EQM08-4KC-D3SX493

Messrs. Digi-Key Corporation

APPROVAL SHEET

(KYOCER A CORPOR ATION SAW FILTER SPECIFIC ATION)

Kindly send us back a copy of this specification sheet with your signature.

The specification shall be regarded as "APPROVED" unless we receive your

disagreement or counterproposal before your placement of initial order for

the part number specified.

Part No.:SF16-0953M4UU01

Jan,17,2011

RoHS Compliant (Pb-Free)

KYOCERA CORPORATION

�EQM08-4KC-D3SX493

0.History

No

Date

Notes

Approved

00

Jan.08

,2011

First Edition

Approved

KYOCERA CORPORATION

Approved

Prepared

0/8

�EQM08-4KC-D3SX493

Approved

1/8

Approved

QA

Engineering

Approved

Prepared

Production

Engineering

1.Scope

This specification shall cover the characteristics of the RF SAW filter.

2.Customer’s Part No.

3.KYOCERA’s Part No.

SF16-0953M4UU01

SF 16 – 0953 M 4 UU 01

①②

③ ④⑤ ⑥ ⑦

① Series ② Package Size ③Frequency ④ Application ⑤ Terminals ⑥In/Out Condition ⑦Custom Specification

4.Electrical Characteristics

Terminating Source Impedance : 50 ohms , Single-ended

Terminating Load Impedance : 50 ohms , Single-ended

Table.1

Items

Frequency Range

Unit

------

MHz

4-1 Norminal Frequency

4-2 Maximum Insertion Loss

4-3 Amplitude Ripple(P-P)

Input VSWR

4-4

Output VSWR

4-5 Absolute Attenuation

4-6 Maximum Input Power

4-7 Operating Temperature

4-8 Storage Temperature

950

950

950

950

0.3

911

931

936

964

to

to

to

to

to

to

to

to

to

956

956

956

956

911

931

936

943

971

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

MHz

dB

dB

971

976

1025

to

to

to

976

1025

3000

MHz

MHz

MHz

dB

dB

dB

dBm

deg.C

deg.C

dB

dB

dB

dB

dB

min.

-

Spec.

typ.

953

max.

-

30

20

15

3

3

2.5

0.1

1.4

1.4

43

38

45

12

10

3.0

2.0

2.5

2.5

-

10

27

27

28

36

57

+ 12

-30 to +85

-

-40 to +95

Specifications can change owing to product and/or technical improvements.

KYOCERA CORPORATION

�EQM08-4KC-D3SX493

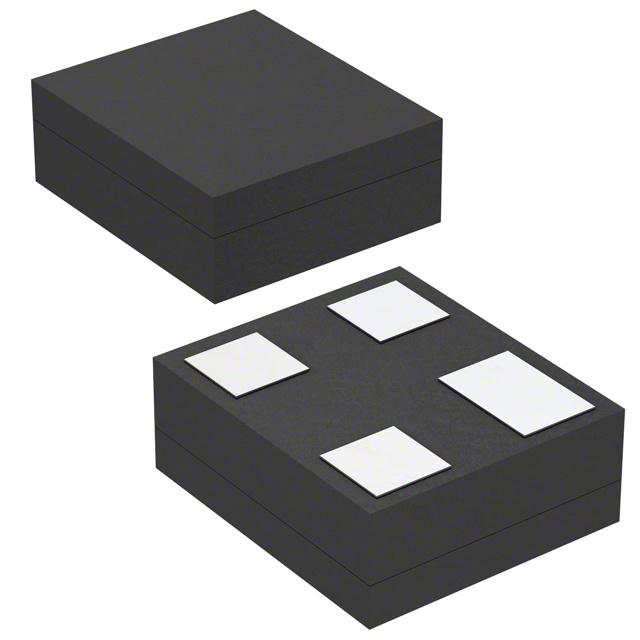

5.Dimensions

0.1

1.4

(3)

(1)

(4)

0.6

(2)

*

(1)

0.1

0.6

…

(2)

0.4

0.6

(4)

4 - 0.4

3 - 0.4

1.6

K68

(3)

2/8

Unit:mm

Tol:+/-0.1mm

The degree of terminal flat : 0.10mm Max.

Terminal quality of the material : Ni Plating + Au Plating

K:Kyocera

68:Part Number

*:Monthly Code

... Weekly Code( ... 1st-10th, .. 11th-20th, . 21th-31th)

Table2 Monthly Code Production

Year

Month

Code

2011

1

a

2015

2

b

3

c

4

d

5

e

6

f

7

g

8

h

9

j

10

k

11

l

12

m

2012

1

n

2016

2

p

3

q

4

r

5

s

6

t

7

u

8

v

9

w

10

x

11

y

12

z

Year

2009

2013

2010

2014

Month

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

KYOCERA CORPORATION

(1)

Input

(2)

GND

(3)

Output

(4)

GND

Code

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

R

S

T

U

V

W

X

Y

Z

�EQM08-4KC-D3SX493

6.Measurement Circuit

(4)

(3)

50ohms

Input

(1)

(2)

50ohms

Output

(1)

: Input

(3)

: Output

(2),(4) : Ground

KYOCERA CORPORATION

3/8

�EQM08-4KC-D3SX493

7.Recommendable Land Pattern

0.1

0.1

(3)

(2)

0.6

3 - 0.4

4 - 0.4

0.6

0.25

(1)

(4)

Unit

0.4

:mm

:Electrode

Temperature(deg.C)

8.Recommendable Reflow Soldering Profile

2 to 3 sec

250 230deg.C

200 180deg.C

150

100

50

60sec.max. 70 to 120sec

30+/-5sec

IR REFLOW SOLDERING

Temperature measurement point is surface of glass epoxy circuit board of 0.8mm thickness.

KYOCERA CORPORATION

4/8

�EQM08-4KC-D3SX493

9.Environmental Characteristics

Item

Hum idity

High Temperature

Storage

Low Tem perature

Storage

Res is tance to

Reflow Solder Heat

Temperature Cy c le

Vibration

Mec hanic al Shoc k 1

Mec hanic al Shoc k 2

ESD

Fig.-1

Condition

Subjec t the filter to 60+ /-2 deg.C and 90%RH to 95%RH

for 100 hours. Then, release the filter into the room

c onditions for 2 hours minimum to the meas urem ent.

It shall fulfill the specific ations in Table 1.

Subjec t the filter to 85+ /-2 deg.C for 100 Hours.

Then, releas e the filter into the room c onditions

for 2 hours minimum to the meas urement.

It shall fulfill the specific ations in Table 1.

Subjec t the filter to –40+/-2 deg.C for 100Hours.

Then, releas e the filter into the room c onditions

for 2 hours minimum to the meas urement.

It shall fulfill the specific ations in Table 1.

Ex pos e filter to inc reasing temperature with

a minimum total ex pos ure above 230 deg.C of 30+/-5

s econds and m ust inc lude 2-3 s econds at peak

temperature of 250 deg.C, twic e.

Then, releas e the filter into the room c onditions

for 2 hours minimum to the meas urement.

It shall fulfill the specific ations in Table 1.

10 Cyc les (1 c yc les :-40 deg.C for 30minutes then

25 deg.C for 15m inutes then 85 deg.C for 30minutes .)

An ex amination is done under the evaluation circ uit board

m ounting c ondition.

Then, releas e the filter into the room c onditions

for 2 hours minimum to the meas urement.

It shall fulfill the specific ations in Table 1.

Subjec t the filter to vibration for 2hour eac h

In the X,Y and Z ax es with the am plitude of 1.5m m,

10 to 55 Hz /min.

It shall fulfill the specific ations in Table 1.

Subjec t the filter to 3 s hoc k s in each direction

of six mutually perpendic ular planes (a total of

18 s hoc k s). Eac h s hoc k s hall be a s ine wave shaped

with a magnitude of 100 G and a duration of 6 ms econds .

It s hall fulfill the s pec ific ations in Table 1.

Drop the filter randomly onto a c onc rete floor

from the Height of 1m, 3 times.

It shall fulfill the specific ations in Table 1.

A direc t c urrent voltage is inc reased to DEV ICE m ounted on the

evaluation c irc uit board. The failure rate whic h oc curred by the direc t

c urrent voltage is inves tigated.A direc t c urrent voltage begins from 39V.

As for the voltage,it inc res es with step of E12 series .A failure voltage

is presc ribed in the direct current voltage that an acc umulate trouble rate

is 0.1%.It is judged with the trouble when inc reas e in the insertion los s

oc curs bey ond 0.3dB before and after the ex am ination.A failure voltage

is more than 50V. ( F ig.-1 )

1MΩ

SW

0Ω

200pF

DUT

DC Source

V

ESD TEST Circuit( Machine Model)

KYOCERA CORPORATION

5/8

�EQM08-4KC-D3SX493

10.Taping Specification

10-1.Tape

10-1-1. Tape Material

Polycarbonate(EC-AP), or PS materials ( conductivity type ).

10-1-2. Tape Dimensions

H

K

A

T

L

R

B

D

E

F

J

G

W

R

Material:Anti-static A-PET

Part

Dim ension

Part

Dim ension

Part

Dim ension

A

1.85+/-0.1

G

4.0+ /-0.1

R

0.3 MAX

B

D

1.90+/-0.1

8.0+/-0.2

H

J

4.0+ /-0.1 2.0+ /-0.05

W

T

0.95+ /-0.2 0.25+/-0.05

E

3.5+ /-0.05

K

1.5+ /-0.1

F

1.75+/-0.1

L

1.1+ /-0.1

Unit[m m]

* W Dimension is depth of pockets.

10-2.Taping

10-2-1.Taping Quantity

One reel of tape shall pack 3,000 filters maximum.

No filter shall be missing and contained continuously in pocket.

10-2-2. Reel Material

Polystyrene + Carbon ( conductivity type )

10-2-3.Reel Dimensions

D

B

E

R

C

T

W

A

Part

Dimension

Part

Dimension

A

178+/-2

E

2+/-0.5

B

60+/-2

R

R1

C

13+/-0.2

W

9.5+/-1

D

21+/-0.8

T

2.0+/-0.2

Unit[mm]

KYOCERA CORPORATION

6/8

�EQM08-4KC-D3SX493

7/8

10-2-4 Leader and blank pocket

Package shall consist of Leader and Blank Pocket as follows.

The power peeling top from carrier shall be 0.098N to 0.98N.

Blank Pocket

Loaded Pocket

10 pitches min .

Blank Pocket

Leader

10 pitches min.

200 mm min.

Parts Direction

OUTPUT

GND

K68

Pulling Side

…

*

GND

INPUT

10-2-5 Reel Label

The following contents are indicated in a reel.

Reel L abel ( EIAJ-C3 L abel )

xxxxxxxx ‥ (a)

Sample

XXXXXXXX

Label

‥(b)

SF16-09 53M4 UU0 1

07 / 02 / 10

‥(d)

(a)

(b)

(c)

(d)

(e)

Customer Parts Number

Quantity

Parts Name

Lot number

Shipping date

Aluminum Pack

Reel Label

‥(e)

Reel Label

SF16-09

53M4 UU0

1‥(c)

T aping

Reel

MSL/ESD Label

T aping Reel

10-2-6 Packing case Label

During transportation, after packing into an aluminum bag for every reel so that a damage

and moisture absorption may not be given to a product, it puts into a packing box.

The following contents are indicated in a packing case.

Box Label ( EIAJ-C3 Label )

XXXXXXXXXXXX‥(a)

XXXXXXXX

Sample

SF16-0953M4UU01‥(b)

SF16-0953M4UU01

xxxxxxxx‥ (c)

(e)

(d)

(a)

(b)

(c)

(d)

(e)

(f)

Customer name

Parts name

Customer Parts number

Lot number

Quantity

Shipping date

‥(f)

KYOCERA CORPORATION

�EQM08-4KC-D3SX493

8/8

12-2-7 Taping flaking off strength Test

Test Condition : 120mm/min 160-180deg

Range of strength : 0.098 – 0.98 N

Top Tape

Career tape

160∼180°

pull

12-2-8 Packing form

The reel is packed in aluminum, and it is packed to the box.

Aluminum packing

Label

MSL/ESD Lab el

13.Precaution in handling

Please handle with below condition.

1. Calculated shelf life in sealed bag: 6 months at ≦ 40℃ and ≦ 90% relative humidity (RH) .

2. After bag is opened, devices should be mounted within 168 hours of factory conditions ≦30℃/ 60% RH.

Exposed over 168 hours parts are recommended to make pre treatment of 60 ℃ 1 hour baking just

before

use. (In case left further longer since unpacked, please check solderability before use.)

3. Expiration date : 6 months form sealing date, which is imprinted on the adjacent bar code label.

4. This components are static sensitivity parts. Please handle with care.

5. On circuit design, it is strongly recommended to put DC cut capacitor for this SAW filter.

7. This component can not be used in resin molding.

KYOCERA CORPORATION

�

很抱歉,暂时无法提供与“SF16-0953M4UU01”相匹配的价格&库存,您可以联系我们找货

免费人工找货