SLA7080M Series

Unipolar 2-Phase Stepping Motor Driver ICs

Features and Benefits

Description

▪ Power supply voltage, VBB , 46 V maximum; 10 to 44 V

normal operating range

▪ Logic supply voltage, VDD, 3 to 5.5 V

▪ Four output currents, IO(max) , options: 1, 1.5, 2, and 3 A

▪ Stepping control for phase input (full or half step)

▪ Built-in sense resistor detects motor current

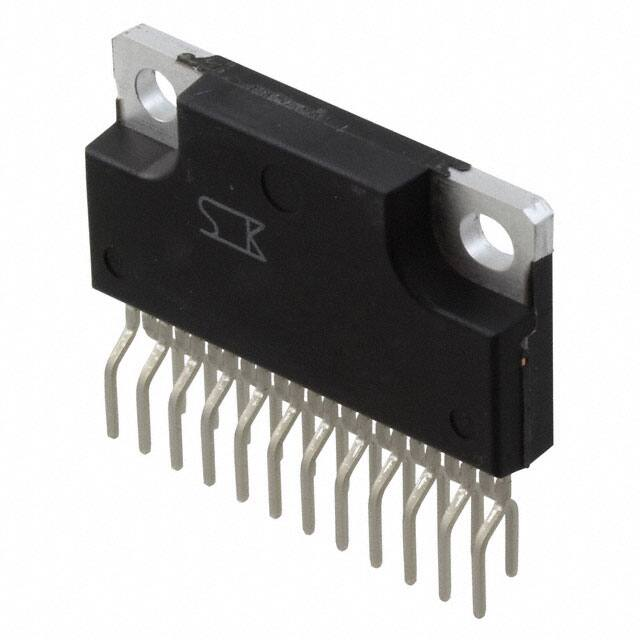

▪ Compact ZIP 23-pin molded package (SLA package)

▪ Self-excitation PWM control with fixed off-time

▪ Built-in synchronous rectifying circuit reduces losses at

PWM-off

▪ Synchronous PWM function prevents noise generation in

motor Hold mode

▪ Sleep function reduces power consumption of drivers in

Standby mode

▪ Protection circuit detects motor coil open/short and

prevents overheating due to avalanche breakdown

▪ Externally-adjustable (3.2 μs /5.2 μs) blanking time

(minimum on-time)

This document describes the function and features of SLA7080M

series, which are unipolar 2-phase stepping motor driver ICs.

Four levels of output current are available from the incorporated

MOSFETs, corresponding to the rated output current ratings.

All current ratings are available with protection against motor

coil shorts or motor open wire detection.

The SLA7080M series has a multichip structure, for enhanced

thermal dispersion. The Control IC (MIC), four power elements

(MOSFET), and dual sense resistors, are all separate ICs.

Built-in sense resistors for each phase allow accurate tracking of performance without additional external components.

Low-power sleep mode as well as reduced power during PWM

off-time maximize energy savings.

Package: 23-pin ZIP (type SLA)

Not to scale

Functional Block Diagram

OUTB

OUTB

+

Comp

-

Protect

PWM

Control

Synchro

Control

PWM

Control

OSC

+

Comp

OSC

SYNC

28610.23, Rev. 1

OUTB

PreDriver

Logic Block

Protect

Rs

OUTB

Reg.

PreDriver

SENSEA

VBB

INA

VDD

INA

INB

INB

B_SEL

FLAG

REF/SLEEP

OUTA

OUTA

OUTA

OUTA

MIC

GND

SANKEN ELECTRIC CO., LTD.

http://www.sanken-ele.co.jp/en/

SENSEB

Rs

�SLA7080M Series

Unipolar 2-Phase Stepping Motor Driver ICs

Selection Guide

Part Number

Output Current

(A)

SLA7080MPR

1

SLA7081MPR

1.5

SLA7082MPR

2

SLA7083MPR

3

Built-In Sense

Resistor

Packing

Yes

18 pieces per tube

Absolute Maximum Ratings, valid at TA = 25°C

Characteristic

Rating

Unit

VM

46

V

Main Supply Voltage

VBB

46

V

Logic Supply Voltage

VDD

6

V

SLA7080MPR

1.0

A

SLA7081MPR

1.5

A

SLA7082MPR

2.0

A

Motor Supply Voltage

Symbol

Output Current

IO

Logic Input Voltage

VIN

REF Input Voltage

VREF

Notes

SLA7083MPR

Allowable Power Dissipation

PD

3.0

A

–0.3 to VDD + 0.3

V

–0.3 to VDD + 0.3

V

4.7

W

No heatsink

Maximum Junction Temperature

TJ(max)

150

ºC

Nominal Operating Temperature

TA

–20 to 85

ºC

Storage Temperature

Tstg

–30 to 150

ºC

Recommended Operating Range

Characteristic

Motor Supply Voltage

Symbol

Notes

VM

Main Supply Voltage

VBB

Logic Supply Voltage

VDD

Case Temperature

TC

VDD surge voltage = ± 0.5 V

Without heatsink

With heatsink

On pin 12, adjacent

to case

Min

Max

Unit

–

44

V

10

44

V

3.0

5.5

V

–

90

ºC

–

80

ºC

All performance characteristics given are typical values for circuit or

system baseline design only and are at the nominal operating voltage and

an ambient temperature, TA, of 25°C, unless otherwise stated.

28610.23, Rev. 1

SANKEN ELECTRIC CO., LTD.

2

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

ELECTRICAL CHARACTERISTICS valid at TA = 25°C, VBB = 24 V and VDD = 5 V, unless otherwise noted

Characteristics

Main Supply Current

Logic Supply Current

Output MOSFET On-Resistance

Output MOSFET Diode Forward

Voltage

Symbol

Min

Typ

Max

Units

IBB

In operation

Conditions

–

–

15

mA

IBBS

Sleep state

–

–

100

μA

–

–

5

mA

SLA7080MPR

–

0.7

0.85

Ω

SLA7081MPR

–

0.45

0.6

Ω

SLA7082MPR

–

0.25

0.4

Ω

SLA7083MPR

–

0.18

0.24

Ω

SLA7080MPR

–

0.85

1.1

V

SLA7081MPR

–

1.0

1.25

V

SLA7082MPR

–

0.95

1.2

V

IDD

RDS(on)

VF

SLA7083MPR

Output MOSFET Breakdown Voltage

Maximum Response Frequency

VDSS

fclk

–

0.95

2.1

V

VBB = 44 V, ID = 1 mA

100

–

–

V

Clock duty cycle = 50%

250

–

–

kHz

V

VIL

–

–

VDD ×

0.25

VIH

VDD ×

0.75

–

–

V

IIL

–

±1

–

μA

IIH

–

±1

–

μA

Logic Input Voltage

Logic Input Current

REF Input Voltage

SLA7080MPR

0.04

–

0.3

V

SLA7081MPR, SLA7083MPR

0.04

–

0.45

V

SLA7082MPR

0.04

–

0.4

V

Sleep state (output off)

2.0

–

VDD

V

IREF

–

±10

–

μA

VSENSE

VREF –

0.03

VREF

VREF +

0.03

V

SLA7080MPR, SLA7081MPR

0.296

0.305

0.314

Ω

SLA7082MPR

0.199

0.205

0.211

Ω

SLA7083MPR

VREF

VREFS

REF Input Current

SENSE Detect Voltage

Sense Resistor1

PWM Minimum On-Time (Blanking

Time)

Rs

ton(min)

0.150

0.155

0.160

Ω

B_SEL = low

–

3.2

–

μs

B_SEL = high

–

5.2

–

μs

–

13

–

μs

100

–

–

μs

PWM Off-Time

toff

Sleep Enable Recovery Time

tSE

Sleep state

tdon

Phase INx → Phase OUTx on

–

1.5

–

μs

tdoff

Phase INx → Phase OUTx off

–

1.0

–

μs

Switching Time

Continued on the next page…

28610.23, Rev. 1

SANKEN ELECTRIC CO., LTD.

3

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

ELECTRICAL CHARACTERISTICS (continued) valid at TA = 25°C, VBB = 24 V and VDD = 5 V, unless otherwise noted

Characteristics

Symbol

Conditions

Min

Typ

Max

Units

Protection Functions2

Overcurrent Detect Voltage

VOCP

0.65

0.7

0.75

V

SLA7080MPR, SLA7081MPR

–

2.3

–

A

SLA7082MPR

–

3.5

–

A

SLA7083MPR

–

4.5

–

A

1.5

2.0

2.5

μs

Measured at back surface of device case; device operating

such that self-generated heat has permeated detection circuits

on MIC; see Thermal Design section

–

140

–

°C

VFLAGL

IFLAGL = 1.25 mA

–

–

1.25

V

VFLAGH

IFLAGH = –1.25 mA

VDD –

1.25

–

–

V

IFLAGL

–

–

1.25

mA

IFLAGH

–1.25

–

–

mA

Overcurrent Detect Current

(VOCP / RS)

IOCP

Delay to Open Load Detect

tOPP

Overtemperature Protection Threshold

Temperature

TTSD

FLAG Output Voltage

FLAG Output Current

At motor coil short circuit

1External

sense resistor value approximately 5 mΩ in addition to value of built-in resistor.

2Protection circuit operates when V

SENSE ≥ VOCP.

Power Derating Chart

Allowable Power Dissipation, PD (W)

5

RθJA = 26.6°C/W

4

3

2

1

0

0

10

20

30

40

50

60

70

80

90

Ambient Temperature, TA (°C)

28610.23, Rev. 1

SANKEN ELECTRIC CO., LTD.

4

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

Performance Characteristics at TA = 25°C

1.4

1.4

1.2

1.2

1.0

SLA7081MPR

MOSFET VDS(on)

vs. Case

Temperature

IO = 1 A

0.8

0.6

IO = 0.5 A

VDS(on) (V)

VDS(on) (V)

1.0

SLA7080MPR

MOSFET VDS(on)

vs. Case

Temperature

IO = 1.5 A

0.8

0.6

0.4

0.4

0.2

0.2

0

–25

0

0

25

50

TC (°C)

75

100

125

–25

1.4

1.4

1.2

1.2

0.8

IO = 2 A

0.6

0.4

100

125

75

100

125

75

100

125

75

100

125

IO = 1 A

0.2

IO = 1 A

0

0

25

50

TC (°C)

75

100

125

–25

1.1

1.0

1.0

SLA7081MPR

MOSFET

Body Diode

Vf vs. Case

Temperature

0.8

25

50

TC (°C)

IO = 1.5 A

0.8

IO = 1 A

IO = 0.5 A

0.7

0

0.9

Vf (V)

IO = 1 A

0.9

Vf (V)

75

IO = 2 A

0.6

1.1

0.7

0.6

–25

50

TC (°C)

IO = 3 A

0.8

0

SLA7080MPR

MOSFET

Body Diode

Vf vs. Case

Temperature

25

0.4

0.2

–25

0

1.0

SLA7083MPR

MOSFET VDS(on)

vs. Case

Temperature

VDS(on) (V)

VDS(on) (V)

1.0

SLA7082MPR

MOSFET VDS(on)

vs. Case

Temperature

IO = 1 A

0.6

0

25

50

TC (°C)

75

100

125

–25

1.1

1.1

1.0

1.0

0

25

50

TC (°C)

IO = 3 A

SLA7083MPR

MOSFET

Body Diode

Vf vs. Case

Temperature

0.8

IO = 1 A

0.7

28610.23, Rev. 1

IO = 1 A

0.8

0.7

0.6

–25

IO = 2 A

0.9

Vf (V)

IO = 2 A

0.9

Vf (V)

SLA7082MPR

MOSFET

Body Diode

Vf vs. Case

Temperature

0.6

0

25

50

TC (°C)

75

100

125

SANKEN ELECTRIC CO., LTD.

–25

0

25

50

TC (°C)

5

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

Functional Description

Logic Block

This circuit block is integrated on the Control IC (MIC). It operates by the logic power supply, VDD , and propagates signals to

each circuit block in accordance with the logic input signals.

Regulator Circuit

This circuit block is integrated on the Control IC (MIC). The

integrated regulator circuit is used in driving the output MOSFET

gates and in powering other internal linear circuits.

Dual Phase Output Control

The SLA7080M series allows dual phase operation based on

external input to the INx pins. The phase-switching logic is

shown in the following table:

¯I¯N¯¯A¯ [¯I¯N¯¯B¯]

OUTA [OUTB]*

¯O

¯¯U¯¯T

¯¯A

¯ [¯O

¯¯U¯¯T

¯¯B¯ ]*

Low

Low

OFF

OFF

High

Low

ON

OFF

Low

High

OFF

ON

High

High

OFF

OFF

*OUT indicates power MOSFET drain state (does not

indicate PWM operation)

PWM Control

This circuit block is integrated on the Control IC (MIC). This is

the main circuit block for pulse width modulated (PWM) control

of self-excitation and external excitation for motor driving. An

illustration of PWM behavior is shown in figure 1.

Phase A [B]

VOUT

One PWM Cycle

ton

toff

ITRIP

A [B]

0

A [B]

ton(min)

Figure 1. PWM waveform on SLA7080M sense resistor, RS ; toff is fixed and

the blanking time, toff(min) , is dynamically selectable.

28610.23, Rev. 1

PWM Off-Time, toff, (for self-excitation), minimum off-time (for

external excitation), and PWM Minimum On-Time (blanking

time), ton(min), are clocked by means of the built-in oscillator.

The length of toff is fixed internally. Like in the SLA7070M

series, the SLA7080M series has a power-saving function that

reduces power consumption during toff. This function recirculates

electromotive force that is stored in the motor coil while the

power MOSFETs are turned on.

The time interval during which the output MOSFETs are on is ton.

The minimum duration for the PWM Minimum On-time, ton(min) ,

is effectively the blanking time selected, even if the application

attempts to shorten ton in order to limit current. The minimum coil

current is at ton(min), so when the coil current is limited at powerdown or other events, it can be no shorter than the blanking time.

Phase A [B]

INA [INB]

PWM control mode is set by the SYNC pin. Set SYNC to logic

high for synchronous PWM, and set it to logic low for asynchronous PWM.

Blanking Time

The blanking time function is provided to limit current in order

to suppress ringing immediately after PWM turns on, and to

improve current control tracking. Blanking time in effect determines PWM Minimum On-Time, ton(min). The length of the blanking time is selected by the B_SEL pin. Set B_SEL to logic high

for 3.2 μs blanking time, and set it to logic low for 5.2 μs.

Some ringing is generated for a few microseconds after PWM

switching (see figure 2). Ringing can result from various causes,

such as capacitance between motor cells, or inappropriate motor

wiring. To suppress this behavior, the blanking time selection sets

a minimum time interval during which current detection signals

from the current sense comparators are ignored after a PWM

switch-on.

Current control (tracking) in the SLA7080M series is regulated

by comparing the detection voltage on the sense resistor, VRS ,

with the reference voltage, VREF. If the ringing noise causes VRS

to exceed VTRIP , the comparator is activated and PWM turns off.

Current control performance at shorter PWM waveforms can

be improved by shortening the blanking time, but this decreases

the effectiveness of ringing suppression, resulting in the seeking behavior shown in figure 3.) To solve this problem, the

SLA7080M series is designed to allow dynamic selection of

blanking time duration. In the event that the seeking behavior

SANKEN ELECTRIC CO., LTD.

6

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

occurs when the short blanking time is selected, the problem may

be eased by the selection of the longer blanking time.

puts, and sets the FLAG pin. To leave protection mode and return

to normal operation, cycle the logic power supply, VDD.

A comparison of these trade-offs is provided in the following

table (comparisons assume that operating conditions other than

the SLA7080M, such as motors, motor power supply voltage,

REF input voltages and so forth, as well as circuit constants, are

identical in each case).

Protection is activated by sensing voltage on the internal sensing

resistors, RS. Overcurrent that flows without passing the sense

resistors cannot be detected. Therefore, this does not detect an

overcurrent condition resulting from the OUT pins or SENSE

pins shorting to GND.

Parameter

Better Performance

Internal Blanking Set Time

Short or Long

Minimize PWM On-time (minimum)

Short

Maximize Ringing Noise Suppression

Long

Minimize Coil Current

Short

Synchronous Control

The SLA7080M series has a chopping synchronous function

to prevent noise which may occasionally be generated during

the motor Hold state. This function can be operated by setting

the SYNC pin to logic high, which generates a timing signal to

synchronize the chopping of the A and B phases. (This function

operates identically to that of the SLA7070M.)

Protection against motor coil opens is available only during

PWM operation. Therefore, it does not work during constant voltage driving, when the motor is rotating at high speed.

Motor Coil Short Circuit Protection (Load Short Circuit)

This function operates by detecting voltage VRS on the internal

sense resistors in the same manner as the current control function.

The threshold voltage, VOCP , is set to 0.7 V typical. When VRS

20 μs/div

This function should be used only during self-excitation PWM

control. The use of synchronous control during normal stepping

motor rotation is not recommended because it produces less

motor torque or may cause motor vibration because the control

current does not stabilize.

Protection Circuit

A built-in protection circuit detects against motor coil opens and

shorts. Operation of the protection circuit disables all of the outFigure 3. PWM waveform exhibiting seeking behavior

5 μs/div

500 ns/div

ITRIP

ITRIP

(A)

(B)

Figure 2. Ringing on PWM waveform while driving a motor. The circled area in

panel A is expanded in time and shown in panel B.

28610.23, Rev. 1

SANKEN ELECTRIC CO., LTD.

7

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

> VOCP the motor coil short-circuit protection starts its operation.

Coil short circuit and the protection circuit behavior are illustrated in figure 4.

Motor Coil Open Protection (Load Open Circuit)

(Patent pending.) This function operates by detecting polarity

reversal of voltage VRS on the internal sense resistors. After the

state is confirmed, the device shuts down the outputs. This allows

detection of a wire of the motor coil breaking. Coil open circuit

and the protection circuit behavior are illustrated in figure 5.

In a unipolar topology, an undetected broken wire on an output pin (motor coil), can cause destruction of the driver due to

overheating. This is because after the wire breaks, the connected

driver MOSFET repeatedly undergoes avalanche breakdown

at PWM turn-off, due to the higher energy applied from back

electromagnetic force, as the energy stored in the motor coil is

dissipated. Avalanche breakdown occurs when the output voltage

surpasses the breakdown voltage between the drain and source of

the MOSFET. Although the MOSFETs in the SLA7080M series

have an ample avalanche breakdown rating for rated operating

temperatures, the avalanche breakdown rating decreases as the

operating temperature rises (as avalanche breakdown is repeated).

When the SLA7080M series protection circuit detects avalanche

breakdown, it allows the breakdown to repeat 3 times to prevent

false detections and then turns off the MOSFET outputs before

overheating can occur.

The detection function operates as follows. When the wire of

the motor coil is broken, the regenerating current that can reach

the MOSFET breakdown level flows during the PWM off-time.

Although the detection voltage, VRS , has negative potential in

normal operation, when a wire breaks in the motor coil, positive

potential appears during a PWM off-time. That is to say, wire

breakage in the motor coil can be detected, when VRS is detected

with positive potential during PWM off-time.

In addition to requiring three breakdown cycles to confirm the

Disconnection

Stepper

Motor

Stepper

Motor

SLA7080M

SLA7080M

VG

VG

VRS

RS

Stepper

Motor

VG

SLA7080M

VG

VOUT

Normal current

RS

ION

IOFF

RS

VRS

ION

IOFF

Coil short circuit

VOCP

Coil short circuit

Output disable

VG

VG

0

VDSS

VOUT

VREF

0

2 × VM

VOUT

0

VM

0

VREF

VRS 0

Avalanche breakdown

VREF

VRS 0

VRS 0

Open detection

(A)

Figure 4. Motor coil short circuit protection operation

28610.23, Rev. 1

(B)

Figure 5. Motor coil open circuit protection in unipolar configuration, (A) PWM normal

operation, (B) PWM operation with motor partially disconnected or broken wire in coil;

VM is the motor control voltage

SANKEN ELECTRIC CO., LTD.

8

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

open circuit condition, the SLA7080M protection function also

provides a fixed delay, topp, before the device shuts down the

outputs. This is to avoid false detections based on ringing after

PWM turn-off. Referring to figure 6, if the breakdown confirmation interval (3 breakdown cycles) plus ringing effects are shorter

than topp , the protection circuit functions correctly. However, if

ringing causes the total period to exceed topp, false detections can

occur. If this is the case, check the motor and wiring layout to

reduce ringing. Variation among device variants and applications

should be taken into consideration. One possible solution is the

addition of a capacitor between the OUTx and GND pins, which

could damp the ringing sufficiently to allow continuation of normal operation when there is no actual avalanche breakdown.

Power Supply

There is no restriction on the on/off sequencing of the main power

supply, VBB, and the logic supply, VDD. Because the SLA7080M

series has a structure that separates the Control IC (MIC) with the

power MOSFET of the output stage, the motor power supply and

the main power supply are electrically separated. Therefore, it is

possible to drive the device by using different voltages for motor

power supply and main power supply. Note that the power supplies have different voltage ranges.

ION

Synchronous Rectification

A dead time, approximately 0.5 μs, is set to prevent simultaneous turn-on of the MOSFETs at switching during synchronous

rectification. During the dead time, the regenerating current flows

through the body diode on each MOSFET chip, as shown in

figure 7.

IOFF

Stepper

Motor

SLA7080M

VG

VG

VRS

RS

Normal current

Back EMF during

dead time

tOPP

tOPP

tOPP

PWM On

VDSS

PWM Off

PWM On

VG

0

VOUT

tDEAD

tDEAD

VG

tCONFIRM

tCONFIRM

0

tCONFIRM

VREF

(A)

(B)

(C)

Figure 6. Alternative topp scenarios: (A) no ringing, breakdown confirmed

after three cycles, (B) ringing plus three cycles is less than topp with no

effect on operations, and (C) ringing is greater than topp generates false

detections of breakdowns

28610.23, Rev. 1

VRS 0

Figure 7. Synchronous rectification operation

SANKEN ELECTRIC CO., LTD.

9

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

Application Information

¯¯A¯, INB, ¯¯I¯N

¯¯B¯, B_SEL, and SYNC pins

INA, ¯¯I¯N

These inputs operate with CMOS input. The default state is high

impedance, and they must be driven to logic high or logic low.

When these logic input pins are used, they should be pulled down

to the ground side using a 1 to 10 kΩ resistor. Any of these pins

that are not used must either be pulled up to the VDD side or be

pulled down to the ground side.

If they are left open, malfunction or permanent damage to the

product may result. For example, in case the signal from the

microcomputer has high impedance, a pull-down or pull-up resistor should be provided. In particular, when an INx pin is in high

impedance during operation, abnormal oscillation of the output

may be caused and in the worst case, this will result in permanent

damage to the MOSFETs.

A low pass filter (LPF) is provided on each the logic input pin.

These improve noise filtering.

Sleep Mode

The SLA7080M can be set into Sleep mode, in which the motor

is not controlled, so it can move freely. To enable Sleep mode, set

the REF pin at more than 2 V. In Sleep mode, the device stops the

main power supply and decreases circuit current.

Because the VOCP level occurs in the Prohibited range, between

those two areas, if the switching time is too lengthy, overcurrent

protection will start operating when VSENSE > VOCP .

FLAG pin

This is the output for the protection circuit:

FLAG Pin Output Logic

High

Protection circuit operation

Internal Sense Resistors, RS

Sense resistors which detect motor currents are incorporated in

this product series. The values of the internal sense resistors, RS ,

can be calculated (for the standard SLA7080M variants listed in

this document) by applying the power loss formula:

P ≈ IO2 × RS .

VDD

Sleep Limit Range

2.00

VREF

(V)

Prohibited Range

100 μs (min)

0.40

0.45

0.30

1.0 A

0.04

Figure 8. External circuit for detecting phase control signals

28610.23, Rev. 1

VOCP Detect

(Typical)

0.70

REF

Phase

Command

Normal operation

It is designed for CMOS output, as shown in the equivalent

circuit in figure 10. Therefore, if the FLAG logic pin is not used,

it must be left open.

When shifting the device directly from the Sleep mode to the

normal operating mode (motor rotation), not only the rise time

of the device, but also the rise time of motor excitation current

should be considered when determining the amount of time lag

from the cancellation of Sleep mode to the next motor phase

input command. As shown in figure 8, a minimum lag of 100 μs

is recommended.

Because of the built-in circuit protection features, be cautious

about taking too long when switching between the Motor Current Setting range and the Sleep Limit range (refer to figure 9).

Low

2.0 A

1.5 A,

3.0 A

Motor Current

Setting Range

Figure 9. Reference voltage, VREF, ranges

SANKEN ELECTRIC CO., LTD.

10

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

The resistance value of the incorporated resistors varies according to the rated currents.

Rated Current

Detected Resistance Value

(A)

(Ω Typical)

1

0.305

1.5

0.305

2

0.205

3

0.155

Each resistance value shown above includes the inherent resistance (approximately 5 mΩ) in the SLA7080M due to product

structure.

In particular, be cautious about noise on the VDD line. When

the noise on VDD line exceeds 0.5 V, device malfunction may

be caused. To avoid this, special attention should be paid to the

layout of the ground circuits. The separation of the VDD ground

and the VBB ground from the product GND pin is effective in

reducing the noise.

Clocking Switch Signals

In normal operation, the input signal for switching is received

from an external microcomputer into the INx pins. However, in

an application where the signal cannot be input, for example, due

to the limitation of ports, this function can be performed using the

following method. Refer to figure 11, which illustrates a topology for a synchronization signal generation circuit that uses clock

signals.

When a logic high level signal is input to the circuit, the capacitor

in the circuit is charged and the SYNC signal is set to logic low

level in the SLA7080M.

VDD

When the clock signal is stopped at low level, the capacitor is discharged by the resistor and the SYNC signal is set to logic high,

causing the SLA7080M to shift to the synchronous mode.

The RC time constant should be determined by the minimum

clock frequency used. In the case of a sequence that keeps the

clock input signal at logic high, an inverter circuit must be added.

Setting Motor Currents for Constant Running

In the SLA7080M series the motor current level, IO , is determined by the internal sense resistors, RS, and the values selected

for the external components R1 and R2 (see figure 12).

Io is calculated by the following formulas:

VREF =

IO =

R2

R1 + R2

(2)

× VDD

VREF

(3)

RS

If VREF is set below 0.04 V, the accuracy of IO setting is highly

likely to be degraded due to the variation between individual

devices and the impedance of the application trace layout.

Lower Limit of Motor Current Control

The SLA7080M series uses a self-excitation PWM current control system with the fixed PWM off-time, toff . When the energy

stored in the motor coil is dissipated in less than toff , the coil

current flows as an intermittent current as shown in figure 13.

That is to say, the PWM average current is decreased and the

motor torque is lowered. When the current begins to flow in the

coil intermittently, this state is considered the lower limit of the

current control, IO(min).

SLA7080MPR

VCC

ESD

protection

Phase

SYNC

FLAG

74HC14

SLA7080M

Figure 10. FLAG pin equivalent circuit

28610.23, Rev. 1

Figure 11. External circuit for detecting phase control signals

SANKEN ELECTRIC CO., LTD.

11

�SLA7080M Series

Unipolar2-PhaseStepingMotorDriverICs

The lower limit of the control current varies subject to application

conditions, such as the motors used, but it can be calculated by

the following formula:

Where:

Tc is LM / RM,

VM is the motor supply voltage,

IO is the set current value,

LM is the motor winding inductance,

RDS(on) is the MOSFET on-resistance,

RM is the motor winding resistance, and

toff is the PWM of -time.

Even if the set control current, IO , is set at less than the calculated

IO(min), there is no harmful effect on the SLA7080M devices,

but the control current will worsen against set current.

Figure 13. Motor current lower limit typical waveforms; circled area

indicates interval when 0 A coil current is generated

Figure 12. Typical application circuit using SMA7080MPR

28610.23, Rev. 1

12

SANKEN ELECTRIC CO., LTD.

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

Verification of Avalanche Energy

Due to the unipolar topology of the SLA7080M series, a surge

voltage (ringing) that exceeds the MOSFET breakdown voltage might be applied to the device. In anticipation of this surge

voltage, the SLA7080M series uses MOSFETs having sufficient

avalanche resistance to withstand such surge voltages. Therefore,

even if a surge voltage occurs, users will be able to use the device

without any problem.

However, if the motor wiring harness is long or the SLA7080M

is used at greater than the rated current or voltage, an avalanche

energy beyond our design expectations may be applied to the

device. Thus, users must test the avalanche energy applied to the

device under actual application conditions.

The following procedure can be used to check the avalanche

energy in an actual application. The following typical values

Stepper

Motor

ID

SLA7080M

VDS(av)

result from testing (refer to figure 15):

VDS(av) = 140 V

ID = 1 A

t = 0.5 μs

The avalanche energy, EAV, is obtained by substituting values into

the following formula:

(2)

EAV ≈ VDS(av)× 0.5 × ID × t

= 140 V × 0.5 × 1 A × 0.5 × 10-6

= 0.035 (mJ)

The EAV thus calculated is compared with the graph shown in

figure 15 to confirm that the EAV is within the safe operating area

of the avalanche breakdown voltage of the MOSFETs.

Thermal Design

The SLA7080M series incorporates a thermal protection function that shuts down all outputs when the Control IC temperature exceeds TTSD. However, a comprehensive overtemperature

protection function is not provided because the Control IC chip

is separate from the MOSFET chips, the power elements which

are the primary sources of heat. It would be unable to respond to

sudden temperature changes in the MOSFETs because of delays

in diffusion of the heat.

Therefore, sufficient thermal evaluation should be performed

with the actual application, so that the junction temperature,

TJ , does not exceed the absolute maximum rating (150°C).

Experimentation is required because it is not practical to calculate a realistic power dissipation value, which involves variable

parameters such as time constants and excitation modes during

actual operation of motors, input frequencies and sequences, and

so forth.

RS

20

16

EAV (mJ)

VDS(av)

SLA7083MPR

12

SLA7082MPR

8

SLA7081MPR

4

ID

0

SLA7080MPR

0

25

t

75

100

125

150

TC (°C)

Figure 14. Test points and waveform for testing avalanche energy of an

application

28610.23, Rev. 1

50

Figure 15. Avalanche breakdown voltages for repeated cycles

SANKEN ELECTRIC CO., LTD.

13

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

Given this situation, for initial design estimates, power dissipation should be calculated by approximation, using worst-case

conditions, at 2-phase excitation:

PD = IO2 × ( RDS(on) + RS ) × 2 ,

(6)

where:

formula:

RθJA ≈ RθCA + RθHS

= ( RθJA – RθCA ) + RθHS ,

(7)

where RθHS is the thermal resistance of the heatsink.

IO is the Output Current,

To estimate the junction temperature rise, ΔTJ , from the device

temperature measured in the actual operating application, ΔTCA ,

the following procedure should be followed:

RDS(on) is the on-resistance of the MOSFETs, and

1.

The temperature rise of the product, ΔTCA , is measured on pin

12, where it enters the case.

Based on the power dissipation of the product thus calculated,

the junction temperature of the product is estimated by using the

temperature rise curves of figure 16.

2.

From the temperature rise thus obtained, the power dissipation,

PD , and the junction temperature, TJ , are estimated using

figure 16.

Unless the temperature exceeds 150°C under the worst conditions (the maximum values of ambient operating temperature),

there will be no problem, but final judgment should be made by

measuring the device temperature during the actual operation

and then verifying power dissipation and junction temperature in

accordance with figure 16.

3.

Calculate the relationship between ΔTCA and the junction

temperature rise, ΔTJ , using the following formula:

PD is the power dissipation of the SLA7080M,

RS is the Sense Resistor Resistance.

When the device is used with a heatsink, the thermal resistance, RθJA , of the device changes (as do the parameters used in

calculating ΔTJA ). This value is calculated from the following

ΔTJ ≈ ΔTJ C + PD × RθJC .

(8)

Note that this thermal design information is provided for preliminary design estimations only. Users should verify the heat

generation of the product in the actual operation, by measuring

the case temperature, TC, and comparing it to the Recommended

Operating Conditions table values.

Change in Temperature, ∆T (°C)

150

125

∆TJA = 26.6 × PD

100

75

∆TCA = 21.3 × PD

50

25

0

0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

Allowable Power Dissipation, PD (W)

Figure 16. Power dissipation estimate for junction-to-ambient and case-toambient temperature change

28610.23, Rev. 1

SANKEN ELECTRIC CO., LTD.

14

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

Pin-out Diagram

Pad Side

2

1

4

3

6

5

8

7

10

9

12

11

14

13

16

15

18

17

20

19

22

21

23

Terminal List Table

Number

1

2

3

4

Function

OUTA

Output (phase A)

¯O

¯¯U¯¯T

¯¯A

¯

5

SENSEA

6

B_SEL

7

INA

8

¯I¯N¯¯A¯

9

INB

10

¯I¯N¯¯B

¯

11

VBB

Main power supply (motor supply)

12

GND

Device ground terminal

13

REF/SLEEP

Current sense (phase A)

Blanking time switching input

Switching input (phase A)

Switching input (phase B)

Control current/sleep enable input

14

VDD

15

GND1

Ground 1 terminal

16

GND2

Ground 2 terminal

17

SYNC

PWM synchronous/non-synchronous switching

18

FLAG

Output of protection circuit monitor

19

SENSEB

20

21

22

23

28610.23, Rev. 1

Name

Logic supply

Current sense (phase B)

¯O

¯¯U¯¯T

¯¯B

¯

Output (phase B)

OUTB

SANKEN ELECTRIC CO., LTD.

15

�Unipolar 2-Phase Stepping Motor Driver ICs

SLA7080M Series

Package Outline Drawing

Dual rows, 23 alternating pins; vertical case mounting; pin #1 opposite pad side

Exposed

heatsink pad

31.3 ±0.2

31 ±0.2

24.4 ±0.2

16.4 ±0.2

4.8 ±0.2

0.6

Gate protrusion

1.7 ±0.1

Ø3.2 ±0.15

Ø3.2 ±0.15

Gate protrusion

16 ±0.2 B

2.45 ±0.2

BSC

12.9 ±0.2

9.9 ±0.2

Branding Area

5 ±0.5

9.3 +0.1

– 0.5

View A

1.27 ±0.5 A

0.65 +0.2

– 0.1

1

3

2

5

4

7

6

9

8

11

10

13

12

15

14

17

16

19

18

21

20

R1

REF

+0.2

0.55 – 0.1

4.3

REF

4.5 ±0.7

23

22

0.7 MAX

A

Measured at pin tips

B

To case top

Terminal core material: Cu

Terminal plating: Ni, with Pb-free solder coating

Recommended attachment: Solder dip (Sn-Ag-Cu)

Deflection at pin bend

View A

Dimensions in millimeters

Branding

1st line,

2nd line,

3rd line,

codes (exact appearance at manufacturer discretion):

type: SLA708xMR

protection: P

lot:

YMDD

Where: Y is the last digit of the year of manufacture

M is the month (1 to 9, O, N, D)

DD is the date

Leadframe plating Pb-free. Device composition

complies with the RoHS directive.

28610.23, Rev. 1

SANKEN ELECTRIC CO., LTD.

16

�SLA7080M Series

Unipolar 2-Phase Stepping Motor Driver ICs

Because reliability can be affected adversely by improper storage

environments and handling methods, please observe the following

cautions.

Cautions for Storage

•

Ensure that storage conditions comply with the standard

temperature (5°C to 35°C) and the standard relative humidity

(around 40 to 75%); avoid storage locations that experience

extreme changes in temperature or humidity.

•

Avoid locations where dust or harmful gases are present and

avoid direct sunlight.

•

Reinspect for rust on leads and solderability of products that have

been stored for a long time.

Cautions for Testing and Handling

When tests are carried out during inspection testing and other

standard test periods, protect the products from power surges

from the testing device, shorts between adjacent products, and

shorts to the heatsink.

Remarks About Using Silicone Grease with a Heatsink

• When silicone grease is used in mounting this product to a

heatsink, it shall be applied evenly and thinly. If more silicone

grease than required is applied, it may produce stress.

• Volatile-type silicone greases may permeate the product and

produce cracks after long periods of time, resulting in reduced

heat radiation effect, and possibly shortening the lifetime of the

product.

• Our recommended silicone greases for heat radiation purposes,

which will not cause any adverse effect on the product life, are

indicated below:

Type

Suppliers

G746

Shin-Etsu Chemical Co., Ltd.

YG6260

Momentive Performance Materials Inc.

SC102

Dow Corning Toray Co., Ltd.

28610.23, Rev. 1

Heatsink Mounting Method

Torque When Tightening Mounting Screws. The recommended tightening

torque for this product package type is: 58.8 to 78.4 N•cm (6.0 to

8.0 kgf•cm).

Soldering

•

When soldering the products, please be sure to minimize the

working time, within the following limits:

260±5°C 10 s

380±5°C 5 s

• Soldering iron should be at a distance of at least 1.5 mm from the

body of the products

Electrostatic Discharge

•

When handling the products, operator must be grounded.

Grounded wrist straps worn should have at least 1 MΩ of

resistance to ground to prevent shock hazard.

•

Workbenches where the products are handled should be

grounded and be provided with conductive table and floor mats.

•

When using measuring equipment such as a curve tracer, the

equipment should be grounded.

•

When soldering the products, the head of soldering irons or the

solder bath must be grounded in other to prevent leak voltages

generated by them from being applied to the products.

•

The products should always be stored and transported in our

shipping containers or conductive containers, or be wrapped in

aluminum foil.

SANKEN ELECTRIC CO., LTD.

17

�SLA7080M Series

Unipolar 2-Phase Stepping Motor Driver ICs

• The contents in this document are subject to changes, for improvement and other purposes, without notice. Make sure that this is the

latest revision of the document before use.

• Application and operation examples described in this document are quoted for the sole purpose of reference for the use of the products herein and Sanken can assume no responsibility for any infringement of industrial property rights, intellectual property rights or

any other rights of Sanken or any third party which may result from its use.

• Although Sanken undertakes to enhance the quality and reliability of its products, the occurrence of failure and defect of semiconductor products at a certain rate is inevitable. Users of Sanken products are requested to take, at their own risk, preventative measures

including safety design of the equipment or systems against any possible injury, death, fires or damages to the society due to device

failure or malfunction.

• Sanken products listed in this document are designed and intended for the use as components in general purpose electronic equipment or apparatus (home appliances, office equipment, telecommunication equipment, measuring equipment, etc.).

When considering the use of Sanken products in the applications where higher reliability is required (transportation equipment and

its control systems, traffic signal control systems or equipment, fire/crime alarm systems, various safety devices, etc.), and whenever

long life expectancy is required even in general purpose electronic equipment or apparatus, please contact your nearest Sanken sales

representative to discuss, prior to the use of the products herein.

The use of Sanken products without the written consent of Sanken in the applications where extremely high reliability is required

(aerospace equipment, nuclear power control systems, life support systems, etc.) is strictly prohibited.

• In the case that you use Sanken products or design your products by using Sanken products, the reliability largely depends on the

degree of derating to be made to the rated values. Derating may be interpreted as a case that an operation range is set by derating the

load from each rated value or surge voltage or noise is considered for derating in order to assure or improve the reliability. In general,

derating factors include electric stresses such as electric voltage, electric current, electric power etc., environmental stresses such

as ambient temperature, humidity etc. and thermal stress caused due to self-heating of semiconductor products. For these stresses,

instantaneous values, maximum values and minimum values must be taken into consideration.

In addition, it should be noted that since power devices or IC's including power devices have large self-heating value, the degree of

derating of junction temperature affects the reliability significantly.

• When using the products specified herein by either (i) combining other products or materials therewith or (ii) physically, chemically

or otherwise processing or treating the products, please duly consider all possible risks that may result from all such uses in advance

and proceed therewith at your own responsibility.

• Anti radioactive ray design is not considered for the products listed herein.

• Sanken assumes no responsibility for any troubles, such as dropping products caused during transportation out of Sanken's distribution network.

• The contents in this document must not be transcribed or copied without Sanken's written consent.

28610.23, Rev. 1

SANKEN ELECTRIC CO., LTD.

18

�