Switch-mode

Power Rectifiers

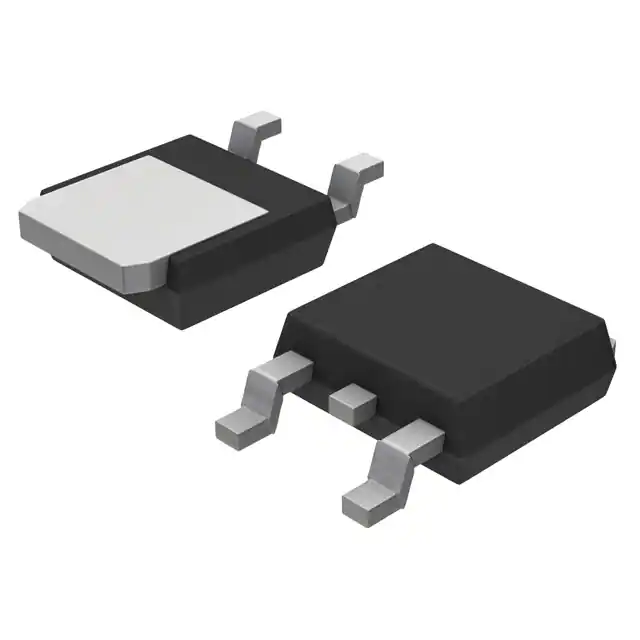

DPAK−3 Surface Mount Package

MBRD620CT,

NRVBD620VCT, SBRV620CT

Series

These state−of−the−art devices are designed for use in switching

power supplies, inverters and as free wheeling diodes.

Features

•

•

•

•

•

Extremely Fast Switching

Extremely Low Forward Drop

Platinum Barrier with Avalanche Guardrings

NRVBD and SBRV Prefixes for Automotive and Other Applications

Requiring Unique Site and Control Change Requirements;

AEC−Q101 Qualified and PPAP Capable

These Devices are Pb−Free and are RoHS Compliant

www.onsemi.com

SCHOTTKY BARRIER

RECTIFIERS

6.0 AMPERES, 20 − 60 VOLTS

DPAK

CASE 369C

1

Mechanical Characteristics:

• Case: Epoxy, Molded

• Weight: 0.4 Gram (Approximately)

• Finish: All External Surfaces Corrosion Resistant and Terminal

•

•

Leads are Readily Solderable

Lead and Mounting Surface Temperature for Soldering Purposes:

260°C Max. for 10 Seconds

ESD Ratings:

♦ Machine Model = C

♦ Human Body Model = 3B

4

3

MARKING DIAGRAM

AYWW

B

6x0TG

A

Y

WW

B6x0T

x

G

= Assembly Location*

= Year

= Work Week

= Device Code

= 2, 3, 4, 5, or 6

= Pb−Free Package

* The Assembly Location Code (A) is front side

optional. In cases where the Assembly Location is

stamped in the package bottom (molding ejecter

pin), the front side assembly code may be blank.

ORDERING INFORMATION

See detailed ordering and shipping information in the

package dimensions section on page 5 of this data sheet.

© Semiconductor Components Industries, LLC, 2016

August, 2020 − Rev. 15

1

Publication Order Number:

MBRD620CT/D

�MBRD620CT, NRVBD620VCT, SBRV620CT Series

MAXIMUM RATINGS

MBRD/NRVBD/SBRV

Symbol

620CT

630CT

640CT

650CT

660CT

Unit

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

VRRM

VRWM

VR

20

30

40

50

60

V

Average Rectified Forward Current

TC = 130°C

Per Diode

Per Device

IF(AV)

Peak Repetitive Forward Current,

TC = 130°C (Square Wave, Duty = 0.5)

Per Diode

IFRM

Nonrepetitive Peak Surge Current − (Surge applied at rated load

conditions halfwave, single phase, 60 Hz)

IFSM

75

A

Peak Repetitive Reverse Surge Current (2 ms, 1 kHz)

IRRM

1

A

TJ

−65 to +175

°C

Storage Temperature

Tstg

−65 to +175

°C

Voltage Rate of Change (Rated VR)

dv/dt

10,000

V/ms

Rating

A

3

6

A

6

Operating Junction Temperature (Note 1)

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

1. The heat generated must be less than the thermal conductivity from Junction−to−Ambient: dPD/dTJ < 1/RqJA.

THERMAL CHARACTERISTICS PER DIODE

Characteristic

Symbol

Value

Unit

Maximum Thermal Resistance, Junction−to−Case

RqJC

6

°C/W

Maximum Thermal Resistance, Junction−to−Ambient (Note 2)

RqJA

80

°C/W

Symbol

Value

Unit

2. Rating applies when surface mounted on the minimum pad size recommended.

ELECTRICAL CHARACTERISTICS PER DIODE

Characteristic

Maximum Instantaneous Forward Voltage (Note 3)

iF = 3 Amps, TC = 25°C

iF = 3 Amps, TC = 125°C

iF = 6 Amps, TC = 25°C

iF = 6 Amps, TC = 125°C

VF

Maximum Instantaneous Reverse Current (Note 3)

(Rated dc Voltage, TC = 25°C)

(Rated dc Voltage, TC = 125°C)

iR

0.7

0.65

0.9

0.85

0.1

15

V

mA

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

3. Pulse Test: Pulse Width = 300 ms, Duty Cycle ≤ 2.0%.

www.onsemi.com

2

�MBRD620CT, NRVBD620VCT, SBRV620CT Series

TYPICAL CHARACTERISTICS

1000

70

100

I R , REVERSE CURRENT (mA)

100

50

30

150°C

10

125°C

1.0

75°C

0.1

0.01

10

0.001

7.0

0.0001

25°C

0

40

20

30

50

VR, REVERSE VOLTAGE (VOLTS)

10

5.0

3.0

Figure 2. Typical Reverse Current,* Per Leg

150°C

2.0

125°C

1.0

0.7

0.5

0.3

0.2

75°C

TC = 25°C

0.1

0

0.2

70

60

*The curves shown are typical for the highest voltage device in the

voltage grouping. Typical reverse current for lower voltage selections

can be estimated from these curves if VR is sufficient below rated VR.

175°C

PF(AV) , AVERAGE POWER DISSIPATION (WATTS)

i F, INSTANTANEOUS FORWARD CURRENT (AMPS)

20

TJ = 175°C

0.4

0.6

0.8

1.0

1.2

1.4

14

13

12

11

10

9.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0

SINE

WAVE

5

10

IPK/IAV = 20

SQUARE

WAVE

dc

TJ = 150°C

0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

vF, INSTANTANEOUS VOLTAGE (VOLTS)

IF(AV), AVERAGE FORWARD CURRENT (AMPS)

Figure 1. Typical Forward Voltage, Per Leg

Figure 3. Average Power Dissipation, Per Leg

www.onsemi.com

3

10

�MBRD620CT, NRVBD620VCT, SBRV620CT Series

I F(AV) , AVERAGE FORWARD CURRENT (AMPS)

TYPICAL CHARACTERISTICS

8.0

RATED VOLTAGE APPLIED

7.0

RqJC = 6°C/W

6.0

TJ = 150°C

5.0

SINE

WAVE

OR

SQUARE

WAVE

4.0

3.0

dc

2.0

1.0

0

80

90

100

110

120

140

130

150

160

TC, CASE TEMPERATURE (°C)

I F(AV) , AVERAGE FORWARD CURRENT (AMPS)

Figure 4. Current Derating, Case, Per Leg

4.0

RqJA = 80°C/W

SURFACE MOUNTED ON MIN.

PAD SIZE RECOMMENDED

TJ = 150°C

3.5

3.0

dc

SQUARE WAVE

OR

SINE WAVE

2.5

VR = 25 V

2.0

1.5

VR = 60 V

1.0

0.5

0

0

20

40

60

100

80

120

140

160

TA, AMBIENT TEMPERATURE (°C)

Figure 5. Current Derating, Ambient, Per Leg

C, CAPACITANCE (pF)

1K

TJ = 25°C

100

10

0

10

20

30

40

50

60

VR, REVERSE VOLTAGE (VOLTS)

Figure 6. Typical Capacitance, Per Leg

www.onsemi.com

4

70

�MBRD620CT, NRVBD620VCT, SBRV620CT Series

ORDERING INFORMATION

Device

Package

Shipping†

MBRD620CTT4G

2500 / Tape & Reel

MBRD630CTT4G

2500 / Tape & Reel

MBRD640CTG

75 Units / Rail

NRVBD640CTG*

75 Units / Rail

NRVBD640CTG−VF01*

75 Units / Rail

MBRD640CTT4G

2500 / Tape & Reel

NRVBD640CTT4G*

2500 / Tape & Reel

NRVBD640VCTT4G*

2500 / Tape & Reel

SBRV640VCTT4G*

2500 / Tape & Reel

MBRD650CTG

75 Units / Rail

MBRD650CTT4G

NRVBD650CTG−VF01*

2500 / Tape & Reel

DPAK

(Pb−Free)

2500 / Tape & Reel

NRVBD650CTT4G*

2500 / Tape & Reel

NRVBD650CTT4G−VF01*

2500 / Tape & Reel

MBRD660CTG

75 Units / Rail

NRVBD660CTG*

75 Units / Rail

NRVBD660CTG−VF01*

75 Units / Rail

MBRD660CTRLG

1800 / Tape & Reel

NRVBD660CTRLG*

1800 / Tape & Reel

MBRD660CTT4G

2500 / Tape & Reel

NRVBD660CTT4G*

2500 / Tape & Reel

SBRV660VCTT4G*

2500 / Tape & Reel

SNRVBD660CTT4G*

2500 / Tape & Reel

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

*NRVBD and SBRV Prefixes for Automotive and Other Applications Requiring Unique Site and Control Change Requirements; AEC−Q101

Qualified and PPAP Capable.

www.onsemi.com

5

�MECHANICAL CASE OUTLINE

PACKAGE DIMENSIONS

DPAK (SINGLE GAUGE)

CASE 369C

ISSUE F

4

1 2

DATE 21 JUL 2015

3

SCALE 1:1

A

E

b3

C

A

B

c2

4

L3

Z

D

1

L4

2

3

NOTE 7

b2

e

c

SIDE VIEW

b

0.005 (0.13)

TOP VIEW

H

DETAIL A

M

BOTTOM VIEW

C

Z

H

L2

GAUGE

PLANE

C

L

L1

DETAIL A

Z

SEATING

PLANE

BOTTOM VIEW

A1

ALTERNATE

CONSTRUCTIONS

ROTATED 905 CW

STYLE 1:

PIN 1. BASE

2. COLLECTOR

3. EMITTER

4. COLLECTOR

STYLE 6:

PIN 1. MT1

2. MT2

3. GATE

4. MT2

STYLE 2:

PIN 1. GATE

2. DRAIN

3. SOURCE

4. DRAIN

STYLE 7:

PIN 1. GATE

2. COLLECTOR

3. EMITTER

4. COLLECTOR

STYLE 3:

PIN 1. ANODE

2. CATHODE

3. ANODE

4. CATHODE

STYLE 8:

PIN 1. N/C

2. CATHODE

3. ANODE

4. CATHODE

STYLE 4:

PIN 1. CATHODE

2. ANODE

3. GATE

4. ANODE

STYLE 9:

STYLE 10:

PIN 1. ANODE

PIN 1. CATHODE

2. CATHODE

2. ANODE

3. RESISTOR ADJUST

3. CATHODE

4. CATHODE

4. ANODE

SOLDERING FOOTPRINT*

6.20

0.244

2.58

0.102

5.80

0.228

INCHES

MIN

MAX

0.086 0.094

0.000 0.005

0.025 0.035

0.028 0.045

0.180 0.215

0.018 0.024

0.018 0.024

0.235 0.245

0.250 0.265

0.090 BSC

0.370 0.410

0.055 0.070

0.114 REF

0.020 BSC

0.035 0.050

−−− 0.040

0.155

−−−

MILLIMETERS

MIN

MAX

2.18

2.38

0.00

0.13

0.63

0.89

0.72

1.14

4.57

5.46

0.46

0.61

0.46

0.61

5.97

6.22

6.35

6.73

2.29 BSC

9.40 10.41

1.40

1.78

2.90 REF

0.51 BSC

0.89

1.27

−−−

1.01

3.93

−−−

GENERIC

MARKING DIAGRAM*

XXXXXXG

ALYWW

AYWW

XXX

XXXXXG

IC

Discrete

= Device Code

= Assembly Location

= Wafer Lot

= Year

= Work Week

= Pb−Free Package

*This information is generic. Please refer to

device data sheet for actual part marking.

Pb−Free indicator, “G” or microdot “G”, may

or may not be present. Some products may

not follow the Generic Marking.

6.17

0.243

SCALE 3:1

DIM

A

A1

b

b2

b3

c

c2

D

E

e

H

L

L1

L2

L3

L4

Z

XXXXXX

A

L

Y

WW

G

3.00

0.118

1.60

0.063

STYLE 5:

PIN 1. GATE

2. ANODE

3. CATHODE

4. ANODE

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. CONTROLLING DIMENSION: INCHES.

3. THERMAL PAD CONTOUR OPTIONAL WITHIN DIMENSIONS b3, L3 and Z.

4. DIMENSIONS D AND E DO NOT INCLUDE MOLD

FLASH, PROTRUSIONS, OR BURRS. MOLD

FLASH, PROTRUSIONS, OR GATE BURRS SHALL

NOT EXCEED 0.006 INCHES PER SIDE.

5. DIMENSIONS D AND E ARE DETERMINED AT THE

OUTERMOST EXTREMES OF THE PLASTIC BODY.

6. DATUMS A AND B ARE DETERMINED AT DATUM

PLANE H.

7. OPTIONAL MOLD FEATURE.

mm Ǔ

ǒinches

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

DOCUMENT NUMBER:

DESCRIPTION:

98AON10527D

DPAK (SINGLE GAUGE)

Electronic versions are uncontrolled except when accessed directly from the Document Repository.

Printed versions are uncontrolled except when stamped “CONTROLLED COPY” in red.

PAGE 1 OF 1

onsemi and

are trademarks of Semiconductor Components Industries, LLC dba onsemi or its subsidiaries in the United States and/or other countries. onsemi reserves

the right to make changes without further notice to any products herein. onsemi makes no warranty, representation or guarantee regarding the suitability of its products for any particular

purpose, nor does onsemi assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation

special, consequential or incidental damages. onsemi does not convey any license under its patent rights nor the rights of others.

© Semiconductor Components Industries, LLC, 2018

www.onsemi.com

�onsemi,

, and other names, marks, and brands are registered and/or common law trademarks of Semiconductor Components Industries, LLC dba “onsemi” or its affiliates

and/or subsidiaries in the United States and/or other countries. onsemi owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property.

A listing of onsemi’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. onsemi reserves the right to make changes at any time to any

products or information herein, without notice. The information herein is provided “as−is” and onsemi makes no warranty, representation or guarantee regarding the accuracy of the

information, product features, availability, functionality, or suitability of its products for any particular purpose, nor does onsemi assume any liability arising out of the application or use

of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages. Buyer is responsible for its products

and applications using onsemi products, including compliance with all laws, regulations and safety requirements or standards, regardless of any support or applications information

provided by onsemi. “Typical” parameters which may be provided in onsemi data sheets and/or specifications can and do vary in different applications and actual performance may

vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. onsemi does not convey any license

under any of its intellectual property rights nor the rights of others. onsemi products are not designed, intended, or authorized for use as a critical component in life support systems

or any FDA Class 3 medical devices or medical devices with a same or similar classification in a foreign jurisdiction or any devices intended for implantation in the human body. Should

Buyer purchase or use onsemi products for any such unintended or unauthorized application, Buyer shall indemnify and hold onsemi and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that onsemi was negligent regarding the design or manufacture of the part. onsemi is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

onsemi Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

�