Single-chip Type with Built-in FET Switching Regulators

Output 1.5A or Less High-efficiency Step-down Switching Regulator with Built-in Power MOSFET

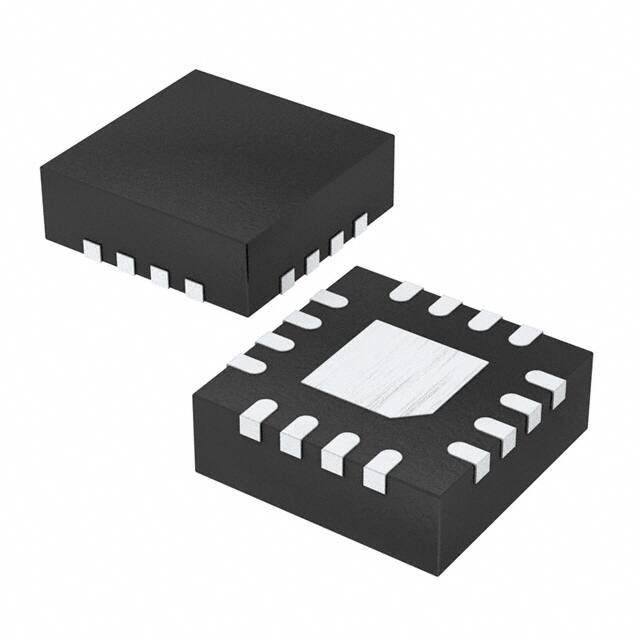

BD9123MUV

No.11027EAT38

●Description ROHM’s high efficiency step-down switching regulator BD9123MUV is a power supply designed to produce a low voltage including 0.85 to 1.2 volts from 5.5/3.3 volts power supply line. Offers high efficiency with our original pulse skip control technology and synchronous rectifier. Employs a current mode control system to provide faster transient response to sudden change in load. ●Features 1) Offers fast transient response with current mode PWM control system. 2) Offers highly efficiency for all load range with synchronous rectifier (Nch/Pch FET) and SLLM (Simple Light Load Mode) 3) Incorporates output voltage inside control function.(3 bit) 4) Incorporates PGOOD function. 5) Incorporates soft-start function. 6) Incorporates thermal protection and ULVO functions. 7) Incorporates short-current protection circuit with time delay function. 8) Incorporates shutdown function Icc=0µA(Typ.) 9) Employs small surface mount package: VQFN016V3030 ●Applications Power supply for LSI including DSP, Micro computer and ASIC ●Absolute maximum ratings (Ta=25℃) Parameter VCC Voltage PVCC Voltage EN,SW,ITH Voltage Logic input voltage Power Dissipation 1 Power Dissipation 2 Power Dissipation 3 Power Dissipation 4 Operating temperature range Storage temperature range Maximum junction temperature

*1 *2 *3 *4 *5

Symbol Vcc PVcc EN, SW, ITH VID Pd1 Pd2 Pd3 Pd4 Topr Tstg Tj

Ratings -0.3~+7 *1 -0.3~+7 *1 -0.3~+7 -0.3~+7 0.27 *2 0.62 * 1.77 * 2.66 *

3 4 5

Unit V V V V W W W W ℃ ℃ ℃

-40~+95 -55~+150 +150

Pd should not be exceeded. IC only 1-layer. mounted on a 74.2mm×74.2mm×1.6mm glass-epoxy board, occupied area by copper foil : 10.29mm2 4-layer. mounted on a 74.2mm×74.2mm×1.6mm glass-epoxy board, 1st and 4th copper foil area : 10.29mm2 , 2nd and 3rd copper foil area : 5505mm2 4-layer. mounted on a 74.2mm×74.2mm×1.6mm glass-epoxy board, occupied area by copper foil : 5505mm2, in each layers

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

1/17

2011.01 - Rev.A

�BD9123MUV

●Operating Conditions (Ta=-40~+95℃) Parameter Power Supply Voltage EN Voltage Logic input voltage Output voltage Setting Range SW average output current

*6 Pd should not be exceeded.

Technical Note

Symbol VCC PVCC VEN VID VOUT ISW

Ratings Min. 2.7 2.7 0 0 0.85 Typ. 3.3 3.3 Max. 5.5 5.5 Vcc 5.5 1.2 1.2

*6

Unit V V V V V A

●Electrical Characteristics (Ta=25℃ VCC=PVCC=5V, EN=VCC, VID=VID=VID= 0V), unless otherwise specified.) Limits Parameter Symbol Unit Conditions Min. Typ. Max. Standby current Active current EN Low voltage EN High voltage EN input current VID Low voltage VID High voltage VID input current Oscillation frequency Pch FET ON resistance Nch FET ON resistance Output voltage ITH SInk current ITH Source Current UVLO threshold voltage UVLO release voltage Power Good Threshold Power Good Release Power Good Delay PGOOD ON Resistance Soft start time Timer latch time Output Short circuit threshold Voltage ISTB ICC VENL VENH IEN VVIDL VVIDH IVID FOSC RONP RONN VOUT ITHSI ITHSO VUVLO1 VUVLO2 VPGOOD1 VPGOOD2 TPG RONPG TSS TLATCH VSCP 2.0 2.0 0.8 0.98 25 25 2.4 2.425 70 85 2.5 0.4 1 0 300 GND VCC 5 GND VCC 5 1 0.35 0.25 1.0 50 50 2.5 2.55 75 90 5 140 0.8 2 10 500 0.8 10 0.8 10 1.2 0.60 0.50 1.02 2.6 2.7 80 95 10 280 1.6 4 µA µA V V µA V V µA MHz Ω Ω V µA µA V V % % ms Ω ms ms V VOUT→0V PVCC=5V PVCC=5V VID=(0,0,0) VOUT =1.2V VOUT =0.8V VCC=5V→0V VCC=0V→5V VOUT→0V 0V→VOUT VVID=5V Standby mode Active mode VEN=5V EN=GND

VOUT×0.5 VOUT×0.7

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

2/17

2011.01 - Rev.A

�BD9123MUV

●Package outline, SYMBOLS 【BD9123MUV】 ●Block Diagram, Application Circuit

VCC EN 13 D9 2 3 VID 12 VID 11

Lot No.

Technical Note

VCC 14 PVCC 15 16 Current Sense/ Protect + Driver Logic

0.1µF 100Ω

1

VREF

Current Comp

SELECTOR

Input 10µF

VID 10 Gm Amp VOUT 9 VCC

RQ S

SLOPE CLK

1 2 3 4 5 6

SW 4.7µH Output

OSC Vcc

Soft Start UVLO TSD

22µF PGND

PGOOD

7

PGOOD

GND

8

ITH RITH CITH

VQFN016V3030 (Unit:mm) Fig.1 BD9123MUV Package outline ●Pin No. & function table Fig.2 BD9123MUV Block Diagram

Pin No.

VID VID VID VOUT

Pin name SW

Function Pch/Nch FET drain output pin

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

12 13 14 15 16 1

SW

11

10

9 8 7 6 5

ITH

EN

PGND GND PGOOD ITH VOUT VID VID VID EN VCC PVCC

Nch FET source pin Ground Power Good pin Gm Amp output pin/Connected phase compensation capacitor Output voltage pin Output voltage control pin Output voltage control pin Output voltage control pin Enable pin(High Active) VCC power supply input pin Pch FET source pin

VCC

PGOOD

PVCC

GND

PVCC

PGND

2

SW

3

SW

4

PGND

Fig 3

Top View

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

3/17

2011.01 - Rev.A

�BD9123MUV

●Characteristics data

2.0 2.0 2.0

Technical Note

【VOUT=1.0V】

OUTPUT VOLTAGE:VOUT[V] OUTPUT VOLTAGE:VOUT[V] 1.6 1.6

【VOUT=1.0V】

OUTPUT VOLTAGE:VOUT[V] 1.6

【VOUT=1.0V】

1.2

1.2

1.2

0.8

0.8

VCC=5V Io=0A Ta=25℃

0.8

0.4

Io=1.2A Ta=25℃

0.4

0.4

VCC=5V Ta=25℃

0.0 0 1 2 3 4 INPUT VOLTAGE:VCC[V] 5

0.0 0 1 2 3 4 EN VOLTAGE:VEN[V] 5

0.0 0 1 2 3 4 EN VOLTAGE:VEN[V] 5

Fig.4 Vcc-VouT

1.04 100

Fig.5 VEN - VOUT

2.0

Fig.6 IOUT-VOUT

【VOUT=1.0V】

OUTPUT VOLTAGE:VOUT[V] 1.02 EFFICIENCY:?[%]

90 80 70 60 50 40 30 20 10 0 100 1

【VOUT=1.0】

FREQUENCY:FOSC[MHz] 1.5

1.00

1.0

0.98

0.5

VCC=5V Io=0A

0.96 -40 -20 0 20 40 60 80 INPUT VOLTAGE:VCC[V]

Vcc=5.0V Ta=25℃

Ta=25℃

0.0

10

100 Io [A]

1000

10000

2.7

3.4 4.1 4.8 INPUT VOLTAGE:VCC[V]

5.5

Fig. 7 Ta-VOUT

1200 1000 FREQUENCY:FOSC[kHz] ON RESISTANCE:RON[O] 800 600 400 200 175 150 125 100 75 50

Fig.8 Efficiency

2.0

Fig.9 Power supply voltageOperating frequency

1.9 1.8 EN VOLTAGE:VEN[V] 1.7 1.6 1.5 1.4 1.3 1.2 1.1 1.0

High side (PMOS FET)

Low side (NMOS FET)

VCC=5V

200 0 -40 -20 0 20 40 60 80 TEMPERATURE:Ta[℃] 100

VCC=5.0V

25 0 -40 -20 0 20 40 60 80 TEMPERATURE:Ta[℃] 100

VCC=5V

-40

-20

0 20 40 60 80 TEMPERATURE:Ta[℃]

100

Fig.10 Ta-Fosc

400 350 ON RESISTANCE:RON[O] 300 250 200 150 100 50 0 -40 -20 0 20 40 60 80 TEMPERATURE:Ta[℃] 100

Fig.11 Ta-RONN,RONP

Fig.12 Ta-VEN

【VOUT=1.0V】

【SLLM control

VOUT=1.0V】 VCC=5V Io=0A Ta=25℃

SW

SW

VO VCC=5V VCC=5V Io=1.2A Ta=25℃

VO

Fig.13 Ta-Icc

Fig.14 Soft start waveform

Fig.15 SW waveform Io=0mA

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

4/17

2011.01 - Rev.A

�BD9123MUV

Technical Note

SW

VO

Vo

VO

VCC=5V Io=1.2A Ta=25℃

IO Ta=25℃

Io Ta=25℃

Fig.16 SW waveform Io=1.2A

Fig.17 Transient Response Io=125mA→850mA(2µA)

VID[2:0]= (1,1,1)→0,0,1)

Fig.18 Transient Response Io=850mA→125mA(2µA)

VID[2:0]=(0,0,1)→(1,1,1)

VID VID

PGOOD

1.2V VO 0.85V VO

1.2V VOUT 0.85V

0.9V 0.75V

TPG

VCC=5V Vo=1V Ta=25℃

Fig.19 BIT CHANCE RESPONSE

Fig.20 BIT CHANCE RESPONSE

Fig.21 PGOOD Delay

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

5/17

2011.01 - Rev.A

�BD9123MUV

●Information on advantages Advantage 1: Offers fast transient response with current mode control system. Conventional product (Load response IO=0.1A→0.6A)

Technical Note

BD9123MUV (Load response IO=0.6A→0.1A)

VOUT

27mV

VOUT

37mV

IOUT

IOUT

Fig.22 Comparison of transient response Advantage 2: Offers high efficiency for all load range.

・For lighter load: Utilizes the current mode control mode called SLLM for lighter load, which reduces various dissipation such as switching dissipation (PSW), gate charge/discharge dissipation, ESR dissipation of output capacitor (PESR) and on-resistance dissipation (PRON) that may otherwise cause degradation in efficiency for lighter load.

Achieves efficiency improvement for lighter load. ・For heavier load: Utilizes the synchronous rectifying mode and the low on-resistance MOS FETs incorporated as power transistor. ON resistance of Pch side MOS FET : 0.35mΩ(Typ.) ON resistance of Nch side MOS FET : 0.25mΩ(Typ.)

100 Efficiency η[%] SLLM ② 50 ① PWM

①inprovement by SLLM system

Achieves efficiency improvement for heavier load. Offers high efficiency for all load range with the improvements mentioned above.

0 0.001

②improvement by synchronous rectifier

0.01 0.1 Output current Io[A]

1

Fig.23 Efficiency Advantage 3: ・Supplied in smaller package due to small-sized power MOS FET incorporated. ・Output capacitor Co required for current mode control: 10µF ceramic capacitor ・Inductance L required for the operating frequency of 1 MHz: 4.7µH inductor Reduces a mounting area required.

VCC VCC 20mm Cin L Co L VOUT Co RITH CITH 15mm

Rf Cf RPGOOD

R PGOOD

CIN

DC/DC Convertor RITH CITH

Fig.24 Example application

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

6/17

2011.01 - Rev.A

�BD9123MUV

Technical Note

●Operation BD9123MUV is a synchronous rectifying step-down switching regulator that achieves faster transient response by employing current mode PWM control system. It utilizes switching operation in PWM (Pulse Width Modulation) mode for heavier load, while it utilizes SLLM (Simple Light Load Mode) operation for lighter load to improve efficiency. ○Synchronous rectifier It does not require the power to be dissipated by a rectifier externally connected to a conventional DC/DC converter IC, and its P.N junction shoot-through protection circuit limits the shoot-through current during operation, by which the power dissipation of the set is reduced. ○Current mode PWM control Synthesizes a PWM control signal with a inductor current feedback loop added to the voltage feedback. ・PWM (Pulse Width Modulation) control The oscillation frequency for PWM is 1 MHz. SET signal form OSC turns ON a Pch MOS FET (while a Nch MOS FET is turned OFF), and an inductor current IL increases. The current comparator (Current Comp) receives two signals, a current feedback control signal (SENSE: Voltage converted from IL) and a voltage feedback control signal (FB), and issues a RESET signal if both input signals are identical to each other, and turns OFF the highside MOS FET (while a lowside MOS FET is turned ON) for the rest of the fixed period. The PWM control repeat this operation. ・SLLM (Simple Light Load Mode) control When the control mode is shifted from PWM for heavier load to the one for lighter load or vise versa, the switching pulse is designed to turn OFF with the device held operated in normal PWM control loop, which allows linear operation without voltage drop or deterioration in transient response during the mode switching from light load to heavy load or vise versa. Although the PWM control loop continues to operate with a SET signal from OSC and a RESET signal from Current Comp, it is so designed that the RESET signal is held issued if shifted to the light load mode, with which the switching is tuned OFF and the switching pulses are thinned out under control. Activating the switching intermittently reduces the switching dissipation and improves the efficiency.

SENSE Current Comp RESET Level Shift Gm Amp. ITH OSC RQ FB SET S Driver Logic SW Load IL VOUT

VOUT

Fig.25 Diagram of current mode PWM control

Current Comp SET

PVCC SENSE FB GND GND GND IL(AVE)

Current Comp SET

PVCC SENSE FB GND GND

RESET SW IL

RESET SW

GND IL 0A

VOUT

VOUT(AVE)

VOUT

VOUT(AVE)

Not switching

Fig.26 PWM switching timing chart

Fig.27 SLLM

TM

switching timing chart

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

7/17

2011.01 - Rev.A

�BD9123MUV

Technical Note

●Description of operations ・Soft-start function EN terminal shifted to “High” activates a soft-starter to gradually establish the output voltage with the current limited during startup, by which it is possible to prevent an overshoot of output voltage and an inrush current. The inclination of standing up is different and the soft start time is different because of constancy depending on the value offset output voltage. When 1V settiing it, it is Tss=1msec(Typ.)

VCC,EN

1.2V 0.85V

VOUT

Tss Tss’

[ms]

Fig.28 Soft start action ・Shutdown function With EN terminal shifted to “Low”, the device turns to Standby Mode, and all the function blocks including reference voltage circuit, internal oscillator and drivers are turned to OFF. Circuit current during standby is 0µA(Typ.). ・UVLO function Detects whether the input voltage sufficient to secure the output voltage of this IC is supplied. And the hysteresis width of 50mV (Typ.) is provided to prevent output chattering.

Hysteresis 50mV

Vcc

EN

VOUT Tss Soft start Standby mode UVLO Operating mode Standby mode UVLO Tss Standby mode EN Tss

Operating mode

Operating mode UVLO

Standby mode

Fig.29 Soft start, Shutdown, UVLO timing chart ・PGOOD function When the output voltage falls below 75% (Typ.) of a set value, the PGOOD pin of Open-Drain is turned off. And the hysteresis width of 15% (Typ.) is provided to prevent output chattering. VOUT 90% The hysteresis width 75%

TGP

PGOOD

Fig.30

PGOOD timing chart

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

8/17

2011.01 - Rev.A

�BD9123MUV

Technical Note

●About setting the output voltage Output voltage shifts step by step as often as bit setting to control the overshoot/undershoot that happen when changing the setting value of output voltage. From the bit switching until output voltage reach to setting value, 8 steps (max) delay will occur.

VID (0,0,1) (1,1,1)

1.2V

VOUT

0.85V

tVID (max)=0.06ms

ⅰ) Switching 3 bit synchronously

VID VID VID

ⅲ) Switching the bit during counting

V2D 2〉 〈 〈1〉 〈0〉 Count STOP VOUT

Count STOP VOUT

5µs(max) About 10µs from bit switching

About 10µs from bit switching

ⅱ) Switching 3 bit with the time lag

VID VID VID

Count STOP VOUT

About 10µs from switching the last bit

Fig.31 Timing chart of setting the output voltage It is possible to set output voltage, shown the diagram 1 below, by setting VID~ 0 or 1. VID terminal is set to VID=(0,0,0) originally by the pull down resistor with high impedance inside IC. By pulling up/ pulling down about 10kΩ, the original value is changeable optionally. Table of output voltage setting VID VID 0 0 0 0 1 1 1 1 0 0 1 1 0 0 1 1

VID 0 1 0 1 0 1 0 1

VOUT 1.0V 0.85V 0.9V 0.95V 1.05V 1.1V 1.15V 1.2V

*After 10µs(max) from the bit change, VOUT change starts. *Requiring time for one step (50 mV shift) of VOUT is 5µs(max). *From the bit switching until output voltage reach to setting value, tVID(max)=0.06ms delay will occur.

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

9/17

2011.01 - Rev.A

�BD9123MUV

Technical Note

・Short-current protection circuit with time delay function Turns OFF the output to protect the IC from breakdown when the incorporated current limiter is activated continuously for the fixed time (TLATCH) or more. The output thus held tuned OFF may be recovered by restarting EN or by re-unlocking UVLO.

VCC

Output Short circuit Threshold Voltage VOUT IL Limit IL

Output voltage OFF Latch

Output voltage OFF UVLO

t1 IRMS(max.) When Vcc=2×VOUT, IRMS=

Fig.36 Input capacitor

If VCC=5V, VOUT=1.2V, and IOUTmax.=1.2A, √ .2(5-1.2) 1 IRMS=1.2× =0.51 [ARMS] 5

A low ESR 10µF/10V ceramic capacitor is recommended to reduce ESR dissipation of input capacitor for better efficiency.

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

12/17

2011.01 - Rev.A

�BD9123MUV

Technical Note

4. Determination of RITH, CITH that works as a phase compensator As the Current Mode Control is designed to limit a inductor current, a pole (phase lag) appears in the low frequency area due to a CR filter consisting of a output capacitor and a load resistance, while a zero (phase lead) appears in the high frequency area due to the output capacitor and its ESR. So, the phases are easily compensated by adding a zero to the power amplifier output with C and R as described below to cancel a pole at the power amplifier.

fp(Min.) A Gain [dB] fp(Max.) 0 fz(ESR) IOUTMin. 0 IOUTMax.

fp=

1 2π×RO×CO

1 fz(ESR)= 2π×ESR×CO Pole at power amplifier When the output current decreases, the load resistance Ro increases and the pole frequency lowers. fp(Min.)= 1 [Hz]←with lighter load 2π×ROMax.×CO 1 2π×ROMin.×CO [Hz]←with heavier load

Phase [deg]

-90

Fig.37 Open loop gain characteristics fp(Max.)=

A Gain [dB] 0

fz(Amp.)

Zero at power amplifier Increasing capacitance of the output capacitor lowers the pole frequency while the zero frequency does not change. (This is because when the capacitance is doubled, the capacitor ESR reduces to half.) fz(Amp.)= 1 2π×RITH.×CITH

0 Phase [deg] -90

Fig.38 Error amp phase compensation characteristics

VCC VCC Cin EN VOUT VID VOUT VIDTerminal A (at resistor side), or GND>Terminal B (at transistor side); and ○if GND>Terminal B (at NPN transistor side), a parasitic NPN transistor is activated by N-layer of other element adjacent to the above-mentioned parasitic diode. The structure of the IC inevitably forms parasitic elements, the activation of which may cause interference among circuits, and/or malfunctions contributing to breakdown. It is therefore requested to take care not to use the device in such manner that the voltage lower than GND (at P-substrate) may be applied to the input terminal, which may result in activation of parasitic elements.

Resistor Pin A Pin A

P+ N P P+ N P+ N

Transistor (NPN) Pin B

C B E B N C E

Pin B

N

N

Parasitic element

P

P+

P substrate Parasitic element

GND

P substrate Parasitic element

GND GND GND

Parasitic element Other adjacent elements

Fig.42 Simplified structure of monorisic IC 7. Ground wiring pattern If small-signal GND and large-current GND are provided, It will be recommended to separate the large-current GND pattern from the small-signal GND pattern and establish a single ground at the reference point of the set PCB so that resistance to the wiring pattern and voltage fluctuations due to a large current will cause no fluctuations in voltages of the small-signal GND. Pay attention not to cause fluctuations in the GND wiring pattern of external parts as well. 8. Selection of inductor It is recommended to use an inductor with a series resistance element (DCR) 50mΩ or less. Especially, in case output voltage is set 1.6V or more, note that use of a high DCR inductor will cause an inductor loss, resulting in decreased output voltage. Should this condition continue for a specified period (soft start time + timer latch time), output short circuit protection will be activated and output will be latched OFF. When using an inductor over 50mΩ, be careful to ensure adequate margins for variation between external devices and this IC, including transient as well as static characteristics. Furthermore, in any case, it is recommended to start up the output with EN after supply voltage is within operation range.

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

16/17

2011.01 - Rev.A

�BD9123MUV

●Ordering part number

Technical Note

B

D

9

Part No.

1

2

3

M

U

V

-

E

2

Part No.

Package MUV : VQFN016V3030

Packaging and forming specification E2: Embossed tape and reel

VQFN016V3030

3.0±0.1

3.0±0.1

Tape Quantity Direction of feed Embossed carrier tape 3000pcs E2

The direction is the 1pin of product is at the upper left when you hold

1PIN MARK

1.0MAX

S

+0.03 0.02 −0.02 (0.22)

( reel on the left hand and you pull out the tape on the right hand

)

0.08 S C0.2

0.4±0.1

1.4±0.1 0.5

1 4 5 8 12 9

16 13

0.75

+0.05 0.25 −0.04

1.4±0.1

1pin (Unit : mm) Reel

Direction of feed

∗ Order quantity needs to be multiple of the minimum quantity.

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

17/17

2011.01 - Rev.A

�Notice

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the consent of ROHM Co.,Ltd. The content specified herein is subject to change for improvement without notice. The content specified herein is for the purpose of introducing ROHM's products (hereinafter "Products"). If you wish to use any such Product, please be sure to refer to the specifications, which can be obtained from ROHM upon request. Examples of application circuits, circuit constants and any other information contained herein illustrate the standard usage and operations of the Products. The peripheral conditions must be taken into account when designing circuits for mass production. Great care was taken in ensuring the accuracy of the information specified in this document. However, should you incur any damage arising from any inaccuracy or misprint of such information, ROHM shall bear no responsibility for such damage. The technical information specified herein is intended only to show the typical functions of and examples of application circuits for the Products. ROHM does not grant you, explicitly or implicitly, any license to use or exercise intellectual property or other rights held by ROHM and other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the use of such technical information. The Products specified in this document are intended to be used with general-use electronic equipment or devices (such as audio visual equipment, office-automation equipment, communication devices, electronic appliances and amusement devices). The Products specified in this document are not designed to be radiation tolerant. While ROHM always makes efforts to enhance the quality and reliability of its Products, a Product may fail or malfunction for a variety of reasons. Please be sure to implement in your equipment using the Products safety measures to guard against the possibility of physical injury, fire or any other damage caused in the event of the failure of any Product, such as derating, redundancy, fire control and fail-safe designs. ROHM shall bear no responsibility whatsoever for your use of any Product outside of the prescribed scope or not in accordance with the instruction manual. The Products are not designed or manufactured to be used with any equipment, device or system which requires an extremely high level of reliability the failure or malfunction of which may result in a direct threat to human life or create a risk of human injury (such as a medical instrument, transportation equipment, aerospace machinery, nuclear-reactor controller, fuelcontroller or other safety device). ROHM shall bear no responsibility in any way for use of any of the Products for the above special purposes. If a Product is intended to be used for any such special purpose, please contact a ROHM sales representative before purchasing. If you intend to export or ship overseas any Product or technology specified herein that may be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to obtain a license or permit under the Law.

Thank you for your accessing to ROHM product informations. More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

www.rohm.com © 2011 ROHM Co., Ltd. All rights reserved.

R1120A

�