ARM

®

PT32M625

Cortex™-M0 Microcontroller

DESCRIPTION

FEATURES

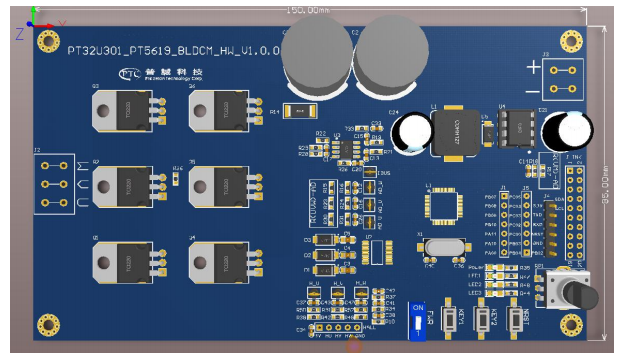

The PT32M625 is a SiP (System in Package) with

mcu PT32U301 and a motor gate driver PT5619. The

PT32M625 microcontroller is a series of low-power

microcontroller incorporating a high-performance

ARM CortexTM-M0 32-bit RISC core. It operates at a

maximum 48Mhz frequency and features up to

32Kbytes of Flash and up to 4Kbytes of SRAM. The

PT5619 is a high-speed 3-phase gate driver for

power MOSFET and IGBT devices with three

independent high and low side referenced output

channels. Built-in dead time protection and

shoot-through protection prevent damage to the

half-bridge.

ARM Cortex M0 Processor

Performance up to 48 MHz

Flash Memory 32K-Byte

System SRAM 4K-Byte

PWM Mode control logic

PT5619

- 90V half-bridge high side driver

- Driver up to 3-phase half-bridge gates

- Built-in dead time control 0.5μs (typ.)

- Shoot-through protection

- Common-mode dV/dt noise cancellation circuit

- Tolerant of negative transient voltage

BLOCK DIAGRAM

Power

POR

GND

4kB INFO

PDR

ARM Cortex-M0

Processor

32kB Flash

VDDA

PVD

NVIC

VDD33

SWD

WAUP

Flash Controller

Clock

UARTx_RXD

S

S

AHB-APB

Bridge#1

PC[11:0]

Three-phase

gate driver

UART 0/1

UARTx_RTS

SPI

AD[7:0]

PB10

PB09

PB[11,4:0]

LW

AHB-APB

Bridge#2

GPIO

A/B/C/D

I2C

PWM 0/1/2

ADC

Watchdog

Timer

VBU

HOU

VSU

VBV

HOV

VSV

VBW

HOW

VSW

LOU

LOV

LOW

SGND

PORT

PORT

System and Clock Controller

S

PB08

PLL

SRAM

(4kB)

High Speed

Bus Matrix

LV

Low Power

Controller

M

LU

LSI OSC.

~30 kHz

PB06

XTAL OSC.

32.768 kHz

HV

HSI OSC.

4 MHz

HW PB07

XTAL OSC.

4-16 MHz

HU PB05

XTAL_OUT

GP Timer 0/1/2

CCPx_B

RTC

Comparator

Tel: 886-2-66296288‧Fax: 886-2-29174598‧ http://www.princeton.com.tw‧2F, No. 233-1, Baociao Rd., Sindian Dist., New Taipei City 23145, Taiwan

�PT32M625

CONTENT

1. ORDER INFORMATION ................................................................................................................................................................. 3

2. PIN CONFIGURATION................................................................................................................................................................... 3

3. PIN DESCRIPTION ........................................................................................................................................................................ 4

3.1 MULTIPLEXING PINS FUNCTION SELECTION ........................................................................................................................ 5

3.2 SIGNAL DESCRIPTION .............................................................................................................................................................. 7

4. FUNCTIONAL DESCRIPTION...................................................................................................................................................... 8

4.1 SYSTEM AND MEMORY OVERVIEW ......................................................................................................................................... 8

4.2 ARM ® CORTEX™-M0 CORE ................................................................................................................................................... 11

4.3 SYSTEM CONTROL (SC) .......................................................................................................................................................... 34

4.4 FLASH CONTROLLER (FC)....................................................................................................................................................... 67

4.5 GENERAL PURPOSE I/O (GPIO) .............................................................................................................................................. 71

4.6 UNIVERSAL ASYNCHRONOUS RECEIVER/TRANSMITTER (UART) ................................................................................... 84

4.7 PULSE WIDTH MODULATION (PWM) .................................................................................................................................... 110

4.8 ANALOG TO DIGITAL CONVERTER (ADC) ........................................................................................................................... 145

4.9 GENERAL PURPOSE TIMERS (GPT) ................................................................................................................................... 178

4.10 ANALOG COMPARATOR (AC) .............................................................................................................................................. 204

4.11 WATCH DOG TIMER (WDT) .................................................................................................................................................. 214

4.12 REAL TIME CLOCK (RTC) ..................................................................................................................................................... 223

4.13 INTER INTEGRATED CIRCUIT (I2C) ..................................................................................................................................... 243

4.14 SERIAL PERIPHERAL INTERFACE (SPI) ............................................................................................................................. 272

4.15 PT5619 FUNCTIONAL DESCRIPTION .................................................................................................................................. 306

5. PT32U301 ELECTRICAL CHARACTERISTICS ....................................................................................................................... 309

5.1 MAXIMUM RATINGS .............................................................................................................................................................. 309

5.2 OPERATING CONDITIONS.................................................................................................................................................... 309

5.3 I/O PIN CHARACTERISTICS.................................................................................................................................................. 309

5.4 ON-CHIP LOW DROP-OUT(LDO) REGULATOR CHARACTERISTICS ................................................................................ 309

5.5 PHASE LOCKED LOOP CHARACTERISTICS ....................................................................................................................... 310

5.6 POWER-ON RESET CHARACTERISTICS ............................................................................................................................ 311

5.7 NRST CHARACTERISTICS.................................................................................................................................................... 312

5.8 8 MHZ XTAL CHARACTERISTICS ......................................................................................................................................... 312

5.9 4 MHZ RCOSC CHARACTERISTICS ..................................................................................................................................... 313

5.10 32 KHZ XTAL .......................................................................................................................................................................... 313

5.11 TEMPERATURE SENSOR CHARACTERISTICS .................................................................................................................. 313

5.12 ADC+ PGA CHARACTERISTICS ........................................................................................................................................... 314

5.13 COMPARATOR CHARACTERISTICS .................................................................................................................................... 315

5.14 RCOSC_32K CHARACTERISTICS ........................................................................................................................................ 315

5.15 POWER CONSUMPTION TABLE .......................................................................................................................................... 316

6

PT5619 ELECTRICAL CHARACTERISTIC ............................................................................................................................ 317

6.1 ABSOLUTE MAXIMUM RATINGS .......................................................................................................................................... 317

6.2 RECOMMENDED OPERATING CONDITIONS ...................................................................................................................... 317

6.3 STATIC ELECTRICAL CHARACTERISTICS.......................................................................................................................... 318

6.4 DYNAMIC ELECTRICAL CHARACTERISTICS ...................................................................................................................... 319

7.

PACKAGE INFORMATION ..................................................................................................................................................... 320

IMPORTANT NOTICE .................................................................................................................................................................... 321

v1.0

2

March 2020

�PT32M625

1. ORDER INFORMATION

Valid Part Number

PT32M625-LQ

Package Type

LQFP 48

Top Code

PT32M625-LQ

VCC

N.C

PB11

PD07

28

27

25

26

LOW

LOU

LOV

32

SGND

N.C

33

29

VSW

34

30

HOW

35

31

VBW

36

2. PIN CONFIGURATION

N.C 37

24

PD08

VSV 38

23

PD09

39

22

PD10

VBV 40

21

PD11_NRST

N.C 41

20

PD12_XTAL_IN

19

PD13_XTAL_OUT

HOV

PT32M625

VSU 42

HOU 43

VBU 44

v1.0

18

PD14_XTAL32_IN

17

PD15_XTAL32_OUT

PA07 12

PA06 11

9

3

PA05 10

7

PA02

PA04

6

PA01

8

5

PA00

PA03

4

PA08

PC02

13

3

PA09

PB01 48

PC01

14

2

VDD33

PB02 47

PC00

VSS33

1

16

15

PB00

N.C 45

PB03 46

March 2020

�PT32M625

3. PIN DESCRIPTION

Each GPIO line can be assigned to one of the peripheral functions. The following table lists out the pin name of all

packages and its respective available alternate function.

Pin Name

PB00

PC00

PC01

PC02

PA00

PA01

PA02

PA03

PA04

PA05

PA06

PA07

PA08

PA09

VDD33

VSS33

PD15_XTAL32_OUT

PD14_XTAL32_IN

PD13_XTAL_OUT

PD12_XTAL_IN

PD11_NRST

PD10

PD09

PD08

PD07

PB11

N.C.

VCC

SGND

LOW

LOV

LOU

VSW

HOW

VBW

VSV

HOV

VBV

VSU

HOU

VBU

PB03

PB02

PB01

v1.0

Pin Type

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Supply

Ground

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Supply

Ground

O

O

O

Supply

O

Supply

Supply

O

Supply

Supply

O

Supply

I/O

I/O

I/O

Description

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

3.3V Voltage Supple

Ground

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

No Connection

Voltage Supply

Logic Ground And Low-Side Gate Drivers Ground

Phase-W Low-Side Gate Driver Output

Phase-V Low-Side Gate Driver Output

Phase-U Low-Side Gate Driver Output

Phase-W High-Side Driver Floating Supply Offset Voltage

Phase-W High-Side Driver Output

Phase-W High-Side Driver Floating Supply

Phase-V High-Side Driver Floating Supply Offset Voltage

Phase-V High-Side Driver Output

Phase-V High-Side Driver Floating Supply

Phase-U High-Side Driver Floating Supply Offset Voltage

Phase-U High-Side Driver Output

Phase-U High-Side Driver Floating Supply

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

General Purpose Digital I/O Pin

4

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27, 33, 37, 41, 45

28

29

30

31

32

34

35

36

38

39

40

42

43

44

46

47

48

March 2020

�PT32M625

3.1 MULTIPLEXING PINS FUNCTION SELECTION

The following tables describes PT32M625’s microcontroller’s available pin and its corresponding alternate function. The

peripheral signals multiplexed to the GPIO lines. Alternate Function (AF) is enabled by configuring the GPIOx_AFRL and

GPIOx_AFRH registers.

Note: In the microcontroller, all pins are in AF0 mode by default, with the exception of following cases:

Crystal Oscillator Pinout: Respective pins PD [15:11] are defaulted to the AF8 functionality.

Serial Wire Debug Interface Pinout: Respective PB [6:5] are defaulted to the AF6 functionality.

*: To enable PT32M625 gate driver functionality, PB [10:5] must be configured to AF7 (PWM signal).

Some pins are not availiabled in PT32M625.

Alternate Functions

Pin Name

AF0

AF1

AF2

AF3

AF4

AF5

SPI_MISO

PWM1_A

CCP1_A

AF6

AF7

AF8

PC06

PC07

PC08

PC09

PC10

PC11

PA00

PA00

UART0_RTS

2

AD0_CAIP0

PA01

PA01

I C_SDA

SPI_MOSI

PWM1_B

CCP1_B

PA02

PA02

UART1_TXD

SPI_MISO

PWM2_A

CCP2_A

AD2_CAIP1

PA03

PA03

UART1_RXD

SPI_MOSI

PWM2_B

CCP_2B

AD3_CAIN1

PA04

PA04

UART1_TXD

PWM1_A

CCP1_A

AD4

PA05

PA05

UART1_RXD

PWM1_B

CCP1_B

AD5

PA06

PA06

UART1_CTS

PWM2_A

CCP2_A

AD6

PA07

PA07

UART1_RTS

PWM2_B

CCP2_B

AD7

PA08

PA08

UART1_TXD

PWM0_A

CCP1_A

CAIP2

PA09

PA09

PWM0_B

CCP0_B

CAIN2

PA10

PA10

CAIP3

PA11

PA11

CAIN3

PD13

XTAL_OUT

PD12

XTAL_IN

I2C_SDA

UART1_RTS

SPI_SCSN

UART1_RXD

AD1_CAIN0

VDDA

VSSA

PD15

XTAL32_O

UT

PD14_

XTAL32_IN

PD13_

XTAL_OUT

PD12_

XTAL_IN

PD11_

NRST

PD11

SPI_SCSN

PD10

PD10

PD09

PD09

SPI_SCSN

PD08

PD08

SPI_SCKK

PD07

PD07

PB11

PB11

PB10

PB10

v1.0

PWM_FALT

CCP1B

PWM1_B

NRST

PWM_FALT

SPI_SCLK

WKUP_V33

PWM2_B*

5

March 2020

�PT32M625

Alternate Functions

Pin Name

PB09

PB09

PB08

PB08

UART1_TXD

SPI_MOSI

PWM_FALT

PWM0_B*

PB07

PB07

I2C_SDA

UART1_RXD

SPI_SCSN

PWM2_B

PWM2_A*

PB06

PB06

UART0_CTS

UART1_CTS

SPI_MOSI

PWM2_A

UART0_TXD

SWCLK

PWM1_A*

PB05

PB05

UART0_RTS

UART1_RTS

SPI_MISO

PWM1_B

UART0_RXD

SWDA

PWM0_A*

UART0_RXD

SWCLK

UART0_CTS

I2C_SCK

SPI_SCKK

PWM1_A

CCP1_A

SWDA

MCO

2

SPI_SCSN

PWM0_B

CCP0_B

2

SPI_MISO

PWM0_A

CCP0_A

RTC_1HZ

PWM2_B

SPI_MISO

PWM1_B*

VDD33

PB04

PB03

PB03

PB02

PB02

PB01

PB01

SPI_MOSI

UART0_TXD

UART0_RXD

I C_SCK

PB00

PB00

PC00

PC00

I C_SDA

PC01

PC01

PWM1_B

PC02

PC02

PWM0_B

PWM_FALT

PC03

PC04

PC05

v1.0

6

March 2020

�PT32M625

3.2 SIGNAL DESCRIPTION

The following table describes the details on signals names classified by peripheral.

Table 3.2-1 : Alternate Function Description

Function Name

I/O

Function Description

Universal Asynchronous Receiver/Transmitter (UART0, UART1), x = 0, 1

UARTx_TXD

O

UART x Data output pins

UARTx_RXD

I

UART x Data Input pins

UARTx_CTSn

I/O

UART x Clear to Send pins

UARTx_RTSn

I/O

UART x Request to Send pins

Serial Wire Debug (SWD)

SWCLK

I

SWD Clock

SWDA

I/O

SWD Data Input/Output

Inter Intergrated Circuit (I2C)

I2C_SDA

I/O

I2C Data

I2C_SCK

I/O

I2C Clock

Serial Peripheral Interface (SPI)

SPI_MISO

I/O

SPI Master Input Slave Output

SPI_MOSI

I/O

SPI Master Output Slave Input

SPI_SCSN

I/O

SPI Chip Select

SPI_SCLK

I/O

SPI Clock

General Purpose Input/Output (GPIO)

PA11-PA00

I/O

GPIO Port A

PB11-PB00

I/O

GPIO Port B

PC11-PC00

I/O

GPIO Port C

PD15-PD04

I/O

GPIO Port D

Pulse Width Modulation (PWM0, PWM1, PWM2), x = 0, 1, 2

PWMx_A

O

PWM x Signals

PWMx_B

O

PWM x Signals

PWM_FALT

I

PWM Fault Input

General-Purpose Timer (GPT0, GPT1, GPT2), x = 0, 1, 2

CCPx_A

I/O

GPTimer x Compare and Capture A

CCPx_B

I/O

GPTimer x Compare and Capture B

Analog to Digital Converter (ADC)

AD[7:0]

ADC Single End Channel Input /

I

*ADC Differential Channel Input Positive or Negative Input

Analog Comparator (AC0, AC1, AC2, AC3), x=0, 1, 2, 3

CAIPx

I

Comparator x Positive Input

CAINx

I

Comparator x Negative Input

System Control (SC)

XTAL32_IN

I

32.768K RTC Clock Input

XTAL32_OUT

O

32.768K RTC Clock Output

XTAL_IN

I

High Speed 8MHZ Crystal Clock Input

XTAL_OUT

O

High Speed 8MHZ Crystal Clock Output

NRST

I

System Reset

WKUP

I

Wakeup

MCO

O

Microcontroller Clock Output

RTC_1HZ

O

RTC 1 Second Output

v1.0

7

March 2020

�PT32M625

4. FUNCTIONAL DESCRIPTION

4.1 SYSTEM AND MEMORY OVERVIEW

The PT32 microcontrollers is a series of low-power microcontrollers incorporating a high-performance ARM

CortexTM-M0 32-bit RISC core operating at a 48 MHz frequency, high-speed embedded memories and an extensive

range of enhanced peripherals and I/O s. A comprehensive set of power-saving modes allows it to be employed in

low-power applications.

The PT32U301 MCUs give you any essential functionality as a General-purpose MCU. With its highly customizable

peripherals, it eases the process of making your own ideal product.

This chapter introduces you to PT32U301 features, its system and memory structure.

v1.0

8

March 2020

�PT32M625

4.1.1 PT32U301 MEMORY MAPPING

The system, bus is implemented as a bus matrix. All system bus addresses are fixed and cannot be remapped.

Figure 4.1-1: Memory Mapping

0x6FFF_FFFF

0xFFFF_FFFF

reserved

0xE001_0000

reserved

Cortex M0 Internal

Peripherals

0xE000_0000

AHB

0x5003_0000

0x5002_0000

reserved

0x5001_0000

0x5000_0000

GPIO A/B/C/D

Eflash Contoller

System Control

0x6002_0000

reserved

AHB Peripherals

0x4802_4000

0x4802_0000

0x5000_0000

ADC

APB2

APB Peripherals 2

0x4800_0000

reserved

APB Peripherals 1

0x4800_C000

0x4000_0000

0x4800_8000

SRAM

0x2000_0000

0x4800_4000

Flash Information

0x4800_0000

0x1FFF_F000

Flash Memory

SPI

UART 0/1

reserved

0x0800_0000

0x4002_0000

0x4001_C000

Code

Comparator

reserved

0x0000_0000

0x4001_0000

0x4000_C000

0x4000_8000

0x4000_4000

0x4000_0000

v1.0

I2C

9

PWM

APB1

RTC

reserved

WDT

GP Timer 0/1/2

March 2020

�PT32M625

Table 4.1-1: Peripheral register boundary addresses

Boundary address

Start

End

Depth

(Byte)

Peripheral Description

Reference

Section

0x0000_0000

0x1FFF_FFFF

6K

Mask ROM, Main Flash memory or System RAM depending

on Booting Configuration

0x0800_0000

0x0800_7FFF

64K

Embedded Flash Memory Field

4.3.2

0x1FFF_F000

0x1FFF_FBFF

3K

Embedded Flash Information Memory Field

4.3.2

0x1FFF_FC00

0x1FFF_FFFF

1K

Embedded Flash Information Memory Field

4.3.2

0x2000_0000

0x2000_0FFF

4K

System RAM

-

0x2000_1000

0x3FFF_FFFF

-

Reserved

-

0x4000_0000

0x4000_3FFF

General-purpose Timer 0/1/2 Control Register

4.7.3

0x4000_4000

0x4000_7FFF

Watchdog Control Register

4.10.3

0x4000_8000

0x4000_BFFF

RTC Control Register

4.10.3

0x4000_C000

0x4000_FFFF

Pulse Width Modulation (PWM) Control Register

0x4001_0000

0x4001_BFFF

0x4001_C000

0x4001_FFFF

0x4002_0000

0x47FF_FFFF

0x4800_0000

BUS

-

AHB

-

Reserved

-

Analog Comparator(AC) Control Register

-

APB1

4.8.4

Reserved

-

0x4800_3FFF

UART 0/1 Control Register

-

0x4800_4000

0x4800_7FFF

SPI Control Register

4.12.3

0x4800_8000

0x4800_BFFF

I2C Control Register

4.12.3

0x4800_C000

0x4801_FFFF

Reserved

0x4802_0000

0x4802_3FFF

ADC Control Register

0x4802_4000

0x4FFF_FFFF

0x5000_0000

0x5000_FFFF

System Control Register

0x5001_0000

0x5001_FFFF

Embedded Flash Control Register

4.5.2

0x5002_0000

0x5002_FFFF

GPIO A/B/C/D Control Register

4.5.2

0x5003_0000

0x6FFF_FFFF

Reserved

-

0x6002_0000

0xDFFF_FFFF

Reserved

-

0xE000_0000

0xE00F_FFFF

ARM ® Cortex™-M0 System Timer (SysTick) Control Register

0xE001_0000

0xFFFF_FFFF

APB2

-

-

Reserved

4.7

4.3

AHB

v1.0

-

Reserved

4.2.1

-

10

March 2020

�PT32M625

4.2 ARM ® CORTEX™-M0 CORE

The ARM Cortex™-M0 processor is the smallest and most energy- efficient ARM processor available. It satisfies the

demand for ever-lower-cost applications with increasing connectivity. The M0 processor is a configurable, multistage,

32-bit RISC processor.

In PT32U301, this processor configures following features:

Built-in Nested Vectored Interrupt Controller (NVIC): 32 external Interrupt

Little-endian

Integrated system timer – SysTick

Halting debug support

Fast multiplier

Support Serial Wire Debug (SWD) connections.

This chapter provide basic information of the following processor peripherals,

CPU System Timer Control (SysTick)

CPU Nested Vectored Interrupt Controller (NVIC)

CPU System Control

For further information, please refer to:

ARM Cortex™-M0 Technical Reference Manual

ARM v6-M Architecture Reference Manual

4.2.1 CPU SYSTEM TIMER CONTROL REGISTER (SYST)

The Cortex™-M0 includes an integrated system timer - SysTick, providing a simple, 24-bit clear-on-write, decrementing,

wrap-on-zero counter with a flexible control mechanism. The counter can be used as a Real Time Operating System

(RTOS) tick timer or as a simple counter.

When the system timer is enabled, it starts counting down from the value in the SysTick Current Value Register

(SYST_CVR) to 0, and reload (wrap) to the value in the SysTick Reload Value Register (SYST_RVR) in the next clock

cycle, then decrements on subsequent clocks. Once the counter transitions to 0, the COUNTFLAG status bit is set. The

COUNTFLAG bit clears on reads.

The SYST_CVR value is UNKNOWN at reset. Before enabling this feature. Software should write to the register to clear

it to zero before enabling the feature. This ensures the timer will count from the SYST_RVR value rather than an arbitrary

value when it is enabled.

If the SYST_RVR is 0, the timer will be maintained with a current value of 0 after it is reloaded with this value. This

mechanism can be used to disable the feature independently from the timer enable bit.

v1.0

11

March 2020

�PT32M625

4.2.2 SYST REGISTER MAPS

Base Address: 0xE000_E000

Offset

Symbol

Type

Reset Value

0x0010

0x0014

0x0018

CSR

RVR

CVR

R/W

R/W

R/W

0x0000_0000

-

See

page

12

13

13

Description

SysTick Control and Status Register

SysTick Reload Value Register

SysTick Current Value Register

SYST_CSR - SYSTICK CONTROL AND STATUS REGISTER

4.2.2.1

The SYST_CSR enables the SysTick features.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

R/W

COUNT

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

R/W

R/W

R/W

CLKSRC

TICKIE

ENABLE

Offset: 0x0010

Bit

Name

Type

Reset

31:17

reserved

RO

0x0

16

COUNT

R/W

0

15:3

reserved

RO

0x0

2

CLKSRC

R/W

0

1

TICKIE

R/W

0

0

ENABLE

R/W

0

v1.0

Description

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Count Flag

0: The SysTick timer has not counted to 0 since the last time this bit was

read.

1: The SysTick timer has counted to 0 since the last time this bit was read

COUNT is cleared on read or by a write to the Current Value register.

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

System Tick Clock Source Selection

0: Clock source is (optional) external reference clock.

1: Core clock used for SysTick.

System Tick Interrupt Enable

0: Counting down to 0 does not cause the SysTick exception to be

pended. Software can use COUNTFLAG to determine if a count to 0 has

occurred.

1: Counting down to 0 will cause the SysTick exception to be pended.

Clearing the SysTick Current Value register by a write in software will not

cause SysTick to be pended.

System Tick Counter Enabled

0: Counter is disabled.

1: Counter operates in a multi-shot manner.

12

March 2020

�PT32M625

SYST_RVR - SYSTICK RELOAD VALUE REGISTER

4.2.2.2

The SYST_RVR specifies the start value to load into the SYST_CVR.

31

RO

30

RO

29

RO

28

RO

27

RO

26

RO

25

RO

24

RO

23

R/W

22

R/W

21

R/W

20

R/W

19

R/W

18

R/W

17

R/W

16

R/W

3

R/W

2

R/W

1

R/W

0

R/W

RELOAD

15

R/W

14

R/W

13

R/W

12

R/W

11

R/W

10

R/W

9

R/W

8

R/W

7

R/W

6

R/W

5

R/W

4

R/W

RELOAD

Offset: 0x0014

Bit

Name

Type

Reset

31:24

reserved

RO

0x0

23:0

RELOAD

R/W

R0

Description

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Reload Value

Value to load into the SysTick Current Value Register (SYST_CVR)

register when the counter reaches 0.

SYST_CVR - SYSTICK CURRENT VALUE REGISTER

4.2.2.3

The SYST_CVR contains the current value of the SysTick counter.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

RO

RO

RO

RO

RO

RO

RO

RO

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

CURRENT

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

CURRENT

Offset: 0x0018

Bit

Name

Type

Reset

31:24

reserved

RO

0x0

23:0

CURRENT

R/W

0

v1.0

Description

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

System Tick Current Value

Current counter value. This is the value of the counter at the time it is

sampled. The counter does not provide read-modify-write protection. The

register is write-clear. A software write of any value will clear the register

to 0.

13

March 2020

�PT32M625

4.2.3 CPU NESTED VECTORED INTERRUPT CONTROLLER (NVIC)

The Cortex™-M0 provides an interrupt controller as an integral part of the exception mode, named as “Nested Vectored

Interrupt Controller (NVIC)”, which is closely coupled with the processor core and provides following features:

Support Nested and Vectored interrupt

Automatic processor state saving and restoration

Reduced and deterministic interrupt latency

32 maskable interrupts

4 levels of priority

The NVIC prioritizes and handles all supported exceptions. All exceptions are handled in “Handler Mode”. This NVIC

architecture supports up to 32 discrete interrupts request (IRQ [31:0]) with up to 4 levels of priority. All of the interrupts

and most of the system exceptions can be configured to different priority levels. When an interrupt occurs, the NVIC will

compare the priority of the new interrupt to the current running one. If the priority of the new interrupt is higher than the

current one, the new interrupt handler will override the current handler.

When an interrupt is accepted, the starting address of the interrupt service routine (ISR) is fetched from a vector table in

memory. There is no need to determine which interrupt is accepted and branch to the starting address of the correlated

ISR by software. While the starting address is fetched, NVIC will also automatically save processor state including the

registers “PC, PSR, LR, R0~R3, R12” to the stack. At the end of the ISR, the NVIC will restore the mentioned registers

from stack and resume the normal execution. Thus it will take less and deterministic time to process the interrupt request.

The NVIC supports “Tail Chaining” which handles back-to-back interrupts efficiently without the overhead of states

saving and restoration and therefore reduces delay time in switching to pending ISR at the end of current ISR. The NVIC

also supports “Late Arrival” which improves the efficiency of concurrent ISRs. When a higher priority interrupt request

occurs before the current ISR starts to execute (at the stage of state saving and starting address fetching), the NVIC will

give priority to the higher one without delay penalty. Thus it advances the real-time capability.

Exceptions Modes and System Interrupt Map

The following table lists the exception models. Software can set four levels of priority on some of these exceptions as well

as on all interrupts. The highest user-configurable priority is denoted as “0” and the lowest priority is denoted as “3”. The

default priority of all the user-configurable interrupts is “0”. Note that priority “0” is treated as the fourth priority on the

system, after three system exceptions “Reset”, “NMI” and “Hard Fault”.

Table 4.2-1: Exception Model

Vector No.

Exception Name

1

Reset

2

3

4 - 10

11

12 - 13

14

15

16 - 47

v1.0

Priority

-3

NMI

Hard Fault

Reserved

SCCall

Reserved

PendSV

Sys Tick

Interrupt(IRQ[31:0])

-2

-1

Reserved

Configurable

Reserved

Configurable

Configurable

Configurable

14

March 2020

�PT32M625

Table 4.2-2: System Interrupt Map

IRQ No.

Name

31

WAKEUP

30

PVD

29 ~ 19

Reserved

18

ADC

17

COMP

16

PWM_FAULT

15

PWM2

14

PWM1

13

PWM0

12

TIMER2

11

TIMER1

10

TIMER0

9

WDT

8

RTC

2

7

IC

6

SPI0

5

UART1

4

UART0

3

GPIO_D

2

GPIO_C

1

GPIO_B

0

GPIO_A

v1.0

Description

CPU Wake Up Interrupt

Power Voltage Detector Interrupt

ADC Interrupt

Analog Comparator Interrupt

PWM Fault Interrupt

PWM2Interrupt

PWM1Interrupt

PWM0 Interrupt

TIMER2 Interrupt

TIMER1 Interrupt

TIMER0 Interrupt

Watch Dog Interrupt

RTC Interrupt

I2C Interrupt

SPI Interrupt

UART1 Interrupt

UART0 Interrupt

GPIO D Port Interrupt

GPIO C Port Interrupt

GPIO B Port Interrupt

GPIO A Port Interrupt

15

March 2020

�PT32M625

4.2.3.1

VECTOR TABLE

When an interrupt is accepted, the processor will automatically fetch the starting address of the interrupt service routine

(ISR) from a vector table in memory. For ARMv6-M, the vector table base address is fixed at 0x00000000. The vector

table contains the initialization value for the stack pointer on reset, and the entry point addresses for all exception

handlers. The vector number on previous page defines the order of entries in the vector table associated with exception

handler entry as illustrated in previous section.

Table 4.2-3: Vector Table Format

Vector Table Word Offset

0

Vector Number

4.2.3.2

Description

SP_main – The Main stack pointer

Exception Entry Pointer using that Vector Number

OPERATION DESCRIPTION

NVIC interrupts can be enabled or disabled by writing to their corresponding Interrupt Set-Enable or Interrupt

Clear-Enable register bit-field. The registers use a write-1-to-enable and write-1-to-clear policy, both registers reading

back the current enabled state of the corresponding interrupts. When an interrupt is disabled, interrupt assertion will

cause the interrupt to become Pending, however, the interrupt will not activate. If an interrupt is Active when it is disabled,

it remains in its Active state until cleared by reset or an exception return. Clearing the enable bit prevents new activations

of the associated interrupt.

NVIC interrupts can be pended/un-pended using a complementary pair of registers to those used to enable/disable the

interrupts, named the Set-Pending Register and Clear-Pending Register respectively. The registers use a

write-1-to-enable and write-1-to-clear policy, both registers reading back the current pended state of the corresponding

interrupts. The Clear-Pending Register has no effect on the execution status of an Active interrupt.

NVIC interrupts are prioritized by updating an 8-bit field within a 32-bit register (each register supporting four interrupts).

The general registers associated with the NVIC are all accessible from a block of memory in the System Control Space

and will be described in next section.

v1.0

16

March 2020

�PT32M625

4.2.4 NVIC REGISTER MAPS

Base Address

Offset

0x0000

0x0080

0x0100

0x0180

0x0300

0x0304

0x0308

0x030C

0x0310

0x0314

0x0318

0x031C

v1.0

0xE000_E100

Symbol

NVIC_ISER

NVIC_ICER

NVIC_ISPR

NVIC_ICPR

NVIC_IPR0

NVIC_IPR1

NVIC_IPR2

NVIC_IPR3

NVIC_IPR4

NVIC_IPR5

NVIC_IPR6

NVIC_IPR7

Type

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

Reset Value

0x0000_0000

0x0000_0000

0x0000_0000

0x0000_0000

0x0000_0000

0x0000_0000

0x0000_0000

0x0000_0000

0x0000_0000

0x0000_0000

0x0000_0000

0x0000_0000

Description

IRQ Set Enable Control Register

IRQ Clear Enable Control Register

IRQ Set Pending Control Register

IRQ Clear Pending Control Register

IRQ0 - IRQ3 Priority Control Register

IRQ4 - IRQ7 Priority Control Register

IRQ8 - IRQ11 Priority Control Register

IRQ12 - IRQ15 Priority Control Register

IRQ16 - IRQ19 Priority Control Register

IRQ20 - IRQ23 Priority Control Register

IRQ24 - IRQ27 Priority Control Register

IRQ28 - IRQ31 Priority Control Register

17

See page

18

18

19

19

20

21

22

23

24

25

26

27

March 2020

�PT32M625

NVIC_ISER - NVIC IRQ SET ENABLE CONTROL REGISTER

4.2.4.1

The NVIC_ISER registers enable interrupts, and show which interrupts are enabled.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

SENTENA

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

SENTENA

Offset: 0x0000

Bit

Name

Type

SETENA

31:0

R/W

Reset

Description

0x0

Interrupt enable

Enable one or more interrupts. Each bit represents and interrupt number

from IRQ0 – IRQ31

0: On a read, indicates the interrupt is disabled.

On a write, no effect

1: On a read, indicates the interrupt is enabled

On a write, enables the interrupt

NVIC_ICER - NVIC IRQ CLEAR ENABLE CONTROL REGISTER

4.2.4.2

The NVIC_ICER registers disable interrupts, and show which interrupts are enabled.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

CLRENA

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

CLRENA

Offset: 0x0080

Bit

Name

31:0

v1.0

CLRENA

Type

Reset

R/W

0x0

Description

Interrupt disable

Disable one or more interrupts. Each bit represents and interrupt number

from IRQ0 to IRQ31.

0: On a read, indicates the interrupt is disabled.

On a write, no effect

1: On a read, indicates the interrupt is enabled

On a write, enables the interrupt

18

March 2020

�PT32M625

NVIC_ISPR - NVIC IRQ SET PENDING CONTROL REGISTER

4.2.4.3

The ISPR registers force interrupts into the pending state, and show which interrupts are pending.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

SETPEND

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

SETPEND

Offset: 0x0100

Bit

Name

31:0

SETPEND

Type

Reset

R/W

0x0

Description

Set Interrupt Pending

Disable one or more interrupts. Each bit represents and interrupt number

from IRQ0 to IRQ31

0: On a read, indicates that the interrupt is not pending.

On a write, no effect

1: On a read, indicates that the interrupt is pending.

On a write, the corresponding interrupt is set to pending even if it is

disabled

NVIC_ICPR - NVIC IRQ CLEAR PENDING CONTROL REGISTER

4.2.4.4

The ICPR registers remove the pending state from interrupts, and show which interrupts are pending.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

CLRPEND

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

CLRPEND

Offset: 0x0180

Bit

31:0

v1.0

Name

CLRPEND

Type

R/W

Reset

Description

0x0

Set Interrupt Pending

Disable one or more interrupts. Each bit represents and interrupt number

from IRQ0 to IRQ31

0: On a read, indicates that the interrupt is not pending.

On a write, no effect

1: On a read, indicates that the interrupt is pending.

On a write, write 1 to clear pending state, so that the corresponding interrupt

in no longer pending

19

March 2020

�PT32M625

NVIC_IPR0 - NVIC IRQ0 - IRQ3 PRIORITY CONTROL REGISTER

4.2.4.5

The IPR0 registers provide an 8-bit priority field for each interrupt and each register holds four priority fields (IRQ [3:0]).

While setting each priority field,“0” always denotes the highest priority and “3” always denotes the lowest priority

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI3

PRI2

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI1

PRI1

Offset: 0x0300

Bit

Name

31:30

PRI3

Type

R/W

Reset

0x0

29:24

reserved

RO

0x0

23:22

PRI2

R/W

0x0

21:16

reserved

RO

0x0

15:14

PRI1

R/W

0x0

13:8

reserved

RO

0x0

7:6

PRI1

R/W

0x0

5:0

reserved

RO

0x0

v1.0

Description

Priority of IRQ3

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ2

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ1

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ0

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

20

April 2020

�PT32M625

NVIC_IPR1 - NVIC IRQ4 - IRQ7 PRIORITY CONTROL REGISTER

4.2.4.6

The IPR1 registers provide an 8-bit priority field for each interrupt and each register holds four priority fields (IRQ [7:4]).

While setting each priority field,“0” always denotes the highest priority and “3” always denotes the lowest priority.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI7

PRI6

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI5

PRI4

Offset: 0x0304

Bit

Name

31:30

PRI7

Type

R/W

Reset

0x0

29:24

reserved

RO

0x0

23:22

PRI6

R/W

0x0

21:16

reserved

RO

0x0

15:14

PRI5

R/W

0x0

13:8

reserved

RO

0x0

7:6

PRI4

R/W

0x0

5:0

reserved

RO

0x0

v1.0

Description

Priority of IRQ7

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ6

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ5

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ4

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

21

April 2020

�PT32M625

NVIC_IPR2 - NVIC IRQ8 - IRQ11 PRIORITY CONTROL REGISTER

4.2.4.7

The IPR2 registers provide an 8-bit priority field for each interrupt and each register holds four priority fields (IRQ [11:8]).

While setting each priority field,“0” always denotes the highest priority and “3” always denotes the lowest priority

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI11

PRI10

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI9

PRI8

Offset: 0x0308

Bit

Name

Type

Reset

Description

Priority of IRQ11

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ10

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ9

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ8

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

31:30

PRI11

R/W

0x0

29:24

reserved

RO

0x0

23:22

PRI10

R/W

0x0

21:16

reserved

RO

0x0

15:14

PRI9

R/W

0x0

13:8

reserved

RO

0x0

7:6

PRI8

R/W

0x0

5:0

reserved

RO

0x0

v1.0

22

April 2020

�PT32M625

NVIC_IPR3 - NVIC IRQ12 - IRQ15 PRIORITY CONTROL REGISTER

4.2.4.8

The IPR3 registers provide an 8-bit priority field for each interrupt and each register holds four priority fields (IRQ [15:12]).

While setting each priority field,“0” always denotes the highest priority and “3” always denotes the lowest priority

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI15

PRI14

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

R/W

RO

RO

RO

RO

RO

PRI13

PRI12

Offset: 0x030C

Bit

Name

31:30

PRI15

Type

R/W

Reset

0x0

29:24

reserved

RO

0x0

23:22

PRI14

R/W

0x0

21:16

reserved

RO

0x0

15:14

PRI13

R/W

0x0

13:8

reserved

RO

0x0

7:6

PRI12

R/W

0x0

5:0

reserved

RO

0x0

v1.0

Description

Priority of IRQ15

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ14

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ13

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ12

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

23

April 2020

�PT32M625

NVIC_IPR4 - NVIC IRQ16 - IRQ19 PRIORITY CONTROL REGISTER

4.2.4.9

The IPR4 registers provide an 8-bit priority field for each interrupt and each register holds four priority fields (IRQ [19:16]).

While setting each priority field,“0” always denotes the highest priority and “3” always denotes the lowest priority

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI19

PRI18

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI17

PRI16

Offset: 0x0310

Bit

Name

Type

Reset

Description

31:30

PRI19

R/W

0x0

29:24

reserved

RO

0x0

23:22

PRI18

R/W

0x0

21:16

reserved

RO

0x0

15:14

PRI17

R/W

0x0

13:8

reserved

RO

0x0

7:6

PRI16

R/W

0x0

5:0

reserved

RO

0x0

Priority of IRQ19

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ18

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ17

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ16

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

v1.0

24

April 2020

�PT32M625

4.2.4.10 NVIC_IPR5 - NVIC IRQ20 - IRQ23 PRIORITY CONTROL REGISTER

The IPR5 registers provide an 8-bit priority field for each interrupt and each register holds four priority fields (IRQ [23:20]).

While setting each priority field,“0” always denotes the highest priority and “3” always denotes the lowest priority.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI23

PRI22

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI21

PRI20

Offset: 0x0314

Bit

Name

31:30

PRI23

Type

R/W

Reset

0x0

29:24

reserved

RO

0x0

23:22

PRI22

R/W

0x0

21:16

reserved

RO

0x0

15:14

PRI21

R/W

0x0

13:8

reserved

RO

0x0

7:6

PRI20

R/W

0x0

5:0

reserved

RO

0x0

v1.0

Description

Priority of IRQ23

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ22

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ21

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ20

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

25

April 2020

�PT32M625

4.2.4.11 NVIC_IPR6 - NVIC IRQ24 - IRQ27 PRIORITY CONTROL REGISTER

The IPR6 registers provide an 8-bit priority field for each interrupt and each register holds four priority fields (IRQ [27:24]).

While setting each priority field, ”0” always denotes the highest priority and “3” always denotes the lowest priority.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI27

PRI26

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI25

PRI24

Offset: 0x0318

Bit

Name

31:30

PRI27

Type

R/W

Reset

0x0

29:24

reserved

RO

0x0

23:22

PRI26

R/W

0x0

21:16

reserved

RO

0x0

15:14

PRI25

R/W

0x0

13:8

reserved

RO

0x0

7:6

PRI24

R/W

0x0

5:0

reserved

RO

0x0

v1.0

Description

Priority of IRQ27

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ26

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ25

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ24

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

26

April 2020

�PT32M625

4.2.4.12 NVIC_IPR7 - NVIC IRQ28 - IRQ31 PRIORITY CONTROL REGISTER

The IPR7 registers provide an 8-bit priority field for each interrupt and each register holds four priority fields (IRQ [31:28]).

While setting each priority field,“0” always denotes the highest priority and “3” always denotes the lowest priority

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI31

PRI30

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

RO

RO

RO

RO

PRI29

PRI28

Offset: 0x031C

Bit

Name

31:30

PRI31

Type

R/W

Reset

0x0

29:24

reserved

RO

0x0

23:22

PRI30

R/W

0x0

21:16

reserved

RO

0x0

15:14

PRI29

R/W

0x0

13:8

reserved

RO

0x0

7:6

PRI28

R/W

0x0

5:0

reserved

RO

0x0

v1.0

Description

Priority of IRQ31

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ30

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ29

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Priority of IRQ28

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

27

April 2020

�PT32M625

4.2.5 CPU SYSTEM CONTROL

The Cortex™-M0 status and operating mode control are managed by CPU System Control Registers. Including CPUID,

Cortex™-M0 interrupt priority and Cortex™-M0 power management can be controlled through these system control

registers.

4.2.6 CPU SYSTEM CONTROL REGISTER MAP

Base Address 0xE000_ED00

Offset

Symbol

Type

Reset Value

0x0000

0x0004

0x000C

0x0010

0x001C

0x0020

SYS_CPUID

SYS_ICSR

SYS_AIRCR

SYS_SCR

SYS_SHPR2

SYS_SHPR3

R/W

R/W

R/W

R/W

R/W

R/W

0x410C_C200

0x0000_0000

0xFA05_0000

0x0000_0000

0x0000_0000

0x0000_0000

Description

System CPUID Register

System Interrupt Control and State Register

System Application Interrupt and Reset Control Register

System Control Register

System Handler Priority Register 2

System Handler Priority Register 3

See

page

28

29

31

32

33

33

SYS_CPUID – CPU ID REGISTER

4.2.6.1

This register provide identification for the processor.

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

R/W

R/W

R/W

R/W

IMPC

PART

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

R/W

R/W

RO

RO

RO

RO

RO

RO

R/W

R/W

RO

RO

R/W

R/W

R/W

R/W

PARTNO

REV

Offset: 0x0000

Bit

Name

Type

Reset

31:24

IMPC

RO

0x41

23:20

reserved

RO

0x0

19:16

15:4

3:0

PART

PARTNO

REV

R/W

RO

R/W

0xC

0xC20

0x0

v1.0

Description

Implementer Code Assigned By ARM

ARM = 0x41

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Architecture Of The Processor

Part Number Of The Processor

Revision Number

28

April 2020

�PT32M625

SYS_ICSR - INTERRUPT CONTROL AND STATE REGISTER

4.2.6.2

This register controls and provides status information.

31

RO

30

RO

29

RO

NMISP

15

RO

14

RO

28

R/W

27

WO

26

R/W

25

WO

PENDSV

PENDSVC

PENDST

PENDSTC

12

RO

11

RO

10

RO

9

RO

13

RO

24

RO

8

RO

23

RO

22

RO

ISRPRE

SRPEND

7

RO

6

RO

VTPEND

21

RO

20

RO

19

RO

18

RO

17

RO

16

RO

VTPEND

5

RO

4

RO

3

RO

2

RO

1

RO

0

RO

VTACT

Offset: 0x0004

Bit

Name

Type

Reset

31

NMISP

RO

0

30:29

reserved

RO

0x0

28

PENDSV

R/W

0

27

PENDSVC

WO

0

26

PENDST

R/W

0

25

PENDSTC

WO

0

24

reserved

RO

0x0

23

ISRPRE

RO

0

22

SRPEND

RO

0

21:18

reserved

RO

0x0

v1.0

Description

NMI (Non-Maskable Interrupt) Set Pending

0: On a read, indicates an NMI exception is not pending. On a write, no

effect.

1: On a read, indicates an NMI exception is pending. On a write, changes

the NMI exception state to pending.

Because NMI is the highest-priority exception, normally the processor

enters the NMI exception handler as soon as it detects a write of 1 to this

bit. Entering the handler then clears this bit to 0. This means a read of this

bit by the NMI exception handler returns 1 only if the NMI signal is

reasserted while the processor is executing that handler.

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

PendSV Set Pending

0: On a read, indicates a PendSV exception is not pending. On a write,

no effect.

1: On a read, indicates a PendSV exception is pending. On a write,

changes the PendSV exception state to pending.

Only by writing a ‘1’ to this bit can set the PendSC exception state to

pending

PendSV Clear Pending

0: No effect.

1: Removes the pending state from the PendSV exception

SysTick Exception Set-Pending Bit

0: On a read, indicates a SysTick exception is not pending. On a write, no

effect.

1: On a read, indicates a SysTick exception is pending. On a write,

changes the PendSV exception state to pending.

SysTick Exception Clear-Pending Bit

0: No effect.

1: Removes the pending state from the SysTick exception

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Debug Interrupt Handling

0: The release from halt does not take an interrupt

1: A pending exception will be serviced On Exit From The Debug Halt

State.

Interrupt Pending Flag, Excluding NMI And Faults

0: Interrupt is not pending

1: Interrupt is pending

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

29

April 2020

�PT32M625

Bit

Name

Type

Reset

17:12

VTPEND

RO

0x0

11:6

reserved

RO

0x0

5:0

VTACT

RO

0x0

v1.0

Description

Interrupt Pending Vector Number

0: No pending exceptions.

Non-zero: Exception number of the highest priority pending enabled

exception.

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Interrupt Pending Vector Number

This field contains the active exception number.

0: Thread mode.

Non-zero: Exception number of the currently active exception.

30

April 2020

�PT32M625

4.2.6.3

SYS_AIRCR - APPLICATION INTERRUPT AND RESET CONTROL REGISTER

This register sets or returns interrupt control data.

31

R/W

30

R/W

29

R/W

28

R/W

27

R/W

26

R/W

25

R/W

24

R/W

23

R/W

22

R/W

21

R/W

20

R/W

19

R/W

18

R/W

17

R/W

16

R/W

7

RO

6

RO

5

RO

4

RO

3

RO

2

R/W

1

R/W

0

RO

SYSRERQ

VTACTC

VTKEY

15

RO

14

RO

13

RO

Offset: 0x000C

Bit

Name

12

RO

11

RO

10

RO

Type

Reset

31:16

VTKEY

R/W

0xFA05

15:3

reserved

RO

0x0

2

SYSRERQ

R/W

0

1

VTACTC

R/W

0

0

reserved

RO

0x0

v1.0

9

RO

8

RO

Description

Register Access Key

When writing to this register, the VTKEY field need to be set to 0x05FA,

otherwise the write operation would be ignored. The VECTORKEY filed

is used to prevent accidental write to this register from resetting the

system or clearing of the exception status.

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

System Reset Request

0: Do not request a rest

1: Request a reset

Clear Active NMI / Fault

Reserved for debug use. When writing to the register, user must write 0

to this bit, otherwise behavior is unpredictable.

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

31

April 2020

�PT32M625

SYS_SCR - SYSTEM CONTROL REGISTER

4.2.6.4

The SCR controls features of entry to and exit from low power state.

31

RO

30

RO

29

RO

28

RO

27

RO

26

RO

25

RO

24

RO

23

RO

22

RO

21

RO

20

RO

19

RO

18

RO

17

RO

16

RO

15

RO

14

RO

13

RO

12

RO

11

RO

10

RO

9

RO

8

RO

7

RO

6

RO

5

RO

4

RO

3

RO

2

R/W

1

R/W

0

RO

SLPDEEP

SLPONEXIT

EVONPEND

Offset: 0x0010

Bit

Name

Type

Reset

31:5

reserved

RO

0x0

4

EVONPEND

RO

0x0

3

reserved

RO

0x0

2

SLPDEEP

R/W

0

1

SLPONEXIT

R/W

0

0

reserved

RO

0x0

v1.0

Description

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Send Event On Pending Bit

0: Only enabled interrupts or events can wake the processor up.

(Disabled interrupts are not included)

1: All enabled interrupts, event and disabled interrupts can wake the

processor up.

When an event or interrupt enters pending state, the event signal wakes

up the processor from WFE. If the processor is not waiting for an event,

the event is registered and affects the next WFE.

The processor also wakes up on execution of an SEV instruction or an

external event.

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

Deep Sleep and Sleep Mode selection

Controls whether the processor uses sleep or deep sleep as its low

power mode:

0: Sleep Mode.

1: Deep Sleep Mode.

Sleep-On-Exit Enable

0: Do not sleep when returning to Thread mode.

1: Enter Sleep or Deep Sleep when returning from ISR to Thread Mode.

Setting this bit to 1 enables an interrupt driven application to avoid

returning to an empty main application.

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

32

April 2020

�PT32M625

SYS_SHPR2 - SYSTEM HANDLER PRIORITY REGISTER 2

4.2.6.5

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

R/W

R/W

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

PRISH11

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

RO

Offset: 0x001C

Bit

Name

Type

Reset

31:30

PRISH11

R/W

0

29:0

reserved

RO

0x0

Description

Priority of System Handler 11 – SVCall

“0” denotes the highest priority and “3” denotes the lowest priority

Software should not rely on the value of a reserved bit. Considering the

compatibility with other products, the values of this should not be written

or read.

SYS_SHPR3 - SYSTEM HANDLER PRIORITY REGISTER 3

4.2.6.6

31