RP504x Series

600 mA PWM/VFM Step-Down DC/DC Converter with Synchronous Rectifier

NO.EA-259-170620

OUTLINE

The RP504x is a low supply current CMOS-based PWM/VFM step-down DC/DC converter with synchronous

rectifier featuring 600 mA*1 output current. Internally, a single converter consists of an oscillator, a reference

voltage unit, an error amplifier, a switching control circuit, a mode control circuit (RP504xxx1A/D), a soft-start

circuit, a Latch-type protection circuit, an under voltage lockout (UVLO) circuit a.nd switching transistors.

The RP504x is employing synchronous rectification for improving the efficiency of rectification by replacing

diodes with built-in switching transistors. Using synchronous rectification not only increases circuit performance

but also allows a design to reduce parts count.

Power controlling method can be selected from forced PWM control type or PWM/VFM auto switching control

type by inputting a signal to the MODE pin. In low output current, forced PWM control switches at fixed frequency

rate in order to reduce noise. Likewise, in low output current, PWM/VFM auto switching control automatically

switches from PWM mode to VFM mode in order to achieve high efficiency.

Output voltage is internally fixed type which allows output voltages that range from 0.8 V to 3.3 V in 0.1 V step.

The output voltage accuracy is as high as ±1.5% or ±18 mV.

Protection circuits included in the RP504x are overcurrent protection circuit and latch type protection circuit.

Overcurrent protection circuit supervises the inductor peak current in each switching cycle, and if the current

exceeds the LX current limit (ILXLIM), it turns off P-channel Tr. Latch type protection circuit latches the built-in driver

to the OFF state and stops the operation of the step-down DC/DC converter if the overcurrent status continues or

VOUT continues being the half of the setting voltage for equal or longer than protection delay time (tprot). To cancel

the latch type protection circuit, select the standby mode or the active mode with the CE pin, or drop the power

supply voltage below the UVLO detector threshold.

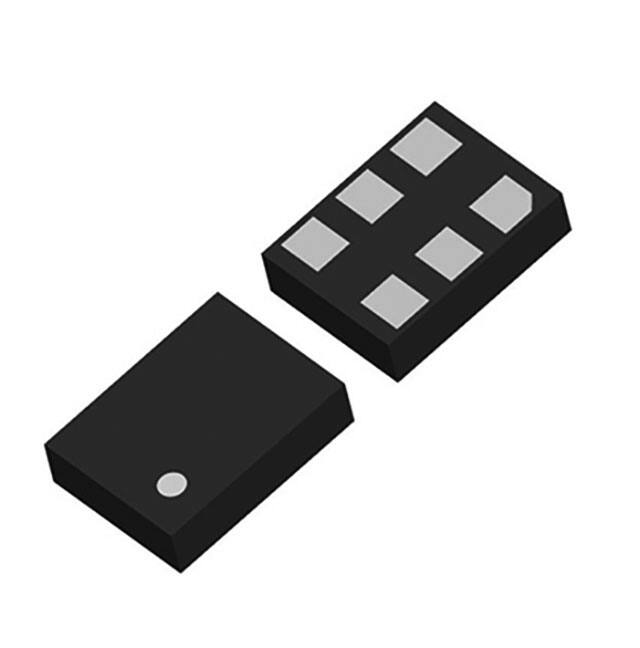

The RP504x is offered in 6-pin DFN(PLP)1216-6F, 6-pin DFN1616-6B and 5-pin SOT-23-5 packages which

achieve the smallest possible footprint solution on boards where area is limited.

*1

This is an approximate value. The output current is dependent on conditions and external components.

1

�RP504x

NO.EA-259-170620

FEATURES

• Supply Current ...................................................... Typ. 25 µA in VFM mode without any load

• Standby Current .................................................... Max. 5 µA

• Input Voltage Range ............................................. 2.3 V to 5.5 V (VOUT ≥ 1.0 V)

• Output Voltage Range........................................... 0.8 V to 3.3 V in 0.1 V step

• Output Voltage Accuracy....................................... ±1.5% (VOUT ≥ 1.2 V), ±18 mV (VOUT < 1.2 V)

• Temperature-Drift Coefficient of Output Voltage ... Typ. ±40 ppm/°C

• Oscillator Frequency ............................................. Typ. 2.25 MHz

• Oscillator Maximum Duty Cycle ............................ Min. 100%

• Built-in Driver ON Resistance ............................... Typ. Pch. 0.34 Ω, Nch. 0.43 Ω (VIN = 3.6 V)

• UVLO Detector Threshold..................................... Typ. 2.0 V

• Soft Start Time ...................................................... Typ. 0.15 ms

• LX Current Limit ..................................................... Typ. 900 mA

• Latch-type Protection Circuit ................................. Typ. 1.5 ms

• Auto-discharge Function ....................................... Only for RP504xxxxD

• Power Controlling Method ..................................... forced PWM control or PWM/VFM auto switching control

• MODE Pin*1 ........................................................... “H”: forced PWM control,

“L”: PWM/VFM auto switching control

• Package .............................................................. DFN1616-6B, DFN(PLP)1216-6F, SOT-23-5

*1

*1

DFN(PLP)1216-6F, DFN1616-6B: forced PWM control by pulling MODE pin “H” or PWM/VFM auto switching control by

pulling MODE pin “L”

SOT-23-5: forced PWM control for RP504xxxxC and PWM/VFM auto switching control for RP504xxxxB

APPLICATIONS

• Power source for battery-powered equipment.

• Power source for hand-held communication equipment, cameras, VCRs, camcorders.

• Power source for HDD, portable equipment.

2

�RP504x

NO.EA-259-170620

SELECTION GUIDE

The set output voltage, the package type, the MODE control pin function and the auto-discharge*1 function

are user-selectable options.

Product Name

Package

Quantity per Reel

Pb Free

Halogen Free

RP504Kxx1$-E2

DFN(PLP)1216-6F

5,000 pcs

Yes

Yes

RP504Lxx1$-TR

DFN1616-6B

5,000 pcs

Yes

Yes

RP504Nxx1$-TR-FE

SOT-23-5

3,000 pcs

Yes

Yes

xx: Specify the set output voltage (VSET) within the range of 0.8 V(08) to 3.3 V(33) in 0.1 V steps.

Refer to the section of PACKAGE INFORMATION for detailed information.

$: Specify the package type, the MODE control pin function and the auto-discharge function.

$

A

DFN1616-6B

DFN(PLP)1216-6F

MODE Control Pin Function

Auto-discharge

Function

MODE Pin

Power Controlling Method

Yes

“H”: forced PWM

“L”: PWM/VFM auto switching control

No

B

SOT-23-5

No

PWM/VFM auto switching control

No

C

SOT-23-5

No

forced PWM control

No

Yes

“H”: forced PWM control

“L”: PWM/VFM auto switching control

Yes

D

*1

Package

DFN1616-6B

DFN(PLP)1216-6F

Auto-discharge function quickly lowers the output voltage to 0 V, when the chip enable signal is switched from the

active mode to the standby mode, by releasing the electrical charge accumulated in the external capacitor.

*2

0.05 V step is also available as a custom code.

3

�RP504x

NO.EA-259-170620

BLOCK DIAGRAMS

VIN

CE

CHIP

ENABLE

CURRENT

RAMP

COMPENSATION

FEEDBACK

OSCILLATOR

VREF

PWM

SOFT

START

CURRENT

PROTECTION

Lx

SWITCHING

CONTROL

UVLO

VOUT

MODE

GND

RP504xxxxA Block Diagram

VIN

CE

CHIP

ENABLE

CURRENT

FEEDBACK

RAMP

COMPENSATION

OSCILLATOR

VREF

SOFT

START

PWM

CURRENT

PROTECTION

SWITCHING

CONTROL

UVLO

MODE

GND

RP504xxxxB Block Diagram

4

Lx

VOUT

�RP504x

NO.EA-259-170620

VIN

CE

CHIP

ENABLE

CURRENT

FEEDBACK

RAMP

COMPENSATION

OSCILLATOR

VREF

PWM

SOFT

START

CURRENT

PROTECTION

Lx

SWITCHING

CONTROL

UVLO

VOUT

MODE

GND

RP504xxxxC Block Diagram

VIN

CE

CHIP

ENABLE

RAMP

COMPENSATION

CURRENT

FEEDBACK

OSCILLATOR

VREF

SOFT

START

PWM

CURRENT

PROTECTION

LX

SWITCHING

CONTROL

UVLO

VOUT

MODE

GND

RP504xxxxD Block Diagram

5

�RP504x

NO.EA-259-170620

PIN DESCRIPTION

6

5

4

6

5

4

5

4

∗

1

2

3

DFN(PLP)1216-6F Pin Configurations

1

2

3

DFN1616-6B Pin Configurations

1

2

3

SOT-23-5 Pin Configurations

RP504Kxx1A, RP504Kxx1D: DFN(PLP)1216-6F Pin Description

Pin No.

Symbol

Description

1

VIN

Input Pin

Mode Control Pin

2

MODE

(“H”: forced PWM control, “L”: PWM/VFM auto switching

control)

3

CE

Chip Enable Pin (Active-high)

4

VOUT

Output Pin

5

GND

Ground Pin

6

LX

LX Switching Pin

RP504Lxx1A, RP504Lxx1D: DFN1616-6B Pin Description

Pin No.

Symbol

Description

1

CE

Chip Enable Pin (Active-high)

Mode Control Pin

2

MODE

(“H”: forced PWM control, “L”: PWM/VFM auto switching

control)

3

VIN

Input Pin

4

LX

LX Switching Pin

5

GND

Ground Pin

6

VOUT

Output Pin

∗ The tab on the bottom of the package enhances thermal performance and is electrically connected to GND (substrate

level). It is recommended that the tab be connected to the ground plane on the board. If not, the tab can be left open.

RP504Nxx1B, RP504Nxx1C: SOT-23-5 Pin Description

Pin No.

Symbol

Description

1

VOUT

Output Pin

2

GND

Ground Pin

3

LX

LX Switching Pin

4

VIN

Input Pin

5

CE

Chip Enable Pin (Active-high)

6

�RP504x

NO.EA-259-170620

ABSOLUTE MAXIMUM RATINGS

Absolute Maximum Ratings

Symbol

Item

*1

(GND = 0 V)

Rating

Unit

−0.3 to 6.5

V

−0.3 to VIN +0.3

V

VIN

VIN Input Voltage

VLX

LX Pin Voltage

VCE

CE Pin Input Voltage

−0.3 to 6.5

V

VMODE

Mode Control Pin Voltage

−0.3 to 6.5

V

VOUT

VOUT Pin Voltage

−0.3 to 6.5

V

900

mA

ILX

LX Pin Output Current

PD

Power Dissipation

(Standard Land Pattern)*1

DFN(PLP)1216-6F

385

DFN1616-6B

640

SOT-23-5

420

mW

Tj

Junction Temperature Range

−40 to 125

°C

Tstg

Storage Temperature Range

−55 to 125

°C

Refer to POWER DISSIPATION for detailed information.

ABSOLUTE MAXIMUM RATINGS

Electronic and mechanical stress momentarily exceeded absolute maximum ratings may cause the permanent

damages and may degrade the life time and safety for both device and system using the device in the field. The

functional operation at or over these absolute maximum ratings is not assured.

RECOMMENDED OPERATING CONDITIONS

Recommended Operating Conditions

Symbol

Item

Rating

VIN

Operating Input Voltage

Ta

Operating Temperature Range

Unit

2.3 to 5.5 (VOUT ≥ 1.0)

V

2.3 to 4.5 (VOUT < 1.0)

V

−40 to 85

°C

RECOMMENDED OPERATING CONDITIONS

All of electronic equipment should be designed that the mounted semiconductor devices operate within the

recommended operating conditions. The semiconductor devices cannot operate normally over the recommended

operating conditions, even if when they are used over such conditions by momentary electronic noise or surge. And

the semiconductor devices may receive serious damage when they continue to operate over the recommended

operating conditions.

7

�RP504x

NO.EA-259-170620

ELECTRICAL CHARACTERISTICS

RP504xxx1A, RP504xxx1D Electrical Characteristics

Symbol

Item

Conditions

Max.

x0.985

x1.015

VOUT < 1.2 V

−0.018

+0.018

VIN = VCE = 3.6 V

or VSET +1 V

Output Voltage Temperature

Coefficient

−40°C ≤ Ta ≤ 85°C

fosc

Oscillator Frequency

VIN = VCE = 3.6 V or VSET +1 V

IDD1

Supply Current 1

IDD2

Supply Current 2

VIN = VCE = VOUT

= 5.5 V

Istandby

Standby Current

VIN = 5.5 V, VCE = 0 V

ICEH

CE "H" Input Voltage

VIN = VCE = 5.5 V

ICEL

CE "L" Input Voltage

IMODEH

IMODEL

∆VOUT/∆Ta

Typ.

VOUT ≥ 1.2 V

Output Voltage

VOUT

(Ta = 25°C)

Min.

±40

1.95

Unit

V

ppm/°C

2.25

2.55

MHz

VIN = VCE = 5.5 V, VOUT = VSET ×

0.8

400

800

µA

VMODE = 0 V

25

40

VMODE = 5.5 V

400

800

0

5

µA

−1

0

1

µA

VIN = 5.5 V, VCE = 0 V

−1

0

1

µA

Mode "H" Input Current

VIN = VMODE = 5.5 V

−1

0

1

µA

Mode "L" Input Current

VIN = 5.5 V, VMODE = 0 V

−1

0

1

µA

µA

IVOUTH

VOUT "H" Input Current

VIN = VOUT = 5.5 V, VCE = 0 V

−1

0

1

µA

IVOUTL

VOUT "L" Input Current

VIN = 5.5 V, VCE = VOUT = 0 V

−1

0

1

µA

ILXLEAKH

LX Leakage Current "H"

VIN = VLX = 5.5 V, VCE = 0 V

−1

0

5

µA

ILXLEAKL

LX Leakage Current "L"

VIN = 5.5 V, VCE = VLX = 0 V

−5

0

1

µA

VCEH

CE "H" Input Voltage

VIN = 5.5 V

1.0

VCEL

CE "L" Input Voltage

VIN = 2.3 V

VMODEH

Mode ”H” Input Voltage

VIN = 5.5 V

VMODEL

Mode ”L” Input Voltage

VIN = 2.3 V

RLOW

Nch On Resistance*2

VIN = 3.6 V, VCE = 0 V

RONP

On Resistance of Pch Tr.

RONN

On Resistance of Nch Tr.

Maxduty

*1

V

0.4

1.0

V

V

0.4

V

30

Ω

VIN = 3.6 V, ILX = −100 mA

0.34

Ω

VIN = 3.6 V, ILX = −100 mA

0.43

Ω

Oscillator Maximum Duty

Cycle

100

%

150

310

µs

tstart

Soft-start Time

VIN = VCE = 3.6 V or VSET +1 V

ILXLIM

Lx Current Limit

VIN = VCE = 3.6 V or VSET +1 V

700

900

tprot

Protection Delay Time

VIN = VCE = 3.6 V or VSET +1 V

0.5

1.5

5

ms

VUVLO1

UVLO Detector Threshold

VIN = VCE

1.9

2.0

2.1

V

VUVLO2

UVLO Released Voltage

VIN = VCE

2.0

2.1

2.2

V

mA

All test items listed under ELECTRICAL CHARACTERISTICS are done under the pulse load condition (Tj ≈ Ta = 25°C) except

Output Voltage Temperature Coefficient.

Test circuit is "OPEN LOOP" and AGND = PGND = 0 V unless otherwise specified.

*1

Only for RP504xxx1A/B/C with no auto-discharge

*2

Only for RP504xxx1D with auto-discharge

8

�RP504x

NO.EA-259-170620

RP504xxxxB, RP504xxxxC Electrical Characteristics

Symbol

Item

Conditions

Typ.

Max.

x0.985

x1.015

VOUT < 1.2 V

−0.018

+0.018

VIN = VCE = 3.6 V

or VSET +1 V

Output Voltage Temperature

Coefficient

−40°C ≤ Ta ≤ 85°C

fosc

Oscillator Frequency

VIN = VCE = 3.6 V or VSET +1 V

IDD1

Supply Current 1

VIN = VCE = 5.5 V,

VOUT = VSET × 0.8

IDD2

Supply Current 2

VIN = VCE = VOUT

= 5.5 V

Istandby

Standby Current

VIN = 5.5 V, VCE = 0 V

ICEH

CE "H" Input Voltage

VIN = VCE = 5.5 V

ICEL

CE "L" Input Voltage

IVOUTH

IVOUTL

∆VOUT/∆Ta

Min.

VOUT ≥ 1.2 V

Output Voltage

VOUT

(Ta = 25°C)

±40

1.95

Unit

V

ppm/°C

2.25

2.55

MHz

400

800

µA

RP504xxx1B

25

40

RP504xxx1C

400

800

0

5

µA

−1

0

1

µA

VIN = 5.5 V, VCE = 0 V

−1

0

1

µA

VOUT "H" Input Current

VIN = VOUT = 5.5 V, VCE = 0 V

−1

0

1

µA

VOUT "L" Input Current

VIN = 5.5 V, VCE = VOUT = 0 V

−1

0

1

µA

ILXLEAKH

LX Leakage Current "H"

VIN = VLX = 5.5 V, VCE = 0 V

−1

0

5

µA

ILXLEAKL

LX Leakage Current "L"

VIN = 5.5 V, VCE = VLX = 0 V

−5

0

1

µA

VCEH

CE "H" Input Voltage

VIN = 5.5 V

1.0

VCEL

CE "L" Input Voltage

VIN =2.3 V

RONP

On Resistance of Pch Tr.

VIN =3.6 V, ILX = −100 mA

0.34

Ω

RONN

On Resistance of Nch Tr.

VIN =3.6 V, ILX = −100 mA

0.43

Ω

Maxduty

Oscillator Maximum Duty

Cycle

µA

V

0.4

100

V

%

150

310

µs

tstart

Soft-start Time

VIN = VCE = 3.6 V or VSET +1 V

ILXLIM

LX Current Limit

VIN = VCE = 3.6 V or VSET +1 V

700

900

tprot

Protection Delay Time

VIN = VCE = 3.6 V or VSET +1 V

0.5

1.5

5

ms

VUVLO1

UVLO Detector Threshold

VIN = VCE

1.9

2.0

2.1

V

VUVLO2

UVLO Released Voltage

VIN = VCE

2.0

2.1

2.2

V

mA

All test items listed under ELECTRICAL CHARACTERISTICS are done under the pulse load condition (Tj ≈ Ta = 25°C) except

Output Voltage Temperature Coefficient.

Test circuit is "OPEN LOOP" and AGND = PGND = 0 V unless otherwise specified.

9

�RP504x

NO.EA-259-170620

OPERATING DESCRIPTIONS

OPERATION OF STEP-DOWN CONVERTER AND OUTPUT CURENT

The step-down DC/DC converter charges energy in the inductor when LX Tr. turns “ON”, and discharges the

energy from the inductor when LX Tr. turns “OFF” and operates with less energy loss, so that a lower output

voltage (VOUT) than the input voltage (VIN) can be obtained. The operation of the step-down DC/DC converter is

explained in the following figures.

IL

ILmax

i1

VIN

Pch Tr

Nch Tr

VOUT

L

ILmin

topen

i1

i2

i2

CL

GND

ton

toff

T=1/fosc

Figure 1. Basic Circuit

Figure 2. Inductor Current (IL) flowing through Inductor

Step1.

P-channel Tr. turns “ON” and IL (i1) flows, L is charged with energy. At this moment, i1 increases from

the minimum inductor current (ILmin), which is 0 A, and reaches the maximum inductor current (ILmax)

in proportion to the on-time period (ton) of P-channel Tr.

Step2. When P-channel Tr. turns “OFF”, L tries to maintain IL at ILmax, so L turns N-channel Tr. “ON” and IL

(i2) flows into L.

Step3. i2 decreases gradually and reaches ILmin after the open-time period (topen) of N-channel Tr., and then

N-channel Tr. turns “OFF”. This is called discontinuous current mode.

As the output current (IOUT) increases, the off-time period (toff) of P-channel Tr. runs out before IL reaches

ILmin. The next cycle starts, and P-channel Tr. turns “ON” and N-channel Tr. turns “OFF”, which means

IL starts increasing from ILmin. This is called continuous current mode.

In the case of PWM mode, VOUT is maintained by controlling ton. During the PWM mode, the oscillator frequency

(fosc) is constantly maintained.

As shown in Figure 2, when the step-down DC/DC operation is constant, ILmin and ILmax during ton of P-channel

Tr. would be the same as ILmin and ILmax during toff of the P-channel Tr.

The current differential between ILmax and ILmin is described as ∆I.

∆I = ILmax − ILMIN = VOUT × topen / L = (VIN − VOUT) × ton / L ....................................... Equation 1

However,

T = 1 / fosc = ton + toff

Duty (%) = ton / T × 100 = ton × fosc × 100

topen ≤ toff

In Equation 1, “VOUT × topen / L” shows the amount of current change in “OFF” state. Also, “(VIN − VOUT) × ton /

L” shows the amount of current change at “ON” state.

10

�RP504x

NO.EA-259-170620

DISCONTINUOUS MODE AND CONTINUOUS MODE

As illustrated in Figure 3, when IOUT is relatively small, topen < toff. In this case, the energy charged into L during

ton will be completely discharged during toff, as a result, ILMIN = 0. This is called discontinuous mode.

When IOUT is gradually increased, eventually topen = toff and when IOUT is increased further, eventually ILMIN > 0.

This is called continuous mode.

IL

ILMAX

IL

ILMAX

ILMIN

ILMIN

topen

t

ton

ICONST

t

toff

ton

T = 1 / fosc

Figure 3. Discontinuous Mode

toff

T = 1 / fosc

Figure 4. Continuous Mode

In the continuous mode, the solution of Equation 1 is described as tonc.

tonc = T × VOUT / VIN ............................................................................................................... Equation 2

When ton < tonc, it indicates discontinuous mode, and when ton = tonc, it indicates continuous mode.

11

�RP504x

NO.EA-259-170620

TIMING CHART

1. Soft-start Time

Starting-up with CE Pin

The IC starts to operate when the CE pin voltage (VCE) exceeds the threshold voltage. The threshold voltage

is preset between CE “H” input voltage (VCEH) and CE “L” input voltage (VCEL).

After the start-up of the IC, soft-start circuit starts to operate. Then, after a certain period of time, the

reference voltage (VREF) in the IC gradually increases up to the specified value.

CE Pin Input Voltage

(VCE)

IC Internal Reference Voltage

(VREF)

Lx Voltage

(VLX)

VCEH

Threshold Level

VCEL

Soft-start Time

Soft-start Circuit

operation starts.

IC operates with PWM mode

during Soft-start time.

Output Voltage

(VOUT)

Depending on Power Supply,

Load Current, External Components

Soft-start time starts when soft-start circuit is activated, and ends when the reference voltage reaches the

specified voltage.

Soft start time is not always equal to the turn-on speed of the step-down DC/DC converter. Please note that the

turn-on speed could be affected by the power supply capacity, the output current, the inductance value and the

COUT value.

Starting-up with Power Supply

After the power-on, when VIN exceeds the UVLO released voltage (VUVLO2), the IC starts to operate. Then, softstart circuit starts to operate and after a certain period of time, VREF gradually increases up to the specified

value. Soft-start time starts when soft-start circuit is activated, and ends when VREF reaches the specified voltage.

VSET

VUVLO2

Input Voltage

(VIN)

VUVLO1

Soft-start Time

IC Internal Reference Voltage

(VREF)

Lx Voltage

(VLX)

IC operates with PWM mode during Soft-start time.

VSET

Output Voltage

(VOUT)

Depending on Power Supply, Load Current,

External Components

Please note that the turn-on speed of VOUT could be affected by the power supply capacity, the output current,

the inductance value, the COUT value and the turn-on speed of VIN determined by CIN.

12

�RP504x

NO.EA-259-170620

2. Under Voltage Lockout (UVLO) Circuit

If VIN becomes lower than VSET, the step-down DC/DC converter stops the switching operation and ON duty

becomes 100%, and then VOUT gradually drops according to VIN.

If the VIN becomes lower than the UVLO detector threshold (VUVLO1), the UVLO circuit starts to operate, VREF

stops, and P-channel and N-channel built-in switch transistors turn “OFF”. As a result, VOUT drops according to

the COUT capacitance value and the load.

To restart the operation, VIN needs to be higher than VUVLO2. The timing chart below shows the voltage shifts of

VREF, VLX and VOUT when VIN value is varied.

Input Voltage

(VIN)

VSET

VUVLO2

VUVLO1

Soft-start Time

IC Internal Reference Voltage

(VREF)

Lx Voltage

(VLX)

Output Voltage

(VOUT)

VSET

Depending on Power Supply, Load Current,

External Components

Falling edge (operating) and rising edge (releasing) waveforms of VOUT could be affected by the initial voltage

of COUT and the output current of VOUT.

13

�RP504x

NO.EA-259-170620

3. Overcurrent Protection Circuit, Latch Type Protection Circuit

Overcurrent protection circuit supervises the inductor peak current (the peak current flowing through Pch Tr.) in

each switching cycle, and if the current exceeds the LX current limit (ILXLIM), it turns off Pch Tr. ILXLIM of the

RP504x is set to Typ.900 mA.

Latch type protection circuit latches the built-in driver to the OFF state and stops the operation of the step-down

DC/DC converter if the overcurrent status continues or VOUT continues being the half of the setting voltage for

equal or longer than protection delay time (tprot).

Please note that ILXLIM and tprot could be easily affected by self-heating or ambient environment. If the VIN drops

dramatically or becomes unstable due to short-circuit, protection operation and tprot could be affected.

Protection Delay Time (tprot)

Lx Current

Lx Current Limit (ILXlim)

Pch Tr. Current

Lx Voltage

(VLX)

To release the latch type protection circuit, restart the IC by inputting "L" signal to the CE pin, or restart the IC

with power-on or make the supply voltage lower than VUVLO1.

The timing chart below shows the voltage shift of VCE, VLX and VOUT when the IC status is changed by the

following orders: VIN rising → stable operation → high load → CE reset → stable operation → VIN falling → VIN

recovering (UVLO reset) → stable operation.

(1)(2) If the large current flows through the circuit or if the IC goes into low VOUT condition due to short-circuit or

other reasons, the latch type protection circuit latches the built-in driver to “OFF” state after tprot. Then,

VLX becomes "L" and VOUT turns “OFF”.

(3) The latch type protection circuit is released by CE reset, which puts the IC into "L" once with the CE pin and

back into "H".

(4) The latch type protection circuit is released by UVLO reset, which makes VIN lower than VUVLO1.

(1)

(3)

(2)

(4)

SET

Input Voltage UVLO Released VoltageV(V

UVLO2)

(VIN)

UVLO Detector Threshold (VUVLO1)

CE Pin

Input Voltage

(VCE)

Lx Voltage

(VLX)

Output Voltage

(VOUT)

UVLO Reset

VSET

CE Reset

Threshold Level

Protection Delay Time

VSET

VSET

Latch-type Protection

Stable

Operation

Soft-start Time

14

Protection Delay Time

Stable

Operation

Soft-start Time

Latch-type Protection

Stable

Operation

Soft-start Time

�RP504x

NO.EA-259-170620

APPLICATION INFORMATION

TYPICAL APPLICATION CIRCUIT

Control

VOUT

CE

RP504N

GND

Load

VIN

VIN

LX

COUT 4.7µF

L 2.2µH

CIN 2.2µF

RP504N Typical Application Circuit: MODE Pin not included

Control

VOUT

CE

RP504L/K

Control

MODE

*1

GND

Load

VIN

VIN

LX

L 2.2µH

CIN 2.2µF

COUT 4.7µF

RP504K/L Typical Application Circuit: MODE Pin included

*1

MODE = “H”: forced PWM control, MODE = “L”: PWM/VFM auto switching control

Recommended Components

Symbol

Capacitance

Type

2.2 µF

CIN

2.2 µF x 2

Manufacturer

C1608JB0J225K(TDK)

Ceramic Capacitor

4.7 µF

COUT

4.7 µF

Ceramic Capacitor

L

2.2 µH

Inductor

C1005JB0J225K (TDK)

JMK105BJ225MV (Taiyo Yuden)

C1005X5R0J475M (TDK)

JMK105BJ475MV (Taiyo Yuden)

C1608JB0J475K (TDK)

GRM188B30J475KE18 (Murata)

MIPSZ2520D2R2 (FDK)

MIPS2520D2R2 (FDK)

MLP2520S2R2M (TDK)

VLS252010T-2R2M (TDK)

15

�RP504x

NO.EA-259-170620

OUTPUT CURRENT AND SELECTION OF EXTERNAL COMPONENTS

The following equations explain the relationship between output current and peripheral components used in the

diagrams in TYPICAL APPLICATIONS.

Ripple Current P-P value is described as IRP, ON resistance of P-channel Tr. is described as RONP, ON

resistance of N-channel Tr. is described as RONN, and DC resistor of the inductor is described as RL.

VIN = VOUT + (RONP + RL) × IOUT + L × IRP / ton .............................................................. Equation 3

Second, when P-channel Tr. is “OFF” (N-channel Tr. Is “ON”), the following equation is satisfied.

L × IRP / toff = RONN × IOUT + VOUT + RL × IOUT ............................................................... Equation 4

Put Equation 4 into Equation 3 to solve ON duty of P-channel Tr. (DON = ton / (toff + ton)):

DON = (VOUT + RONN × IOUT + RL × IOUT) / (VIN + RONN × IOUT − RONP × IOUT) ................... Equation 5

Ripple Current is described as follows:

IRP = (VIN − VOUT − RONP × IOUT − RL × IOUT) × DON / fosc / L ......................................... Equation 6

Peak current that flows through L, and LX Tr. is described as follows:

ILXMAX = IOUT + IRP / 2 .................................................................................................... Equation 7

Consider ILXMAX when setting conditions of input and output, as well as selecting the external components.

The above calculation formulas are based on the ideal operation of the ICS in continuous mode.

16

�RP504x

NO.EA-259-170620

TECHNICAL NOTES

The performance of power supply circuits using this IC largely depends on the peripheral circuits. Please be very

careful when setting the peripheral parts. When designing the peripheral circuits of each part, PCB patterns, and

this IC, please do not exceed the rated values (Voltage, Current, Power).

•

Ensure the VIN and GND lines are sufficiently robust. A large switching current flows through the GND lines,

the VDD line, the VOUT line, an inductor, and LX. If their impedance is too high, noise pickup or unstable

operation may result. Set the external components as close as possible to the IC and minimize the wiring

between the components and the IC, especially between a capacitor (CIN) and the VIN pin. The wiring between

•

•

VOUT and load and between L and VOUT should be separated.

Choose a low ESR ceramic capacitor. The capacitance of CIN should be more than or equal to 2.2 µF. The

capacitance of a capacitor (COUT) should be between 4.7 µF to 10 µF.

The Inductance value should be set within the range of 2.2 µH to 4.7 µH. However, the inductance value is

limited by output voltage. Refer to the table below. The phase compensation of this IC is designed according

to the COUT and L values. Choose an inductor that has small DC resistance, has enough allowable current

and is hard to cause magnetic saturation. If the inductance value of an inductor is extremely small, the peak

current of LX may increase. The increased LX peak current reaches “LX limit current” to trigger overcurrent

•

protection circuit even if the load current is less than 600 mA.

Overcurrent protection circuit, Latch-type protection circuit may be affected by self-heating and heat radiation

environment.

PCB LAYOUT

RP504Nxx1B/C (PKG: SOT-23-5) typical board layout

Topside

Backside

17

�RP504x

NO.EA-259-170620

RP504Lxx1A/D (PKG: DFN1616-6B) typical board layout

Topside

Backside

RP505Kxx1A/D (PKG: DFN(PLP)1216-6F) typical board layout

Topside

18

Backside

�RP504x

NO.EA-259-170620

TYPICAL CHARACTERISTICS

Note: Typical Characteristics are intended to be used as reference data; they are not guaranteed.

1) Output Voltage vs. Output Current

RP504x

VOUT = 0.8 V

RP504x

MODE = “L”PWM/VFM Auto Switching Control

MODE = “H” Forced PWM Control

0.820

0.815

VIN=3.6V

0.810

VIN=4.5V

0.805

0.800

0.795

0.790

0.785

Output Voltage V OUT (V)

Output Voltage V OUT (V)

0.820

0.780

0.01

0.815

VIN=3.6V

0.810

VIN=4.5V

0.805

0.800

0.795

0.790

0.785

0.780

0.1

1

10

100

0

100

Output Current IOUT (mA)

RP504x

VOUT = 1.2 V

1.210

VIN=5.0V

1.205

1.200

1.195

1.190

1.185

Output Voltage V OUT (V)

Output Voltage V OUT (V)

1.215

1.180

1.215

VIN=3.6V

1.210

VIN=5.0V

1.205

1.200

1.195

1.190

1.185

1.180

0.1

1

10

Output Current IOUT (mA)

RP504x

100

0

VOUT = 1.8 V

100 200 300 400 500

Output Current IOUT (mA)

RP504x

MODE = “L”PWM/VFM Auto Switching Control

600

VOUT = 1.8 V

MODE = “H” Forced PWM Control

1.830

VIN=3.6V

VIN=5.0V

1.810

1.800

1.790

Output Voltage V OUT (V)

1.830

Output Voltage V OUT (V)

VOUT = 1.2 V

1.220

VIN=3.6V

VIN=3.6V

1.820

VIN=5.0V

1.810

1.800

1.790

1.780

1.780

0.01

600

MODE = “H” Forced PWM Control

1.220

1.820

200 300 400 500

Output Current IOUT (mA)

RP504x

MODE = “L”PWM/VFM Auto Switching Control

0.01

VOUT = 0.8 V

0.1

1

10

Output Current IOUT (mA)

100

0

100

200

300

400

500

600

Output Current IOUT (mA)

19

�RP504x

NO.EA-259-170620

RP504x VOUT = 3.3 V

MODE = “L”PWM/VFM Auto Switching Control

RP504x VOUT = 3.3 V

MODE = “H” Forced PWM Control

3.320

VIN=4.3V

3.310

VIN=5.0V

3.300

3.290

3.280

VIN=4.3V

Output Voltage V OUT (V)

Output Voltage V OUT (V)

3.320

3.310

VIN=5.0V

3.300

3.290

3.280

3.270

3.270

0.01

0.1

1

10

Output Current IOUT (mA)

0

100

100

200

300

400

500

600

Output Current IOUT (mA)

2) Output Voltage vs. Input Voltage

RP504x VOUT = 1.2 V

MODE = “H” Forced PWM Control

0.820

1.220

0.815

1.215

Output Voltage V OUT (V)

Output Voltage V OUT (V)

RP504x VOUT = 0.8 V

MODE = “H” Forced PWM Control

0.810

0.805

0.800

IOUT=1mA

0.795

IOUT=50mA

0.790

IOUT=250mA

0.785

0.780

1.210

1.205

1.200

1.195

1.190

2.5

3

3.5

4

Input Voltage VIN(V)

4.5

2

RP504x VOUT = 1.8 V

MODE = “H” Forced PWM Control

Output Voltage V OUT (V)

Output Voltage V OUT (V)

1.82

1.81

1.8

IOUT=1mA

1.79

IOUT=50mA

IOUT=250mA

1.78

1.77

2.5

3

3.5

4

4.5

Input Voltage VIN(V)

5

5.5

2.5

3

3.5

4

4.5

Input Voltage VIN(V)

5

5.5

RP504x VOUT = 3.3 V

MODE = “H” Forced PWM Control

1.83

20

IOUT=250mA

1.185

1.180

2

2

IOUT=1mA

IOUT=50mA

3.35

3.34

3.33

3.32

3.31

3.3

3.29

3.28

3.27

3.26

3.25

IOUT=1mA

IOUT=50mA

IOUT=250mA

3.5

4

4.5

Input Voltage VIN(V)

5

5.5

�RP504x

NO.EA-259-170620

3) Output Voltage vs. Temperature

Output Voltage V OUT (V)

1.830

1.820

VIN=3.6V

1.810

1.800

1.790

1.780

1.770

-50

-25

0

25

50

75

Temperature Ta(°C)

100

4) Efficiency vs. Output Current

RP504x

VOUT = 0.8 V

100

Efficiency (%)

80

100

VIN=4.5V, VMODE=0V

90

VIN=3.6V, VMODE=0V

70

60

50

VIN=VMODE=4.5V

40

30

VIN=VMODE=3.6V

20

VIN=3.6V, VMODE=0V

70

60

50

40

VIN=VMODE=5.0V

30

VIN=VMODE=3.6V

10

0.1

1

10

100

Output Current IOUT (mA)

0

0.01

1000

VOUT = 1.8 V

VIN=5.0V, VMODE=0V

100

VIN=3.6V, VMODE=0V

90

80

70

60

50

40

VIN=VMODE=5.0V

30

20

VIN=VMODE=3.6V

10

0

0.01

0.1

1

10

100

1000

Output Current IOUT (mA)

0.1

1

10

100

Output Current IOUT (mA)

RP504x

Efficiency (%)

RP504x

Efficiency (%)

VIN=5.0V, VMODE=0V

20

10

0

0.01

VOUT = 1.2 V

80

Efficiency (%)

90

RP504x

1000

VOUT = 3.3 V

VIN=5.0V, VMODE=0V

100 VIN=4.3V, VMODE=0V

90

80

70

60

50

VIN=VMODE=4.3V

40

30

20

VIN=VMODE=3.6V

10

0

0.01

0.1

1

10

100

1000

Output Current IOUT (mA)

21

�RP504x

NO.EA-259-170620

5) Supply Current vs. Temperature

6) Supply Current vs. Input Voltage

RP504x VOUT = 1.8 V (VIN = 5.5 V)

MODE = “L”PWM/VFM Auto Switching Control

RP504x VOUT = 1.8 V

MODE = “L”PWM/VFM Auto Switching Control

40

Closed Loop

35

Supply Current (µA)

Supply Current (µA)

40

Open Loop

30

25

20

15

10

35

Closed Loop

30

Open Loop

25

20

15

10

-50

-25

0

25

50

Temperature Ta(°C)

75

100

2

2.5

3

3.5

4

4.5

Input Voltage VIN (V)

5

5.5

7) Output Voltage Waveform

RP504x VOUT = 0.8 V (VIN = 3.6 V)

MODE = “L”PWM/VFM Auto Switching Control

RP504x VOUT = 0.8 V (VIN = 3.6 V)

MODE = “H” Forced PWM Control

0

5

10

Time t (µs)

15

20

Output Voltage

IL

100

50

0

-50

-100

0

RP504x VOUT = 1.2V (VIN = 3.6 V)

MODE = “L”PWM/VFM Auto Switching Control

0

22

5

10

Time t (µs)

15

20

0.04

0.03

0.02

0.01

0.00

-0.01

Output Ripple Voltage (AC)

Vripple (V)

300

200

100

0

-100

2

3

4 5 6 7

Time t (µs)

8

9 10

IOUT=10mA

Inductor Current IL (mA)

Output Ripple Voltage (AC)

Vripple (V)

Output Voltage

IL

1

RP504x VOUT = 1.2 V (VIN = 3.6 V)

MODE = “H” Forced PWM Control

IOUT=10mA

0.04

0.03

0.02

0.01

0.00

-0.01

Inductor Current IL (mA)

300

200

100

0

-100

0.04

0.03

0.02

0.01

0.00

-0.01

Output Voltage

Inductor Current IL (mA)

IL

Output Ripple Voltage (AC)

Vripple (V)

Output Voltage

IOUT=10mA

Inductor Current IL (mA)

Output Ripple Voltage (AC)

Vripple (V)

IOUT=10mA

0.04

0.03

0.02

0.01

0.00

-0.01

IL

100

50

0

-50

-100

0

1

2

3

4 5 6 7

Time t (µs)

8

9 10

�RP504x

NO.EA-259-170620

VOUT = 1.8 V (VIN = 3.6 V)

RP504x

MODE = “L”PWM/VFM Auto Switching Control

MODE = “H” Forced PWM Control

IL

300

200

100

0

-100

0

5

RP504x

10

Time t (µs)

15

IOUT=10mA

0.04

0.03

0.02

0.01

0.00

-0.01

Output Voltage

IL

100

50

0

-50

-100

0

20

VOUT = 3.3 V (VIN = 5.0 V)

1

2

3

4 5 6 7

Time t (µs)

RP504x

MODE = “L”PWM/VFM Auto Switching Control

8

9 10

VOUT = 3.3 V (VIN = 5.0 V)

MODE = “H” Forced PWM Control

IL

300

200

100

0

-100

0

5

10

Time t (µs)

15

IOUT=10mA

Output Ripple Voltage (AC)

Vripple (V)

Output Ripple Voltage (AC)

Vripple (V)

Output Voltage

Inductor Current IL (mA)

IOUT=10mA

0.04

0.03

0.02

0.01

0.00

-0.01

0.04

0.03

0.02

0.01

0.00

-0.01

Output Voltage

IL

200

150

100

50

0

-50

-100

0

20

8) Frequency vs. Temperature

Inductor Current IL (mA)

Inductor Current IL (mA)

Output Ripple Voltage (AC)

Vripple (V)

Output Voltage

Output Ripple Voltage (AC)

Vripple (V)

IOUT=10mA

0.04

0.03

0.02

0.01

0.00

-0.01

VOUT = 1.8 V (VIN = 3.6 V)

1

2

3

4 5 6 7

Time t (µs)

8

Inductor Current IL (mA)

RP504x

9 10

9) Frequency vs. Input Voltage

2.5

2.5

Frequency fosc (MHz)

Frequency fosc (MHz)

-40°C

VIN=3.6V

2.4

2.3

2.2

2.1

2

2.4

25°C

85°C

2.3

2.2

2.1

2

-50

-25

0

25

50

Temperature Ta (°C)

75

100

2

2.5

3

3.5

4

4.5

5

5.5

Input Voltage VIN (V)

23

�RP504x

NO.EA-259-170620

10) Soft Start Time vs. Temperature

Soft Start Time tstart (µs)

220

210

200

190

180

170

-50

-25

0

25

50

75

Temperature Ta(°C)

100

11) UVLO Detector Threshold / Released Voltage vs. Temperature

UVLO Detector Threshold Voltage

UVLO Released Voltage

2.3

UVLO Voltage V UVLO2 (V)

UVLO Voltage V UVLO1 (V)

2.3

2.2

2.1

2.0

2.2

2.1

2.0

1.9

1.9

-50

-25

0

25

50

Temperature Ta(°C)

75

-50

100

-25

0

25

50

75

Temperature Ta(°C)

100

12) CE Input Voltage vs. Temperature

CE “H” Input Voltage (VIN = 5.5 V)

CE “H” Input Voltage (VIN = 2.3 V)

(V)

1

CE

0.9

CE Input Voltage V

CE Input Voltage V

CE

(V)

1

0.8

0.7

0.6

0.5

0.8

0.7

0.6

0.5

0.4

0.4

-50

24

0.9

-25

0

25

50

Temperature Ta(°C)

75

100

-50

-25

0

25

50

Temperature Ta(°C)

75

100

�RP504x

NO.EA-259-170620

13) LX Current Limit vs. Temperature

LX Current Limit llim (mA)

1000

950

900

850

800

-50

-25

0

25

50

75

Temperature Ta(°C)

100

0.60

ON(Ω)

0.60

15) Pch Tr. ON Resistance vs. Temperature

0.50

0.50

Pch Tr.ONResistance R

Nch Tr.ONResistance R

ON(Ω)

14) Nch Tr. ON Resistance vs. Temperature

0.40

0.30

0.20

0.10

0

-50

-25

0

25

50

75

Temperature Ta(°C)

0.40

0.30

0.20

0.10

0

100

-50

-25

0

25

50

75

Temperature Ta(°C)

100

16) Load Transient Response

RP504x081x (VIN = 3.6 V)

RP504x081x (VIN = 3.6 V)

0.90

0.80

0.70

Output Voltage

0.60

200

200

0

0

Output Current

300mA-->1mA

1.00

0.90

0.80

Output Voltage

0.70

Output Current IOUT (mA)

1.00

400

Output Voltage VOUT (V)

Output Current

1mA-->300mA

MODE = “L”PWM/VFM Auto Switching Control

400

Output Current IOUT (mA)

Output Voltage VOUT (V)

MODE = “L”PWM/VFM Auto Switching Control

0.60

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

-100

0

100 200 300 400 500 600 700 800 900

Time t (µs)

25

�RP504x

NO.EA-259-170620

RP504x081x (VIN = 3.6 V)

RP504x081x (VIN = 3.6 V)

400

200

200

0

1.00

0.90

0.80

1.00

0.90

0.80

Output Voltage

0.70

0.60

0.60

-10 0 10 20 30 40 50 60 70 80 90

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

Time t (µs)

600

400

400

200

0

1.00

0.90

0.80

Output Voltage

0.70

Output Voltage VOUT (V)

Output Current

200mA-->500mA

600

200

Output Current

500mA-->200mA

1.00

0.90

0.80

Output Voltage

0.70

0.60

0.60

-10 0

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

RP504x121x (VIN = 3.6 V)

1.20

1.15

Output Voltage

1.10

200

200

0

0

Output Current

300mA-->1mA

1.30

1.25

1.20

Output Voltage

1.15

1.10

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

26

400

Output Voltage VOUT (V)

1.25

MODE = “L”PWM/VFM Auto Switching Control

400

Output Current IOUT (mA)

Output Voltage VOUT (V)

1.30

10 20 30 40 50 60 70 80 90

Time t (µs)

RP504x121x (VIN = 3.6 V)

MODE = “L”PWM/VFM Auto Switching Control

Output Current

1mA-->300mA

0

Output Current IOUT (mA)

RP504x081x (VIN = 3.6 V)

Output Current IOUT (mA)

Output Voltage VOUT (V)

RP504x081x (VIN = 3.6 V)

-100

0

100 200 300 400 500 600 700 800 900

Time t (µs)

Output Current IOUT (mA)

0.70

Output Voltage

0

Output Current

300mA-->1mA

Output Current IOUT (mA)

400

Output Voltage VOUT (V)

Output Current

1mA-->300mA

MODE = “H” Forced PWM Control

Output Current IOUT (mA)

Output Voltage VOUT (V)

MODE = “H” Forced PWM Control

�RP504x

NO.EA-259-170620

RP504x121x (VIN = 3.6 V)

RP504x121x (VIN = 3.6 V)

400

200

200

0

1.30

1.25

1.20

Output Voltage

1.15

Output Current

300mA-->1mA

1.30

1.25

1.20

Output Voltage

1.15

1.10

1.10

-10 0 10 20 30 40 50 60 70 80 90

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

Time t (µs)

600

400

400

200

0

1.30

1.25

1.20

200

Output Current

500mA-->200mA

1.30

1.25

1.20

Output Voltage

1.15

1.10

1.10

-10 0 10 20 30 40 50 60 70 80 90

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

Time t (µs)

RP504x181x (VIN = 3.6 V)

RP504x181x (VIN = 3.6 V)

MODE = “L”PWM/VFM Auto Switching Control

1.90

1.85

1.80

Output Voltage

1.70

400

200

200

0

Output Voltage VOUT (V)

Output Current

1mA-->300mA

MODE = “L”PWM/VFM Auto Switching Control

400

Output Current IOUT (mA)

Output Voltage VOUT (V)

0

0

Output Current

300mA-->1mA

1.90

1.85

1.80

1.75

Output Current IOUT (mA)

1.15

Output Voltage

Output Voltage VOUT (V)

Output Current

200mA-->500mA

600

Output Current IOUT (mA)

RP504x121x (VIN = 3.6 V)

Output Current IOUT (mA)

Output Voltage VOUT (V)

RP504x121x (VIN = 3.6 V)

1.75

0

Output Current IOUT (mA)

400

Output Voltage VOUT (V)

Output Current

1mA-->300mA

MODE = “H” Forced PWM Control

Output Current IOUT (mA)

Output Voltage VOUT (V)

MODE = “H” Forced PWM Control

Output Voltage

1.70

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

-100

0

100 200 300 400 500 600 700 800 900

Time t (µs)

27

�RP504x

NO.EA-259-170620

RP504x181x (VIN = 3.6 V)

RP504x181x (VIN = 3.6 V)

400

200

200

0

1.90

1.85

1.80

Output Voltage

1.75

1.70

0

Output Current

300mA-->1mA

1.90

1.85

1.80

Output Voltage

1.75

1.70

1.65

1.65

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

RP504x181x (VIN = 3.6 V)

RP504x181x (VIN = 3.6 V)

600

1.85

1.80

1.75

Output Voltage

1.70

200

1.90

1.80

Output Voltage

1.75

1.70

-10 0 10 20 30 40 50 60 70 80 90

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

Time t (µs)

RP504x331x (VIN = 5.0 V)

MODE = “L”PWM/VFM Auto Switching Control

3.50

3.40

3.30

Output Voltage

3.10

400

200

200

0

Output Voltage VOUT (V)

Output Current

1mA-->300mA

RP504x331x (VIN = 5.0 V)

MODE = “L”PWM/VFM Auto Switching Control

400

Output Current IOUT (mA)

Output Voltage VOUT (V)

0

1.85

1.65

1.65

0

Output Current

300mA-->1mA

3.50

3.40

3.30

Output Voltage

3.20

3.10

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

28

400

-100

0

100 200 300 400 500 600 700 800 900

Time t (µs)

Output Current IOUT (mA)

0

1.90

Output Current

500mA-->200mA

Output Current IOUT (mA)

200

Output Voltage VOUT (V)

400

Output Current

200mA-->500mA

Output Current IOUT (mA)

Output Voltage VOUT (V)

600

3.20

Output Current IOUT (mA)

400

Output Voltage VOUT (V)

Output Current

1mA-->300mA

MODE = “H” Forced PWM Control

Output Current IOUT (mA)

Output Voltage VOUT (V)

MODE = “H” Forced PWM Control

�RP504x

NO.EA-259-170620

RP504x331x (VIN = 5.0 V)

RP504x331x (VIN = 5.0 V)

400

200

200

0

3.50

3.40

3.30

Output Voltage

3.20

3.10

3.50

3.40

3.30

Output Voltage

3.20

3.10

-10 0 10 20 30 40 50 60 70 80 90

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

Time t (µs)

RP504x331x (VIN = 5.0 V)

400

400

200

0

3.50

3.40

3.30

Output Voltage

3.20

3.10

Output Voltage VOUT (V)

600

Output Current IOUT (mA)

Output Current

200mA-->500mA

600

200

Output Current

500mA-->200mA

0

3.50

3.40

3.30

Output Voltage

3.20

Output Current IOUT (mA)

RP504x331x (VIN = 5.0 V)

Output Voltage VOUT (V)

0

Output Current

300mA-->1mA

Output Current IOUT (mA)

400

Output Voltage VOUT (V)

Output Current

1mA-->300mA

MODE = “H” Forced PWM Control

Output Current IOUT (mA)

Output Voltage VOUT (V)

MODE = “H” Forced PWM Control

3.10

-10 0 10 20 30 40 50 60 70 80 90

-10 0 10 20 30 40 50 60 70 80 90

Time t (µs)

Time t (µs)

17) Mode Switching Waveform

RP504x (VOUT = 1.2 V, IOUT = 1 mA)

RP504x (VOUT = 1.2 V, IOUT = 1 mA)

MODE = “L” --> MODE = “H”

MODE = “H" --> MODE = “L”

1.30

1.25

1.20

1.15

-100

Output Voltage

0

100

200

Time t (µs)

300

400

0

Mode Input Voltage

1.30

1.25

1.20

Output Voltage

1.15

-200

0

200

400

600

Mode Input Voltage

VMODE (V)

0

Output Voltage VOUT (V)

Mode Input Voltage

5

Mode Input Voltage

VMODE (V)

Output Voltage VOUT (V)

5

800

Time t (µs)

29

�RP504x

NO.EA-259-170620

RP504x (VOUT = 1.8 V, IOUT = 1 mA)

RP504x (VOUT = 1.8 V, IOUT = 1 mA)

MODE = "L" --> MODE = "H"

MODE = "H" --> MODE = "L"

1.85

1.80

Output Voltage

0

100

200

Time t (µs)

300

400

0

Mode Input Voltage

1.90

1.85

1.80

Output Voltage

1.75

-200

0

200

400

Time t (µs)

600

800

Mode Input Voltage

VMODE (V)

1.90

1.75

-100

30

0

Output Voltage VOUT (V)

Mode Input Voltage

5

Mode Input Voltage

VMODE (V)

Output Voltage VOUT (V)

5

�POWER DISSIPATION

DFN(PLP)1216-6F

Ver. A

The power dissipation of the package is dependent on PCB material, layout, and environmental conditions.

The following conditions are used in this measurement.

Measurement Conditions

Standard Test Land Pattern

Environment

Mounting on Board (Wind Velocity = 0 m/s)

Board Material

Glass Cloth Epoxy Plastic (Double-Sided Board)

Board Dimensions

40 mm × 40 mm × 1.6 mm

Top Side: Approx. 50%

Copper Ratio

Bottom Side: Approx. 50%

φ 0.3 mm × 26 pcs

Through-holes

Measurement Result

(Ta = 25°C, Tjmax = 125°C)

Standard Test Land Pattern

Power Dissipation

385 mW

θja = (125 − 25°C) / 0.385 W = 260°C/W

Thermal Resistance

θjc = 30°C/W

40

600

500

Standard Test Land Pattern

385

400

300

40

Power Dissipation PD (mW)

700

200

100

0

0

25

50

75 85 100

125

Ambient Temperature (°C)

Power Dissipation vs. Ambient Temperature

IC Mount Area (mm)

Measurement Board Pattern

i

�PACKAGE DIMENSIONS

DFN(PLP)1216-6F

Ver. A

DFN(PLP)1216-6F Package Dimensions (Unit: mm)

i

�POWER DISSIPATION

DFN1616-6B

Ver. A

The power dissipation of the package is dependent on PCB material, layout, and environmental conditions.

The following conditions are used in this measurement.

Measurement Conditions

Standard Test Land Pattern

Environment

Mounting on Board (Wind Velocity = 0 m/s)

Board Material

Glass Cloth Epoxy Plastic (Double-Sided Board)

Board Dimensions

40 mm × 40 mm × 1.6 mm

Top Side: Approx. 50%

Copper Ratio

Bottom Side: Approx. 50%

φ 0.5 mm × 32 pcs

Through-holes

Measurement Result

(Ta = 25°C, Tjmax = 125°C)

Standard Test Land Pattern

Power Dissipation

640 mW

θja = (125 − 25°C) / 0.64 W = 156°C/W

θjc = 23 °C/W

40

700

640

600

Standard Test Land Pattern

500

400

40

Power Dissipation PD (mW)

Thermal Resistance

300

200

100

Measurement Board Pattern

0

0

25

50

75 85 100

125

150

Ambient Temperature (°C)

IC Mount Area (mm)

Power Dissipation vs. Ambient Temperature

Measurement Board Pattern

i

�PACKAGE DIMENSIONS

DFN1616-6B

Ver. A

1.30±0.05

(3X0.15)

B

0.70±0.05

X4

1.60

0.05

4

6

∗

0.25±0.05

1.60

A

INDEX

0.4max.

0.1±0.05

3

0.5

0.20±0.05

1

0.05 M AB

Bottom View

S

0.05 S

DFN1616-6B Package Dimensions (Unit: mm)

*

∗ The tab on the bottom of the package shown by blue circle is a substrate potential (GND). It is recommended that this

tab be connected to the ground plane pin on the board but it is possible to leave the tab floating.

i

�POWER DISSIPATION

SOT-23-5

Ver. A

The power dissipation of the package is dependent on PCB material, layout, and environmental conditions.

The following conditions are used in this measurement.

Measurement Conditions

Standard Test Land Pattern

Environment

Mounting on Board (Wind Velocity = 0 m/s)

Board Material

Glass Cloth Epoxy Plastic (Double-Sided Board)

Board Dimensions

40 mm x 40 mm x 1.6 mm

Copper Ratio

Top Side: Approx.50%

Bottom Side: Approx. 50%

Through-holes

φ 0.5 mm x 44 pcs

Measurement Result

(Ta = 25°C, Tjmax = 125°C)

Standard Test Land Pattern

Free Air

Power Dissipation

420 mW

250 mW

Thermal Resistance

θja = (125 − 25°C) / 0.42 W = 238°C/W

400°C/W

40

500

Standard Test Land Pattern

420

400

300

Free Air

250

40

Power Dissipation (mW)

600

200

100

0

0

25

50

75 85 100

125

150

Ambient Temperature (°C)

Power Dissipation vs. Ambient Temperature

IC Mount Area (mm)

Measurement Board Pattern

i

�SOT-23-5

PACKAGE DIMENSIONS

Ver. A

2.9±0.2

1.1±0.1

1.9±0.2

0.8±0.1

(0.95)

4

1

2

0~0.1

0.2min.

+0.2

1.6-0.1

5

2.8±0.3

(0.95)

3

0.4±0.1

+0.1

0.15-0.05

SOT-23-5 Package Dimensions

i

�1. The products and the product specifications described in this document are subject to change or discontinuation of

production without notice for reasons such as improvement. Therefore, before deciding to use the products, please

refer to Ricoh sales representatives for the latest information thereon.

2. The materials in this document may not be copied or otherwise reproduced in whole or in part without prior written

consent of Ricoh.

3. Please be sure to take any necessary formalities under relevant laws or regulations before exporting or otherwise

taking out of your country the products or the technical information described herein.

4. The technical information described in this document shows typical characteristics of and example application circuits

for the products. The release of such information is not to be construed as a warranty of or a grant of license under

Ricoh's or any third party's intellectual property rights or any other rights.

5. The products listed in this document are intended and designed for use as general electronic components in standard

applications (office equipment, telecommunication equipment, measuring instruments, consumer electronic products,

amusement equipment etc.). Those customers intending to use a product in an application requiring extreme quality

and reliability, for example, in a highly specific application where the failure or misoperation of the product could result

in human injury or death (aircraft, spacevehicle, nuclear reactor control system, traffic control system, automotive and

transportation equipment, combustion equipment, safety devices, life support system etc.) should first contact us.

6. We are making our continuous effort to improve the quality and reliability of our products, but semiconductor products

are likely to fail with certain probability. In order to prevent any injury to persons or damages to property resulting from

such failure, customers should be careful enough to incorporate safety measures in their design, such as redundancy

feature, fire containment feature and fail-safe feature. We do not assume any liability or responsibility for any loss or

damage arising from misuse or inappropriate use of the products.

7. Anti-radiation design is not implemented in the products described in this document.

8. The X-ray exposure can influence functions and characteristics of the products. Confirm the product functions and

characteristics in the evaluation stage.

9. WLCSP products should be used in light shielded environments. The light exposure can influence functions and

characteristics of the products under operation or storage.

10. There can be variation in the marking when different AOI (Automated Optical Inspection) equipment is used. In the

case of recognizing the marking characteristic with AOI, please contact Ricoh sales or our distributor before attempting

to use AOI.

11. Please contact Ricoh sales representatives should you have any questions or comments concerning the products or

the technical information.

Halogen Free

Ricoh is committed to reducing the environmental loading materials in electrical devices

with a view to contributing to the protection of human health and the environment.

Ricoh has been providing RoHS compliant products since April 1, 2006 and Halogen-free products since

April 1, 2012.

https://www.e-devices.ricoh.co.jp/en/

Sales & Support Offices

Ricoh Electronic Devices Co., Ltd.

Shin-Yokohama Office (International Sales)

2-3, Shin-Yokohama 3-chome, Kohoku-ku, Yokohama-shi, Kanagawa, 222-8530, Japan

Phone: +81-50-3814-7687 Fax: +81-45-474-0074

Ricoh Americas Holdings, Inc.

675 Campbell Technology Parkway, Suite 200 Campbell, CA 95008, U.S.A.

Phone: +1-408-610-3105

Ricoh Europe (Netherlands) B.V.

Semiconductor Support Centre

Prof. W.H. Keesomlaan 1, 1183 DJ Amstelveen, The Netherlands

Phone: +31-20-5474-309

Ricoh International B.V. - German Branch

Semiconductor Sales and Support Centre

Oberrather Strasse 6, 40472 Düsseldorf, Germany

Phone: +49-211-6546-0

Ricoh Electronic Devices Korea Co., Ltd.

3F, Haesung Bldg, 504, Teheran-ro, Gangnam-gu, Seoul, 135-725, Korea

Phone: +82-2-2135-5700 Fax: +82-2-2051-5713

Ricoh Electronic Devices Shanghai Co., Ltd.

Room 403, No.2 Building, No.690 Bibo Road, Pu Dong New District, Shanghai 201203,

People's Republic of China

Phone: +86-21-5027-3200 Fax: +86-21-5027-3299

Ricoh Electronic Devices Shanghai Co., Ltd.

Shenzhen Branch

1205, Block D(Jinlong Building), Kingkey 100, Hongbao Road, Luohu District,

Shenzhen, China

Phone: +86-755-8348-7600 Ext 225

Ricoh Electronic Devices Co., Ltd.

Taipei office

Room 109, 10F-1, No.51, Hengyang Rd., Taipei City, Taiwan (R.O.C.)

Phone: +886-2-2313-1621/1622 Fax: +886-2-2313-1623

�