DATASHEET

ISL68201

FN8696

Rev.5.00

Jul 12, 2018

Single-Phase R4 Digital Hybrid PWM Controller with PMBus/SMBus/I2C and PFM

The ISL68201 is a single-phase, synchronous buck PWM

controller featuring the Renesas proprietary R4™ Technology.

It supports a wide 4.5V to 24V input voltage range and a wide

0.5V to 5.5V output range. Integrated LDOs provide controller

bias voltage, allowing for single supply operation. The

ISL68201 includes a PMBus/SMBus/I2C interface for device

configuration and telemetry (VIN, VOUT, IOUT, and temperature)

and fault reporting.

The Renesas proprietary R4 control scheme has extremely fast

transient performance, accurately regulated frequency control,

and all internal compensation. An efficiency enhancing PFM

mode can be enabled to greatly improve light-load efficiency.

The ISL68201’s serial bus allows for easy R4 loop

optimization, resulting in fast transient performance over a

wide range of applications, including all ceramic output filters.

The ISL68201 has four 8-bit configuration pins, which provide

very flexible configuration options (frequency, VOUT, R4 gain,

etc.) without the need for built-in NVM memory. This results in

a design flow that closely matches traditional analog

controllers, while still offering the design flexibility and feature

set of a digital PMBus/SMBus/I2C interface. The ISL68201

also features remote voltage sensing and completely eliminates

any potential difference between remote and local grounds. This

improves regulation and protection accuracy. A precision enable

input is available to coordinate the start-up of the ISL68201 with

other voltage rails, especially useful for power sequencing.

Applications

• High efficiency and high density POL digital power

• FPGA, ASIC, and memory supplies

• Data center: servers, storage systems

• Wired infrastructure: routers, switches, and optical

networking

Features

• Renesas proprietary R4 Technology

- Linear control loop for optimal transient response

- Variable frequency and duty cycle control during load

transient for fastest possible response

- Inherent voltage feed-forward for wide range input

• Input voltage range: 4.5V to 24V

• Output voltage range: 0.5V to 5.5V

• ±0.5% DAC accuracy with remote sense

• Support all ceramic solutions

• Integrated LDOs for single input rail solution

• SMBus/PMBus/I2C compatible, up to 1.25MHz

• 256 boot-up voltage levels with a configuration pin

• Eight switching frequency options from 300kHz to 1.5MHz

• PFM operation option, compatible with ISL99140 for

improved light-load efficiency

• Start-up into precharged load

• Precision enable input to set higher input UVLO and power

sequence as well as fault reset

• Power-good monitor for soft-start and fault detection

• Comprehensive fault protection for high system reliability

- Over-temperature protection

- Output overcurrent and short-circuit protection

- Output overvoltage and undervoltage protection

- Open remote sense protection

• Compatible with 5V or 3.3V PWM input DrMOS or Smart

Power Stage (SPS)

• Compatible with PowerNavigator software

• Wireless infrastructure: base stations

Related Literature

For a full list of related documents, visit our website

• ISL68201 product page

TABLE 1. SINGLE-PHASE R4 DIGITAL HYBRID PWM CONTROLLER OPTIONS

PART

NUMBER

INTEGRATED

DRIVER

PWM

OUTPUT

PMBus/SMBus/I2C

INTERFACE

ISL68200

Yes

No

Yes

Discrete MOSFETs or Dual Channel MOSFETs

ISL68201

No

Yes

Yes

Renesas Power Stages:

ISL99140, ISL99227, ISL99125B, ISL99135B

Renesas Drivers:

ISL6596, ISL6609, ISL6627, ISL6622, ISL6208

FN8696 Rev.5.00

Jul 12, 2018

COMPATIBLE DEVICES

Page 1 of 33

�ISL68201

Table of Contents

Typical Applications Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pin Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Functional Pin Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Thermal Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Recommended Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IC Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable and Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resistor Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Soft-Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Boot-Up Voltage Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermal Monitoring and Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IOUT Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PGOOD Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PFM Mode Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SMBus, PMBus, and I2C Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

R4 Modulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

10

10

10

12

12

16

18

19

20

21

21

21

26

General Application Design Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Filter Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Capacitor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Design and Layout Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage Regulator Design Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

28

28

29

30

Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Package Outline Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

FN8696 Rev.5.00

Jul 12, 2018

Page 2 of 33

�ISL68201

Typical Applications Circuits

1.0µ F

4.7µ F

VCC

PV C C

7VLD O

4.75 TO 24V

V IN

1.0µ F

2

I C/

S M B us/

PM B us

SA LE R T

ISL99140

SC L

SD A

PG O O D

FC CM

PGOOD

EN

PW M

PW M

LG

LG IN

IO U T

V O UT < 7VLD O

UG

EN

V CC

BOOT

‐ 1.7V

0.5V TO 5.5V

PH A S E

100

10k

N TC

VC C

1.54k

VC C

N TC

4

0.1µ F N CP 18X H 103J03R B

B E TA = 3380

PR O G 1-4

C SE N

C SR TN

VSEN

RGND

GND

FIGURE 1. WIDE RANGE INPUT AND OUTPUT APPLICATIONS

1.0µF

4.7µF

VCC

PVCC

VIN

7VLDO

4.5 TO 5.5V

1.0µF

2

I C/

SMBus/

PMBus

SALERT

ISL99140

SCL

SDA

PGOOD

FCCM

PGOOD

EN

PWM

PWM

PHASE

LG

LGIN

IOUT

‐

V OUT < 7VLDO 1.7V

0.5V TO 2.5V

UG

EN

VCC

BOOT

100

10k

VCC

NTC

1.54k

VCC

NTC

0.1µF

4

PROG1-4

NCP18XH103J03RB

BETA = 3380

CSEN

CSRTN

VSEN

RGND

GND

FIGURE 2. 5V INPUT APPLICATION

FN8696 Rev.5.00

Jul 12, 2018

Page 3 of 33

�PROG4

SCL

SDA SALERT

PROG2

ISL68201

FN8696 Rev.5.00

Jul 12, 2018

Block Diagram

PROG3

7VLDO VIN PVCC

POR

VCC

SOFT-START

AND

FAULT LOGIC

SMBus/PMBus/I2C

INTERFACE

EN

OTP

OCP

VIN VOUT IOUT

TEMP

FCCM

DRIVER

FCCM

PGOOD

CIRCUITRY

PGOOD

LGIN

PWM AND PFM

CONTROL

RGND

-

VSEN

INTERNAL

COMPENSATION

+ AMPLIFIER

PVCC

OVERVOLTAGE/

UNDERVOLTAGE

PWM

DRIVER

PWM

GND

5V LDO

R4

MODULATOR

PROG1

VIN

7V LDO

REFERENCE

VOLTAGE

CIRCUITRY

OVERCURRENT (OCP) AND

OVER-TEMPERATURE (OTP)

SWITCHING

FREQUENCY

CURRENT SENSE

AND TEMPERATURE

COMPENSATION

7VLDO

CSEN

CSRTN

NTC

GND

Page 4 of 33

IOUT

FIGURE 3. ISL68201 SIMPLIFIED FUNCTIONAL BLOCK DIAGRAM

�ISL68201

Ordering Information

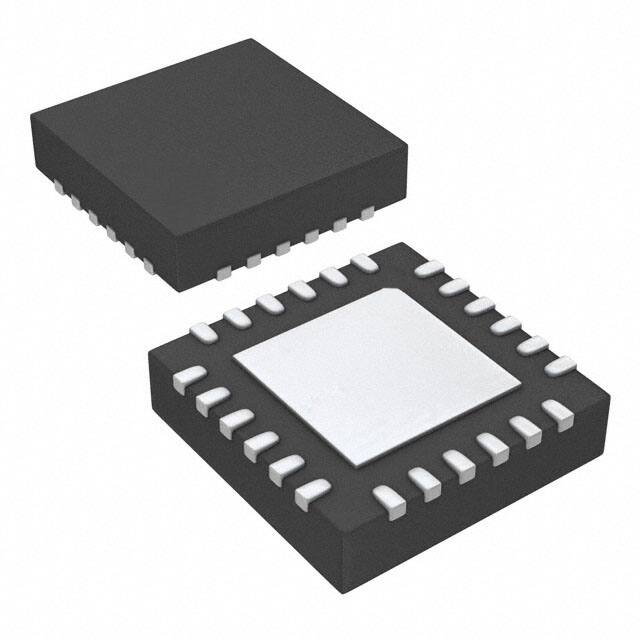

PART NUMBER

(Notes 2, 3)

PART

MARKING

TEMP RANGE

(°C)

TAPE AND REEL

(UNITS) (Note 1)

PACKAGE

(RoHS Compliant)

PKG.

DWG. #

ISL68201IRZ

ISL 68201I

-40 to +85

-

24 Ld 4x4 QFN

L24.4x4C

ISL68201IRZ-T

ISL 68201I

-40 to +85

6k

24 Ld 4x4 QFN

L24.4x4C

ISL68201IRZ-T7A

ISL 68201I

-40 to +85

250

24 Ld 4x4 QFN

L24.4x4C

ISL68201IRZ-TK

ISL 68201I

-40 to +85

1k

24 Ld 4x4 QFN

L24.4x4C

ISL68201-99125DEMO1Z

16A Demo Board with On-Board Transient

ISL68201-99135DEMO1Z

20A Demo Board with On-Board Transient

ISL68201-99140DEMO1Z

35A Demo Board with On-Board Transient

NOTES:

1. Refer to TB347 for details about reel specifications.

2. These Pb-free plastic packaged products employ special Pb-free material sets, molding compounds/die attach materials, and 100% matte tin plate

plus anneal (e3 termination finish, which is RoHS compliant and compatible with both SnPb and Pb-free soldering operations). Pb-free products are

MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-020.

3. For Moisture Sensitivity Level (MSL), see the ISL68201 product information page. For more information about MSL, see TB363.

Pin Configuration

LGIN

PVCC

PWM

GND

FCCM

GND

24 LD 4X4 QFN

TOP VIEW

24

23

22

21

20

19

EN

1

18

PROG1

VIN

2

17

PROG2

7VLDO

3

16

PROG3

VCC

4

15

PROG4

SCL

5

14

IOUT

SALERT

6

13

NTC

7

8

9

10

11

12

SDA

PGOOD

RGND

VSEN

CSRTN

CSEN

GND

(PAD)

Functional Pin Descriptions

PIN NUMBER

SYMBOL

DESCRIPTION

1

EN

Precision enable input. Pulling EN above the rising threshold voltage initiates the soft-start sequence, while pulling EN below the

failing threshold voltage suspends the Voltage Regulator (VR) operation.

2

VIN

Input voltage pin for the R4 loop and LDOs (5V and 7V). Place a high quality low ESR ceramic capacitor (1.0μF, X7R) in

close proximity to the pin. An external series resistor is not advised.

3

7VLDO

4

VCC

Logic bias supply that should be connected to PVCC rail externally. Place a high quality low ESR ceramic capacitor

(1μF, X7R) from this pin to GND.

5

SCL

Synchronous clock signal input of SMBus/PMBus/I2C.

6

SALERT

7

SDA

FN8696 Rev.5.00

Jul 12, 2018

7V LDO from VIN biases the current sensing amplifier. Place a high quality low ESR ceramic capacitor (1.0μF, X7R, 10V+) in

close proximity to the pin.

Output pin for transferring the active low signal driven asynchronously from the VR controller to the SMBus/PMBus.

I/O pin for transferring data signals between the SMBus/PMBus/I2C host and VR controller.

Page 5 of 33

�ISL68201

Functional Pin Descriptions (Continued)

PIN NUMBER

SYMBOL

8

PGOOD

9

RGND

This pin monitors the negative rail of the regulator output. Connect to ground at the point of regulation.

10

VSEN

This pin monitors the positive rail of the regulator output. Connect to the point of regulation.

11

CSRTN

12

CSEN

13

NTC

Input pin for the temperature measurement. Connect this pin through an NTC thermistor (10kΩ, ~ 3380) and a decoupling

capacitor (~0.1μF) to GND, and a resistor (1.54kΩ)to VCC of the controller. The voltage at this pin is inversely proportional to

the VR temperature.

14

IOUT

Output current monitor pin. An external resistor sets the gain and an external capacitor provides the averaging function; an

external pull-up resistor to VCC is recommended to calibrate the no load offset. See “IOUT Calibration” on page 19.

15

PROG4

Programming pin for Modulator (R4) RR impedance and output slew rate during Soft-Start (SS) and Dynamic VID (DVID).

It also sets AV gain multiplier to 1x or 2x and determines the AV gain on PROG3.

16

PROG3

Programming pin for ultrasonic PFM operation, fault behavior, switching frequency, and R4 (AV) control loop gain.

17

PROG2

Programming pin for PWM/PFM mode, temperature compensation, and serial bus (SMBus/PMBus/I2C) address.

18

PROG1

Programming pin for boot-up voltage.

19, 21

GND

Ground pin, connect directly to system ground plane.

20

FCCM

Output signal low to work with DrMOS ISL99140 for diode emulation in PFM mode; signal high for PWM mode.

22

PWM

PWM output and is compatible with 3.3V or 5V PWM input external driver, DrMOS, or Smart Power Stage.

23

PVCC

Output of the 5V LDO and input for the LGATE and UGATE MOSFET driver circuits. Place a high quality low ESR ceramic

capacitor (4.7μF or higher, X7R) in close proximity to the pin.

24

LGIN

Low-side gate signal input to complete the internal FLL loop. A 100Ω series impedance from low-side gate drive signal to

this pin is required.

PAD

GND

Return of logic bias supply VCC. Connect directly to the system ground plane with at least four vias.

FN8696 Rev.5.00

Jul 12, 2018

DESCRIPTION

Power-good, open-drain indicator output.

This pin monitors the negative flow of output current with a series resistor and for overcurrent protection and telemetry.

The series resistor sets the current gain and should be within 40Ωand 3.5kΩ.

This pin monitors the positive flow of output current for overcurrent protection and telemetry.

Page 6 of 33

�ISL68201

Absolute Maximum Ratings

Thermal Information

VCC, PVCC, VSEN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to +7.0V

Input Voltage, VIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +27V

7VLDO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-0.3V to GND, 7.75V

All Other Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0.3V to GND, VCC + 0.3V

ESD Rating

Human Body Model (Tested per JS-001-2010) . . . . . . . . . . . . . . . . .2.5kV

Machine Model (Tested per JESD22-A115C) . . . . . . . . . . . . . . . . . 200V

Charge Device Model (Tested per JS-002-2014) . . . . . . . . . . . . . . . . 1kV

Latch-Up (Tested per JESD78D, Class 2, Level A) . . . . ±100mA at +125°C

Thermal Resistance (Typical)

JA (°C/W) JC (°C/W)

24 Ld QFN (Notes 4, 5) . . . . . . . . . . . . . . . .

39

2.5

Junction Temperature Range . . . . . . . . . . . . . . . . . . . . . . .-55°C to +150°C

Storage Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-65°C to +150°C

Pb-Free Reflow Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . see TB493

Recommended Operating Conditions

Ambient Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . -40°C to +85°C

Wide Range Input Voltage, VIN, Figure 1 . . . . . . . . . . . . . . . . . 4.75V to 24V

5V Application Input Voltage, VIN, VCC, PVCC, Figure 2 . . . . . . 4.5V to 5.5V

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product

reliability and result in failures not covered by warranty.

NOTES:

4. JA is measured in free air with the component mounted on a high-effective thermal conductivity test board with “direct attach” features. See TB379.

5. For JC, the “case temp” location is the center of the exposed metal pad on the package underside.

Electrical Specifications

-40°C to +85°C, unless otherwise stated.

All typical specifications TA = +25°C, VCC = 5V. Boldface limits apply across the operating temperature range,

PARAMETER

MIN

(Note 6)

TYP

MAX

(Note 6)

UNIT

EN = 5V, VCC = 5V, fSW = 500kHz, DAC = 1V

14

16.5

mA

EN = 0V, VCC = 5V

14

16.5

mA

EN = 5V, VCC = 5V, fSW = 500kHz, DAC = 1V

2

SYMBOL

TEST CONDITIONS

VCC AND PVCC

VCC Input Bias Current

PVCC Input Bias Current

IVCC

IPVCC

EN = 0V, VCC = 5V

mA

1.0

mA

4.2

4.35

V

3.95

4.15

V

4.2

4.35

V

3.80

3.95

4.15

V

VCC AND VIN POR THRESHOLD

VCC, PVCC Rising POR Threshold Voltage

VCC, PVCC Falling POR Threshold Voltage

3.80

VIN, 7VLDO Rising POR Threshold Voltage

VIN, 7VLDO Falling POR Threshold Voltage

ENABLE INPUT

EN High Threshold Voltage

VENTHR

0.81

0.84

0.87

V

EN Low Threshold Voltage

VENTHF

0.71

0.76

0.81

V

DAC ACCURACY

DAC Accuracy

(TA = 0°C to +85°C)

DAC Accuracy

(TA = -45°C to +85°C)

2.5V < DAC ≤ 5.5V

-0.5

0.5

%

1.6V < DAC ≤ 2.5V

-0.75

0.75

%

1.2V < DAC ≤ 1.6V

-10

10

mV

0.5V ≤ DAC ≤ 1.2V

-8

8

mV

2.5V < DAC ≤ 5.5V

-0.75

0.75

%

1.6V < DAC ≤ 2.5V

-1.0

1.0

%

1.2V < DAC ≤ 1.6V

-11

11

mV

0.5V ≤ DAC ≤ 1.2V

-9

9

mV

CHANNEL FREQUENCY

300kHz Configuration

PWM mode

260

300

335

kHz

400kHz Configuration

PWM mode

345

400

450

kHz

FN8696 Rev.5.00

Jul 12, 2018

Page 7 of 33

�ISL68201

Electrical Specifications

All typical specifications TA = +25°C, VCC = 5V. Boldface limits apply across the operating temperature range,

-40°C to +85°C, unless otherwise stated. (Continued)

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

(Note 6)

TYP

MAX

(Note 6)

UNIT

500kHz Configuration

PWM mode

435

500

562

kHz

600kHz Configuration

PWM mode

510

600

670

kHz

700kHz Configuration

PWM mode

610

700

790

kHz

850kHz Configuration

PWM mode

730

850

950

kHz

1000kHz Configuration

PWM mode

865

1000

1120

kHz

1500kHz Configuration

PWM mode

1320

1500

1660

kHz

0.0616

0.078

0.096

mV/µs

0.13

0.157

0.18

mV/µs

0.25

0.315

0.37

mV/µs

0.53

0.625

0.70

mV/µs

1.05

1.25

1.40

mV/µs

2.10

2.50

2.80

mV/µs

4.20

5.00

5.60

mV/µs

8.60

10.0

10.9

mV/µs

140

200

260

µs

250

µA

SOFT-START AND DYNAMIC VID

Soft-Start and DVID Slew Rate

Soft-Start Delay from Enable High

Excluding 5.5ms POR timeout.

See Figures 21 and 22

REMOTE SENSE

Bias Current of VSEN and RGND Pins

Maximum Differential Input Voltage

6.0

V

POWER-GOOD

PGOOD Pull-Down Impedance

RPG

PGOOD = 5mA sink

PGOOD Leakage Current

IPG

PGOOD = 5V

10

50

Ω

1.0

µA

5.15

V

LDOs

5V LDO Regulation

VIN = 12V, load = 50mA

4.85

5V Dropout

VIN = 4.75V, load = 50mA

4.45

V

125

mA

5V LDO Current Capability

7V LDO Regulation

250µA load

7V Dropout

VIN = 4.75V, 250µA load

7V LDO Current Capability

Not recommended for external use

7.2

5.00

7.4

7.5

V

4.50

V

2

mA

CURRENT SENSE

Average OCP Trip Level

IOC_TRIP

82

Short-Circuit Protection Threshold

100

123

130

µA

% IOCP

Sensed Current Tolerance

74

78

83

µA

Sensed Current Tolerance

35

38

42

µA

Maximum Common-Mode Input Voltage

FN8696 Rev.5.00

Jul 12, 2018

7VLDO = 7.4V

5.7

V

VCC = PVCC = 7VLDO = 4.5V

2.8

V

Page 8 of 33

�ISL68201

Electrical Specifications

All typical specifications TA = +25°C, VCC = 5V. Boldface limits apply across the operating temperature range,

-40°C to +85°C, unless otherwise stated. (Continued)

PARAMETER

SYMBOL

TEST CONDITIONS

MIN

(Note 6)

TYP

MAX

(Note 6)

UNIT

68

74

80

% DAC

FAULT PROTECTION

UVP Threshold Voltage

Latch

Start-Up OVP Threshold Voltage

0V ≤ VBOOT ≤ 1.08V

1.10

1.15

1.25

V

1.08V < VBOOT ≤ 1.55V

1.58

1.65

1.75

V

1.55V < VBOOT ≤ 1.85V

1.88

1.95

2.05

V

1.85V < VBOOT ≤ 2.08V

2.09

2.15

2.25

V

2.08V < VBOOT ≤ 2.53V

2.56

2.65

2.75

V

2.53V < VBOOT ≤ 3.33V

3.36

3.45

3.6

V

3.33V < VBOOT ≤ 5.5V

5.52

5.65

5.85

V

Start-Up OVP Hysteresis

100

mV

OVP Rising Threshold Voltage

VOVRTH

0.5 ≤ DAC ≤ 5.5

114

120

127

% DAC

OVP Falling Threshold Voltage

VOVFTH

0.5 ≤ DAC ≤ 5.5

96

100

108

% DAC

Over-Temperature Shutdown Threshold

READ_TEMP = 72h

20

22.31

26

% VCC

Over-Temperature Shutdown Reset Threshold

READ_TEMP = 8Eh

25

27.79

30

% VCC

1

V

SMBus/PMBus/I2C

Signal Input Low Voltage

Signal Input High Voltage

Signal Output Low Voltage

1.6

V

4mA pull-up current

DATE, ALERT # Pull-Down Impedance

11

CLOCK Maximum Speed

V

50

Ω

1.25

MHz

CLOCK Minimum Speed

0.05

Telemetry Update Rate

108

Timeout

PMBus Accessible Timeout from All Rails’ POR

0.4

25

See Figure 21

MHz

µs

30

35

ms

5.5

6.5

ms

NOTE:

6. Compliance to datasheet limits is assured by one or more methods: production test, characterization, and/or design.

FN8696 Rev.5.00

Jul 12, 2018

Page 9 of 33

�ISL68201

Operation

The following sections provide a detailed description of the

ISL68201 operation.

In addition, based on the ON_OFF_CONFIG [02h] setting, the IC

can be enabled or disabled by the serial bus command

“OPERATION [01h]” and/or EN pin. See Table 11 on page 25 for

more details.

IC Supplies

Resistor Reader

The ISL68201 has four bias pins: VIN, 7VLDO, PVCC, and VCC.

The PVCC and 7VLDO voltage rails are 5V LDO and 7.4V LDO

supplied by VIN, respectively, while the VCC pin needs to connect

to the PVCC rail externally to be biased. For 5V input applications,

all these pins should be tied together and biased by a 5V supply.

Because the VIN pin voltage information is used by the R4

Modulator loop, the user CANNOT bias VIN with a series resistor.

In addition, the VIN pin CANNOT be biased independently from

other rails.

The ISL68201 offers four programming pins to customize their

regulator specifications. The details of these pins are summarized

in Table 2, followed by the detailed description of resistor reader

operation.

Enable and Disable

The IC is disabled until the 7VLDO, PVCC, VCC, VIN, and EN pins

increase above their respective rising threshold voltages and the

typical 5.5ms timeout (worst case = 6.5ms) expires, as shown in

Figures 21 and 22 on page 22. The controller becomes disabled

when the 7VLDO, PVCC, VCC, VIN, or EN pins drop below their

respective falling POR threshold voltages.

The precision threshold EN pin allows the user to set a precision

input UVLO level with an external resistor divider, as shown in

Figure 4. For 5V input applications or wide range input

applications, the EN pin can directly connect to VCC, as shown in

Figure 5. If an external enable control signal is available and is an

open-drain signal, a pull-up impedance (100k or higher) can be

used.

EXTERNAL CIRCUIT

ISL68201

VIN

100k

PIN

BIT

NAME

PROG1 [7:0]

BOOT-UP

VOLTAGE

PROG2 [7:7]

PWM/PFM

[6:5]

DESCRIPTION

Sets output boot-up voltage, 256

different options: 0, 0.5V to 5.5V (see

Table 7)

Enables PFM mode or forced PWM.

Temperature Adjusts NTC temperature compensation:

Compensation OFF, +5, +15, +30°C.

[4:0]

ADDR

Sets serial bus 32 different addresses

(see Table 10).

PROG3 [7:7]

USPFM

Ultrasonic (25kHz clamp) PFM enable

[6:6] Fault Behavior OCP fault behavior:

Latch, infinite 9ms retry

[5:3]

fSW

[2:0]

R4 Gain

PROG4 [7:5]

Sets switching frequency (fSW).

Sets error amplifier gain (AV).

RAMP_RATE

Sets soft-start and DVID ramp rate.

[4:3]

RR

Selects RR impedance for R4 loop.

[2:2]

AVMLTI

Selects AV gain multiplier (1x or 2x)

[1:0]

Not Used

Renesas has developed a high resolution ADC using a technique

with a simple 1%, 100ppm/K or better temperature coefficient

resistor divider. The same type of resistors are preferred so that it

has similar change over temperature. In addition, the divider is

compared to the internal divider off VCC and GND nodes and

therefore must refer to VCC and GND pins, not through any RC

decoupling network.

EN

SOFTSTART

TABLE 2. DEFINITION OF PROG PINS

9.09k

VIN UVLO = 10.08V/9.12V

FIGURE 4. INPUT UVP CONFIGURATION

ISL68201

EXTERNAL CIRCUIT

ISL68201

VCC

REGISTER

TABLE

REN

SOFTSTART

EXTERNAL CIRCUIT

VCC

OPTIONAL

EN

RUP

ADC

RDW

VIN UVLO = 4.20/3.95V

REN is needed ONLY if the user wants to

control the IC with an external enable signal

FIGURE 6. SIMPLIFIED RESISTOR DIVIDER ADC

FIGURE 5. 5V INPUT OR WIDE RANGE INPUT CONFIGURATION

FN8696 Rev.5.00

Jul 12, 2018

Page 10 of 33

�ISL68201

The RUP and RDW values for a particular parameter set can be

found using the PowerNavigator GUI. Data for corresponding

registers can be read out using the serial PMBus command (DC

to DF). Note: The case of 10kΩ RUP or RDW is the same as 0kΩ

RUP or RDW.

TABLE 5. PROG 3 RESISTOR READER EXAMPLE

PROG3

(DE)

RUP

(kΩ)

00h

Open

0

Disabled

RDW ULTRASONIC

FAULT

(kΩ)

PFM

BEHAVIOR

R4 GAIN

fSW

(kHz)

1x

2x

Retry

300

42

84

TABLE 3. PROG 1 RESISTOR READER EXAMPLE

20h

Open

21.5

Disabled

Retry

700

42

84

PROG1

(DC)

RUP

(kΩ)

RDW

(kΩ)

VOUT

(V)

40h

Open

34.8

Disabled

Latch

300

42

84

00h

Open

0

0.797

60h

Open

52.3

Disabled

Latch

700

42

84

20h

Open

21.5

0.852

80h

Open

75

Enabled

Retry

300

42

84

40h

Open

34.8

0.898

A0h

Open

105

Enabled

Retry

700

42

84

60h

Open

52.3

0.953

C0h

Open

147

Enabled

Latch

300

42

84

80h

Open

75

1.000

A0h

Open

105

1.047

E0h

Open

499

Enabled

Latch

700

42

84

C0h

Open

147

1.102

1Fh

0

Open

Disabled

Retry

600

1

2

E0h

Open

499

1.203

3Fh

21.5

Open

Disabled

Retry

1500

1

2

1Fh

0

Open

1.352

5Fh

34.8

Open

Disabled

Latch

600

1

2

3Fh

21.5

Open

1.500

7Fh

52.3

Open

Disabled

Latch

1500

1

2

5Fh

34.8

Open

1.797

9Fh

75

Open

Enabled

Retry

600

1

2

7Fh

52.3

Open

2.500

BFh

105

Open

Enabled

Retry

1500

1

2

9Fh

75

Open

3.000

BFh

105

Open

3.297

DFh

147

Open

Enabled

Latch

600

1

2

DFh

147

Open

5.000

FFh

499

Open

Enabled

Latch

1500

1

2

FFh

499

Open

0.000

TABLE 6. PROG 4 RESISTOR READER EXAMPLE

TABLE 4. PROG 2 RESISTOR READER EXAMPLE

PROG2

(DD)

RUP

(kΩ)

RDW

(kΩ)

PWM/PFM

TEMP

COMP

PM_ADDR

(7-BIT)

00h

Open

0

Enabled

30

60h

20h

Open

21.5

Enabled

15

60h

40h

Open

34.8

Enabled

5

60h

60h

Open

52.3

Enabled

OFF

60h

80h

Open

75

Disabled

30

60h

A0h

Open

105

Disabled

15

60h

C0h

Open

147

Disabled

5

60h

E0h

Open

499

Disabled

OFF

60h

1Fh

0

Open

Enabled

30

7F

3Fh

21.5

Open

Enabled

15

7F

5Fh

34.8

Open

Enabled

5

7F

7Fh

52.3

Open

Enabled

OFF

7F

9Fh

75

Open

Disabled

30

7F

BFh

105

Open

Disabled

15

7F

DFh

147

Open

Disabled

5

7F

FFh

499

Open

Disabled

OFF

7F

FN8696 Rev.5.00

Jul 12, 2018

PROG4

(DF

RUP

(kΩ)

RDW

(kΩ)

SS RATE

(mV/µs)

(kΩ

AVMLTI

00h

Open

0

1.25

200

1x

20h

Open

21.5

2.5

200

1x

40h

Open

34.8

5

200

1x

60h

Open

52.3

10

200

1x

80h

Open

75

0.078

200

1x

A0h

Open

105

0.157

200

1x

C0h

Open

147

0.315

200

1x

E0h

Open

499

0.625

200

1x

1Fh

0

Open

1.25

800

2x

3Fh

21.5

Open

2.5

800

2x

5Fh

34.8

Open

5

800

2x

7Fh

52.3

Open

10

800

2x

9Fh

75

Open

0.078

800

2x

BFh

105

Open

0.157

800

2x

DFh

147

Open

0.315

800

2x

FFh

499

Open

0.625

800

2x

RR

Page 11 of 33

�ISL68201

Soft-Start

The ISL68201-based regulator has four periods during soft-start,

as shown in Figure 7 on page 12. When the EN pin reaches

above its enable threshold, after a 5.5ms timeout (worst

case = 6.5ms) of bias supplies, the controller begins the first

soft-start ramp after a fixed soft-start delay period tD1 as shown

in Figures 21 and 22 on page 22. The output voltage reaches the

boot-up voltage (VBOOT) at a fixed slew rate in period tD2. Then,

the controller regulates the output voltage at VBOOT for another

period tD3 until SMBus/PMBus/ I2C sends a new VOUT

command. If the VOUT command is valid, the ISL68201 initiates

the ramp until the voltage reaches the new VOUT_COMMAND

voltage in period tD4. The soft-start time is the sum of the four

periods, as shown in Equation 1.

t SS = t D1 + t D2 + t D3 + t D4

(EQ. 1)

tD1 is a fixed delay with a typical value of 200µs. tD3 is determined

by the time to obtain a new valid VOUT_COMMAND voltage from

SMBus/PMBus/I2C bus. If the VOUT_COMMAND is valid before the

output reaches the boot-up voltage, the output turns around to

respond to the new VOUT_COMMAND code.

VBOOT< PRE-CHARGED < OVP

V PRECHARGED V PRECHARGED – V BOOT

t D2 = -------------------------------------------- + ----------------------------------------------------------------------- s

RAMP_RATE

RAMP_RATE

The ISL68201 supports precharged load start-up to the

maximum VOUT of 5.5V with sufficient boot capacitor charge. For

an extended precharged load, the boot capacitor discharges to

“PVCC - VOUT - VD” by the high-side drive circuits’ standby current.

For instance, during an extended 4V precharged load, the boot

capacitor reduces to a less-than-1V boot capacitor voltage, which

is insufficient to power up the VR; in this case, it is recommended

to let the output drop below 2.5V with an external bleed resistor

before issuing another soft-start command.

Boot-Up Voltage Programming

An 8-bit pin PROG1 is dedicated for the boot-up voltage

programmability, which offers 256 options 0V and 0.5V to 5.5V,

as in Table 7. The most popular boot-up voltage levels are placed

on the tie-low spots (0h, 20h, 40h, 60h, 80h, A0h, C0h, E0h) and

the tie-high spots (1Fh, 3Fh, 5Fh, 7Fh, 9Fh, BFh, DFh, FFh) for

easy programming, as summarized in Table 3. A 0V boot-up

voltage is considered as “OFF,” the driver is in tri-state and the

internal DAC sets to 0V.

In addition, if the VOUT_COMMAND (21h) is executed

successfully 5.5ms (typically, worst 6.5ms) after VCC POR and

before Enable, it overrides the boot-up voltage set by the PROG1

pin.

VOUT

VBOOT

PRE-CHARGED 10mV), reduce the

“TCOMP” value. If the IOUT pin voltage decreases over 10mV

as the temperature increases (that is, V1 - V2 > 10mV),

increase the “TCOMP” value. The “TCOMP” value can be

adjusted through the serial bus for easy thermal

compensation optimization.

IOUT Calibration

FIGURE 19. RECOMMENDED PLACEMENT OF NTC

The ISL68201 multiplexes the “TCOMP” value with the NTC

digital signal to obtain the adjustment gain to compensate the

temperature impact on the sensed channel current. The

compensated current signal is used for IOUT and overcurrent

protection functions. Use the TCOMP “OFF” code to disable

thermal compensation when the current sensing element is the

resistor or smart power stage (internally thermal compensated)

that has little thermal drifting.

TABLE 8. TCOMP VALUES

D1h

TCOMP (°C)

D1h

TCOMP (°C)

0h

30

2h

5

1h

15

3h

OFF

The thermal compensation design procedure for inductor current

sensing is summarized as follows:

1. Properly choose the voltage divider for the NTC pin to match

the NTC voltage vs temperature curve with the recommended

curve in Figure 18 on page 18.

The current flowing out of the IOUT pin is equal to the sensed

average current inside ISL68201. A resistor is placed from the

IOUT pin to GND to generate a voltage, which is proportional to

the load current and the resistor value, as shown in Equation 12:

R x xI OCP

2.5Vx -------------------------

2.5VxR ISEN

100A

R IOUT = ---------------------------------- = ----------------------------------------------63.875AxR x

63.875AxR x

2.5VxI OCP

25VxI OCP

= --------------------------------------------- = ----------------------------- k

63.875Ax100A

63.875A

where VIOUT is the voltage at the IOUT pin, RIOUT is the resistor

between the IOUT pin and GND, ILOAD is the total output current

of the converter, RISEN is the sense resistor connected to the

CSRTN pin, and RX is the DC resistance of the current sense

element, either the DCR of the inductor or RSENSE depending on

the sensing method. Scale the RIOUT resistor to ensure that the

voltage at the IOUT pin is typically 2.5V at 63.875A load current.

The IOUT voltage is linearly digitized every 108µs and stored in

the READ_IOUT register (8Ch).

4. Use Equation 9 to calculate the resistance of the NTC, and

find out the corresponding NTC temperature TNTC from the

NTC datasheet or using Equation 10, where is equal to 3380

for recommended NTC.

V TM xR

TM

R NTC at T NTC = ----------------------------V CC – V

(EQ. 9)

TM

T NTC = --------------------------------------------------------------------------------- – 273.15

R NTC at T NTC

ln --------------------------------------------- + ----------------- R NTC at 25C 298.15

FN8696 Rev.5.00

Jul 12, 2018

(EQ. 10)

EXTERNAL CIRCUIT

ISL68201

VCC

2. Operate the actual board under the full load and the desired

airflow condition.

3. After the board reaches the thermal steady state (often takes

15 minutes), record the temperature (TCSC) of the current

sense component (inductor) and the voltage at NTC and VCC

pins.

(EQ. 12)

RIOUT_UP

DIGITIZED

IOUT (8Ch)

IOUT

RIOUT_DW

FIGURE 20. IOUT NO LOAD OFFSET CALIBRATION

Place a small capacitor between IOUT and GND to reduce the

noise impact and provide averaging, > 200µs (typically).

To deal with layout and design variation of different platforms,

the ISL68201 is intentionally trimmed to negative at no load,

thus, an offset can easily be added to calibrate the digitized IOUT

reading (8Ch). Hence, the analog vs digitized current slope is set

Page 19 of 33

�ISL68201

by the equivalent impedance of RIOUT_UP//RIOUT_DW = RIOUT

(as in Figure 20); the slope of the ideal curve should set to 1A/A

with 0A offset.

For a precision digital IOUT, follow the fine-tuned procedure below.

Steps 1 to 5 must be completed before Step 6.

1. Properly tune L/DCR or ESL/RSEN matching as shown on

page 17 over the range of temperature operation. +25%

over-matching L/DCR at room temperature is needed for

-40°C operation.

2. Properly complete thermal compensation as shown in

“Thermal Monitoring and Compensation” on page 18.

3. Finalize the RISEN resistor to set OCP for overall operating

conditions and board variations as shown in “Overcurrent and

Short-Circuit Protection” on page 20.

4. Collect no load IOUT current with sufficient prototypes and

determine the mean of no load IOUT current.

5. The pull-up impedance on IOUT pin should be

“VCC/IOUT_NO_LOAD”. For instance, a mean of -2.5µA IOUT at

0A load needs RIOUT_UP = 2MΩ.

6. Start with the value below and then fine-tune the RIOUT_DW

value until the average slope of various boards equals 1A/A.

R IOUT_UP xR IOUT

R IOUT_DW = -------------------------------------------------R IOUT_UP – R IOUT

(EQ. 13)

Fault Protection

The ISL68201 provides high system reliability with many fault

protections, as summarized in Table 9.

TABLE 9. FAULT PROTECTION SUMMARY

FAULT

Input UVLO

Bias UVLO

DESCRIPTION

FAULT ACTION

Shut down and recover

VIN pin UVLO; or set by EN pin

when VIN > UVLO

with an external divider for a

higher level. See Figures 4 and 5.

VCC, PVCC, 7VLDO UVLO

Shut down and recover

when Bias > UVLO

Start-Up OVP Higher than VBOOT. See Electrical Latch OFF, reset by VCC

Specifications on page 7.

or toggling enable

(including EN pin and/

Output OVP Rising = 120%; Falling = 100%

or OPERATION

command based on

Output UVP 74% of VOUT, Latch OFF

the ON_OFF_CONFIG

setting)

Output OCP

Average OCP = 100µA with

128µs blanking time.

Short-Circuit Peak OCP = 130% of Average

Protection

OCP with 50ns filter.

OTP

Latch OFF (reset by VCC

or toggling enable

including EN pin and/

or OPERATION

command based on

the ON_OFF_CONFIG

setting), or retry every

9ms; option is

programmable by

PROG3 or D3[0]

Rising = 22.31%VCC (~+136°C); Shut down above

Falling =27.79%VCC (~+122°C). +136°C and recover

when temperature

drops below +122°C

FN8696 Rev.5.00

Jul 12, 2018

The UVLO and OTP faults respond to the current state with

hysteresis, output OVP and output UVP faults are latch events,

and output OCP and output short-circuit faults can be latch or

retry events depending upon the PROG3 or D3[0] setting. All fault

latch events can be reset by VCC cycling, toggling the Enable pin

and/or the serial bus OPERATION command based on the

ON_OFF_CONFIG setting, while the OCP retry event has a hiccup

time of 9ms and the regulator can be recovered when the fault is

removed.

OVERVOLTAGE PROTECTION

The OVP fault detection circuit triggers after the voltage between

VSEN+ and VSEN- is above the rising overvoltage threshold.

When an OVP fault is declared, the controller latches off and the

PGOOD pin asserts low. The fault remains latched and can be

reset by VCC cycling or toggling EN pin and/or the serial bus

OPERATION command based on the ON_OFF_CONFIG setting.

Although the controller latches off in response to an OVP fault,

the LGATE gate-driver output retains the ability to toggle the lowside MOSFET on and off, in response to the output voltage

transversing the OVP rising and falling thresholds. The LGATE

gate driver turns on the low-side MOSFET to discharge the output

voltage, protecting the load. The LGATE gate driver turns off the

low-side MOSFET when the sensed output voltage is lower than

the falling overvoltage threshold (typically 100%). If the output

voltage rises again, the LGATE driver turns on the low-side MOSFET

again when the output voltage is above the rising overvoltage

threshold (typically 120%). By doing so, the IC protects the load

when there is a consistent overvoltage condition.

In addition to normal operation OVP, 5.5ms (typically, worst

case = 6.5ms) after all rails (VCC, PVCC, 7VLDO, VIN) POR and

before the end of soft-start, the start-up OVP circuits are enabled

to protect against an OVP event, while the OVP level is set higher

than VBOOT. See Electrical Specifications on page 7.

UNDERVOLTAGE PROTECTION

The UVP fault detection circuit triggers when the output voltage is

below the undervoltage threshold (typically 74% of DAC). When a

UVP fault is declared, the controller latches off, forcing the LGATE

and UGATE gate-driver outputs low, and the PGOOD pin asserts

low. The fault remains latched and can be reset by VCC cycling or

toggling the EN pin and/or the serial bus OPERATION command

based on the ON_OFF_CONFIG setting.

OVERCURRENT AND SHORT-CIRCUIT PROTECTION

The average Overcurrent Protection (OCP) is triggered when the

internal current out of the IOUT pin goes above the fault

threshold (typically 100µA) with 128µs blanking time. It also has

a fast (50ns filter) secondary overcurrent protection whose

threshold is +30% above average OCP. This protects inductor

saturation from a short-circuit event and provides a more robust

power train and system protection. When an OCP or short-circuit

fault is declared, the controller latches off, forcing the LGATE and

UGATE gate-driver outputs low, or retries with a hiccup time of

9ms. The fault response is programmable by PROG3 or D3[0].

However, the latched off event can be reset by VCC cycling,

toggling the EN pin, and/or the serial bus OPERATION command

based on the ON_OFF_CONFIG setting.

Page 20 of 33

�ISL68201

Equation 14 provides a starting point to set a preliminary OCP

trip point, in which IOCP is the targeted OCP trip point and DI (as

in Equation 15) is the peak-to-peak inductor ripple current.

PFM Mode Operation

I

R x x ----- + I OCP

2

R ISEN2 = ------------------------------------------------------------100Ax 100% + 30%

In PFM mode, programmable by PROG2 or serial bus D0[0:0],

the switching frequency is dramatically reduced to minimize the

switching loss and significantly improve light-load efficiency. The

ISL68201 can enter and exit PFM mode seamlessly as the load

changes. The PFM mode is only compatible with the ISL99140

DrMOS with SMOD input by connecting to ISL68201’s FCCM

output pin. Incompatible power stages should operate in PWM

mode.

R ISEN = MAX (R ISEN1, R ISEN2

SMBus, PMBus, and I2C Operation

To deal with layout and PCB contact impedance variation, follow

the fine-tuning procedure below for a more precise OCP. Steps 1 to

3 must be completed before Step 4.

The ISL68201 features SMBus, PMBus, and I2C with 32

programmable addresses through the PROG2 pin, while

SMBus/PMBus includes an Alert# line (SALERT) and Packet Error

Check (PEC) to ensure data properly transmitted. The telemetry

update rate is 108µs (typically). The supported

SMBus/PMBus/I2C addresses are summarized in Table 10. The

7-bit format address does not include the last bit (write and

read): 40-47h, 60-67h, and 70-7Fh.

R x xI OCP

R ISEN1 = -----------------------100A

(EQ. 14)

1. Properly tune L/DCR or ESL/RSEN matching as shown on

page 17 over the range of temperature operation. +25%

over-matching L/DCR at room temperature is needed for

-40°C operation.

2. Properly complete thermal compensation as shown in

“Thermal Monitoring and Compensation” on page 18.

3. Collect OCP trip points (IOCP_MEASURED) with sufficient

prototypes and determine the mean for overall operating

conditions and board variations.

4. Change RISEN by IOCP_TARGETED/IOCP_MEASURED

percentage to meet the targeted OCP.

Note that if the inductor peak-to-peak current is higher or closer

to 30%, the +30% threshold could be triggered instead of the

average OCP threshold. However, the fine-tuning procedure can

still be used.

OVER-TEMPERATURE PROTECTION

As shown in Figure 16 on page 18, there is a comparator with

hysteresis to compare the NTC pin voltage to the threshold set.

When the NTC pin voltage is lower than 22.31% of the VCC

voltage (typically +136°C), it triggers Over-Temperature

Protection (OTP) and shuts down the ISL68201. When the NTC

pin voltage is above 27.79% of the VCC voltage (typically

+122.4°C), the ISL68201 resumes normal operation. When an

OTP fault is declared, the controller forces the LGATE and UGATE

gate-driver outputs low.

PGOOD Monitor

The PGOOD pin indicates when the converter is capable of

supplying regulated voltage. If there is a fault condition of a rail’s

(VCC, PVCC, 7VLDO, or VIN) UVLO, output Overcurrent (OCP),

Overvoltage (OVP), Undervoltage (UVP), or Over-Temperature (OTP),

PGOOD is asserted low. Note that the PGOOD pin is an undefined

impedance with insufficient VCC (typically

VOUT_MAX, or VOUT OPEN SENSE)

Input Voltage (N = - 4, Max = 31.9375V)

VIN (V) = HEX2DEC(88 hex data - E000h) * 0.0625V

Page 25 of 33

�ISL68201

TABLE 11. SMBus, PMBus, AND I2C SUPPORTED COMMANDS (Continued)

COMMAND

CODE

ACCESS

WORD

LENGTH

(BYTE)

8Dh[15:0]

R

TWO

98h[7:0]

R

ONE

02h

PMBUS_REVISION

AD[15:0]

BLOCK R

TWO

8201h

IC_DEVICE_ID

AE[15:0]

BLOCK R

TWO

0003h

D0[0:0]

R/W

ONE

PROG2[7:7]

ENABLE_PFM

PFM OPERATION

0h = PFM Enabled (DCM at light load)

1h = PFM Disabled (always CCM mode)

D1[1:0]

R/W

ONE

PROG2[6:5]

TEMP_COMP

Thermal Compensation:

0h = 30°C; 01h = 15°C; 02h = 5°C; 03h = OFF

D2[0:0]

R/W

ONE

PROG3[7:7]

D3[0:0]

R/W

ONE

PROG3[6:6]

OCP_BEHAVIOR

D4[2:0]

R/W

ONE

PROG3[2:0]

AV_GAIN

D5{2:0]

R/W

ONE

PROG4[7:5]

RAMP_RATE

D6[1:0]

R/W

ONE

PROG4[4:3]

SET_RR

DC[7:0]

R

ONE

READ_PROG1

Read PROG1

DD{7:0]

R

ONE

READ_PROG2

Read PROG2

DE[7:0]

R

ONE

READ_PROG3

Read PROG3

DF[7:0]

R

ONE

READ_PROG4

Read PROG4

DEFAULT

VALUE

COMMAND NAME

READ_TEMP

DESCRIPTION

VR Temperature

TEMP (°C) = 1/{ln[Rup*HEX2DEC(8D hex

data)/(511 - HEX2DEC(8D hex data)/RNTC(at +25°C)]/Beta +

1/298.15} -273.15

Indicates PMBus Revision 1.2

ISL68201 Device ID

IC_DEVICE_REVISION ISL68201 Device Revision

ENABLE_ULTRASONIC Ultrasonic PFM Enable

0h = 25kHz Clamp Disabled

1h = 25kHz Clamp Enabled

Set latch or infinite retry for OCP fault:

0h = Retry every 9ms; 01 = Latch-OFF

R4 AV GAIN (PROG4, AV Gain Multiplier = 2x)

0h = 84; 1h = 73; 2h = 61; 3h = 49

4h = 38; 5h = 26; 6h = 14; 7h = 2

R4 AV GAIN (PROG4, AV Gain Multiplier = 1x)

0h = 42; 1h = 36.5; 2h = 30.5; 3h = 29.5

4h = 19; 5h = 13; 6h = 7; 7h = 1

Soft-Start and Margining DVID Rate (mV/µs)

0h = 1.25; 1h = 2.5; 2h = 5; 3h = 10; 4h = 0.078; 5h = 0.157

6h = 0.315; 7h = 0.625;

Set RR

0h = 200k; 01h = 400k; 02h = 600k; 03h = 800k

NOTE: Serial bus communication is valid 5.5m (typically, worst 6.5ms) after VCC, VIN, 7VLDO, and PVCC above POR. The telemetry update rate is 108µs.

R4 Modulator

STABILITY

The R4 modulator is an evolutionary step in R3 technology. Like

R3, the R4 modulator is a linear control loop and variable

frequency control during load transients to eliminate beat

frequency oscillation at the switching frequency and maintains

the benefits of current-mode hysteretic controllers. In addition,

the R4 modulator reduces regulator output impedance and uses

accurate referencing to eliminate the need for a high-gain

voltage amplifier in the compensation loop. The result is a

topology that can be tuned to voltage-mode hysteretic transient

speed while maintaining a linear control model and removes the

need for any compensation. This greatly simplifies the regulator

design for customers and reduces external component cost.

The removal of compensation derives from the R4 modulator’s

lack of need for high DC gain. In traditional architectures, high DC

gain is achieved with an integrator in the voltage loop. The

integrator introduces a pole in the open-loop transfer function at

low frequencies. That, combined with the double-pole from the

output L/C filter, creates a three pole system that must be

compensated to maintain stability.

FN8696 Rev.5.00

Jul 12, 2018

Classic control theory requires a single-pole transition through

unity gain to ensure a stable system. Current-mode architectures

(includes peak, peak-valley, current-mode hysteric, R3, and R4)

generate a zero at or near the L/C resonant point, effectively

canceling one of the system’s poles. The system still contains

two poles, one of which must be canceled with a zero before

unity gain crossover to achieve stability.

Page 26 of 33

�ISL68201

COMPENSATION TO COUNTER

INTEGRATOR

FOR HIGH DC GAIN

INTEGRATOR POLE

R4 LOOP GAIN (dB)

L/C DOUBLE-POLE

VOUT

p1

VCOMP

SYSTEM HAS 2 POLES

AND 1 ZERO

p2

VDAC

FIGURE 25. CLASSICAL INTEGRATOR ERROR-AMPLIFIER

CONFIGURATION

Because R4 does not require a high-gain voltage loop, the

integrator can be removed, reducing the number of inherent

poles in the loop to two. The current-mode zero continues to

cancel one of the poles, ensuring a single-pole crossover for a

wide range of output filter choices. The result is a stable system

with no need for compensation components or complex

equations to properly tune the stability.

NO COMPENSATOR IS

NEEDED

ec

/d

B

0d dec

-2

/

B

c

0d

/ de

-2

dB

-40

Figure 25 illustrates the classic integrator configuration for a

voltage loop error amplifier. While the integrator provides the

high DC gain required for accurate regulation in traditional

technologies, it also introduces a low-frequency pole into the

control loop. Figure 26 shows the open-loop response that results

from the addition of an integrating capacitor in the voltage loop.

The compensation components found in Figure 25 are necessary

to achieve stability.

CURRENT-MODE

ZERO

z1

f (Hz)

FIGURE 28. UNCOMPENSATED R4 OPEN-LOOP RESPONSE

TRANSIENT RESPONSE

In addition to requiring a compensation zero, the integrator in

traditional architectures also slows system response to transient

conditions. The change in COMP voltage is slow in response to a

rapid change in output voltage. If the integrating capacitor is

removed, COMP moves as quickly as VOUT, and the modulator

immediately increases or decreases switching frequency to

recover the output voltage.

Figure 27 shows the R4 error amplifier that does not require an

integrator for high DC gain to achieve accurate regulation. The

result to the open loop response can be seen in Figure 28.

IOUT

t

R4

R3

VCOMP

R3 LOOP GAIN (dB)

INTEGRATOR POLE

p1

t

L/C DOUBLE-POLE

VOUT

p2

-20dB CROSSOVER

REQUIRED FOR STABILITY

p3

COMPENSATOR TO

ADD z2 IS NEEDED

CURRENT-MODE

ZERO

z1

0

-2

d

-40

ec

ec

c

de

/d

dB

B/

-60dB/d

f (Hz)

FIGURE 26. UNCOMPENSATED INTEGRATOR OPEN-LOOP RESPONSE

R2

VOUT

VCOMP

R1

+

VDAC

FIGURE 27. NON-INTEGRATED R4 ERROR-AMPLIFIER

CONFIGURATION

FN8696 Rev.5.00

Jul 12, 2018

t

FIGURE 29. R3 vs R4 IDEALIZED TRANSIENT RESPONSE

The dotted red and blue lines in Figure 29 represent the time

delayed behavior of VOUT and VCOMP in response to a load

transient when an integrator is used. The solid red and blue lines

illustrate the increased response of R4 in the absence of the

integrator capacitor.

To optimize transient response and improve phase margin for

very wide range applications, the ISL68201 integrates selectable

AV and RR options that move the DC gain and z1 point, as shown

in Figure 28. However, the defaulted AV gain of 42 and RR of

200kΩ can cover many cases and provides sufficient gain and

phase margin. For some extreme cases, lower AV gain and bigger

RR values are needed to provide a better phase margin and

improve transient ringback. The optimal choice AV and RR can

be obtained by simple monitoring transient response when

adjusting AV and RR values through the serial bus.

Page 27 of 33

�ISL68201

General Application Design

Guide

Thus, after the output capacitors are selected, the maximum

allowable ripple voltage, VP-P(MAX), determines the lower limit on

the inductance, as shown in Equation 16.

This design guide provides a high-level explanation of the steps

necessary to design a single-phase buck converter. It is assumed

that the reader is familiar with many of the basic skills and

techniques referenced in the following. In addition to this guide,

complete reference designs that include schematics, bills of

materials, and example board layouts are provided.

Output Filter Design

The output inductors and the output capacitor bank together to

form a low-pass filter responsible for smoothing the pulsating

voltage at the phase nodes. The output filter also must provide

the transient energy until the regulator can respond. The output

filter limits the system transient response, because it has a low

bandwidth compared to the switching frequency. The output

capacitor must supply or sink load current while the current in

the output inductors increases or decreases to meet the

demand.

In high-speed converters, the output capacitor bank is usually the

most costly (and often the largest) part of the circuit. Output filter

design begins with minimizing the cost of this part of the circuit.

The critical load parameters in choosing the output capacitors are

the maximum size of the load step, I; the load current slew rate,

di/dt; and the maximum allowable output voltage deviation under

transient loading, VMAX. Capacitors are characterized according

to their capacitance, ESR, and ESL (equivalent series inductance).

At the beginning of the load transient, the output capacitors

supply all of the transient current. The output voltage initially

deviates by an amount approximated by the voltage drop across

the ESL. As the load current increases, the voltage drop across

the ESR increases linearly until the load current reaches its final

value. The capacitors selected must have sufficiently low ESL and

ESR so that the total output voltage deviation is less than the

allowable maximum. Neglecting the contribution of inductor

current and regulator response, the output voltage initially

deviates by an amount, as shown in Equation 15:

I

ESL

1

V I ESR + ---------------- V IN + ----------------- --------------------------L OUT

C OUT 8 N f

(EQ. 15)

SW

V OUT 1 – D

I = --------------------------------------L OUT f

SW

The filter capacitor must have sufficiently low ESL and ESR so

that V < VMAX.

Most capacitor solutions rely on a mixture of high-frequency

capacitors with relatively low capacitance in combination with

bulk capacitors having high capacitance but limited

high-frequency performance. Minimizing the ESL of the

high-frequency capacitors allows them to support the output

voltage as the current increases. Minimizing the ESR of the bulk

capacitors allows them to supply the increased current with less

output voltage deviation. The ESR of the bulk capacitors also

creates the majority of the output voltage ripple. As the bulk

capacitors sink and source the inductor AC ripple current, a

voltage develops across the bulk capacitor ESR equal to

IL(P-P) (ESR).

FN8696 Rev.5.00

Jul 12, 2018

V OUT V IN – V OUT

L OUT ESR -------------------------------------------------------f SW V IN V P-P(MAX)

(EQ. 16)

Because the capacitors are supplying a decreasing portion of the

load current while the regulator recovers from the transient, the

capacitor voltage becomes slightly depleted. The output

inductors must be capable of assuming the entire load current

before the output voltage decreases more than VMAX. This

places an upper limit on inductance.

Equation 17 gives the upper limit on L for cases when the trailing

edge of the current transient causes a greater output to voltage

deviation than the leading edge. Equation 18 addresses the

leading edge. Normally, the trailing edge dictates the selection of

L because duty cycles are usually less than 50%. Nevertheless,

both inequalities should be evaluated, and L should be selected

based on the lower of the two results. In Equations 17 and 18,

L is the per-channel inductance and C is the total output

capacitance.

2 C V OUT

L OUT -------------------------------V MAX – I ESR

I 2

(EQ. 17)

1.25 C- V

L OUT ------------------MAX – I ESR V IN – V OUT

I 2

(EQ. 18)

Input Capacitor Selection

The input capacitors are responsible for sourcing the AC

component of the input current flowing into the upper MOSFETs.

Their RMS current capacity must be sufficient to handle the AC

component of the current drawn by the upper MOSFETs, which is

related to duty cycle and the number of active phases. The input

RMS current can be calculated with Equation 19.

I IN RMS =

D

D – D 2 Io 2 + ------ I 2

12

(EQ. 19)

Use Figure 30 on page 29 to determine the input capacitor RMS

current requirement given the duty cycle, maximum sustained

output current (IO), and the ratio of the per-phase peak-to-peak

inductor current (IL(P-P) to IO). Select a bulk capacitor with a ripple

current rating that minimizes the total number of input capacitors

required to support the RMS current calculated. The voltage rating of

the capacitors should also be at least 1.25 times greater than the

maximum input voltage.

Low capacitance, high-frequency ceramic capacitors are needed

in addition to the bulk capacitors to suppress leading and falling

edge voltage spikes. The result of the high current slew rates

produced by the upper MOSFETs turn on and off requires low ESL

ceramic capacitors, which should be placed as close as possible

to each upper MOSFET drain to minimize board parasitic

impedances and maximize noise suppression.

Page 28 of 33

�ISL68201

Tables 12 and 13 provide a design and layout checklist that the

designer can reference.

INPUT-CAPACITOR CURRENT (IRMS/IO)

0.6

TABLE 12. DESIGN AND LAYOUT CHECKLIST

IL(P-P) = 0.75 IO

0.4

IL(P-P) = 0

PIN

NAME

NOISE

SENSITIVITY

EN

YES

There is an internal 1µs filter. Decoupling the

capacitor is NOT needed, but if needed, use a

low time constant one to avoid too large a

shutdown delay.

VIN

YES

Place 16V+ X7R 1µF in close proximity to the

pin and the system ground plane.

7VLDO

YES

Place 10V+ X7R 1µF in close proximity to the

pin and the system ground plane.

VCC

YES

Place X7R 1µF in close proximity to the pin and

the system ground plane.

SCL, SDA

YES

50kHz to 1.25MHz signal when the SMBus,

PMBus, or I2C is sending commands. Pairing

up with SALERT and routing carefully back to

SMBus, PMBus or I2C master. 20 mils spacing

within SDA, SALERT, and SCL; and more than

30 mils to all other signals. Refer to the SMBus,

PMBus or I2C design guidelines and place

proper terminated (pull-up) resistance for

impedance matching. Tie them to GND when

not used.

SALERT

NO

Open-drain and high dv/dt pin during

transitions. Route it in the middle of SDA and

SCL. Tie it to GND when not used.

PGOOD

NO

Open-drain pin. Tie it to GND when not used.

RGND,

VSEN

YES

Differential pair routed to the remote sensing

points with sufficient decoupling ceramics

capacitors and not across or go above/under

any switching nodes (BOOT, PHASE, UGATE,

LGATE) or planes (VIN, PHASE, VOUT) even

though they are not in the same layer. At least

20 mils spacing from other traces. DO NOT

share the same trace with CSRTN.

CSRTN

YES

Connect to the output rail side of the output

inductor or current sensing resistor pin with a

series resistor in close proximity to the pin. The

series resistor sets the current gain and should

be within 40Ωand 3.5kΩ. Decoupling

(~ 0.1µF/X7R) on the output end (not the pin) is

optional and might be required for long sense

trace and a poor layout (see Figures 9 and 10).

CSEN

YES

Connect to the phase node side of the output

inductor or current sensing resistor pin with

L/DCR or ESL/RSEN matching network in close

proximity to CSEN and CSRTN pins.

Differentially routing back to the controller with

at least 20 mils spacing from other traces.

Should NOT cross or go above/under the

switching nodes [BOOT, PHASE, UGATE, LGATE],

and power planes (VIN, PHASE, VOUT) even

though they are not in the same layer.

IL(P-P) = 0.5 IO

0.2

0

0

0.2

0.4

0.6

DUTY CYCLE (VOUT/VIN)

0.8

1.0

FIGURE 30. NORMALIZED INPUT-CAPACITOR RMS CURRENT vs

DUTY CYCLE FOR SINGLE-PHASE CONVERTER

Design and Layout Considerations

To ensure a first pass design, the schematics design must be

done correctly with correct pinout and net names, and the board

must be carefully laid out.

As a general rule, power layers should be close together, either

on the top or bottom of the board, with the weak analog or logic

signal layers on the opposite side of the board or internal layers.

The ground-plane layer should be in between power layers and

the signal layers to provide shielding, often the layer below the

top and the layer above the bottom should be the ground layers.

The two sets of components in a DC/DC converter are the power

components and the small signal components. The power

components are the most critical because they switch large

amounts of energy. The small signal components connect to

sensitive nodes or supply critical bypassing current and signal

coupling.

The power components should be placed first. These include

MOSFETs, input and output capacitors, and the inductor. Keeping

the distance between the power train and the control IC short

helps keep the gate drive traces short. These drive signals

include the LGATE, UGATE, GND, PHASE, and BOOT.

When placing MOSFETs, keep the source of the upper MOSFETs

and the drain of the lower MOSFETs as close as thermally

possible. Input high-frequency capacitors should be placed close

to the drain of the upper MOSFETs and the source of the lower

MOSFETs. Place the output inductor and output capacitors

between the MOSFETs and the load. Place high frequency output

decoupling capacitors (ceramic) as close as possible to the

decoupling target, making use of the shortest connection paths

to any internal planes. Place the components in such a way that

the area under the IC has less noise traces with high dV/dt and

di/dt, such as gate signals, phase node signals, and VIN plane.

FN8696 Rev.5.00

Jul 12, 2018

DESCRIPTION

Page 29 of 33

�ISL68201

TABLE 12. DESIGN AND LAYOUT CHECKLIST (Continued)

PIN

NAME

NOISE

SENSITIVITY

NTC

YES

IOUT

PROG1-4

GND

FCCM

PWM

YES

NO

YES

NO

NO

TABLE 13. TOP LAYOUT TIPS

DESCRIPTION

NUMBER

DESCRIPTION

Place an NTC 10k (Murata, NCP15XH103J03RC,

= 3380) in close proximity to the output

inductor’s output rail, not close to MOSFET side

(see Figure 19); the return trace should be

20 mils away from other traces. Place 1.54kΩ

pull-up and decoupling capacitor (typically

0.1µF) in close proximity to the controller. The

pull-up resistor should be exactly tied to the

same point as VCC pin, not through an RC filter.

If not used, connect this pin to VCC.

1

The layer next to controller (top or bottom) should be a ground

layer. Separate analog ground and power ground with a 0Ω

resistor is highly NOT recommended. Directly connect GND

PAD to low noise area of the system ground with at least four

vias.

2

Never place controller and its external components above or

under VIN plane or any switching nodes.

3

Never share CSRTN and VSEN on the same trace.

4

Place the input rail decoupling ceramic capacitors closely to

the high-side FET on the same layer as possible. Never use

only one via and a trace connect the input rail decoupling

ceramics capacitors; must connect to VIN and GND planes.

5

Place all decoupling capacitors in close proximity to the

controller and the system ground plane.

6

Connect remote sense (VSEN and RGND) to the load and

ceramic decoupling capacitors nodes; never run this pair

above or below switching noise plane.

7

Always double check critical component pinout and their

respective footprints.

Scale R so that the IOUT pin voltage is 2.5V at

63.875A load. Place R and C in general

proximity to the controller. The time constant of

RC should be sufficient as an averaging

function (>200µs) for the digital IOUT. An

external pull-up resistor to VCC placeholder is

recommended to cancel IOUT offset at 0A load.

See “IOUT Calibration” on page 19

The resistor divider must be referenced to VCC

pin and the system ground (GND); they can be

placed anywhere. DO NOT use decoupling

capacitors on these pins.

Directly connect to a low noise area of the

system ground. The GND PAD should use at

least four vias. Separate analog ground and

power ground with a 0Ω resistor is highly NOT

recommended.

DO NOT place it across or under external

components of the controller. Keep it at least

20 mils away from sensitive nodes.

DO NOT place it across or under external

components of the controller. Keep it at least

20 mils away from any other traces.

LGIN

NO

Keep it at least 20 mils away from sensitive

nodes. A series 100Ω resistor to low-side gate

signal is required for noise attenuation.

PVCC

YES

Place X7R 4.7µF in proximity to the PVCC pin

and the system ground plane.

FN8696 Rev.5.00

Jul 12, 2018

Voltage Regulator Design Materials

To support VR design and layout, Renesas also developed a set of

tools and evaluation boards, as listed in Table 14 and Ordering

Information on page 5. Contact the local office or field support

for the latest available information.

TABLE 14. AVAILABLE DESIGN ASSISTANCE MATERIALS

ITEM

1

DESCRIPTION

SMBus/PMBus/I2C communication tool with the

PowerNavigator GUI.

2

Evaluation board schematics in OrCAD format and

layout in Allegro format. See Ordering Information

on page 5 for details.

Page 30 of 33

�ISL68201

Revision History

The revision history provided is for informational purposes only and is believed to be accurate, but not warranted.