LI

FE

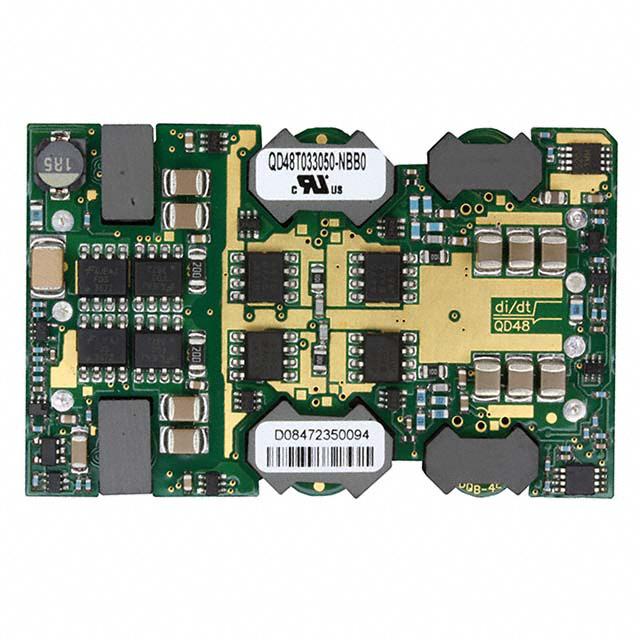

The

QD48T033050

dual

output

through-hole

mounted

DC-DC converter offers unprecedented performance in a quarter brick

package by providing two independently regulated high current

outputs with total power of 100 W. This is accomplished by the use of

patent pending circuit and packaging techniques to achieve ultra-high

efficiency, excellent thermal performance and a very low body profile.

In telecommunications applications the QD48 converters provide up

to 15 A @ 3.3 V and 10 A @ 5 V simultaneously – with thermal

performance far exceeding existing dual quarter bricks and

comparable to dual half-bricks. Low body profile and the preclusion of

heatsinks minimize airflow shadowing, thus enhancing cooling for

downstream devices. The use of 100% surface-mount technologies

for assembly, coupled with Power Bel Solutions advanced electric and

thermal circuitry and packaging, results in a product with extremely

high quality and reliability.

F

EN

D

O

RoHS lead-free solder and lead-solder-exempted products are

available

Delivers simultaneously up to 15 A on 3.3 VDC and up to 10 A on 5.0

VDC output

Can replace two single output quarter-bricks

Minimal cross-channel interference

High efficiency: 88% @ full load, 89% @ half load

Starts-up into pre-biased output

No minimum load required

No heat sink required

Low profile: 0.28” [7.2 mm]

Low weight: 1 oz [28 g] typical

Industry-standard footprint: 1.45” x 2.30”

Industry-standard pinout

Meets Basic Insulation Requirements of EN60950

Withstands 100 V input transient for 100ms

On-board LC input filter

Fixed-frequency operation

Fully protected

Output voltage trim range: ±10% for both outputs

Trim resistor via industry-standard equations

High reliability: MTBF 2.6 million hours, calculated per Telcordia TR332, Method I Case 1

Positive or negative logic ON/OFF option

Approved to the latest edition and amendment of ITE Safety standards,

UL/CSA 60950-1 and IEC60950-1

Meets conducted emissions requirements of FCC

Class B and EN55022 Class B with external filter

All materials meet UL94, V-0 flammability rating

�QD48T033050

2

Conditions: TA = 25ºC, Airflow = 300 LFM (1.5 m/s), Vin = 48 VDC, unless otherwise specified.

PARAMETER

Absolute Maximum Ratings

CONDITIONS / DESCRIPTION

Input Voltage

Continuous

MIN

TYP

MAX

UNITS

0

80

VDC

Operating Ambient Temperature

-40

85

°C

Storage Temperature

-55

125

°C

75

VDC

Input Characteristics

Operating Input Voltage Range

36

Non-latching

Turn-on Threshold

Turn-off Threshold

Input Transient Withstand (Susceptibility)

100 ms

Isolation Characteristics

I/O Isolation

Non-latching

Non-latching

F

Peak Short-Circuit Current

3.3 V

5.0 V

RMS Short-Circuit Current

3.3 V

5.0 V

At nominal output voltage 3.3 V

At nominal output voltage 5.0 V

34

31

32

17

11.5

35

VDC

33

VDC

100

VDC

10,000

4.700

μF

μF

15

10

ADC

ADC

18.5

13

20

15

ADC

ADC

20

15

30

30

A

A

4

4

Arms

Arms

0

0

Non-latching. Short=10mΩ.

Non-latching. Short=10mΩ.

O

Output Current Range

3.3 V

5.0 V

Current Limit Inception

3.3 V

5.0 V

Plus full load (resistive)

Plus full load (resistive)

33

LI

Output Characteristics

External Load Capacitance

3.3 V

5.0 V

48

FE

Input Under Voltage Lockout

Non-latching

Non-latching

2000

Isolation Capacitance

VDC

ρF

1.3

10

EN

D

Isolation Resistance

MΩ

Feature Characteristics

Switching Frequency

Output Voltage Trim Range1

3.3 V

5.0 V

Output Over-Voltage Protection

3.3 V

5.0 V

See section: Output Voltage Adjust/TRIM

435

Simultaneous with 3.3 V output

-10

-10

Non-latching

Non-latching

3.85

5.85

4.125

6.15

kHz

+10

+10

%

%

4.25

6.4

V

V

Over-Temperature Shutdown (PCB)

Non-latching

120

°C

Auto-Restart Period

Applies to all protection features

100

ms

4

ms

Turn-On Time

5.0 V 3.3 V tracks 5.0 V

ON/OFF Control (Positive Logic)

Converter Off

-20

0.8

VDC

Converter On

2.4

20

VDC

ON/OFF Control (Negative Logic)

Converter Off

2.4

20

VDC

Converter On

-20

0.8

VDC

tech.support@psbel.com

�QD48T033050

3

Input Characteristics

Maximum Input Current

3.3 VDC @ 15 ADC, 5.0 VDC @ 10 ADC,

Vin = 36 V

Input Stand-by Current

Vin = 48 V, converter disabled

2.6

Input No Load Current (0 load on the output)

Vin = 48 V, converter enabled

72

mAdc

Input Reflected-Ripple Current

See Figure 36 - 25MHz bandwidth

6

mAPK-PK

Input Voltage Ripple Rejection

120Hz

TBD

dB

3.2

ADC

mAdc

Output Characteristics

Output Voltage Set Point (no load)

3.3 V

5.0 V

-40ºC to 85ºC

-40ºC to 85ºC

3.267

4.950

3.333

5.050

VDC

VDC

FE

Output Regulation

3.300

5.000

±2

±2

mV

mV

-10

-6

mV

mV

LI

Over Line

3.3 V

5.0 V

Over Load2

3.3 V

5.0 V

Cross Regulation3

3.3 V

5.0 V

Output Voltage Range

3.3 V

5.0 V

For Iout2 (5.0 V) change from 0 to 10 A

For Iout1 (3.3 V) change from 0 to 15 A

Over line, load and cross regulation

Over line, load and cross regulation

Full load + 1 μF ceramic

Full load + 1 μF ceramic

F

Output Ripple and Noise - 25MHz bandwidth

3.3 V

5.0 V

Dynamic Response

3.234

4.9

20

25

mV

mV

3.366

5.100

VDC

VDC

30

35

mVPK-PK

mVPK-PK

ΔIout = 25% of IoutMax

O

Load Change: 50% to 75% to 50%

di/dt = 0.1 A/μS

3.3 V

5.0 V

-3

-5

Co = 10 μF tant. + 1 μF ceramic (Fig.23)

Co = 10 μF tant. + 1 μF ceramic (Fig.24)

40

50

mV

mV

100

20

µs

µs

90

90

mV

mV

60

60

µs

µs

3.3 V 100% Load, 5.0V 100% Load

88

%

3.3 V 50% Load, 5.0V 50% Load

89

%

Setting Time to 1%

3.3 V

5.0 V

EN

D

di/dt = 5 A/μS

Co = 300 μF tant. + 1 μF ceramic (Fig.25)

Co = 300 μF tant. + 1 μF ceramic (Fig.26)

3.3 V

5.0 V

Setting Time to 1%

3.3 V

5.0 V

Efficiency

1)

2)

3)

Vout1 and Vout2 can be simultaneously increased or decreased up to 10% via the Trim function. When trimming up, in order

not to exceed the converter‘s maximum allowable output power capability equal to the product of the nominal output voltage

and the allowable output current for the given conditions, the designer must, if necessary, decrease the maximum current

(originally obtained from the derating curves) by the same percentage to ensure the converter’s actual output power remains

at or below the maximum allowable output power.

Load regulation is affected with resistance of the output pins (approximately 0.3 mΩ) since there is no remote sense.

Cross regulation is affected with resistance of the RETURN pin (approximately 0.3 mΩ) since there is no remote sense.

Europe, Middle East

+353 61 225 977

North America

+1 408 785 5200

© 2016 Bel Power Solutions & Protection

BCD.00790_AB

Asia-Pacific

+86 755 298 85888

�QD48T033050

4

FE

These power converters have been designed to be stable with no external capacitors when used in low inductance input

and output circuits.

However, in many applications, the inductance associated with the distribution from the power source to the input of the

converter can affect the stability of the converter. The addition of a 33 µF electrolytic capacitor with an ESR < 1 across

the input helps ensure stability of the converter. In many applications, the user has to use decoupling capacitance at the

load. The converter will exhibit stable operation with external load capacitance up to 10,000 µF on 3.3 V and 4,700uF on 5

V output.

The ON/OFF pin is used to turn the power converter on or off remotely via a system signal. There are two remote control

options available, positive logic and negative logic and both are referenced to Vin(-). Typical connections are shown in

Fig. 1.

Q

TM

Vin (+)

Family

Converter

ON/OFF

Vin

Rload2

LI

(Top View)

Vout2 (+)

TRIM

RTN

Rload1

Vin (-)

Vout1 (+)

F

CONTROL

INPUT

Figure 1. Circuit configuration for ON/OFF function.

EN

D

O

The positive logic version turns on when the ON/OFF pin is at logic high and turns off when at logic low. The converter is on

when the ON/OFF pin is left open.

The negative logic version turns on when the pin is at logic low and turns off when the pin is at logic high. The ON/OFF pin

can be hard wired directly to Vin(-) to enable automatic power up of the converter without the need of an external control

signal.

ON/OFF pin is internally pulled-up to 5 V through a resistor. A mechanical switch, open collector transistor, or FET can be

used to drive the input of the ON/OFF pin. The device must be capable of sinking up to 0.2 mA at a low level voltage of

0.8 V. An external voltage source of ±20 V max. may be connected directly to the ON/OFF input, in which case it should be

capable of sourcing or sinking up to 1 mA depending on the signal polarity. See the Start-up Information section for system

timing waveforms associated with use of the ON/OFF pin.

The converter’s output voltages can be adjusted simultaneously up 10% or down 10% relative to the rated output voltages

by the addition of an externally connected resistor. For output voltage 3.3 V, trim up to 10% is guaranteed only at Vin ≥ 40

V, and it is marginal (8% to 10%) at Vin = 36 V.

The TRIM pin should be left open if trimming is not being used. To minimize noise pickup, a 0.1 µF capacitor is connected

internally between the TRIM and RETURN pins.

Vin

Q Family

Converter

Vout2 (+)

(Top View)

TRIM

TM

Vin (+)

R T-INCR

Rload2

ON/OFF

RTN

Rload1

Vin (-)

Vout1 (+)

Figure 2. Configuration for increasing output voltage.

tech.support@psbel.com

�QD48T033050

5

To increase the output voltage (refer to Fig. 2), a trim resistor, RT-INCR, should be connected between the TRIM (Pin 6) and

RETURN (Pin 5), with a value from the table below.

Q Family

Converter

Vout2 (+)

(Top View)

TRIM

TM

Vin (+)

R T-DECR

Rload2

ON/OFF

Vin

RTN

Rload1

Vin (-)

FE

Vout1 (+)

Figure 3. Configuration for decreasing output voltage.

Δ = percentage of increase or decrease Vout(NOM).

TRIM RESISTOR

(VOUT INCREASE)

Δ [%]

RT-INCR [kΩ]

1

54.9

F

Note 1:

Both outputs are trimmed up or down simultaneously.

LI

To decrease the output voltage, a trim resistor RT-DECR, (Fig. 3) should be connected between the TRIM (Pin 6) and Vout1(+)

pin (Pin 4), with a value from the table below, where:

TRIM RESISTOR

(VOUT DECREASE)

Δ [%]

RT-DECR [kΩ]

68.1

-2

30.1

14.3

-3

17.8

9.31

-4

11.5

6.34

-5

7.68

4.32

-6

5.36

7

2.80

-7

3.48

8

1.69

-8

2.10

9

0.825

-9

1.05

10

0

-10

0

3

4

5

EN

D

6

O

-1

24.9

2

Note 2:

The above trim resistor values match those typically used in industry-standard dual quarter bricks.

Europe, Middle East

+353 61 225 977

North America

+1 408 785 5200

© 2016 Bel Power Solutions & Protection

BCD.00790_AB

Asia-Pacific

+86 755 298 85888

�QD48T033050

6

FE

Input under-voltage lockout is standard with this converter. The converter will shut down when the input voltage drops below

a pre-determined voltage.

The input voltage must be at least 35 V for the converter to turn on. Once the converter has been turned on, it will shut off

when the input voltage drops below 31 V. This feature is beneficial in preventing deep discharging of batteries used in

telecom applications.

LI

The converter is protected against overcurrent or short circuit conditions on both outputs. Upon sensing an over-current

condition, the converter will switch to constant current operation and thereby begin to reduce output voltages. If, due to

current limit, the output voltage Vout1 (3.3 V) drops, than Vout2 (5.0 V) will follow Vout1 with less than 1 V difference. Drop

on Vout2 output due to current limit will not affect voltage on Vout1. For further load increase, if either Vout1 drops below 1

VDC or Vout2 drops below 2 VDC, the converter will shut down (Figs. 29 and 30).

Once the converter has shut down, it will attempt to restart nominally every 100 ms with a 2% duty cycle (Figs. 31 and 32).

The attempted restart will continue indefinitely until the overload or short circuit conditions are removed or the output voltage

Vout1 rises above 1 VDC and Vout2 above 2 VDC.

O

F

The converter will shut down if the output voltage across either Vout1(+) (Pin 4) or Vout2(+) (Pin 7) and RETURN (Pin 5)

exceeds the threshold of the OVP circuitry. The OVP protection is separate for Vout1 and Vout2 with their own reference

independent of the output voltage regulation loops. Once the converter has shut down, it will attempt to restart every 100

ms until the OVP condition is removed.

The converter will shut down under an over temperature condition to protect itself from overheating caused by operation

outside the thermal derating curves, or operation in abnormal conditions such as system fan failure. After the converter has

cooled to a safe operating temperature, it will automatically restart.

EN

D

The converters meet North American and International safety regulatory requirements per UL60950 and EN60950. Basic

Insulation is provided between input and output.

To comply with safety agencies requirements, an input line fuse must be used external to the converter. A 5-A fuse is

recommended for use with this product.

EMC requirements must be met at the end-product system level, as no specific standards dedicated to EMC characteristics

of board mounted component dc-dc converters exist. However, Power Bel Solutions tests its converters to several system

level standards, primary of which is the more stringent EN55022, Information technology equipment - Radio disturbance

characteristics - Limits and methods of measurement.

With the addition of a simple external filter (see application notes), all versions of the QD48T converters pass the requirements

of Class B conducted emissions per EN55022 and FCC, and meet at a minimum, Class A radiated emissions per EN 55022

and Class B per FCC Title 47CFR, Part 15-J. Please contact Power Bel Solutions Applications Engineering for details of this

testing.

tech.support@psbel.com

�QD48T033050

7

VIN

Scenario #1: Initial Startup From Bulk Supply

ON/OFF function enabled, converter started via application of

VIN. See Figure 4.

t1

t2

t3

Comments

ON/OFF pin is ON; system front-end power is

toggled on, VIN to converter begins to rise.

VIN crosses Under-Voltage Lockout protection circuit

threshold; converter enabled.

Converter begins to respond to turn-on command

(converter turn-on delay).

Output voltage VOUT1 reaches 100% of nominal value

ON/OFF

STATE

OFF

ON

VOUT2

VOUT2

VOUT1

Output voltage VOUT2 reaches 100% of nominal

value.

For this example, the total converter startup time (t4- t1) is

typically 4 ms.

FE

Time

t0

VOUT1

t4

t0

t1 t2

t3

t

t4

Comments

VINPUT at nominal value.

Arbitrary time when ON/OFF pin is enabled (converter

enabled).

t2

End of converter turn-on delay.

t3

Output voltage VOUT1 reaches 100% of nominal value.

t4

Output voltage VOUT2 reaches 100% of nominal value.

For this example, the total converter startup time (t4- t1) is

typically 4 ms.

VIN

ON/OFF

STATE OFF

O

F

Time

t0

t1

LI

Figure 4. Start-up scenario #1.

Scenario #2: Initial Startup Using ON/OFF Pin

With VIN previously powered, converter started via ON/OFF pin.

See Figure 5.

EN

D

Scenario #3: Turn-off and Restart Using ON/OFF Pin

With VIN previously powered, converter is disabled and then

enabled via ON/OFF pin. See Figure 6.

ON

VOUT2

VOUT2

VOUT1

VOUT1

t0

t1 t2

t3

t

t4

Figure 5. Startup scenario #2.

VIN

Time

t0

t1

Comments

VIN and VOUT are at nominal values; ON/OFF pin ON.

ON/OFF pin arbitrarily disabled; converter output falls

to zero; turn-on inhibit delay period (100 ms typical) is

initiated, and ON/OFF pin action is internally inhibited.

t2

ON/OFF pin is externally re-enabled.

If (t2- t1) ≤ 100 ms, external action of ON/OFF

pin is locked out by startup inhibit timer.

If (t2- t1) > 100 ms, ON/OFF pin action is

internally enabled.

t3

Turn-on inhibit delay period ends. If ON/OFF pin is

ON, converter begins turn-on; if off, converter awaits

ON/OFF pin ON signal; see Figure 5.

t4

End of converter turn-on delay.

t5

Output voltage VOUT1 reaches 100% of nominal value.

t6

Output voltage VOUT2 reaches 100% of nominal value.

For the condition, (t2- t1) ≤ 100 ms, the total converter startup time

(t6- t2) is typically 104 ms. For (t2- t1) > 100 ms, startup will be

typically 4 ms after release of ON/OFF pin.

100 ms

ON/OFF

STATE OFF

ON

VOUT2

VOUT2

VOUT1

VOUT1

t0

t1

t2

t3 t4

t5 t6

t

Figure 6. Startup scenario #3.

Europe, Middle East

+353 61 225 977

North America

+1 408 785 5200

© 2016 Bel Power Solutions & Protection

BCD.00790_AB

Asia-Pacific

+86 755 298 85888

�QD48T033050

8

FE

The converter has been characterized for many operational aspects, to include thermal derating (maximum load current as

a function of ambient temperature and airflow) for vertical and horizontal mounting, efficiency, start-up and shutdown

parameters, output ripple and noise, transient response to load step-change, overload and short circuit.

The following pages contain specific plots or waveforms associated with the converter. Additional comments for specific

data are provided below.

F

LI

All data presented were taken with the converter soldered to a test board, specifically a 0.060” thick printed wiring board

(PWB) with four layers. The top and bottom layers were not metalized. The two inner layers, comprising two-ounce copper,

were used to provide traces for connectivity to the converter.

The lack of metalization on the outer layers as well as the limited thermal connection ensured that heat transfer from the

converter to the PWB was minimized. This provides a worst-case but consistent scenario for thermal derating purposes.

All measurements requiring airflow were made in Power Bel Solutions vertical and horizontal wind tunnel facilities using

infrared (IR) thermography and thermocouples for thermometry.

Ensuring that the components on the converter do not exceed their ratings is important to maintaining high reliability. If one

anticipates operating the converter at or close to the maximum loads specified in the derating curves, it is prudent to check

actual operating temperatures in the application. Thermographic imaging is preferable; if this capability is not available, then

thermocouples may be used. Power Bel Solutions recommends the use of AWG #40 gauge thermocouples to ensure

measurement accuracy. Careful routing of the thermocouple leads will further minimize measurement error. Refer to Figure

37 for optimum measuring thermocouple location.

The output current at which either any FET junction temperature did not exceed a maximum specified temperature

(120°C) as indicated by the thermographic image, or

(ii) The nominal rating of the converter (15 A on Vout1 and 10 A on Vout2.)

During normal operation, derating curves with maximum FET temperature less than or equal to 120°C should not be

exceeded. Temperature on the PCB at the thermocouple location shown in Fig. 37 should not exceed 118°C in order to

operate inside the derating curves.

EN

D

(i)

O

Available output power and load current vs. ambient temperature and airflow rates are given in Figs. 7-14. Ambient

temperature was varied between 25°C and 85°C, with airflow rates from 30 to 500 LFM (0.15 to 2.5 m/s), and vertical and

horizontal converter mounting.

For each set of conditions, the maximum load current was defined as the lowest of:

Efficiency vs. load current plots are shown in Figs. 15-20 for ambient temperature of 25ºC, airflow rate of 300 LFM (1.5 m/s),

both vertical and horizontal orientations, and input voltages of 36 V, 48 V and 72 V, for different combinations of the loads

on outputs Vout1 and Vout2.

Output voltage waveforms during the turn-on transient using the ON/OFF pin, are shown without and with full rated load

currents (resistive load) in Figs. 21 and 22, respectively.

tech.support@psbel.com

�QD48T033050

9

110

100

100

90

90

80

70

60

50

500 LFM (2.5 m/s)

400 LFM (2.0 m/s)

300 LFM (1.5 m/s)

200 LFM (1.0 m/s)

100 LFM (0.5 m/s)

30 LFM (0.15 m/s)

30

20

60

50

500 LFM (2.5 m/s)

400 LFM (2.0 m/s)

300 LFM (1.5 m/s)

200 LFM (1.0 m/s)

100 LFM (0.5 m/s)

30 LFM (0.15 m/s)

40

30

20

10

10

0

0

20

30

40

50

60

70

80

90

20

30

40

50

60

70

80

90

Ambient Temperature [°C]

Ambient Temperature [°C]

Figure 8. Available output power for balanced load current

(Iout1 = 1.5·Iout2) vs. ambient air temperature and airflow rates

for converter mounted horizontally with Vin = 48 V, air flowing

from pin 3 to pin 4 and maximum FET temperature 120 C.

F

Figure 7. Available output power for balanced load current

(Iout1 = 1.5·Iout2) vs. ambient air temperature and airflow rates

for converter mounted vertically with Vin = 48 V, air flowing

from pin 3 to pin 1 and maximum FET temperature 120 C.

120

120

100

90

80

70

60

500 LFM (2.5 m/s)

400 LFM (2.0 m/s)

300 LFM (1.5 m/s)

200 LFM (1.0 m/s)

100 LFM (0.5 m/s)

30 LFM (0.15 m/s)

50

40

30

O

110

EN

D

% of Max. Load Current Iout1, Iout2

70

LI

40

80

FE

Total Output Power [W]

110

20

10

30

40

50

60

70

110

100

90

80

70

60

500 LFM (2.5 m/s)

400 LFM (2.0 m/s)

300 LFM (1.5 m/s)

200 LFM (1.0 m/s)

100 LFM (0.5 m/s)

30 LFM (0.15 m/s)

50

40

30

20

10

0

0

20

% of Max. Load Current Iout1, Iout2

Total Output Power [W]

Figure 33 shows the output voltage ripple waveform, measured at full rated load current on both outputs with a 1 µF ceramic

capacitor across both outputs. Note that all output voltage waveforms are measured across a 1 F ceramic capacitor.

The input reflected ripple current waveforms are obtained using the test setup shown in Fig. 34. The corresponding

waveforms are shown in Figs. 35 and 36.

80

90

20

30

40

50

60

70

80

90

Ambient Temperature [°C]

Ambient Temperature [°C]

Figure 9. Available balanced load current (Iout1 = 1.5·Iout2)

vs. ambient air temperature and airflow rates for converter

mounted vertical-ly with Vin = 48 V, air flowing from pin 3 to

pin 1 and maximum FET temperature 120 C.

Figure 10. Available balanced load current (Iout1 = 1.5·Iout2)

vs. ambient temperature and airflow rates for converter

mounted horizontally with Vin = 48 V, air flowing from pin 3 to

pin 4 and maximum FET temperature 120 C.

Europe, Middle East

+353 61 225 977

North America

+1 408 785 5200

© 2016 Bel Power Solutions & Protection

BCD.00790_AB

Asia-Pacific

+86 755 298 85888

�QD48T033050

110

110

100

100

90

90

Total Output Power [W]

80

70

60

50

500 LFM (2.5 m/s)

400 LFM (2.0 m/s)

300 LFM (1.5 m/s)

200 LFM (1.0 m/s)

100 LFM (0.5 m/s)

30 LFM (0.15 m/s)

40

30

20

80

70

60

50

500 LFM (2.5 m/s)

400 LFM (2.0 m/s)

300 LFM (1.5 m/s)

200 LFM (1.0 m/s)

100 LFM (0.5 m/s)

30 LFM (0.15 m/s)

40

30

20

10

10

0

0

20

30

40

50

60

70

80

20

90

30

40

60

70

80

90

Figure 12. Available output power for balanced load current

(Iout1 = 1.5·Iout2) vs. ambient air temperature and airflow rates

for converter mounted vertically with Vin = 48 V, air flowing

from pin 4 to pin 3 and maximum FET temperature 120 C.

LI

Figure 11. Available output power for balanced load current

(Iout1 = 1.5·Iout2) vs. ambient air temperature and airflow rates

for converter mounted vertically with Vin = 48 V, air flowing

from pin 3 to pin 4 and maximum FET temperature 120 C.

110

100

90

80

70

40

30

20

O

500 LFM (2.5 m/s)

400 LFM (2.0 m/s)

300 LFM (1.5 m/s)

200 LFM (1.0 m/s)

100 LFM (0.5 m/s)

30 LFM (0.15 m/s)

50

10

0

20

30

110

100

90

80

70

60

F

60

% of Max. Load Current Iout1, Iout2

120

120

40

50

60

70

80

500 LFM (2.5 m/s)

400 LFM (2.0 m/s)

300 LFM (1.5 m/s)

200 LFM (1.0 m/s)

100 LFM (0.5 m/s)

30 LFM (0.15 m/s)

50

40

30

20

10

0

90

20

30

40

Ambient Temperature [°C]

EN

D

Figure 13. Available balanced load current (Iout1 = 1.5·Iout2)

vs. ambient air temperature and airflow rates for converter

mounted vertical-ly with Vin = 48 V, air flowing from pin 3 to

pin 4 and maximum FET temperature 120 C.

0.95

0.90

0.90

0.85

0.85

72 V

48 V

36 V

0.75

60

70

72 V

48 V

36 V

0.70

Iout2 = 5 Adc

Iout2 = 5 Adc

0.65

2

4

6

8

10

90

0.80

0.75

0.70

0

80

Figure 14. Available balanced load current (Iout1 = 1.5·Iout2)

vs. ambient air temperature and airflow rates for converter

mounted vertical-ly with Vin = 48 V, air flowing from pin 4 to

pin 3 and maximum FET temperature 120 C.

0.95

0.80

50

Ambient Temperature [°C]

Efficiency

Efficiency

50

Ambient Temperature [°C]

Ambient Temperature [°C]

% of Max. Load Current Iout1, Iout2

FE

Total Output Power [W]

10

0.65

12

14

16

Load Current Iout1 [Adc]

Figure 15. Efficiency vs. load current Iout1 and input voltage

for converter mounted vertically with air flowing from pin 3 to

pin 1 at a rate of 300 LFM (1.5 m/s), for Iout2 = 5 A and

Ta = º

0

2

4

6

8

10

12

14

16

Load Current Iout1 [Adc]

Figure 16. Efficiency vs. load current Iout1 and input voltage

for converter mounted horizontally with air flowing from pin 3

to pin 4 at a rate of 300 LFM (1.5 m/s), for Iout2 = 5 A and

ºC.

tech.support@psbel.com

�11

0.95

0.95

0.90

0.90

0.85

0.85

Efficiency

0.80

72 V

48 V

36 V

0.75

0.80

72 V

48 V

36 V

0.75

0.70

0.70

Iout1 = 7.5 Adc

Iout1 = 7.5 Adc

0.65

0.65

0

1

2

3

4

5

6

7

8

9

10

0

11

1

2

3

4

5

6

7

8

9

10

11

Load Current Iout2 [Adc]

Load Current Iout2 [Adc]

0.95

Figure 18. Efficiency vs. load current Iout2 and input voltage

for converter mounted horizontally with air flowing from pin 3

to pin 4 at a rate of 300 LFM (1.5 m/s), for Iout1 = 7.5 A and

ºC.

LI

Figure 17. Efficiency vs. load current Iout2 and input voltage

for converter mounted vertically with air flowing from pin 3 to

pin 1 at a rate of 300 LFM (1.5 m/s), for Iout1 = 7.5 A and

ºC.

0.95

0.90

0.90

0.85

0.85

F

Efficiency

Efficiency

FE

Efficiency

QD48T033050

0.80

72 V

48 V

36 V

0.70

0.65

0

2

4

6

8

10

12

14

72 V

48 V

36 V

0.75

O

0.75

0.80

16

0.70

0.65

0

Load Current Iout1 = 1.5·Iout2 [Adc]

2

4

6

8

10

12

14

16

Load Current Iout1 = Iout2 [Adc]

Figure 20. Efficiency vs. balanced load current (Iout1/Iout2 =

const.) and input voltage for converter mounted horizontally

with air flowing from pin 3 to pin 4 at a rate of 300 LFM (1.5

Figure 21. Turn-on transient waveforms at no load current and

Vin = 48 V, triggered via ON/OFF pin. Top trace: ON/OFF

signal (5 V/div.). Bottom traces: Vout1 (blue, 1 V/div.), Vout2

(red, 1 V/div.). Time scale: 1 ms/div.

Figure 22. Turn-on transient waveforms at full rated load

current (resistive) and Vin = 48 V, triggered via ON/OFF pin.

Top trace: ON/OFF signal (5 V/div.). Bottom traces: Vout1

(blue, 1 V/div.), Vout2 (red, 1 V/div.). Time scale: 1 ms/div.

EN

D

Figure 19. Efficiency vs. balanced load current (Iout1 =

1.5·Iout2) and input voltage for converter mounted vertically

with air flowing from pin 3 to pin 1 at a rate of 300 LFM (1.5

Europe, Middle East

+353 61 225 977

North America

+1 408 785 5200

© 2016 Bel Power Solutions & Protection

BCD.00790_AB

Asia-Pacific

+86 755 298 85888

�QD48T033050

FE

12

Figure 23. Output voltage response to Iout1 load current stepchange of 3.75 A (50%-75%-50%) at Iout2 = 5 A and Vin = 48 V.

Ch1 = Vout1 (50 mV/div), Ch2 = Vout2 (50 mV/div), Ch3 = Iout1 (10

A/div.), Ch4 = Iout2 (10 A/div.). Current slew rate: 0.1 A/s, Co =

10 F tantalum + 1 F ceramic. Time scale: 0.5 ms/div.

O

F

LI

Figure 24. Output voltage response to Iout2 load current stepchange of 2.5 A (50%-75%-50%) at Iout1 = 7.5 A and Vin = 48 V.

Ch1 = Vout1 (50 mV/div), Ch2 = Vout2 (50 mV/div), Ch3 = Iout1 (10

A/div.), Ch4 = Iout2 (10 A/div.). Current slew rate: 0.1 A/s, Co =

10 F tantalum + 1 F ceramic. Time scale: 0.5 ms/div.

EN

D

Figure 25. Output voltage response to Iout1 load current stepchange of 3.75 A (50%-75%-50%) at Iout2 = 5 A and Vin = 48 V.

Ch1 = Vout1 (100 mV/div), Ch2 = Vout2 (100 mV/div), Ch3 = Iout1

(10 A/div.), Ch4 = Iout2 (10 A/div.). Current slew rate: 5 A/s, Co =

300 F tantalum + 1 F ceramic. Time scale: 0.5 ms/div.

Figure 27. Output voltage response to both Iout1 and Iout2 (out of

phase) load current step-change of 3.75 A (Iout1) and 2.5 A (Iout2)

(50%-75%-50%) at Vin = 48 V. Ch1 = Vout1 (50 mV/div), Ch2 =

Vout2 (50 mV/div), Ch3 = Iout1 (10 A/div.), Ch4 = Iout2 (10 A/div.).

Current slew rate: 0.1 A/s, Co = 10 F tantalum + 1 F ceramic.

Time scale: 1 ms/div.

Figure 26. Output voltage response to Iout2 load current stepchange of 2.5 A (50%-75%-50%) at Iout1 = 7.5 A and Vin = 48 V.

Ch1 = Vout1 (100 mV/div), Ch2 = Vout2 (100 mV/div), Ch3 = Iout1

(10 A/div.), Ch4 = Iout2 (10 A/div.). Current slew rate: 5 A/s, Co =

300 F tantalum + 1 F ceramic. Time scale: 0.5 ms/div.

Figure 28. Output voltage response to both Iout1 and Iout2 (out of

phase) load current step-change of 3.75 A (Iout1) and 2.5 A (Iout2)

(50%-75%-50%) at Vin = 48 V. Ch1 = Vout1 (100 mV/div), Ch2 =

Vout2 (100 mV/div), Ch3 = Iout1 (10 A/div.), Ch4 = Iout2 (10 A/div.).

Current slew rate: 5 A/s, Co = 300 F tantalum + 1 F ceramic.

Time scale: 1 ms/div.

Note: The only cross-talk during transient is due to the common

RETURN pin for both outputs.

tech.support@psbel.com

�QD48T033050

13

4.0

6.0

Vout1

Vout2

5.0

Vout [Vdc]

Vout [Vdc]

3.0

2.0

4.0

3.0

2.0

1.0

1.0

0

0

5

10

15

0

20

5

10

FE

0

15

Iout [Adc]

Iout [Adc]

LI

Figure 30. Output voltage Vout2 vs. load current Iout2

showing current limit point and converter shutdown point.

When Vout2 is in current limit, Vout1 will follow with less than 1

V difference until Vout2 reaches shut-down threshold of 2 V.

Input voltage has almost no effect on Vout2 current limit

characteristic.

O

F

Figure 29. Output voltage Vout1 vs. load current Iout1

showing current limit point and converter shutdown point.

When Vout1 is in current limit, Vout2 is not affected until Vout1

reaches the shut-down threshold of 1 V. Input voltage has

almost no effect on Vout1 current limit

characteristic.

EN

D

Figure 31. Load current Iout1 into a 10 mΩ short circuit on

Vout1 during re-start, with Vout2 open (no load), at Vin = 48 V.

Ch2 = Iout1 (20 A/div, 20 ms/div). ChB = Iout1 (20 A/div, 1

ms/div) is an expansion of the on-time portion of Iout1.

Figure 32. Load current Iout2 into a 10 mΩ short circuit on

Vout2 during re-start, with Vout1 open (no load), at Vin = 48 V.

Ch2 = Iout2 (20 A/div, 20 ms/div). ChB = Iout2 (20 A/div, 1

ms/div) is an expansion of the on-time portion of Iout2.

iS

10 H

source

inductance

Vsource

Figure 33. Output voltage ripple at full rated load current into a

resistive load on both outputs with Co = 1uF (ceramic) and Vin

= 48 V. Ch2 = Vout2, Ch1 = Vout1 (both 20 mV/div). Time

iC

33 F

ESR