CX3225SB54000D0WPSC1 数据手册

Specifications

Drawing No.

UKY1C-H1-14D79-00[43] 1/11

Issued Date.

Dec,12,2014

TO: KED USA

Note:In case of specification change, KYOCERA Part Number also will be changed.

Product Name

Quartz Crystal

Product Model

CX3225SB

Frequency

54000kHz

Customer Part Number

-

Customer Specification Number

-

KYOCERA Part Number

CX3225SB54000D0WPSC1

Remarks

Pb-Free、RoHS Compliant、MSL 1

Customer Acceptance

Accept Signature

Approved Date

Department

Person in charge

Seller

KYOCERA Crystal Device Corporation

Manufacturer

(Sales Division)

6 Takeda Tobadono-cho, Fushimi-ku, Kyoto

612-8501 Japan

TEL. No. 075-604-3500

FAX. No. 075-604-3501

Crystal Units Division

5850, Higashine-Koh, Higashine-Shi, Yamagata

999-3701 Japan

TEL. No. 0237-43-5611

FAX. No. 0237-43-5615

Design Department

Quality Assurance

Approved by

Checked by

Issued by

KYOCERA Crystal Device Corporation

Crystal Units Engineering Section 1

T. Noritake

K. Yamazaki

Crystal Units Division

T. Nitoube

Y. Kikuchi

KYOCERA Crystal Device Corporation

KBS-5079E

�Drawing No.

UKY1C-H1-14D79-00[43] 2/11

Revision History

Rev.No.

1

Description of revise

First Edition

Date

Approved by

Checked by

Issued by

Dec,12,2014

K. Yamazaki

T. Nitoube

Y. Kikuchi

KYOCERA Crystal Device Corporation

KBS-5079E

�Drawing No.

UKY1C-H1-14D79-00[43] 3/11

1. APPLICATION

This specification sheet is applied to quartz crystal “CX3225SB54000D0WPSC1”

2. KYOCERA PART NUMBER

CX3225SB54000D0WPSC1

3. RATINGS

Items

SYMB.

Rating

Unit

Operating Temperature

Topr

-40 to +85

°C

Storage Temperature range

Tstg

-40 to +85

°C

Remarks

4. CHARACTERISTICS

ELECTRICAL CHARACTERISTICS

Items

Electrical Specification

SYMB.

Min

Typ.

Max

Mode of Vibration

Fundamental

Test Condition

Unit

Nominal Frequency

F0

54

MHz

Nominal

Temperature

Load Capacitance

TNOM

+25

°C

CL

8.0

pF

Frequency Stability

& Accuracy

Equivalent Series

Resistance

Shunt

Capacitance

Pull ability

df/F

Drive Level

-50.0

+50.0

ESR

23

C0

2.0

31

Pd

0.01

Remarks

PPM

*Note

Initial:±15ppm

TC:±30ppm

Ω

pF

ppm/pF

200

μW

Insulation

IR

500

MΩ

100V(DC)

Resistance

*Note : The sum of Frequency stability and accuracy is guaranteed with the following conditions

1) Temperature range of -40°C to +85°C

2) Frequency drift after 2 solder reflows

3) Drive power from 25 μA to 200 μA

4) 15 years of aging at any temperature from -40°C to +85°C

KYOCERA Crystal Device Corporation

KBS-5079E

�Drawing No.

UKY1C-H1-14D79-00[43] 4/11

5. Measurement Condition

5.1 Frequency measurement

Measuring instrument

: IEC PI-Network Test Fixture

Load Capacitance

: 8.0pF

Drive Level

: 10μW

5.2 Equivalent series resistance (ESR) measurement

Measuring instrument

: IEC PI-Network Test Fixture

Load Capacitance

: Series

Drive Level

: 10μW

KYOCERA Crystal Device Corporation

KBS-5079E

�Drawing No.

UKY1C-H1-14D79-00[43] 5/11

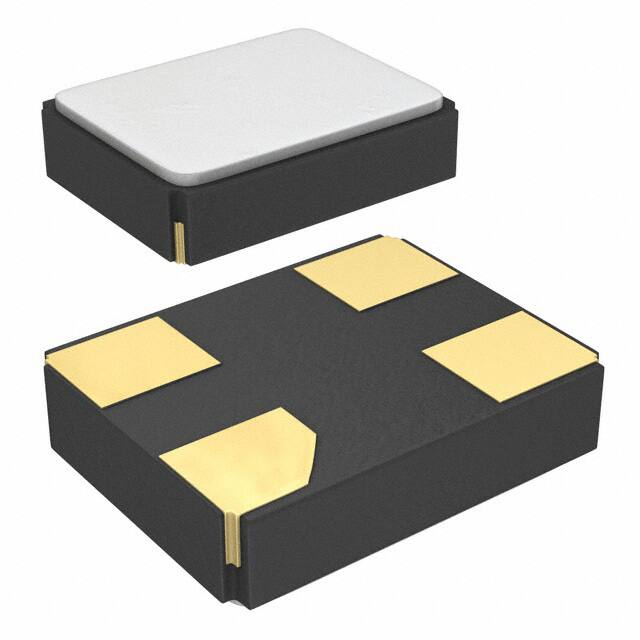

6. APPEARANCES, PHYSICAL DIMENSION

OUTLINE DIMENSION (not to scale)

1

(TOP VIEW)

(Connection)

(Top View)

3.20±0.10

#4

#4 GND

#3

2.50±0.10

54000

K401Y

#2

#1 HOT

#2 GND

4-R0.20

3

4

(Side View)

(Bottom View)

PIN

NO.

#1

#2

#3

#4

PIN Layout

HOT

GND

HOT

GND

4-1.0±0.1

#2

#1

4-0.75±0.1

2

0.20±0.04

0.55±0.05

#1

8-0.10±0.1

#3 HOT

C 0.30

UNIT: mm

#4

#3

MARKING

1 Nominal Frequency Move the number of maximum indication beams of the

frequency to five digits,and omit less than kHz.

2 Identification

[K] mark is surely 1Pin direction.

3 Date Code

Year…LAST 1 DIGIT of YEAR AND WEEK

(Ex)Jan, 01, 2014 → 401

4 Manufacturing Location

Y…Japan(Yamagata)

Z…Japan(Shiga Yohkaichi)

T…Thailand

F…Philippines

※The font of marking is reference.

KYOCERA Crystal Device Corporation

KBS-5079E

�Drawing No.

UKY1C-H1-14D79-00[43] 6/11

7. RECOMMENDED LAND PATTERN (not to scale)

1.0

1.3

1.05

1.85

0.8

1.05

1.3

UNIT: mm

2.3

KYOCERA Crystal Device Corporation

KBS-5079E

�Drawing No.

UKY1C-H1-14D79-00[43] 7/11

8.TAPING & REEL

8-1.Dimensions

4.0±0.1

φ1.55±0.05

Unreeling direction

1.75±0.1

2.0±0.05

(3.7)

3.5±0.1

3.5±0.05

(3.0)

2.8±0.1

1.0±0.1

4.0±0.05

0.25±0.05

8.0±0.2

φ1.05±0.1

8-2.Leader and trailer tape

Components

Empty compartment

Empty compartment

Leader

END

START

160mm or more

100~200mm

400~560mm

8-3.Direction(The direction shall be seen from the top cover tape side)

Unreeling direction

12345

K123Y

12345

K123Y

12345

K123Y

12345

K123Y

8-4.Specification

1. Material of the carrier tape is either polystyrene or A-PET (ESD).

2. Material of the cover tape is polyester (ESD).

3. The seal tape shall not cover the sprocket holes and not protrude from the carrier tape.

4. Tensile strength of carrier tape: 10N or more.

5. The R of the corner of each cavity is 0.2RMAX.

6. The alignment between centers of the cavity and sprocket hole shall be 0.05mm or less.

7. The orientation shall be checked from the top cover tape side as shown in 8-3.

8. Peeling force of cover tape: 0.1 to 1.0N.

9. The component will fall out naturally when cover tape is removed and set upside down.

.

165°~180°

Cover tap

Career tape

KYOCERA Crystal Device Corporation

KBS-5079E

�Drawing No.

UKY1C-H1-14D79-00[43] 8/11

8-5.Reel Specification

t

W

C

D

E

B

A

In the case of Φ180 Reel (3,000 pcs max, every 1,000 pcs)

Symbol

Dimension

Symbol

Dimension

A

B

C

D

φ180 +0/-3

φ60 +1/-0

φ13±0.2

φ21±0.8

E

W

t

2.0±0.5

9±1

2.0±0.5

(Unit : mm)

In the case of Φ330 Reel (10,000 pcs max, every 1,000 pcs)

Symbol

Dimension

Symbol

Dimension

A

B

C

D

φ330±2.0

φ100±1.0

φ13±0.2

φ21±0.8

E

W

t

2.0±0.5

9.5±0.5

2.2±0.1

(Unit : mm)

KYOCERA Crystal Device Corporation

KBS-5079E

�Drawing No.

UKY1C-H1-14D79-00[43] 9/11

9. Environmental requirements

After following test, frequency shall not change more than ±10×10-6

And CI,±20% or 5Ω of large value.

9.1 Resistance to Shock

Test condition

Natural dropped from height 100cm onto hard wood

board in 3 times

9.2 Resistance to Vibration

9.3 Resistance to Heat

Test condition

frequency

: 10 - 55 - 10 Hz

Amplitude

: 1.5mm

Cycle time

: 15 minutes

Direction

: X,Y,Z (3direction),2 h each.

Test condition

The quartz crystal unit shall be stored at a

temperature of +85±2°C for 500 h.

Then it shal be subjected to standard atmospheric

conditions for 1 h ,after whichi measurement shall

be made.

9.4 Resistance to Cold

Test condition

The quartz crystal unit shall be stored at a

temperature of -40±2°C for 500 h.

Then it shal be subjected to standard atmospheric

conditions for 1 h ,after whichi measurement shall

be made.

9.5 Thermal Shock

Test condition

The quartz crystal unit shall be subjected to 500

succesive change of temperature cycles ,each as

shown in table below,Then it shall be subjected

to standard atmospheric conditions for 1h,after

which measurements shall be made.

Cycle

:-40±2°C(30min.)to +25±2°C(5min.)

to +85±2°C(30min.)to +25±2°C(5min.)

KYOCERA Crystal Device Corporation

KBS-5079E

�Drawing No.

9.6 Resistance to Moisture

9.7 Soldering condition

UKY1C-H1-14D79-00[43] 10/11

Test condition

The quartz crystal unit shall be stored at a

temperature of +60±2°C wich relative humidity of

90% to 95% for 240 h. Then it shall be subjected

to standard atmospheric conditions for 1h,after

which measurements shall be made

1.) Material of solder

Kind … lead free solder paste

Melting point … +220±5°C

2.) Reflow temp.profile

Temp [°C]

Preheating

+150 to +180

Peak

+260±5

Total

―

Frequency shift : ±2ppm

3.) Hand Soldering +350°C 3 sec MAX

4.) Reflow Times

2 times

Time[sec]

150 (typ.)

10 (max.)

300 (max.)

Reflow temp.profile

9.8 Intensity for bending in circuit board

Solder this product in center of the circuit board of 40mm×100mm,

and add the deflection of 3mm as the bottom figure.

Test board : t=1.6mm

20

PUSH

1.6

board

10

R5

Product

45

45

R230

press jig

UNIT : mm

KYOCERA Crystal Device Corporation

KBS-5079E

�Drawing No.

UKY1C-H1-14D79-00[43] 11/11

10. Cautions for use

(1)Soldering upon mounting

There is a possibility to influence product characteristics when Solder paste or conductive glue comes in

contact with product lid or surface.

(2)When using mounting machine

Please minimize the shock when using mounting machine to avoid any excess stress to the product.

(3)Conformity of a circuit

We strongly recommend to make sure that Negative resistance (Gain) of IC is designed to be 5 times the

ESR (Equivalent Series Resistance) of crystal unit.

11. Storage conditions

Please store product in below conditions, and use within 6 months.

Temperature +18 to +30°C, and Humidity of 20 to 70 % in the packaging condition.

12. Manufacturing location

Kyocera Crystal Device Corporation Plant

Kyocera Crystal Device Corporation Shiga Yohkaichi Plant

Kyocera Crystal Device (Thailand) Co., Ltd

Kyocera Crystal Device Philippines, Inc.

13. Quality Assurance

To be guaranteed by Kyocera Crystal Device Quality Assurance Division

14. Quality guarantee

In case when Kyocera Crystal Device Corporation rooted failure occurred within 1year after its delivery,

substitute product will be arranged based on discussion. Quality guarantee of product after 1year of its delivery is

waivered.

15. Others

In case of any questions or opinions regarding the Specification, please have it in written manner

within 45 days after issued date.

KYOCERA Crystal Device Corporation

KBS-5079E

�

CX3225SB54000D0WPSC1 价格&库存

很抱歉,暂时无法提供与“CX3225SB54000D0WPSC1”相匹配的价格&库存,您可以联系我们找货

免费人工找货