Messrs. Digi-Key

Product Specification

(KYOCERA CORPORATION CERAMIC RESONATOR SPECIFICATION)

RoHS compliant

CONFIRMED

(Please sign here and send one copy back to us.)

Specification

No.

Type Name

00

EQM08-5KC-G5PQ801-00

(QK-SB210-PD0621-A)

PRQV8.00CR1510Y00L

Apr, 16, 2014

Approved by

T.Sugihara

Checked by

K.Katsuyama

Checked by

T.Matsuoka

Issued by

N.Arima

�EQM08-5KC-G5PQ801-00

(QK-SB210-PE0621-A)

(1/8)

1. Scope

This document shall cover the specifications of the ceramic resonator applied for clock oscillator of a

microcomputer.

2. Kyocera's Type Name

PRQV8.00CR1510Y00L

3. Customer's Type Name

4. Electrical Characteristics

Table 1 Product Specification

Items

Specifications

Oscillating Frequency

8.00 MHz

Initial Frequency Tolerance

± 0.15 %

Resonant Impedance

Temperature Characteristics

on Oscillating Frequency

(Temperature Drift)

Standard Test IC

Withstanding Voltage

Max. Input Signal Voltage

Insulation Resistance

Operating Temperature

Range

Storage Temperature

Range

Aging for 10 Years

on Oscillating Frequency

500 Ω max.

± 0.10 %

( -40 to +125 °C )

MC74HCU04 (Freescale)

100V D.C. 10 seconds max

15 Vp-p

100 MΩ min (at 10V D.C.)

-40 to +125 °C

-40 to +125 °C

±0.05%

at 25°C from initial value

4-1. Measurement Condition

The reference temperature shall be 25 ± 2 °C. The measurement shall be performed in the

temperature range from 15 °C to 35 °C unless otherwise the result is doubtful.

4-2. Measurement Circuit

Oscillating frequency shall be measured using the Kyocera standard test circuit shown in Fig 1.

�EQM08-5KC-G5PQ801-00

(QK-SB210-PE0621-A)

(2/8)

Vdd=5.0V

14

MC74HCU04

(Freescale)

1

2

3

4

7

Out

Rf

Resonator

C1

C2

Rf=1MΩ

C1=C2=10 pF (Reference)

Fig 1 Standard Measuring Circuit

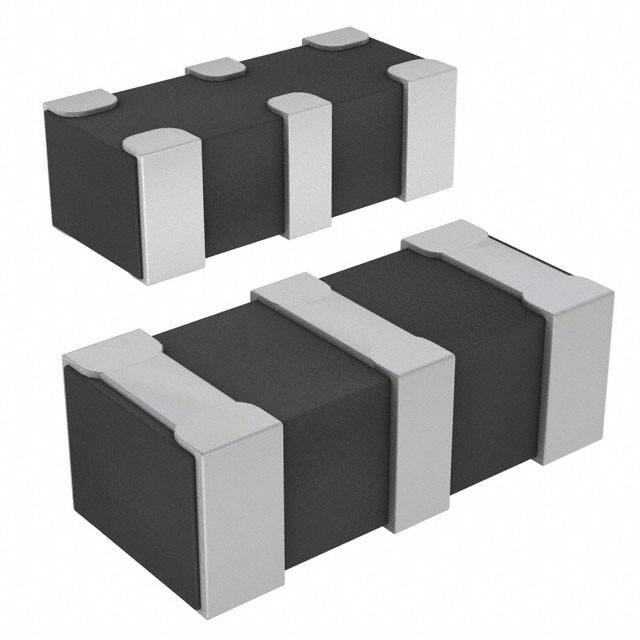

5. Appearance & Dimensions

Oscillating Frequency

e.g.: xxx=800 show the oscillating frequency of 8.00

MHz, respectively.

Date Code

2013

2014

2015

2016

K800

Note:

Jan.

Jan.

Jan.

Jan.

~

~

~

~

Dec.

Dec.

Dec.

Dec.

A~M

N~Z

a~m

n~z

(except “ I ”)

(except “O” )

(except “ i ”)

(except “o”)

The alphabet should be repeated after Jan.2017.

Day Code

Day

Code

Day

Code

Day

Code

1

A

11

L

21

W

2

B

12

M

22

X

3

C

13

N

23

Y

4

D

14

P

24

Z

5

E

15

Q

25

a

6

F

16

R

26

b

7

G

17

S

27

c

8

H

18

T

28

d

9

J

19

U

29

e

10

K

20

V

30

f

31

g

Appearance

There should be no mechanical damages, which are

markedly out of this specification.

Terminal:

Fig 2 Dimensions

Unit: mm

Ni/Sn plating

�EQM08-5KC-G5PQ801-00

(QK-SB210-PE0621-A)

(3/8)

6. Part Numbering Guide

PRQV 8.00 C R 15 10 Y 00L

A

B

C D E F

G

H

7. Environmental Characteristics

Table 2 Enviromental Characteristics

Items

7-1. Humidity

7-2. High

Temperature

7-3. Low

Temperature

7-4. Temperature

Cycle

7-5. Mechanical

Shock

7-6. Vibration

7-7. Solderability

7-8. Reflow

Soldering

7-9. Cleaning

A. Series (MHz Band SMD Ceramic Resonator)

B. Oscillating Frequency (eg. 8.00 MHz)

C. Type

D. Packing (Tape & Reel 3000 pcs/Reel)

E. Initial Frequency Tolerance

F. Bult-in Capacitor (10pF: Standard)

G. Operating Temp. Range

H. Unique Code

Conditions

After leaving in a chamber at 80 to 85 % R.H. and 85 ± 2°C for 1000 +12/-0 hours

and then left at room temperature for 1 hour the resonator shall meet the

specifications shown in Table 3.

After leaving in a chamber at 125 ± 2°C for 1000 +12/-0 hours and then left at room

temperature for 1 hour, the resonator shall meet the specifications shown in Table

3.

After leaving in a chamber at –40 ±3°C for 1000 +12/-0 hours and then left at room

temperature for 1 hour, the resonator shall meet the specifications shown in Table

3.

After leaving in a chamber at –40 ± 3 °C for 30 minutes, then the resonator is left at

125 ± 2°C for 30 minutes. This procedure is one cycle. After leaving in 1000 cycles,

and then left at room temperature for 1 hour, the resonator shall meet the

specifications shown in Table 3.

After applying the acceleration at 29430m/sec2 {3000G} in each of X, Y and Z axis

(each 3 time), the resonator shall meet the specifications in Table 3.

After applying the vibration at amplitude 1.5 mm and 10 to 55 Hz of vibration

frequency in each of 3 mutually perpendicular directions for 1 hour, the resonator

shall meet the specifications shown in Table 3.

At first, being soaked in the Methanol (JIS K1501) solution containing Rosin (JIS

K5902) for 5 seconds and next being soaked in a bath of Pb/Sn solder at 235 ± 5°C

for 4 ± 0.5 seconds, then more than 95% the surface of the electrode terminal shall

be soldered.

At first, leaving at 150 to 180°C of pre-heat for 90 to 120 seconds, next left at peak

temperature 260+0/-5°C, over 230°C for 30 to 40seconds (2times). Finally leaving

at room temperature for 1 hour. The resonator shall meet the specifications shown

in Table 3.

1)Ultrasonic cleaning: The resonator is washed with iso-propyl alcohol at room

temperature with condition of 20KW/m3 and 28kHz for 60sec.

No significant damage on the resonator shall occur and marking shall be safely

readable.

2)Soaking cleaning: The resonator is soaked in iso-propyl alcohol at room

temperature for 90sec. No significant damage on the resonator shall

occur and marking shall be safely readable.

After soldered on the board specified as below, then the load which cause 3 mm

bent to the board is applied, the resonator shall meet the specifications in Table 3

1.2

1.2

and cause no defect in the appearance.

50

20

R230

3.0

7-10. Bend

strength

1.9~ 2.1

F

45

(Units: mm)

45

3 - 0.4

Material: Glass-epoxy

Thickness: 0.8mm / Size: L100mm x W40

Recommendable land pattern

Solder paste: 0.2mm Thickness

Fig.3 Bend Strength

�EQM08-5KC-G5PQ801-00

(QK-SB210-PE0621-A)

(4/8)

Table 3 Environmental Characteristics Standard

Items

Specifications

Oscillating Frequency

(from initial value)

±0.2 % max

Resonant Impedance

550 Ω max.

8. Recommendable land pattern

1.2

1.9 ~ 2.1

1.2

Unit: (mm)

0.4

Fig.4 Recommended Land pattern

9. Recommendable reflow profile

300

Reflow

Peak 260 oC max

(Over 230 ºC, 30 to 40 seconds)

Temperature (oC)

250

200

150

Preheat

150 to 180 oC

100

50

90 to 120

seconds

Over 200 oC

within 80 seconds

0

Time(Sec)

Fig.5 Recommended IR Reflow profile

�EQM08-5KC-G5PQ801-00

(QK-SB210-PE0621-A)

(5/8)

10. Taping Specifications

10-1. Tape

10-1-1. Dimensions

K

P0

D0

T

E

P2

F

W

0

B

A0

T2

P1

D1

Fig.6 Emboss Carrier Tape Dimensions

Table 4 Emboss Carrier

Tape Dimensions

Symbol

A0

Dimensions

B0

W

F

E

P1

P2

1.55±0.1

3.45±0.1

8.00±0.2

3.50±0.05

1.75±0.1

4.00±0.1

2.00±0.05

P0

D0

T

T2

K

D1

4.00±0.1

1.50+0.1/-0

0.25±0.05

1.40max.

1.10±0.05

1.0±0.1

Symbol

Dimensions

Unit: (mm)

10-2. Taping

10-2-1. Taping Quantity

One reel of the tape shall pack 3000 pcs resonators maximum. No resonator shall be

missing and contained continuously in pocket.

10-2-2. Reel Dimensions

W1

E

A

C

N

D

Fig.7 Reel

Table 5 Reel Dimensions

Symbol

A

Dimensions

Symbol

Dimensions

W2

Unit: (mm)

N

W1

W2

180+0/-9

60±1.0

9.2±0.1

12.0 max.

C

D

E

13.0±0.2

21.0±0.8

2.0±0.5

�EQM08-5KC-G5PQ801-00

(QK-SB210-PE0621-A)

(6/8)

10-2-3. Taping Package

D

Kxxx

Kxxx

Kxxx

Kxxx

Kxxx

Taping package shall be composed of leader, blank pockets and loaded pockets, as

described in Fig.8. The peeling force between top and carrier tapes shall be in the

range from 0.1N {10gf} to 0.7N {70gf} with the condition described in Fig.9.

C

B

A

A: Leader Tape

B: Blank Pocket (160 mm min)

A+B: 400- 560 mm

C: Loaded Pocket

D: Blank Pocket (40 – 190 mm )

Fig.8 Packing Method

Top Tape

Carrier Tape

Pulling Direction

165º to 180º

Pulling

Direction

Direction

of Feed

Fig.9 Peeling Strength

10-2-5. Reel Label

Reel label shall contain information described on the basis of EIAJ C-3 format.

A) Customer P/N

B) Lot No.

C) Quantity

D) Shipping date

E) Vender name

10-2-6. Exterior Package Label

The resonators shall be packed properly to avoid defect in transportation and the

marking of the exterior package shall contain information described as below.

A) Name of customer

B) P/O No.

C) Customer P/N

D) Lot No.

E) Quantity

F) Shipping date

G) Vender name

�EQM08-5KC-G5PQ801-00

(QK-SB210-PE0621-A)

(7/8)

11. Agreement on this Specification

Should any part of the content of this specification become questionable, it shall be settled by

mutual deliberations.

12. Remarks on Usage

12-1.In case that such stronger shock and vibration, higher temperature that shall be specified

were to be applied to the resonator, it would occasionally become out of order. So please pay

plenty of attention to its usage.

12-2.This part is available for reflow soldering only. The ceramic resonator may be damaged in

case of reflow soldering at temperatures higher than 260 oC.

12-3.Ensure that your circuit design is fully characterized for your IC. For recommendations of

component values, please contact IC manufacturer or our local sales office before mass

production. Please note there may be some oscillation problems in case of not suitable

circuit design.

12-4.Storage condition

Please use the ceramic resonator within one year from the shipping date under room

storage condition less than 30 oC and 60%RH with the shipped package.

12-5.Fail-safe

Be sure to provide an appropriate fail-safe function on your system or subsystem to prevent

a second damage that may be caused by an abnormality or failure related to our product.

12-6Limitation of use

Make sure to contact us in advance before considering using this product for the

following applications which would require particularly high reliability due to

possibility of direct harm to lives and/or properties.

(1)Use in aerospace or space

(2)Use in seabed or underground

(3)Use in control of power station – firepower, waterpower, nuclearpower, etc

(4)Use in medical treatments including instruments related to lifesaver

(5)Use in transportation – trains, ships, etc.

(6)Use in traffic controls

(7)Use in protection/prevention against disasters or crimes

(8)Others – Use in the equivalent applications mentioned above

12-7. This product is designed and manufactured with intention to be used in general electronic

equipments for standard applications but with no intention to be used in the following

environments which may affect performance of this product. Therefore, make sure to have

enough confirmation on performance and reliability of this product in the following

environments in advance before use.

(1) Use in liquids such as water, oil, medical liquid, organic solvent, etc

(2) Use in direct sunshine, rain, wind, or dust/dirt

(3) Use in sea wind or place with corrosive gas such as CI2, H2S, NH3, SO2, NO2,

etc

(4) Use in environment with strong static electricity or electromagnetic wave

(5) Use in located nearly to heat generating part or flammable materials such as vinyl

wires

(6) Use in sealed or coated by materials such as resin, etc

(7) Use in condensation

�EQM08-5KC-G5PQ801-00

(QK-SB210-PE0621-A)

(8/8)

13. Placement of the Resonator

The resonator should be placed on PCB as described follow to avoid any mechanical stresses

applied to the part.

Long Edge

Long Edge

Short Edge

Resonator

Resonator

Short Edge

PCB

PCB

Non-Preferable Location

Preferable Location

Fig.10 Mounting Direction

14. Environment Hazardous Substance (RoHS Compliant Certificate)

The environment hazardous substance in Table 6 is not being used to the raw materials and also

manufacturing process of this product and packaging (except impurities).

Lead (Pb) used in the resonator products is exempted from RoHS requirements in the ANNEX.

Table 6 Enviromental Load Substance

Substances

Substances Inhibited by the Law in Japan

Products

Content

Reel and Packages

None

None

None

None

None

None

None

None

4

Cadmium and cadmium compounds

PBB (polybrominated biphenyl) s and PBDE

(polybrominated biphenyl ether) s

Chlorinated paraffins (Chlorines Flame

retarder/Plasticizer)

PCB (polychlorinated biphenyl) s

5

Poly chloridation naphthalenes

None

None

None

None

7

Organo tin compounds

(Tributyl tins/ Triphenyl tins)

Asbestos

None

None

8

Azo compounds

None

None

9

Lead (Pb)

Yes

None

1

2

3

6

Others

�

很抱歉,暂时无法提供与“PRQV8.00CR1510Y00L”相匹配的价格&库存,您可以联系我们找货

免费人工找货