ecoSWITCHt

Advanced Load Management

Controlled Load Switch with Low RON

NCP45560

The NCP45560 load switch provides a component and

area-reducing solution for efficient power domain switching with

inrush current limit via soft−start. In addition to integrated control

functionality with ultra low on−resistance, this device offers system

safeguards and monitoring via fault protection and power good

signaling. This cost effective solution is ideal for power management

and hot-swap applications requiring low power consumption in a

small footprint.

Features

•

•

•

•

•

•

•

•

•

•

•

•

www.onsemi.com

RON TYP

VCC

VIN

4.1 mW

3.3 V

1.8 V

4.3 mW

3.3 V

5.0 V

4.9 mW

3.3 V

12 V

1

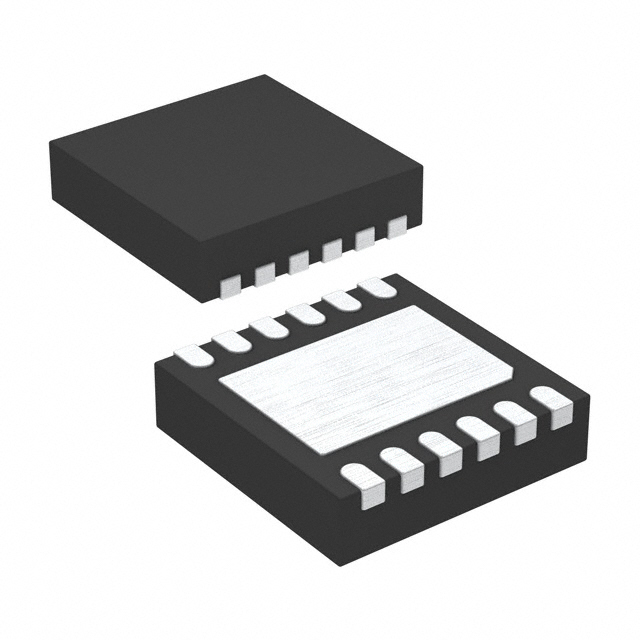

DFN12, 3x3

CASE 506CD

MARKING DIAGRAM

NCP45

560−x

ALYWG

G

x = H for NCP45560−H

= L for NCP45560−L

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

Portable Electronics and Systems

Notebook and Tablet Computers

Telecom, Networking, Medical, and Industrial Equipment

Set−Top Boxes, Servers, and Gateways

Hot−Swap Devices and Peripheral Ports

VCC

EN

17 A

*IMAX_DC is defined as the maximum steady state

current the load switch can pass at room ambient

temperature without entering thermal lockout.

Advanced Controller with Charge Pump

Integrated N-Channel MOSFET with Ultra Low RON

Input Voltage Range 0.5 V to 13.5 V

Soft-Start via Controlled Slew Rate

Adjustable Slew Rate Control

Power Good Signal

Thermal Shutdown

Undervoltage Lockout

Short-Circuit Protection

Extremely Low Standby Current

Load Bleed (Quick Discharge)

This is a Pb−Free Device

Typical Applications

•

•

•

•

•

IMAX_DC*

VIN

PG

PIN CONFIGURATION

Bandgap

&

Biases

Charge

Pump

Thermal,

Undervoltage

&

Short−Circuit

Protection

Control

Logic

Delay and

Slew Rate

Control

VIN

1

12

VOUT

EN

2

11

VOUT

VCC

3

10

VOUT

GND

4

9

VOUT

SR

5

8

VOUT

PG

6

7

BLEED

13: VIN

(Top View)

SR

GND

BLEED

VOUT

© Semiconductor Components Industries, LLC, 2015

May, 2020 − Rev. 7

ORDERING INFORMATION

See detailed ordering and shipping information on page 13 of

this data sheet.

Figure 1. Block Diagram

1

Publication Order Number:

NCP45560/D

�NCP45560

Table 1. PIN DESCRIPTION

Pin

Name

Function

1, 13

VIN

Drain of MOSFET (0.5 V – 13.5 V), Pin 1 must be connected to Pin 13

2

EN

NCP45560−H − Active−high digital input used to turn on the MOSFET, pin has an internal

pull down resistor to GND

NCP45560−L − Active−low digital input used to turn on the MOSFET, pin has an internal pull

up resistor to VCC

3

VCC

Supply voltage to controller (3.0 V − 5.5 V)

4

GND

Controller ground

5

SR

Slew rate adjustment; float if not used

6

PG

Active−high, open−drain output that indicates when the gate of the MOSFET is fully charged,

external pull up resistor ≥ 1 kW to an external voltage source required; tie to GND if not used.

7

BLEED

8−12

VOUT

Load bleed connection, must be tied to VOUT either directly or through a resistor

≤ 1 kW

Source of MOSFET connected to load

Table 2. ABSOLUTE MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Supply Voltage Range

VCC

−0.3 to 6

V

Input Voltage Range

VIN

−0.3 to 18

V

VOUT

−0.3 to 18

V

EN Digital Input Range

VEN

−0.3 to (VCC + 0.3)

V

PG Output Voltage Range (Note 1)

VPG

−0.3 to 6

V

Thermal Resistance, Junction−to−Ambient, Steady State (Note 2)

RθJA

28.6

°C/W

Thermal Resistance, Junction−to−Ambient, Steady State (Note 3)

RθJA

49.7

°C/W

Thermal Resistance, Junction−to−Case (VIN Paddle)

RθJC

1.7

°C/W

Continuous MOSFET Current @ TA = 25°C (Notes 3 and 4)

IMAX

17

A

Output Voltage Range

Continuous MOSFET Current @ TA = 25°C (Notes 2 and 4)

IMAX

18.3

A

Transient MOSFET Current (for up to 500 ms)

IMAX_TRANS

40

A

Total Power Dissipation @ TA = 25°C (Note 2)

Derate above TA = 25°C

PD

3.49

34.9

W

mW/°C

Total Power Dissipation @ TA = 25°C (Note 3)

Derate above TA = 25°C

PD

2.01

20.1

W

mW/°C

TSTG

−40 to 150

°C

Storage Temperature Range

Lead Temperature, Soldering (10 sec.)

TSLD

260

°C

ESD Capability, Human Body Model (Notes 5 and 6)

ESDHBM

3.0

kV

ESD Capability, Machine Model (Note 5)

ESDMM

200

V

ESD Capability, Charged Device Model (Note 5)

ESDCDM

1.0

kV

LU

100

mA

Latch−up Current Immunity (Notes 5 and 6)

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. PG is an open−drain output that requires an external pull up resistor ≥ 1 kW to an external voltage source.

2. Surface−mounted on FR4 board using 1 sq−in pad, 1 oz Cu.

3. Surface−mounted on FR4 board using the minimum recommended pad size, 1 oz Cu.

4. Ensure that the expected operating MOSFET current will not cause the Short−Circuit Protection to turn the MOSFET off undesirably.

5. Tested by the following methods @ TA = 25°C:

ESD Human Body Model tested per JESD22−A114

ESD Machine Model tested per JESD22−A115

ESD Charged Device Model per ESD STM5.3.1

Latch−up Current tested per JESD78

6. Rating is for all pins except for VIN and VOUT which are tied to the internal MOSFET’s Drain and Source. Typical MOSFET ESD performance

for VIN and VOUT should be expected and these devices should be treated as ESD sensitive.

www.onsemi.com

2

�NCP45560

Table 3. OPERATING RANGES

Rating

Symbol

Min

Max

Unit

Supply Voltage

VCC

3

5.5

V

Input Voltage

VIN

0.5

13.5

V

Ground

0

V

Ambient Temperature

GND

TA

−40

85

°C

Junction Temperature

TJ

−40

125

°C

ETRANS

0

210

mJ

OFF to ON Transition Energy Dissipation Limit (See application section)

Table 4. ELECTRICAL CHARACTERISTICS (TJ = 25°C unless otherwise specified)

Conditions (Note 7)

Parameter

Symbol

Min

Typ

Max

Unit

4.1

5.0

mW

4.3

5.3

MOSFET

On−Resistance

VCC = 3.3 V; VIN = 1.8 V

RON

VCC = 3.3 V; VIN = 5 V

VCC = 3.3 V; VIN = 12 V

Leakage Current (Note 8)

4.9

6.8

VEN = 0 V; VIN = 13.5 V

ILEAK

0.1

1.0

mA

VEN = 0 V; VCC = 3 V

ISTBY

0.65

2.0

mA

3.2

4.5

280

400

530

750

115

144

CONTROLLER

Supply Standby Current (Note 9)

VEN = 0 V; VCC = 5.5 V

Supply Dynamic Current (Note 10)

VEN = VCC = 3 V; VIN = 12 V

IDYN

VEN = VCC = 5.5 V; VIN = 1.8 V

Bleed Resistance

RBLEED

VEN = 0 V; VCC = 3 V

VEN = 0 V; VCC = 5.5 V

Bleed Pin Leakage Current

VEN = VCC = 3 V, VIN = 1.8 V

86

72

IBLEED

VEN = VCC = 3 V, VIN = 12 V

EN Input High Voltage

VCC = 3 V − 5.5 V

VIH

EN Input Low Voltage

VCC = 3 V − 5.5 V

VIL

EN Input Leakage Current

NCP45560−H; VEN = 0 V

IIL

NCP45560−L; VEN = VCC

IIH

97

121

6.0

10

60

70

2.0

mA

W

mA

V

0.8

V

90

500

nA

90

500

EN Pull Down Resistance

NCP45560−H

RPD

76

100

124

kW

EN Pull Up Resistance

NCP45560−L

RPU

76

100

124

kW

PG Output Low Voltage (Note 11)

VCC = 3 V; ISINK = 5 mA

VOL

0.2

V

PG Output Leakage Current (Note 12)

VCC = 3 V; VTERM = 3.3 V

IOH

5.0

100

nA

Slew Rate Control Constant (Note 13)

VCC = 3 V

KSR

33

40

mA

Thermal Shutdown Threshold (Note 14)

VCC = 3 V − 5.5 V

TSDT

Thermal Shutdown Hysteresis (Note 14)

VCC = 3 V − 5.5 V

THYS

VIN Undervoltage Lockout Threshold

VCC = 3 V

VUVLO

VIN Undervoltage Lockout Hysteresis

VCC = 3 V

VHYS

25

Short−Circuit Protection Threshold

VCC = 3 V; VIN = 0.5 V

VSC

200

100

285

500

26

FAULT PROTECTIONS

VCC = 3 V; VIN = 13.5 V

145

°C

20

0.25

0.35

°C

0.45

V

40

60

mV

265

350

mV

7. VEN shown only for NCP45560−H, (EN Active−High) unless otherwise specified.

8. Average current from VIN to VOUT with MOSFET turned off.

9. Average current from VCC to GND with MOSFET turned off.

10. Average current from VCC to GND after charge up time of MOSFET.

11. PG is an open-drain output that is pulled low when the MOSFET is disabled.

12. PG is an open-drain output that is not driven when the gate of the MOSFET is fully charged, requires an external pull up resistor ≥ 1 kW to

an external voltage source, VTERM.

13. See Applications Information section for details on how to adjust the slew rate.

14. Operation above TJ = 125°C is not guaranteed.

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

www.onsemi.com

3

�NCP45560

Table 5. SWITCHING CHARACTERISTICS (TJ = 25°C unless otherwise specified) (Notes 15 and 16)

Parameter

Conditions

Output Slew Rate

Symbol

SR

VCC = 3.3 V; VIN = 1.8 V

Output Turn−on Delay

Min

12.4

VCC = 5.0 V; VIN = 1.8 V

12.6

VCC = 3.3 V; VIN = 12 V

13.7

VCC = 5.0 V; VIN = 12 V

14.0

TON

VCC = 3.3 V; VIN = 1.8 V

195

VCC = 5.0 V; VIN = 1.8 V

180

VCC = 3.3 V; VIN = 12 V

280

VCC = 5.0 V; VIN = 12 V

Output Turn−off Delay

4.1

VCC = 5.0 V; VIN = 1.8 V

3.5

VCC = 3.3 V; VIN = 12 V

1.4

VCC = 5.0 V; VIN = 12 V

0.8

TPG,ON

VCC = 3.3 V; VIN = 1.8 V

Power Good Turn−off Time

1.71

VCC = 5.0 V; VIN = 1.8 V

1.08

VCC = 3.3 V; VIN = 12 V

2.15

VCC = 5.0 V; VIN = 12 V

1.35

TPG,OFF

VCC = 3.3 V; VIN = 1.8 V

28

VCC = 5.0 V; VIN = 1.8 V

21

VCC = 3.3 V; VIN = 12 V

28

VCC = 5.0 V; VIN = 12 V

21

15. See below figure for Test Circuit and Timing Diagram.

16. Tested with the following conditions: VTERM = VCC; RPG = 100 kW; RL = 10 W; CL = 0.1 mF.

OFF ON

RPG

EN

VIN

VCC

NCP45560−H

BLEED

Dt

CL

TOFF

10%

DV

SR =

TPG,ON

VPG

RL

SR

50%

90%

VOUT

VOUT

50%

TON

VTERM

PG

GND

VEN

Max

Unit

kV/s

ms

265

TOFF

VCC = 3.3 V; VIN = 1.8 V

Power Good Turn−on Time

Typ

DV

90%

Dt

TPG,OFF

50%

50%

Figure 2. Switching Characteristics Test Circuit and Timing Diagrams

www.onsemi.com

4

ms

ms

ns

�NCP45560

TYPICAL CHARACTERISTICS

(TJ = 25°C unless otherwise specified)

7.5

5.3

5.1

4.9

4.7

4.5

4.3

4.1

3.9

0.5

2.5

4.5

6.5

8.5

10.5

5.0

VIN = 1.8 V

4.5

4.0

3.5

0

15

30

45

60

75

90 105 120

VIN, INPUT VOLTAGE (V)

TJ, JUNCTION TEMPERATURE (°C)

Figure 3. On−Resistance vs. Input Voltage

Figure 4. On−Resistance vs. Temperature

2.5

2.0

1.5

1.0

3.5

4.0

4.5

5.0

5.5

7

6

5

4

VCC = 5.5 V

3

2

1

VCC = 3 V

0

−45 −30 −15

0

15

30

45

60

75

90 105 120

VCC, SUPPLY VOLTAGE (V)

TJ, JUNCTION TEMPERATURE (°C)

Figure 5. Supply Standby Current vs. Supply

Voltage

Figure 6. Supply Standby Current vs.

Temperature

550

500

450

400

350

300

VCC = 5.5 V

250

VCC = 3 V

200

150

VIN = 5.0 V

5.5

3.0

−45 −30 −15

3.0

3.0

6.0

12.5

3.5

0.5

VIN = 12 V

VCC = 3.3 V

6.5

ISTBY, SUPPLY STANDBY CURRENT (mA)

3.7

3.5

7.0

RON, ON−RESISTANCE (mW)

VCC = 3 V

VCC = 5.5 V

IDYN, SUPPLY DYNAMIC CURRENT (mA)

IDYN, SUPPLY DYNAMIC CURRENT (mA)

ISTBY, SUPPLY STANDBY CURRENT (mA)

RON, ON−RESISTANCE (mW)

5.5

0.5

2.5

4.5

6.5

8.5

10.5

12.5

600

550

500

VIN = 1.8 V

450

400

350

300

VIN = 12 V

250

200

150

3.0

3.5

4.0

4.5

5.0

5.5

VIN, INPUT VOLTAGE (V)

VCC, SUPPLY VOLTAGE (V)

Figure 7. Supply Dynamic Current vs. Input

Voltage

Figure 8. Supply Dynamic Current vs. Supply

Voltage

www.onsemi.com

5

�NCP45560

TYPICAL CHARACTERISTICS

115

700

600

550

500

450

400

350

300

250

200

−45

VCC = 3.0 V, VIN = 12 V

−15

15

45

75

110

105

100

95

105

3.0

3.5

4.0

4.5

5.0

5.5

TJ, JUNCTION TEMPERATURE (°C)

VCC, SUPPLY VOLTAGE (V)

Figure 9. Supply Dynamic Current vs.

Temperature

Figure 10. Bleed Resistance vs. Supply

Voltage

70

135

60

IBLEED, BLEED PIN LEAKAGE

CURRENT (mA)

145

VCC = 3 V

125

115

VCC = 5.5 V

105

95

85

−45

IBLEED, BLEED PIN LEAKAGE CURRENT (mA)

RBLEED, BLEED RESISTANCE (W)

VCC = 5.5 V, VIN = 1.8 V

650

−15

15

45

75

VCC = 3 V

50

VCC = 5.5 V

40

30

20

10

0

105

0.5

2.5

4.5

6.5

8.5

10.5

12.5

TJ, JUNCTION TEMPERATURE (°C)

VIN, INPUT VOLTAGE (V)

Figure 11. Bleed Resistance vs. Temperature

Figure 12. Bleed Pin Leakage Current vs. Input

Voltage

IPD/PU, EN PULL DOWN/UP RESISTANCE (kW)

RBLEED, BLEED RESISTANCE (W)

IDYN, SUPPLY DYNAMIC CURRENT (mA)

(TJ = 25°C unless otherwise specified)

80

70

VCC = 3 V, VIN = 12 V

60

50

40

30

20

VCC = 3 V, VIN = 1.8 V

10

0

−45

−15

15

45

75

105

120

115

110

105

100

95

90

85

−45

−15

15

45

75

105

TJ, JUNCTION TEMPERATURE (°C)

TJ, JUNCTION TEMPERATURE (°C)

Figure 13. Bleed Pin Leakage Current vs.

Temperature

Figure 14. EN Pull Down/Up Resistance vs.

Temperature

www.onsemi.com

6

�NCP45560

TYPICAL CHARACTERISTICS

VOL, PG OUTPUT LOW VOLTAGE (V)

0.140

ISINK = 5 mA

0.135

0.130

0.125

0.120

0.115

3.5

4.0

4.5

5.0

5.5

VCC = 3 V

0.16

0.14

VCC = 5.5 V

0.12

0.10

0.08

−45

−15

15

45

75

105

Figure 15. PG Output Low Voltage vs. Supply

Voltage

Figure 16. PG Output Low Voltage vs.

Temperature

36

VCC = 5.5 V

35

34

VCC = 3 V

33

32

31

30

29

0.5

2.5

4.5

6.5

8.5

10.5

12.5

35.5

35.0

VCC = 5.5 V

34.5

34.0

33.5

VCC = 3 V

33.0

32.5

32.0

−45

−15

15

45

75

105

VIN, INPUT VOLTAGE (V)

TJ, JUNCTION TEMPERATURE (°C)

Figure 17. Slew Rate Control Constant vs.

Input Voltage

Figure 18. Slew Rate Control Constant vs.

Temperature

14.5

320

310

VCC = 5.5 V

300

290

VCC = 3 V

280

270

260

250

ISINK = 5 mA

0.18

TJ, JUNCTION TEMPERATURE (°C)

37

28

0.20

VCC, SUPPLY VOLTAGE (V)

SR, OUTPUT SLEW RATE (kV/s)

VSC, SHORT−CIRCUIT PROTECTION

THRESHOLD (mV)

3.0

KSR, SLEW RATE CONTROL CONSTANT (mA)

0.110

KSR, SLEW RATE CONTROL CONSTANT (mA)

VOL, PG OUTPUT LOW VOLTAGE (V)

(TJ = 25°C unless otherwise specified)

0.5

2.5

4.5

6.5

8.5

10.5

12.5

VCC = 5.5 V

14.0

13.5

VCC = 3 V

13.0

12.5

12.0

11.5

11.0

10.5

10.0

9.5

0.5

2.5

4.5

6.5

8.5

10.5

12.5

VIN, INPUT VOLTAGE (V)

VIN, INPUT VOLTAGE (V)

Figure 19. Short−Circuit Protection Threshold

vs. Input Voltage

Figure 20. Output Slew Rate vs. Input Voltage

www.onsemi.com

7

�NCP45560

TYPICAL CHARACTERISTICS

VCC = 3.3 V, VIN = 12 V

13.5

13.0

12.5

VCC = 5 V, VIN = 1.8 V

12.0

TOFF, OUTPUT TURN−OFF DELAY (ms)

−20

0

20

40

60

80

100

120

310

290

VCC = 3 V

270

250

VCC = 5.5 V

230

210

190

170

150

0.5

2.5

4.5

6.5

8.5

10.5

12.5

TJ, JUNCTION TEMPERATURE (°C)

VIN, INPUT VOLTAGE (V)

Figure 21. Output Slew Rate vs. Temperature

Figure 22. Output Turn−on Delay vs. Input

Voltage

300

TOFF, OUTPUT TURN−OFF DELAY (ms)

TON, OUTPUT TURN−ON DELAY (ms)

11.5

−40

VCC = 3.3 V, VIN = 12 V

275

250

225

200

VCC = 5 V, VIN = 1.8 V

175

150

−40

−20

0

20

40

60

80

100

120

6

5

4

VCC = 3 V

3

2

VCC = 5.5 V

1

0

0.5

2.5

4.5

6.5

8.5

10.5

12.5

VIN, INPUT VOLTAGE (V)

Figure 23. Output Turn−on Delay vs.

Temperature

Figure 24. Output Turn−off Delay vs. Input

Voltage

4.5

4.0

4.0

VCC = 5 V, VIN = 1.8 V

3.5

3.0

2.5

2.0

VCC = 3.3 V, VIN = 12 V

1.5

1.0

−40

7

TJ, JUNCTION TEMPERATURE (°C)

TPG,ON, PG TURN−ON TIME (ms)

SR, OUTPUT SLEW RATE (kV/s)

14.0

TON, OUTPUT TURN−ON DELAY (ms)

(TJ = 25°C unless otherwise specified)

−20

0

20

40

60

80

100

3.5

3.0

2.5

2.0

1.5

VCC = 5.5 V

1.0

0.5

120

VCC = 3 V

0.5

2.5

4.5

6.5

8.5

10.5

12.5

TJ, JUNCTION TEMPERATURE (°C)

VIN, INPUT VOLTAGE (V)

Figure 25. Output Turn−off Delay vs.

Temperature

Figure 26. Power Good Turn−on Time vs. Input

Voltage

www.onsemi.com

8

�NCP45560

TYPICAL CHARACTERISTICS

(TJ = 25°C unless otherwise specified)

TPG,OFF, PG TURN−OFF TIME (ns)

32

2.6

2.4

VCC = 3.3 V, VIN = 12 V

2.2

2.0

1.8

1.6

1.4

1.2

VCC = 5 V, VIN = 1.8 V

1.0

0.8

−40

−20

0

20

40

60

80

VIN = 13.5 V

28

26

VIN = 0.5 V

24

22

20

18

120

100

30

3.0

3.5

4.0

4.5

5.0

TJ, JUNCTION TEMPERATURE (°C)

VCC, SUPPLY VOLTAGE (V)

Figure 27. Power Good Turn−on Time vs.

Temperature

Figure 28. Power Good Turn−off Time vs.

Supply Voltage

35.0

TPG,OFF, PG TURN−OFF TIME (ns)

TPG,ON, PG TURN−ON TIME (ms)

2.8

32.5

VCC = 3.3 V, VIN = 12 V

30.0

27.5

25.0

VCC = 5 V, VIN = 1.8 V

22.5

20.0

17.5

−40 −20

0

20

40

60

80

100

TJ, JUNCTION TEMPERATURE (°C)

Figure 29. Power Good Turn−off Time vs.

Temperature

www.onsemi.com

9

120

5.5

�NCP45560

APPLICATIONS INFORMATION

Enable Control

than or equal to 1 kW to an external voltage source, VTERM,

compatible with input levels of other devices connected to

this pin (as shown in Figures 30 and 31).

The power good output can be used as the enable signal for

other active−high devices in the system (as shown in

Figure 32). This allows for guaranteed by design power

sequencing and reduces the number of enable signals needed

from the system controller. If the power good feature is not

used in the application, the PG pin should be tied to GND.

The NCP45560 has two part numbers, NCP45560−H and

NCP45560−L, that only differ in the polarity of the enable

control.

The NCP45560−H device allows for enabling the

MOSFET in an active−high configuration. When the VCC

supply pin has an adequate voltage applied and the EN pin

is at a logic high level, the MOSFET will be enabled.

Similarly, when the EN pin is at a logic low level, the

MOSFET will be disabled. An internal pull down resistor to

ground on the EN pin ensures that the MOSFET will be

disabled when not being driven.

The NCP45560−L device allows for enabling the

MOSFET in an active−low configuration. When the VCC

supply pin has an adequate voltage applied and the EN pin

is at a logic low level, the MOSFET will be enabled.

Similarly, when the EN pin is at a logic high level, the

MOSFET will be disabled. An internal pull up resistor to

VCC on the EN pin ensures that the MOSFET will be

disabled when not being driven.

Slew Rate Control

The NCP45560 devices are equipped with controlled

output slew rate which provides soft start functionality. This

limits the inrush current caused by capacitor charging and

enables these devices to be used in hot swap applications.

The slew rate can be decreased with an external capacitor

added between the SR pin and ground (as shown in

Figures 30 and 31). With an external capacitor present, the

slew rate can be determined by the following equation:

Slew Rate +

Power Sequencing

K SR

[Vńs]

C SR

(eq. 1)

The NCP45560 devices will function with any power

sequence, but the output turn−on delay performance may

vary from what is specified. To achieve the specified

performance, there are two recommended power sequences:

1. VCC → VIN → VEN

2. VIN → VCC → VEN

VCC must be at 2 V or higher when EN is asserted to ensure

that the enable is latched properly for correct operation. If

EN comes up before VCC reaches 2 V, then the EN may not

take effect.

where KSR is the specified slew rate control constant, found

in Table 4, and CSR is the slew rate control capacitor added

between the SR pin and ground. The slew rate of the device

will always be the lower of the default slew rate and the

adjusted slew rate. Therefore, if the CSR is not large enough

to decrease the slew rate more than the specified default

value, the slew rate of the device will be the default value.

The SR pin can be left floating if the slew rate does not need

to be decreased.

Load Bleed (Quick Discharge)

The NCP45560 devices are equipped with short−circuit

protection that is used to help protect the part and the system

from a sudden high−current event, such as the output, VOUT,

being shorted to ground. This circuitry is only active when

the gate of the MOSFET is fully charged.

Once active, the circuitry monitors the difference in the

voltage on the VIN pin and the voltage on the BLEED pin.

In order for the VOUT voltage to be monitored through the

BLEED pin, it is required that the BLEED pin be connected

to VOUT either directly (as shown in Figure 31) or through

a resistor, REXT (as shown in Figure 30), which should not

exceed 1 kW. With the BLEED pin connected to VOUT, the

short−circuit protection is able to monitor the voltage drop

across the MOSFET.

If the voltage drop across the MOSFET is greater than or

equal to the short−circuit protection threshold voltage, the

MOSFET is immediately turned off and the load bleed is

activated. The part remains latched in this off state until EN

is toggled or VCC supply voltage is cycled, at which point the

MOSFET will be turned on in a controlled fashion with the

normal output turn−on delay and slew rate. The current

through the MOSFET that will cause a short−circuit event

Short−Circuit Protection

The NCP45560 devices have an internal bleed resistor,

RBLEED, which is used to bleed the charge off of the load to

ground after the MOSFET has been disabled. In series with

the bleed resistor is a bleed switch that is enabled whenever

the MOSFET is disabled. The MOSFET and the bleed

switch are never concurrently active.

It is required that the BLEED pin be connected to VOUT

either directly (as shown in Figure 31) or through an external

resistor, REXT (as shown in Figure 30). REXT should not

exceed 1 kW and can be used to increase the total bleed

resistance.

Care must be taken to ensure that the power dissipated

across RBLEED is kept at a safe level. The maximum

continuous power that can be dissipated across RBLEED is

0.4 W. REXT can be used to decrease the amount of power

dissipated across RBLEED.

Power Good

The NCP45560 devices have a power good output (PG)

that can be used to indicate when the gate of the MOSFET

is fully charged. The PG pin is an active−high, open−drain

output that requires an external pull up resistor, RPG, greater

www.onsemi.com

10

�NCP45560

to the low RON. When the EN signal is asserted high, the load

switch transitions from an OFF state to an ON state. During

this time, the resistance from VIN to VOUT transitions from

high impedance to RON, and additional energy is dissipated

in the device for a short period of time. The worst case

energy dissipated during the OFF to ON transition can be

approximated by the following equation:

can be calculated by dividing the short−circuit protection

threshold by the expected on−resistance of the MOSFET.

Thermal Shutdown

The thermal shutdown of the NCP45560 devices protects

the part from internally or externally generated excessive

temperatures. This circuitry is disabled when EN is not

active to reduce standby current. When an over−temperature

condition is detected, the MOSFET is immediately turned

off and the load bleed is activated.

The part comes out of thermal shutdown when the

junction temperature decreases to a safe operating

temperature as dictated by the thermal hysteresis. Upon

exiting a thermal shutdown state, and if EN remains active,

the MOSFET will be turned on in a controlled fashion with

the normal output turn−on delay and slew rate.

E + 0.5 @ V IN @ ǒI INRUSH ) 0.8 @ I LOADǓ @ dt

Where VIN is the voltage on the VIN pin, IINRUSH is the

inrush current caused by capacitive loading on VOUT, and dt

is the time it takes VOUT to rise from 0 V to VIN. IINRUSH can

be calculated using the following equation:

I INRUSH + dv @ C L

dt

The undervoltage lockout of the NCP45560 devices turns

the MOSFET off and activates the load bleed when the input

voltage, VIN, is less than or equal to the undervoltage

lockout threshold. This circuitry is disabled when EN is not

active to reduce standby current.

If the VIN voltage rises above the undervoltage lockout

threshold, and EN remains active, the MOSFET will be

turned on in a controlled fashion with the normal output

turn−on delay and slew rate.

ecoSWITCH LAYOUT GUIDELINES

Electrical Layout Considerations

Correct physical PCB layout is important for proper low

noise accurate operation of all ecoSWITCH products.

Power Planes: The ecoSWITCH is optimized for extremely

low Ron resistance, however, improper PCB layout can

substantially increase source to load series resistance by

adding PCB board parasitic resistance. Solid connections to

the VIN and VOUT pins of the ecoSWITCH to copper

planes should be used to achieve low series resistance and

good thermal dissipation. The ecoSWITCH requires ample

heat dissipation for correct thermal lockout operation. The

internal FET dissipates load condition dependent amounts

of power in the milliseconds following the rising edge of

enable, and providing good thermal conduction from the

packaging to the board is critical. Direct coupling of VIN to

VOUT should be avoided, as this will adversely affect slew

rates.

Capacitive Load

The peak in−rush current associated with the initial

charging of the application load capacitance needs to stay

below the specified IMAX. CL (capacitive load) should be

less than Cmax as defined by the following equation:

I max

SR typ

(eq. 4)

Where dv/dt is the programmed slew rate, and CL is the

capacitive loading on VOUT. To prevent thermal lockout or

damage to the device, the energy dissipated during the OFF

to ON transition should be limited to ETRANS listed in

operating ranges table.

Undervoltage Lockout

C max +

(eq. 3)

(eq. 2)

Where IMAX is the maximum load current, and SRtyp is the

typical default slew rate when no external load capacitor is

added to the SR pin.

OFF to ON Transition Energy Dissipation

The energy dissipation due to load current traveling from

VIN to VOUT is very low during steady state operation due

www.onsemi.com

11

�NCP45560

VTERM = 3.3 V

Power Supply

or Battery

RPG

100 kW

3.0 V − 5.5 V

0.5 V − 13.5 V

VIN

PG

EN

Thermal,

Undervoltage

&

Short−Circuit

Protection

Charge

Pump

Delay and

Slew Rate

Control

SR

CSR

VOUT

Control

Logic

GND

Bandgap

&

Biases

BLEED

VCC

Controller

REXT

Load

Figure 30. Typical Application Diagram − Load Switch

www.onsemi.com

12

�NCP45560

VCC

3.0 V − 5.5 V

EN

VTERM

PG

GND

VIN

0.5 V − 13.5 V

RPG

BACKPLANE

VIN

PG

EN

Delay and

Slew Rate

Control

CSR

VOUT

Charge

Pump

SR

Control

Logic

GND

Thermal,

Undervoltage

&

Short−Circuit

Protection

Bandgap

&

Biases

BLEED

VCC

REMOVABLE

CARD

Load

Figure 31. Typical Application Diagram − Hot Swap

VTERM = 3.3 V

EN

PG

EN

PG

RPG

10 kW

Controller

RPD

100 kW PG

RPD

100 kW PG

NCP45560−H

NCP45560−H

Figure 32. Simplified Application Diagram − Power Sequencing with PG Output

ORDERING INFORMATION

Device

EN Polarity

Package

Shipping†

NCP45560IMNTWG−H

Active−High

NCP45560IMNTWG−L

Active−Low

DFN12

(Pb−Free)

3000 / Tape & Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

ecoSWITCH is a trademark of Semiconductor Components Industries, LLC (SCILLC).

www.onsemi.com

13

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

DFN12 3x3, 0.5P

CASE 506CD

ISSUE A

DATE 18 FEB 2014

1

SCALE 4:1

PIN ONE

INDICATOR

0.10 C

2X

2X

0.10 C

L1

ÇÇÇ

ÇÇÇ

ÇÇÇ

DETAIL A

ALTERNATE

CONSTRUCTIONS

E

MOLD CMPD

A3

DETAIL B

A1

A

0.05 C

NOTE 4

SIDE VIEW

D2

6

1

DETAIL B

A3

ALTERNATE

CONSTRUCTION

A1

SEATING

PLANE

C

0.10

DETAIL A

ÇÇÇ

ÇÇÇ

ÉÉÉ

DIM

A

A1

A3

b

D

D2

E

E2

e

L

L1

L2

K

EXPOSED Cu

TOP VIEW

0.05 C

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ASME Y14.5M, 1994.

2. CONTROLLING DIMENSION: MILLIMETERS.

3. DIMENSION b APPLIES TO PLATED

TERMINAL AND IS MEASURED BETWEEN

0.15 AND 0.30 MM FROM TERMINAL TIP.

4. COPLANARITY APPLIES TO THE EXPOSED

PAD AS WELL AS THE TERMINALS.

L

L

A B

D

M

GENERIC

MARKING DIAGRAM*

C A B

L

12X

0.10

M

XXXXX

XXXXX

ALYWG

G

C A B

L2

E2

K

7

12

e

e/2

BOTTOM VIEW

12X

b

0.10

M

C A-B B

0.05

M

C

NOTE 3

A

L

Y

W

G

= Assembly Location

= Wafer Lot

= Year

= Work Week

= Pb−Free Package

(Note: Microdot may be in either location)

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “ G”,

may or may not be present.

RECOMMENDED

SOLDERING FOOTPRINT*

2.86

MILLIMETERS

MIN

MAX

0.80

1.00

0.00

0.05

0.20 REF

0.20

0.30

3.00 BSC

2.60

2.80

3.00 BSC

1.90

2.10

0.50 BSC

0.20

0.40

−−−

0.15

0.10 REF

0.15 MIN

11X

0.32

12X

0.48

2.10

PACKAGE

OUTLINE

3.30

1

0.50

PITCH

0.45

DIMENSIONS: MILLIMETERS

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

98AON67174E

DFN12 3X3, 0.5P

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

ON Semiconductor and

are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor reserves the right to make changes without further notice to any products herein. ON Semiconductor makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability arising out of the application or use of any product or circuit, and specifically

disclaims any and all liability, including without limitation special, consequential or incidental damages. ON Semiconductor does not convey any license under its patent rights nor the

rights of others.

© Semiconductor Components Industries, LLC, 2019

www.onsemi.com

�onsemi,

, and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates

and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property.

A listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi reserves the right to make changes at any time to any

products or information herein, without notice. The information herein is provided “as−is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the

information, product features, availability, functionality, or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use

of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products

and applications using onsemi products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information

provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/or specifications can and do vary in different applications and actual performance may

vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. onsemi does not convey any license

under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized for use as a critical component in life support systems

or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should

Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

onsemi Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�