic influence of the layout, and the RCD

capacitor. The power dissipation of the RCD clamp can be

obtained from equation 11:

V clamp

2

P clamp + 1 @ I 1pk @ L leak @ f op @

2

V clamp * V refl

where:

Lleak

Vclamp

Vrefl

An RC snubber network is connected across the inductor

L2 to dampen the parasitic oscillations caused when the

freewheel and forward diodes are switched.

Both the clamp and snubber networks dissipate heat and

affect the converter efficiency.

Regulation Loop Design

A standard loop topology with a TLV431 shunt regulator

is used. The optocoupler provides good isolation between

input and output sides of the converter. The output voltage

is set up by the R9 and R10 divider ratio according to

equation 14:

(eq. 11)

ǒ

V out + 1, 25 @ 1 )

2

L leak @ I 1pk @ f op

R9

R 10

Ǔ

(eq. 14)

The maximum current flowing through the optocoupler

LED is determined by resistor R7. The internal consumption

of the TLV431 is low, thus avoiding another biasing

element, bypassing the LED. Resistor R8 and C12 constitute

the feedback loop compensation circuit. The optimal values

for these components are based on the feedback response

measurements.

The optimal values of the clamping devices are given by

equations 12 and 13:

2 @ V clamp @ ǒV clamp * V reflǓ

(eq. 13)

where:

Vripple is the ripple voltage level on the clamping

capacitor; this ripple should be minimized.

is value of the leakage inductance

is value of the clamp voltage

is value of the reflected voltage (Vrefl = Vin max

for forward converters with max. DC = 50%)

R clamp +

V clamp

V ripple @ f op @ R clamp

(eq. 12)

http://onsemi.com

5

�NCP1216AFORWGEVB

Figure 3. PCB Layout (Top Side)

Figure 4. PCB Layout (Bottom Side)

Figure 5. Component Arrangement (Top Side)

Figure 6. Component Arrangement (Bottom Side)

http://onsemi.com

6

�NCP1216AFORWGEVB

PCB Layout Design

Performance of the Converter

A double-sided PCB is used to minimize the size of the

converter. The board is designed with respect to the power

dissipation created by the power devices, thus large cooling

areas are used. Sound grounding techniques and appropriate

isolation distances were incorporated into the layout. The

PCB layout and component arrangement can be seen on

Figures 3, 4, 5 and 6.

The power conversion efficiency of the DC/DC converter

is shown in Figures 7 and 8.

86

EFFICIENCY (%)

85, 5

Table 1. BILL OF MATERIALS

L1

10 mH DS3316P−103−Coilcraft

L2

100 mH B0754−A−Coilcraft

L3

1.0 mH DS3316P−102−Coilcraft

T1

C0972−A−Coilcraft

T2

Toroid f6.0 mm, Material T30−Epcos

Ns = 38 Turns

C1, C2,

C3

22 m/100 V Nippon Chemi−Con−KMF

C4

22 m/25 V Nippon Chemi−Con−KMF

C5

1,5 nF/500 V Through Hole Ceramic Capacitor

C6

4n7 Y2 Type Capacitor

C7

2,2 nF/500 V Through Hole Ceramic Capacitor

84, 5

84

36

R1

12 kW SMD 0805

R2

1,8 kW SMD 0805

R3

10 W SMD 0805

R4

0R SMD1206

R5

8,2 kW/1.0 W Through Hole

R6

100 W/1.0 W Through Hole

R7

560 W SMD1206

R8

18 kW SMD 0805

R9

39 kW SMD 0805

R10

4,3 kW SMD 0805

D1

MMSD914T1−ON Semiconductor

D2, D3

MURA2403T3−ON Semiconductor

D4

MURB1620CT−ON Semiconductor

Q1

FQD18N20V2TF−Fairchild

IC1

NCP1216A−ON Semiconductor

IC2

PC817−SHARP

IC3

TLV431BSN1T1−ON Semiconductor

66

76

86

90

85

EFFICIENCY (%)

33 nF SMD 1206

56

Figure 7. DC/DC Converter Efficiency

vs. Input Voltage

220 m/25 V Nippon Chemi−Con−LXZ

C12

46

INPUT VOLTAGE (V)

80

75

70

65

60

0

5

10

15

20

25

OUTPUT POWER (W)

30

35

Figure 8. DC/DC Converter Efficiency

vs. Output Power (Vin = 48 V)

The no-load consumption as a function of input voltage is

shown in Figure 9.

150

NO LOAD CONSUMPTION (mW)

C8, C9,

C10, C11

85

140

130

120

110

100

90

80

70

36

40

44

48

52

56

60

64

68

72

76

80

INPUT VOLTAGE (V)

Figure 9. No Load Consumption vs. Input Voltage

http://onsemi.com

7

�NCP1216AFORWGEVB

The gate (trace 1) and drain (trace 2) waveforms of the

power MOSFET Q1 are shown in Figures 10, 11, 12 and 13

for several converter conditions.

GATE

DRAIN

GATE

DRAIN

Figure 13. Detailed Burst During Overload

The load regulation for an output current step from 10%

to 100% can be seen in Figure 14.

Figure 10. Vinput = 48 V, Iout = 3.0 A

GATE

DRAIN

Figure 14. Load Regulation (Iout changing

from 10% to 100%−0.3 A to 3.0 A)

Figure 11. No Load Operation

GATE

DRAIN

Figure 12. Overload Operation

http://onsemi.com

8

�onsemi,

, and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates

and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A

listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

The evaluation board/kit (research and development board/kit) (hereinafter the “board”) is not a finished product and is not available for sale to consumers. The board is only intended

for research, development, demonstration and evaluation purposes and will only be used in laboratory/development areas by persons with an engineering/technical training and familiar

with the risks associated with handling electrical/mechanical components, systems and subsystems. This person assumes full responsibility/liability for proper and safe handling. Any

other use, resale or redistribution for any other purpose is strictly prohibited.

THE BOARD IS PROVIDED BY ONSEMI TO YOU “AS IS” AND WITHOUT ANY REPRESENTATIONS OR WARRANTIES WHATSOEVER. WITHOUT LIMITING THE FOREGOING,

ONSEMI (AND ITS LICENSORS/SUPPLIERS) HEREBY DISCLAIMS ANY AND ALL REPRESENTATIONS AND WARRANTIES IN RELATION TO THE BOARD, ANY

MODIFICATIONS, OR THIS AGREEMENT, WHETHER EXPRESS, IMPLIED, STATUTORY OR OTHERWISE, INCLUDING WITHOUT LIMITATION ANY AND ALL

REPRESENTATIONS AND WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE, NON−INFRINGEMENT, AND THOSE ARISING FROM A

COURSE OF DEALING, TRADE USAGE, TRADE CUSTOM OR TRADE PRACTICE.

onsemi reserves the right to make changes without further notice to any board.

You are responsible for determining whether the board will be suitable for your intended use or application or will achieve your intended results. Prior to using or distributing any systems

that have been evaluated, designed or tested using the board, you agree to test and validate your design to confirm the functionality for your application. Any technical, applications or

design information or advice, quality characterization, reliability data or other services provided by onsemi shall not constitute any representation or warranty by onsemi, and no additional

obligations or liabilities shall arise from onsemi having provided such information or services.

onsemi products including the boards are not designed, intended, or authorized for use in life support systems, or any FDA Class 3 medical devices or medical devices with a similar

or equivalent classification in a foreign jurisdiction, or any devices intended for implantation in the human body. You agree to indemnify, defend and hold harmless onsemi, its directors,

officers, employees, representatives, agents, subsidiaries, affiliates, distributors, and assigns, against any and all liabilities, losses, costs, damages, judgments, and expenses, arising

out of any claim, demand, investigation, lawsuit, regulatory action or cause of action arising out of or associated with any unauthorized use, even if such claim alleges that onsemi was

negligent regarding the design or manufacture of any products and/or the board.

This evaluation board/kit does not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling (WEEE), FCC,

CE or UL, and may not meet the technical requirements of these or other related directives.

FCC WARNING – This evaluation board/kit is intended for use for engineering development, demonstration, or evaluation purposes only and is not considered by onsemi to be a finished

end product fit for general consumer use. It may generate, use, or radiate radio frequency energy and has not been tested for compliance with the limits of computing devices pursuant

to part 15 of FCC rules, which are designed to provide reasonable protection against radio frequency interference. Operation of this equipment may cause interference with radio

communications, in which case the user shall be responsible, at its expense, to take whatever measures may be required to correct this interference.

onsemi does not convey any license under its patent rights nor the rights of others.

LIMITATIONS OF LIABILITY: onsemi shall not be liable for any special, consequential, incidental, indirect or punitive damages, including, but not limited to the costs of requalification,

delay, loss of profits or goodwill, arising out of or in connection with the board, even if onsemi is advised of the possibility of such damages. In no event shall onsemi’s aggregate liability

from any obligation arising out of or in connection with the board, under any theory of liability, exceed the purchase price paid for the board, if any.

The board is provided to you subject to the license and other terms per onsemi’s standard terms and conditions of sale. For more information and documentation, please visit

www.onsemi.com.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

onsemi Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

www.onsemi.com

1

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�