NCS36000GEVB

NCS36000 PIR Sensor

Evaluation Board

User's Manual

General

The Passive InfraRed (PIR) sensor evaluation board is designed to

evaluate the NCS36000, a fully integrated mixed-signal CMOS device

designed for low-cost passive infrared controlling applications. This

device integrates two low-noise amplifiers and a LDO regulator to

drive the sensor. The output of the amplifiers goes to a window

comparator that uses internal voltage references from the regulator.

The detection logic processes the output from the window comparator

and provides the output to the ‘OUT’ pin. A blinking LED indicates

startup and depending on the status of the ‘LED_EN’ pin the LED also

lights up when a valid movement is detected.

The EVB can be powered from a micro-USB cable connected to

a host-USB interface (e.g. pc). Alternatively an external power source

ranging from 4–9 V can be connected to pins ‘GND’ and ‘+’ of the 3

pins header ‘H1’.

www.onsemi.com

EVAL BOARD USER’S MANUAL

General Usage

Power the evaluation board by plugging a micro-USB cable in

connector USB1 or by connecting an external power source with

a voltage ranging 4–9 V DC between ‘GND’ and ‘+’ terminal of pin

header H1.

After power up, the LED1 starts blinking. This lasts about

30 seconds depending on the ‘TIMER’ setting. When LED1 stops

blinking, the evaluation board is ready for normal operation.

There are two potentiometers on the board. One is labeled

‘SENSITIVITY’ which controls the gain of the band-pass filter. For

more information, see the ‘Filter characteristics’ section. The other

potentiometer is labeled ‘TIMER’ and controls the system oscillator

frequency. Its setting affects the logic subsystems that determine if

a movement is detected or not. For more information see the ‘Timing

characteristics’ section.

Wave your hand above the Fresnel lens. This motion is detected

when LED1 turns on. Simultaneously the logic level on the ‘OUT’ pin

of pin header ‘H1’ is high. ‘OUT’ is the output of the digital signal

processing block. It is possible to monitor the input of the window

comparator by probing the ‘OP2_O’ test pin ‘TP2’.

The total current consumption of the application can easily be

measured by removing the 0 W jumper marked ‘CURR’ and putting an

Amp meter in series.

Jumpers JP3 (MODE) and JP5 (LED Enable) has following

function:

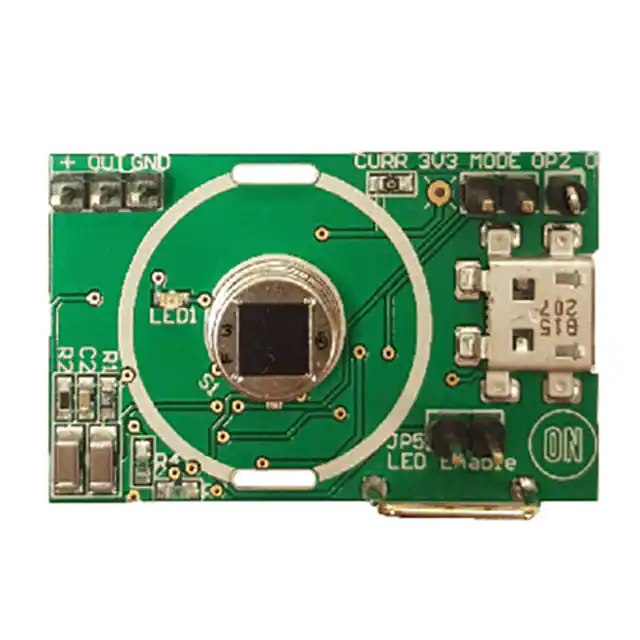

Figure 1. Top View of Evaluation Board

Figure 2. Bottom View of Evaluation Board

Table 1. JUMPER SETTING

Jumper

State

MODE

Open

Dual Pulse Mode

Function

MODE

Close

Single Pulse Mode

LED EN

Open

LED will Not Toggle*

LED EN

Close

LED Toggles after Motion Detected

* During start-up LED1 will blink for about 30 s. After this initialization period the

LED is disabled.

© Semiconductor Components Industries, LLC, 2015

July, 2015 − Rev. 0

1

Publication Order Number:

EVBUM2304/D

�NCS36000GEVB

H1

+

TP1

D1

U1

GND

VIN

1

OUT

5

USB1

BAV170

VBUS

C9

4,7 � F

D−

ON /

OFF

3

NR/FB

4

2

GND

3V3

CURR

MC78PC33

C10

GND_bar

C11

100 nF

R8

4,7 � F

3V3

D+

ID

GND

R7

3V3

NC

VDD

14

VREF

C6

IRA−E900

1

LDO & VREF

9

LED

12

MODE

10

XLED_EN

JP 5

JP 3

OP 1_P 5

R5

C5

3

8

WINDOW

COMPARATOR

100 nF

2

S1

6

OUT

11

DIGITAL

CONTROL

U2

680 E

LED1

OP 1_N

7

3

43 k

100 nF

VSS

OP 1_O

C2

C3

560 k

10 k

2

OP 2_N

33 � F

R1

R3

P1

10 k

OP 2_O

R7

P2 500 k

47 k

C7

20 k

100 nF

SENSITIVITY

TP2

C1

MODE

3V3

OSC

10 nF

R4

1M

LED_EN

13

1

C4

10 nF

R2

33 � F

OSC

NCS36000

4

TIMER

PC 20 150116.1

Figure 3. Schematic Diagram

Filter Characteristics

The table shows the gain and the cut-off frequencies for

different values of P1 + R4 combination, where P1is the

‘SENSITIVITY’ potentiometer.

The band-pass filter is built around 2 low noise

operational amplifiers as illustrated in Figure 3. The gain is

determined by:

G[dB] + 20 @ log

Example:

G[dB] + 20 @ log

NJƪ

1)

NJƪ

R2

R1

ƫ ƪ

@ 1)

ƫ ƪ

P1 ) R4

R3

560k

800k

1)

@ 1)

10k

10k

ƫNj

ƫNj

Table 2. GAIN SETTING

(eq. 1)

(eq. 2)

G[dB] + 73.3 dB

The lower cut-off frequency is mainly determined by

poles formed by R1 − C1 and R3 − C3. The higher cut-off

frequency is dominated by the pole formed by (P1 + R4) –

C4.

P1 + R4

Gain

f−3dB Lo

f−3dB Hi

300 kW

64.4 dB

0.72 Hz

24.3 Hz

500 kW

68.8 dB

0.71 Hz

20.4 Hz

700 kW

71.7 dB

0.71 Hz

16.7 Hz

800 kW

72.8 dB

0.70 Hz

16.0 Hz

900 kW

73.8 dB

0.70 Hz

14.8 Hz

1,1 MW

75.5 dB

0.69 Hz

13.1 Hz

1,3 MW

76.9 dB

0.69 Hz

11.7 Hz

In Figure 4 gain versus frequency is plotted for different

potentiometer settings.

www.onsemi.com

2

�NCS36000GEVB

80

Band-Pass Filter (dB)

75

70

65

60

55

50

45

40

35

100m 200m 400m

1

2

4

10

20

40

100

Frequency (Hz)

Figure 4. Gain of the Band-Pass Filter vs. Frequency; RVAR = P1 + R4

Timing Characteristics

window comparator input exceeds VH (positive threshold)

or VL (negative threshold) AND the pulse duration TSP is at

least 3 clock periods:

Potentiometer P2, marked ‘TIMER’ sets the oscillator

frequency, which is the clock of the detection system.

Changing the frequency influences the reaction time and the

sensitivity of the system.

In single pulse mode (Jumper JP3 “MODE” closed) a

signal from the sensor is detected when the amplitude at the

T SP u 3 @ T CLK

(eq. 3)

This will trigger a mono-flop and ‘OUT’ will be toggled

high for 120 clock periods.

Figure 5. Single Pulse Detection

In dual pulse mode (Jumper JP3 “MODE” removed), 2

consecutive pulses will trigger the mono-flop when the

interval TDP between these 2 consecutive pulses is less than

360 clock cycles:

T DP t 360 @ T CLK

T CLK + ǒP 2 ) R 7Ǔ @ C 7 @ 0.727

(eq. 5)

A good choice for most applications is a clock period

TCLK = 16 ms, equivalent to an oscillator frequency,

fCLK = 62.5 Hz. From equation 5 this corresponds with

P2 + R7 = 220 kW and C7 = 100 nF. By using equations 3

and 4 this results in TSP = 48 ms and TDP = 5,76 s.

(eq. 4)

The oscillator clock period depends on P2 + R7 and C7 and

can be calculated as:

www.onsemi.com

3

�NCS36000GEVB

Figure 6. Dual Pulse Detection

Interfacing Microcontroller

The easiest way to connect a MCU development PCB to

the PIR sensor evaluation board is by using pin header H1.

Power and ground connections can be shared and the logic

levels are 3,3 V compliant. By connecting “OUT” to

a general purpose I/O of the microcontroller the sensor

output can be easily monitored.

It is possible to control the evaluation board more

advanced, but this requires some additional wiring. Some

suggestions are illustrated in Figure 7 described in the next

paragraphs.

Figure 7. Schematic Diagram

The sensitivity is set by the gain of low noise amplifier 2.

See Table 2. In series of R3 a digital potentiometer can be

placed controlled by the microcontroller. P1 is removed and

R4 is set to 300 kW. See Figure 7 where a CAT5119 in the

10 k version is used needing only 2 control lines. Increasing

the gain will extend the detection range.

Motion detection is influenced by the mode of operation.

In single pulse mode the output toggles for every pulse

received under the condition the amplitude and duration are

high enough. In dual pulse mode 2 consecutive pulses need

to be detected. This avoids false detections. By connecting

the MODE input (JP3) directly to an I/O of the

microcontroller this selection can be made in software.

www.onsemi.com

4

�NCS36000GEVB

Test-point TP2 is the output of the second low noise

amplifier. It is possible to bypass the integrated Detection

Logic of NCS36000 by connecting TP2 to an ADC of an

external microcontroller. This allows the user to build

a customized detection algorithm in software.

www.onsemi.com

5

�onsemi,

, and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates

and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A

listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

The evaluation board/kit (research and development board/kit) (hereinafter the “board”) is not a finished product and is not available for sale to consumers. The board is only intended

for research, development, demonstration and evaluation purposes and will only be used in laboratory/development areas by persons with an engineering/technical training and familiar

with the risks associated with handling electrical/mechanical components, systems and subsystems. This person assumes full responsibility/liability for proper and safe handling. Any

other use, resale or redistribution for any other purpose is strictly prohibited.

THE BOARD IS PROVIDED BY ONSEMI TO YOU “AS IS” AND WITHOUT ANY REPRESENTATIONS OR WARRANTIES WHATSOEVER. WITHOUT LIMITING THE FOREGOING,

ONSEMI (AND ITS LICENSORS/SUPPLIERS) HEREBY DISCLAIMS ANY AND ALL REPRESENTATIONS AND WARRANTIES IN RELATION TO THE BOARD, ANY

MODIFICATIONS, OR THIS AGREEMENT, WHETHER EXPRESS, IMPLIED, STATUTORY OR OTHERWISE, INCLUDING WITHOUT LIMITATION ANY AND ALL

REPRESENTATIONS AND WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE, NON−INFRINGEMENT, AND THOSE ARISING FROM A

COURSE OF DEALING, TRADE USAGE, TRADE CUSTOM OR TRADE PRACTICE.

onsemi reserves the right to make changes without further notice to any board.

You are responsible for determining whether the board will be suitable for your intended use or application or will achieve your intended results. Prior to using or distributing any systems

that have been evaluated, designed or tested using the board, you agree to test and validate your design to confirm the functionality for your application. Any technical, applications or

design information or advice, quality characterization, reliability data or other services provided by onsemi shall not constitute any representation or warranty by onsemi, and no additional

obligations or liabilities shall arise from onsemi having provided such information or services.

onsemi products including the boards are not designed, intended, or authorized for use in life support systems, or any FDA Class 3 medical devices or medical devices with a similar

or equivalent classification in a foreign jurisdiction, or any devices intended for implantation in the human body. You agree to indemnify, defend and hold harmless onsemi, its directors,

officers, employees, representatives, agents, subsidiaries, affiliates, distributors, and assigns, against any and all liabilities, losses, costs, damages, judgments, and expenses, arising

out of any claim, demand, investigation, lawsuit, regulatory action or cause of action arising out of or associated with any unauthorized use, even if such claim alleges that onsemi was

negligent regarding the design or manufacture of any products and/or the board.

This evaluation board/kit does not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling (WEEE), FCC,

CE or UL, and may not meet the technical requirements of these or other related directives.

FCC WARNING – This evaluation board/kit is intended for use for engineering development, demonstration, or evaluation purposes only and is not considered by onsemi to be a finished

end product fit for general consumer use. It may generate, use, or radiate radio frequency energy and has not been tested for compliance with the limits of computing devices pursuant

to part 15 of FCC rules, which are designed to provide reasonable protection against radio frequency interference. Operation of this equipment may cause interference with radio

communications, in which case the user shall be responsible, at its expense, to take whatever measures may be required to correct this interference.

onsemi does not convey any license under its patent rights nor the rights of others.

LIMITATIONS OF LIABILITY: onsemi shall not be liable for any special, consequential, incidental, indirect or punitive damages, including, but not limited to the costs of requalification,

delay, loss of profits or goodwill, arising out of or in connection with the board, even if onsemi is advised of the possibility of such damages. In no event shall onsemi’s aggregate liability

from any obligation arising out of or in connection with the board, under any theory of liability, exceed the purchase price paid for the board, if any.

The board is provided to you subject to the license and other terms per onsemi’s standard terms and conditions of sale. For more information and documentation, please visit

www.onsemi.com.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

onsemi Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

www.onsemi.com

1

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�