Si5357 Data Sheet

12-Output Any-Frequency Clock Generator

KEY FEATURES

Based on Skyworks proprietary MultiSynth™ flexible frequency synthesis technology, the

Si5357 generates any combination of output frequencies with excellent jitter performance. The device's highly flexible architecture enables a single device to generate a

wide range of integer and non-integer related frequencies on up to 12 clock outputs

with 0 ppm frequency synthesis error. The device offers multiple banks of outputs that

can each be tied to independent voltages, enabling usage in mixed-supply applications.

Given its frequency, format, and supply voltage flexibility, the Si5357 is ideally suited to

replace multiple clock ICs and oscillators with a single device.

The Si5357 is quickly and easily configured using ClockBuilder Pro™ software. ClockBuilder Pro assigns a custom part number for each unique configuration. Devices are

factory-programmable free of charge, making it easy to get a custom clock uniquely

tailored for each application. Devices can also be in-circuit programmed via an I2C serial

interface.

• Any-frequency 12-output LVCMOS

programmable clock generator

• Offered in 32-pin QFN, up to 12 outputs

• MultiSynth technology enables anyfrequency synthesis on any output up to

170 MHz

• Highly configurable output path featuring a

cross point mux

• Up to three independent fractional

synthesis output paths

• Up to five independent integer dividers

• Input frequency range:

• External crystal: 16 to 50 MHz

• Differential clock: 10 to 170 MHz

• LVCMOS clock: 10 to 170 MHz

Applications:

• Servers, Storage

• Print Imaging

• Audio processing

1

• Output frequency range: 5 to 170 MHz

• Broadcast Video

• Test and Measurement

• Industrial, Embedded Computing

• Temperature range: –40 to +85 °C

• RoHS-6 compliant

• Down and center spread spectrum

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

1

�Table of Contents

1. Features List

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Ordering Guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Functional Block Diagram .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 5

3.2 Modes of Operation .

3.2.1 Initialization . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 6

. 6

3.3 Frequency Configuration

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 6

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

6

6

6

7

3.5 Outputs . . . . . . . . . . .

3.5.1 LVCMOS Output Terminations . .

3.5.2 LVCMOS Output Signal Swing . .

3.5.3 LVCMOS Output Polarity . . . .

3.5.4 Output Enable/Disable . . . . .

3.5.5 Synchronous Output Disable Feature

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

7

7

7

7

8

8

3.6 Spread Spectrum .

3.4 Inputs . . . . . . . . . . .

3.4.1 External Reference Input (XA/XB)

3.4.2 Input Clocks . . . . . . .

3.4.3 Input Selection . . . . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 8

3.7 Universal Hardware Input Pins.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 8

3.8 Custom Factory Pre-programmed Parts

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 9

3.9 I2C Serial Interface

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 9

3.10 In-Circuit Programming .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 9

4. Register Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10

5. Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . .11

6. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 Pin Descriptions (32-QFN) .

.

.

.

.

.

.

.

.18

7. Package Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

7.1 Si5357 5x5 mm 32-QFN Package Diagram .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.21

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

9. Top Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25

10. Document Change List . . . . . . . . . . . . . . . . . . . . . . . . . .

26

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

2

2

.

.

.

8. PCB Land Pattern

.

.

18

.

�Si5357 Data Sheet • Features List

1. Features List

• Any-frequency 12-output LVCMOS programmable clock generator

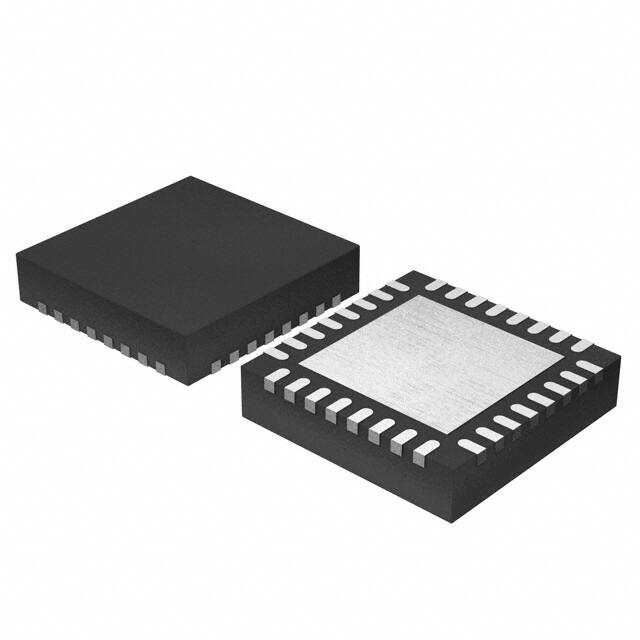

• Offered in 32-pin QFN, up to 12 outputs

• MultiSynth technology enables any-frequency synthesis on any

output up to 170 MHz

• Highly configurable output path featuring a cross point mux

• Up to three independent fractional synthesis output paths

• Up to five independent integer dividers

3

• Input frequency range:

• External crystal: 16 to 50 MHz

• Differential clock: 10 to 170 MHz

• LVCMOS clock: 10 to 170 MHz

• Output frequency range: 5 to 170 MHz

• Operating temperature range: –40 to +85 °C ambient

• RoHS-6 compliant

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

3

�Si5357 Data Sheet • Ordering Guide

2. Ordering Guide

Si5357A DXXXXX - GMR

Operating Temp Range: -40 to +85 ° C

GM = 32-QFN, ROHS6 compliant

R = Tape & Reel (ordering option)

D = Product Revision

XXXXX = NVM code (optional)

For blank devices, order Si5357A-C-GM(R).

For custom NVM configurations, a unique 5-digit ordering code

will be assigned by ClockBuilder Pro

Figure 2.1. Orderable Part Number Guide

4

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

4

�Si5357 Data Sheet • Functional Description

3. Functional Description

The Si5357 is a high-performance, low-jitter clock generator capable of synthesizing up to 12 user-programmable clock frequencies

up to 170 MHz. The device supports free-run operation using an external crystal, or it can lock to an external clock signal. The output

drivers support up to 12 differential clocks or 24 LVCMOS clocks, or a combination of both. VDDO pins are provided for versatility,

which can be set to 3.3 V, 2.5 V, 1.8 V, or 1.5 V to power the multi-format output drivers. The core voltage supply (VDD) accepts

3.3 V, 2.5 V, or 1.8 V and is independent from the output supplies (VDDOxs). Using its two-stage synthesis architecture and patented

high-resolution low-jitter MultiSynth technology, the Si5357 can generate an entire clock tree from a single device.

The Si5357 combines a wideband PLL with next generation MultiSynth technology to offer the industry’s highest output count high

performance programmable clock generator, while maintaining excellent jitter performance. The PLL locks to either an external 16–30

MHz crystal (XA/XB) for generating free-running clocks or to an external clock (CLKIN_2/CLKIN_2#) for generating synchronous clocks.

In free-run mode, the oscillator frequency is multiplied by the PLL and then divided down either by an integer divider or MultiSynth for

fractional synthesis.

The Si5357 features user-defined universal hardware input pins which can be configured in the ClockBuilder Pro software utility.

Universal hardware pins can be used for OE, spread spectrum enable, input clock selection, output frequency selection, or I2C address

select.

The device provides the option of storing a user-defined clock configuration in its non-volatile memory (NVM), which becomes the

default clock configuration at power-up. To enable in-system programming, a power up mode is available through OTP which powers up

the chip in an OTP defined default mode but with no outputs enabled. This allows a host processor to first write a user defined subset of

the registers and then restart the power-up sequence to activate the newly programmed configuration without re-downloading the OTP.

3.1 Functional Block Diagram

VDDO0

OUT0

÷INT

OUT1

VDDO1

CLKIN_2

CLKIN_2

Multi

Synth

÷INT

XTAL

OUT2

÷INT

OUT3

PLL

Multi

Synth

OSC

VDDO2

OUT4

INT

NVM

SCLK

SDATA

÷INT

OUT5

VDDO3

INT

OUT6

I2C

INT

÷INT

OUT7

Input1

Input2

Input3

Input4

INT

HW Input

Control

VDDO4

OUT8

INT

÷INT

OUT9

Input5

VDDO5

OUT10

÷INT

OUT11

Figure 3.1. Block Diagram for 12-Output Si5357 in 32-QFN

5

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

5

�Si5357 Data Sheet • Functional Description

3.2 Modes of Operation

The Si5357 supports both free-run and synchronous modes of operation. The default mode selection is set in ClockBuilder Pro.

Alternatively, a universal hardware input pin can be defined as CLKIN_SEL to select between a crystal or clock input. There is also the

option to select the input source via the serial interface by writing to the input select register.

3.2.1 Initialization

When power is applied, the device begins an initialization period where it downloads default register values and configuration data

from NVM and performs other initialization tasks. Communicating with the device through the serial interface is possible when this

initialization period is complete. The clock outputs will be squelched until the device initialization is done.

3.3 Frequency Configuration

The phase-locked loop is fully integrated and does not require external loop filter components. Its function is to phase lock to the

selected input and provide a common synchronous reference to the high-performance MultiSynth fractional or integer dividers.

A crosspoint mux connects any of the MultiSynth divided frequencies or INT divided frequencies to individual output drivers or banks

of output drivers. Additional output integer dividers provide further frequency division by an even integer from 1 to 63. The frequency

configuration of the device is programmed by setting the input dividers (P), the PLL feedback fractional divider (Mn/Md), the MultiSynth

fractional dividers (Nn/Nd), and the output integer dividers (R). Skyworks’ Clockbuilder Pro configuration utility determines the optimum

divider values for any desired input and output frequency plan

3.4 Inputs

The Si5357 requires an external 16–50 MHz crystal at its XA/XB pins to operate in free-run mode, or an external input clock (CLKIN_2/

CLKIN_2#) for synchronous operation. An external crystal is not required in synchronous mode.

3.4.1 External Reference Input (XA/XB)

An external crystal (XTAL) is used in combination with the internal oscillator (OSC) on Si5357 to produce a low jitter reference

for the PLL when operating in the free-run mode. The Si5357 Reference Manual provides additional information on PCB layout

recommendations for the crystal to ensure optimum jitter performance.

For free-running operation, the internal oscillator can operate from a low-frequency fundamental mode crystal (XTAL) with a resonant

frequency of 16 to 50 MHz. A crystal can easily be connected to pins XA and XB without external components, as shown in the figure

below. Internal loading capacitance (CL) values from 2 pf to 30 pf can be selected via register settings or internal CL can be totally

disabled allowing for external CL. Alternatively, an external CL can be used along with the internal CL.

Figure 3.2. External Reference Input (XA/XB)

3.4.2 Input Clocks

An input clock is available to synchronize the PLL when operating in synchronous mode. This input can be configured as LVPECL,

LVDS or HCSL differential, or LVCMOS. The recommended input termination schemes are shown in the Si5357 Family Reference

Manual. Unused inputs can be disabled by register configuration.

6

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

6

�Si5357 Data Sheet • Functional Description

3.4.3 Input Selection

The active clock input is selected by register control, or by defining two universal input pins as CLKIN_SEL[1:0] in ClockBuilder Pro.

A register bit determines input selection as pin or register selectable. If there is no clock signal on the selected input at power up, the

device will not generate output clocks.

In a typical application, the Si5357 reference input is configured immediately after power-up and initialization. If the device is switched

to another input more than ±1000 ppm offset from the initial input, the device must be recalibrated manually to the new frequency,

temporarily turning off the clock outputs. After the VCO is recalibrated, the device will resume producing clock outputs. If the selected

inputs are within ±1000 ppm, any phase error difference will propagate through the device at a rate determined by the PLL bandwidth.

Hitless switching and phase build-out are not supported by the Si5357.

3.5 Outputs

The Si5357 supports up to 12 LVCMOS output drivers.

Utilizing the reference clock enables a fan-out buffer function from an input clock source to any bank of outputs.

Individual output integer output dividers (R) allow the generation of additional synchronous frequencies. These integer dividers are

configurable as divide by 1 (default) through 63.

3.5.1 LVCMOS Output Terminations

LVCMOS outputs can be dc-coupled, as shown in the figure below.

1.71 to 6.36V

Zo=50Ω

OUTx

Set output driver

to 50Ω mode.

Zo=50Ω

OUTxb

Figure 3.3. LVCMOS Output Termination Example, Option 1

1.425 to 3.63V

OUTx

Set output driver

to 25Ω mode.

Rs

OUTxb

Rs

Rs = Zo – Rdrv

Figure 3.4. LVCMOS Output Termination Example, Option 2

3.5.2 LVCMOS Output Signal Swing

The signal swing (VOL/VOH) of the LVCMOS output drivers is set by the voltage on the VDDO pin for the respective bank.

3.5.3 LVCMOS Output Polarity

When a driver is configured as an LVCMOS output it generates a clock signal on both pins (OUTx and OUTxb). By default, the clock

on the OUTxb pin is generated with complimentary polarity with the clock on the OUTx pin. The polarity of these clocks is configurable

enabling in phase clock generation and/or inverted polarity with respect to other output drivers.

7

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

7

�Si5357 Data Sheet • Functional Description

3.5.4 Output Enable/Disable

The universal hardware input pins can be programmed to operate as output enable (OEb), controlling one or more outputs. Pin

assignment is done using ClockBuilder Pro. An output enable pin provides a convenient method of disabling or enabling the output

drivers. When the output enable pin is held high, all designated outputs will be disabled. When held low, the designated outputs will be

enabled. Outputs in the enabled state can be individually disabled through register control.

3.5.5 Synchronous Output Disable Feature

Output clocks are always enabled and disabled synchronously. The output will wait until a clock period has completed before the driver

is disabled. This prevents unwanted runt pulses from occurring when disabling an output.

3.6 Spread Spectrum

To help reduce electromagnetic interference (EMI), the Si5357 supports spread spectrum modulation. The output clock frequencies can

be modulated to spread energy across a broader range of frequencies, lowering system EMI. The Si5357 implements spread spectrum

using its patented MultiSynth technology to achieve previously unattainable precision in both modulation rate and spreading magnitude.

Spread spectrum can be enabled through I2C, or by configuring one of the universal hardware input pins using ClockBuilder Pro.

The Si5357 features both center and down spread spectrum modulation capability, from 0.1% to 2.5%. Each MultiSynth is capable of

generating an independent spread spectrum clock. The feature is enabled using a user-defined universal hardware input pin or via

the device I2C interface. Spread spectrum can be applied to any output clock derived from a MultiSynth fractional divider, supporting

frequencies up to 170 MHz. Since the spread spectrum clock generation is performed in the MultiSynth fractional dividers, the spread

spectrum waveform is highly consistent across process, voltage, and temperature. The Si5357 features two independent MultiSynth

dividers, enabling the device to provide two independent spread profiles simultaneously to the clock output banks.

3.7 Universal Hardware Input Pins

Universal hardware input pins are user configurable control input pins that can have one or more of the functions listed below assigned

to them using ClockBuilder Pro.

If more hardware input pins are needed, the differential input pins can be alternatively configured as two universal hardware input pins.

Contact Skyworks for further details. Universal hardware input pins can be utilized for the following functions:

Table 3.1. Universal Hardware Input Pins

Description

Function

SSEN_EN0

Spread spectrum enable on MultiSynth0 (N0).

SSEN_EN1

Spread spectrum enable on MultiSynth0 (N1).

FS_INTx

Used to switch an integer output divider frequency from frequency A to frequency B.

FS_MSx

Used to switch a MultiSynth output divider output from frequency and/or change spread

spectrum profile.

OE

Output enable for one or more outputs.

I2C address select

Sets the LSB of the I2C address to either 0 or 1.

CLKIN_SEL[1:0]

Selects between crystal or clock inputs.

Spread Spectrum Enable Pins (SSEN[1:0])

SSEN_EN[1:0] pins are active pins that enable/disable spread spectrum on all outputs that correspond to MutliSynth0 or MultiSynth1,

respectively. The change in frequency or spread spectrum will be instantaneous and may not be glitch free.

Table 3.2. SPREAD_EN Pin Selection Table

8

SSEN_ENx

Function

0

Spread Spectrum disabled on MultiSynthx

1

Spread Spectrum enabled on MultiSynthx

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

8

�Si5357 Data Sheet • Functional Description

Output Frequency Select Pins

There are five integer dividers, one corresponding to each of the five output banks. Using ClockBuilder Pro, a universal hardware input

pin can be assigned for each integer divider, providing the capability to select between two different pre-programmed divide values.

Divider values of every integer from 8 to 255 are available in ClockBuilder Pro for each integer divider.

Table 3.3. FS_INT Pin Selection Table

FS_INTx

Output Frequency from INTx

0

Frequency A, as defined in ClockBuilder Pro

1

Frequency B, as defined in ClockBuilder Pro

Output Enable

A universal hardware input pin can be defined to control output enable of a differential output, a bank of differential outputs, or as a

global output enable pin controlling all outputs. Upon de-assertion of an OE pin, the corresponding output will be disabled within 2-6

clock cycles. Asserting an OE pin from disable to enable will take < 20 µs for the output to have a clean clock.

Output enabled/disabled for LVCMOS are done in pairs. Each differential buffer True and Compliment output can generate an LVCMOS

clock and the OE pin associated with the True and Compliment output buffer will control the respective LVCMOS pair.

For example: If DIFF0 is configured to be SE1 and DIFF0# is configured to be SE2 and OE1 is the associated OE pin, de-asserting the

OE1 pin will disable both SE1 and SE2 outputs. The disable and enable of the outputs to a known state is glitch free.

I2C Address Pin

The AI2C can be assigned as a universal hardware input pin as an I2C address select function.

CLKIN_SEL[0:1] Pins

These pins are used to set the input source clock between the input clock channels (Crystal, CLK2/CLK#). Upon switching the input

clock source, the output will not be glitch free. It is intended for the user to set this pin to a known state before the system is powered up

or have the receiver address any unintended output signals when switching to a different input source clock.

3.8 Custom Factory Pre-programmed Parts

Custom pre-programmed parts can be ordered corresponding to a specific configuration file generated using the ClockBuilder Pro

software utility. Skyworks writes the configuration file prior to shipping. Use the ClockBuilder Pro custom part number wizard (https://

www.skyworksinc.com/en/application-pages/clockbuilder-pro-software) to quickly and easily request and generate a custom part number for your ClockBuilder Pro configuration file. A factory pre-programmed part will generate clocks at power-up.

In less than three minutes, you will be able to generate a custom part number with a detailed data sheet addendum matching your

design’s configuration. Once you receive the confirmation email with the data sheet addendum, simply place an order with your local

Skyworks sales representative. Samples of your pre-programmed device will ship within two weeks.

3.9 I2C Serial Interface

The Si5357 is fully compatible with rev6 of the I2C specification, including Standard, Fast, and Fast+ modes. Configuration and

operation of the Si5357 can be controlled by reading and writing registers using the I2C . Communication with a 1.8 V to 3.3 V host is

supported. See the Si5357 Family Reference Manual for details.

3.10 In-Circuit Programming

The Si5332 is in-system configurable using the I2C interface by the following two methods:

• In-ciruit configuration of device registers after power-up. With this method changes to volatile register memory can be done as required to produce the desired outputs. This does not alter internal NVM; therefore, register memory changes are lost at power-down.

Refer to the Si5332 Family Reference Manual available on our web site for details.

• In-circuit re-configuration of internal NVM. Writing to internal NVM requires use of the CBPro Field Programmer (CBPROG-DONGLE) and CBPro software. See UG286: ClockBuilderPro Field Programmer Kit user's guide available on our web site for more

information. (One important note: The Si5332 core VDDs (VDD_DIG, VDDA, and VDD_XTAL) must be powered by 3.3V during

in-circuit NVM programming.)

9

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

9

�Si5357 Data Sheet • Register Map

4. Register Map

Refer to the Si5357 Family Reference Manual for a complete list of registers descriptions and settings.

10

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

10

�Si5357 Data Sheet • Electrical Specifications

5. Electrical Specifications

Table 5.1. Recommended Operating Conditions

(VDD = VDDA = VDD_DIG = VDD_XTAL = 1.8 V to 3.3 V +10%/-5%, VDDO = 1.8 V ±5%, 2.5 V ±5%, or 3.3 V ±5%, TA = –40 to 85 °C)

Parameter

Symbol

Test Condition

Min

Typ

Max

Units

Ambient Temperature

TA

–40

25

85

°C

Junction Temperature

TJMAX

—

—

125

°C

Core Supply Voltage

VDDA,

VDD_DIG,

VDD-xtal

1.71

—

3.63

V

VDDO

1.425

—

3.63

V

Output Driver Supply Voltage

Note:

1. All minimum and maximum specifications are guaranteed and apply across the recommended operating conditions. Typical

values apply at nominal supply voltages and an operating temperature of 25 °C unless otherwise noted.

Table 5.2. DC Characteristics

(VDD = VDDA = VDD_DIG = VDD_XTAL = 1.8 V to 3.3 V +10%/-5%, VDDO = 1.8 V ±5%, 2.5 V ±5%, or 3.3 V ±5%, TA = –40 to 85 °C)

Parameter

Symbol

Core Supply Current

Output Buffer Supply Current

Test Condition

IDD

IDDOx

3.3 V VDDO

Min

Typ

Max

Units

—

45

70

mA

—

16

19

mA

—

9

11

mA

—

7.5

8.5

mA

270

—

mW

LVCMOS1 output

@ 170 MHz

2.5 V VDDO

LVCMOS1 output

@ 170 MHz

1.8 VDDO

LVCMOS1 output

@ 170 MHz

Total Power Dissipation

Pd

32-pin

Note 1

Notes:

1. LVCMOS outputs measured into a 5 inch 50 Ω PCB trace with 4 pF load.

LVCMOS Output Test Configuration

IDDO

5 inch

OUT

50

4 pF

2. Detailed power consumption for any configuration can be estimated using ClockBuilderPro when an evaluation board (EVB) is not

available.

11

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

11

�Si5357 Data Sheet • Electrical Specifications

Table 5.3. Clock Input Specifications

(VDD = VDDA = VDD_DIG = VDD_XTAL = 1.8 V to 3.3 V +10%/-5%, VDDO = 1.8 V ±5%, 2.5 V ±5%, or 3.3 V ±5%, TA = –40 to 85 °C)

Parameter

Symbol

Test Condition

Min

Typ

Max

Units

Input Clock (AC-coupled Differential Input Clock on CLKIN_2/CLKIN_2# )

Frequency

FIN

Differential

10

—

250

MHz

Voltage Swing

VPP

Differential AC-coupled

< 170 MHz

0.5

—

1.8

VPP_diff

Slew Rate

SR/SF

20-80%

0.75

—

—

V/ns

Duty Cycle

DC

40

—

60

%

Input Impedance

RIN

10

—

—

kΩ

Input Capacitance

CIN

2

3.5

6

pF

170

MHz

Input Clock (DC-coupled LVCMOS Input Clock on CLKIN_2)

Frequency

FIN

10

—

Input High Voltage

VIH

0.8 × VDD

—

Input Low Voltage

VIL

—

Slew Rate1,2

SR/SF

20-80%

—

—

V

0.2 × VDD

V

0.75

—

—

V/ns

Duty Cycle

DC

40

—

60

%

Input Capacitance

CIN

2

3.5

6

pF

Notes:

1. Imposed for jitter performance.

2. Rise and fall times can be estimated using the following simplified equation: tr/tf80-20 = ((0.8 - 0.2) * VIN_Vpp_se) / SR.

12

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

12

�Si5357 Data Sheet • Electrical Specifications

Table 5.4. External Crystal Input Specification

(VDD = VDDA = VDD_DIG = VDD_XTAL = 1.8 V to 3.3 V +10%/-5%, VDDO = 1.8 V ±5%, 2.5 V ±5%, or 3.3 V ±5%, TA = –40 to 85 °C)

Parameter

Symbol

Crystal Frequency

Fxtal

Load Capacitance

CL

Test Condition

Min

Typ

16-50

16 - 30 MHz

6

12

31 - 50 MHz

Shunt Capacitance

Max

MHz

18

pF

10

pF

16 - 30 MHz

—

—

7

pF

31 - 50 MHz

—

—

2

pF

16 - 30 MHz

—

—

50

Ω

31 - 50 MHz

—

—

50

Ω

250

—

—

µW

Internal cap disabled

—

2.5

—

pF

Internal cap enabled

(per pad)

3

—

29

pF

-0.3

—

1.3

V

Min

Typ

Max

Units

VIL

-0.1

—

0.3 × VDD1

V

VIH

0.7 × VDD

—

1.1 × VDD

V

Input Capacitance

CIN

—

—

4

pF

Pull-up/down Resistance

RIN

—

50

—

kΩ

ESR

CO

Units

CL

Max Crystal Drive Level

dL

Input Capacitance 1

CIN

Input Voltage

VXIN

Notes:

1. Internal capacitance on the xtal input pads is programmable or can be disabled.

Table 5.5. Control Pins

(VDD = VDDA = VDD_DIG = VDD_XTA = 1.8 V to 3.3 V +10%/-5%, TA = –40 to 85 °C)

Parameter

Symbol

Test Condition

Si5357 Control Input Pins (Inputx)

Input Voltage

Note:

1. VDD indicates all core voltages VDD_DIG, VDDA, and VDD_XTAL which are required to all be using the same nominal voltage.

13

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

13

�Si5357 Data Sheet • Electrical Specifications

Table 5.6. LVCMOS Clock Output Specifications

(VDD = VDDA = VDD_DIG = VDD_XTA = 1.8 V to 3.3 V +10%/-5%, VDDO = 1.8 V ±5%, 2.5 V ±5%, or 3.3 V ±5%, TA = –40 to 85 °C)

Parameter

Symbol

Test Condition

Min

Typ

Max

Units

Frequency

fout

1.8-3.3 V CMOS

5

—

170

MHz

1.5 V CMOS

5

—

133.33

MHz

tR/tF

50 Ω impedance, 5”

trace, CL = 4 pf

—

0.5

0.8

ns

tR/tF

50 Ω impedance, 5”

trace CL = 4 pf

—

0.6

0.95

ns

tR/tF

50 Ω impedance, 5”

trace CL = 4 pf

—

0.75

1.3

ns

tR/tF

50 Ω impedance, 5”

trace CL = 4 pf

—

0.9

1.3

ns

3.3 V

—

46

—

Ω

2.5 V

—

48

—

Ω

1.8 V

—

53

—

Ω

1.5 V

—

58

—

Ω

3.3 V

—

23

—

Ω

2.5 V

—

24

—

Ω

1.8 V

—

27

—

Ω

1.5 V

—

29

—

Ω

VOH

–4 mA load

VDDO-0.3

—

—

V

VOL

4 mA load

—

—

0.3

V

DC

XO and PLL mode

45

—

55

%

Rise/Fall Time, 3.3 V

(20-80%)

Rise/Fall Time, 2.5 V

(20-80%)

Rise/Fall Time, 1.8 V

(20-80%)

Rise/Fall Time, 1.5 V

(20-80%)

CMOS Output Resistance

(Single Strength)

CMOS Output Resistance

(Double Strength)

CMOS Output Voltage

Duty Cycle

14

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

14

�Si5357 Data Sheet • Electrical Specifications

Table 5.7. Performance Characteristics

(VDD = VDDA = VDD_DIG = VDD_XTA = 1.8 V to 3.3 V +10%/-5%, VDDO = 1.8 V ±5%, 2.5 V ±5%, or 3.3 V ±5%, TA = –40 to 85 °C)

Parameter

Symbol

Test Condition

Min

Typ

Max

Units

tVDD

0 V to VDDmin

0.1

—

10

ms

tinitialization

Time for I2C to become

operational after core

supply exceeds VDDmin

—

15

ms

Clock Stabilization from Power-up

tSTABLE

Time for clock outputs to

appear after POR

—

15

25

ms

Input to Output Propagation Delay

tPROP

Buffer mode

—

2.5

4

ns

0.1

—

2.5

%

Power Ramp

Initialization Time

—

(PLL Bypass)

Spread Spectrum PP Frequency Deviation

SSDEV

0.5% Spread Frequency Deviation

SSDEV

MultiSynth Output < 250

MHz

0.4

0.45

0.5

%

Spread Spectrum Modulation Rate

SSDEV

MultiSynth Output < 250

MHz

30

31.5

33

kHz

Notes:

1. Outputs at same frequencies and using the same driver format.

2. The maximum step size is only limited by the register lengths; however, the MultiSynth output frequency must be kept between 5

MHz and 170 MHz.

3. Update rate via I2C is also limited by the time it takes to perform a write operation.

4. Default value is ~31.5 kHz.

15

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

15

�Si5357 Data Sheet • Electrical Specifications

Table 5.8. Jitter Performance Specifications

(VDD = VDDA = VDD_DIG = VDD_XTA = 1.8 V to 3.3 V +10%/-5%, VDDO = 1.8 V ±5%, 2.5 V ±5%, or 3.3 V ±5%, TA = –40 to 85 °C)

Parameter

Symbol

Test Condition

Typ

Jitter Generation,

Locked to External 25 MHz

Clock

JPER

N = 10, 000 cycles Integer or Fractional Mode. 1,2 Measured in the time domain. Performance is limited by the

noise floor of the equipment.

12

ps Pk-Pk

11

ps Pk

Jitter Generation,

Locked to External 25 MHz

Crystal

JPER

12

ps Pk-Pk

JCC

N = 10, 000 cycles Integer or Fractional Mode. 1,2 Measured in the time domain. Performance is limited by the

noise floor of the equipment.

11

ps Pk

Power Supply Noise Rejection3

PSNR

25 kHz

–67

—

50 kHz

–66

—

100 kHz

–69

—

500 kHz

–73

—

1 MHz

–72

—

JCC

Max

Units

dBc

Notes:

1. Integer mode assumes that the output dividers (Nn/Nd) are configured with an integer value.

2. Fractional and DCO modes assume that the output dividers (Nn/Nd) are configured with a fractional value and the feedback

divider is integer.

3. Measured at 156.25 MHz carrier frequency. 100 mVpp sine wave noise added and noise spur amplitude measured.

Table 5.9. Thermal Characteristics

Parameter

Symbol

Test Condition1

Value

Units

θJA

Still Air

32.8

°C/W

Air Flow 1 m/s

28.8

Air Flow 2 m/s

27.6

Si5357 — 32 QFN

Thermal Resistance, Junction to Ambient

Thermal Resistance, Junction to Case

θJC

18.5

Thermal Resistance, Junction to Board

θJB

15.1

ψJB

14.9

ψJT

0.5

Thermal Resistance, Junction to Top Center

Note:

1. Based on PCB Dimension: 3” x 4.5”, PCB Thickness: 1.6 mm, PCB Land/Via under GND pad: 36, Number of Cu Layers: 4.

16

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

16

�Si5357 Data Sheet • Electrical Specifications

Table 5.10. Absolute Maximum Ratings1,2,3

Parameter

Symbol

Test Condition

Value

Units

Storage Temperature Range

TSTG

–55 to +150

°C

DC Supply Voltage

VDD

–0.5 to 3.8

V

VDDA

–0.5 to 3.8

V

VDDxtal

–0.5 to 3.8

V

VDDO

–0.5 to 3.8

V

–0.3 to 1.3

V

Input Voltage Range

VI

Latch-up Tolerance

LU

ESD Tolerance

HBM

Junction Temperature

Soldering Temperature

(Pb-free profile)

Soldering Temperature Time at TPEAK

(Pb-free profile)

XIN/XOUT

JESD78 Compliant

100 pF, 1.5 kΩ

2.0

kV

TJCT

–55 to 125

°C

TPEAK

260

°C

TP

20 to 40

sec

Notes:

1. Permanent device damage may occur if the absolute maximum ratings are exceeded. Functional operation should be restricted

to the conditions as specified in the operational sections of this data sheet. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

2. For more packaging information, go to https://www.skyworksinc.com/en/Support.

3. The device is compliant with JEDEC J-STD-020.

17

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

17

�Si5357 Data Sheet • Pin Descriptions

6. Pin Descriptions

OUT11

OUT10

INPUT5

INPUT4

OUT9

OUT8

32

31

30

29

28

27

26

VDDO4

VDDO5

6.1 Pin Descriptions (32-QFN)

25

VDD_DIG

1

24

INPUT3

CLKIN_2

2

23

VDDO3

CLKIN_2

3

22

OUT7

VDD_XTAL

4

21

OUT6

XA/CLKIN1

5

20

VDDO2

XB

6

19

OUT5

VDDA

7

18

OUT4

INPUT1

8

17

INPUT2

9

10

11

12

13

14

15

16

SCLK

SDATA

OUT0

OUT1

VDDO0

OUT2

OUT3

VDDO1

33

GND

Figure 6.1. 32-QFN

Table 6.1. Si5357 Pin Descriptions, (32-QFN)

18

Pin Number

Pin Name

Pin Type

Function

1

VDD_DIG

P

Voltage supply for digital functions. Connect to 1.8–3.3 V. Part of internal

core VDD voltage. Must be connected to same voltage as VDDA and

VDD_XTAL.

2

CLKIN_2

I

3

CLKIN_2b

I

These pins accept both differential and single-ended clock signals. Refer

to Section 3.4.2 Input Clocks for input termination options. These pins are

high-impedance and must be terminated externally. If both the CLKIN_2

and CLKIN_2b inputs are unused and powered down, then both inputs can

be left floating. ClockBuilder Pro will power down an input that is set as

"Unused".

4

VDD_XTAL

P

Voltage supply for crystal oscillator. Connect to 1.8–3.3 V. Part of internal

core VDD voltage. Must be connected to same voltage as VDDA and

VDD_DIG.

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

18

�Si5357 Data Sheet • Pin Descriptions

Pin Number

Pin Name

Pin Type

5

XA/CLK1IN

I

6

XB

O or P

7

VDDA

P

Function

These pins are used for an optional XTAL input when operating the device

in free-run mode.

Core Supply Voltage. Connect to 1.8–3.3 V. Part of internal core VDD

voltage. Must be connected to same voltage as VDD_XTAL and VDD_DIG.

See the Si5357 Family Reference Manual for power supply filtering recommendations.

Must be connected to same voltage as VDD_DIG and VDD_XTAL.

8

INPUT1

I

Universal HW Input pin. This hardware input pin is user definable through

ClockBuilder Pro. Refer to Section 3.7 Universal Hardware Input Pins for a

list of definitions that hardware input pins can be used for.

9

SCLK

I

Serial Clock Input

SCLK is a digital input internally referenced to VDD_DIG. SCLK must have

an external pull-up resistor (I2C bus pull-up) to same voltage as VDD_DIG.

This pin functions as the serial clock input for I2C.

10

SDATA

I/O

Serial Data Interface

SDA is a digital open-drain bi-directional internally referenced to VDD_DIG.

SDA must have an external pull-up resistor (I2C bus pull-up) to same voltage as VDD_DIG.

This is the bidirectional data pin (SDATA) for the I2C mode.

11

OUT0

O

LVCMOS Clock Outputs

12

OUT1

O

Termination recommendations are provided in 3.5.1 LVCMOS Output Terminations. Unused outputs should be left unconnected.

13

VDDO0

P

Supply Voltage (1.8–3.3 V or 1.5 V) for OUT0 or OUT1

See the Si5357 Family Reference Manual for power supply filtering recommendations.

Leave VDDOx pins of unused output drivers unconnected. An alternate

option is to connect the VDDOx pin to a power supply and disable the

output driver to minimize current consumption.

14

OUT2

O

LVCMOS Clock Outputs

15

OUT3

O

Termination recommendations are provided in 3.5.1 LVCMOS Output Terminations. Unused outputs should be left unconnected.

16

VDDO1

P

Supply Voltage (1.8–3.3 V or 1.5 V) for OUT2 and OUT3

See the Si5357 Family Reference Manual for power supply filtering recommendations.

Leave VDDOx pins of unused output drivers unconnected. An alternate

option is to connect the VDDOx pin to a power supply and disable the

output driver to minimize current consumption.

19

17

INPUT2

I

Universal HW Input pin. This hardware input pin is user definable through

ClockBuilder Pro. Refer to Section 3.7 Universal Hardware Input Pins for a

list of definitions that hardware input pins can be used for.

18

OUT4

O

LVCMOS Clock Outputs

19

OUT5

O

Termination recommendations are provided in 3.5.1 LVCMOS Output Terminations. Unused outputs should be left unconnected.

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

19

�Si5357 Data Sheet • Pin Descriptions

Pin Number

Pin Name

Pin Type

20

VDDO2

P

Function

Supply Voltage (1.8–3.3 V or 1.5 V) for OUT4 and OUT5

See the Si5357 Family Reference Manual for power supply filtering recommendations.

Leave VDDOx pins of unused output drivers unconnected. An alternate

option is to connect the VDDOx pin to a power supply and disable the

output driver to minimize current consumption.

21

OUT6

O

LVCMOS Clock Outputs

22

OUT7

O

Termination recommendations are provided in 3.5.1 LVCMOS Output Terminations. Unused outputs should be left unconnected.

23

VDDO3

P

Supply Voltage (1.8–3.3 V or 1.5 V) for OUT6 and OUT7

See the Si5357 Family Reference Manual for power supply filtering recommendations.

Leave VDDOx pins of unused output drivers unconnected. An alternate

option is to connect the VDDOx pin to a power supply and disable the

output driver to minimize current consumption.

24

INPUT3

I

Universal HW Input pin. This hardware input pin is user definable through

ClockBuilder Pro. Refer to Section 3.7 Universal Hardware Input Pins for a

list of definitions that hardware input pins can be used for.

25

VDDO4

P

Supply Voltage (1.8–3.3 V or 1.5 V) for OUT8 and OUT9

See the Si5357 Family Reference Manual for power supply filtering recommendations.

Leave VDDOx pins of unused output drivers unconnected. An alternate

option is to connect the VDDOx pin to a power supply and disable the

output driver to minimize current consumption.

26

OUT8

O

LVCMOS Clock Outputs

27

OUT9

O

Termination recommendations are provided in 3.5.1 LVCMOS Output Terminations. Unused outputs should be left unconnected.

28

INPUT4

I

Universal HW Input pin. This hardware input pin is user definable through

ClockBuilder Pro. Refer to Section 3.7 Universal Hardware Input Pins for a

list of definitions that hardware input pins can be used for.

29

INPUT5

I

Universal HW Input pin. This hardware input pin is user definable through

ClockBuilder Pro. Refer to Section 3.7 Universal Hardware Input Pins for a

list of definitions that hardware input pins can be used for.

30

OUT10

O

LVCMOS Clock Outputs

31

OUT11

O

Termination recommendations are provided in 3.5.1 LVCMOS Output Terminations. Unused outputs should be left unconnected.

32

VDDO5

P

Supply Voltage (1.8–3.3 V or 1.5 V) for OUT10 and OUT11

See the Si5357 Family Reference Manual for power supply filtering recommendations.

Leave VDDOx pins of unused output drivers unconnected. An alternate

option is to connect the VDDOx pin to a power supply and disable the

output driver to minimize current consumption.

33

GND PAD

P

Ground Pad

This pad provides electrical and thermal connection to ground and must be

connected for proper operation.

20

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

20

�Si5357 Data Sheet • Package Outline

7. Package Outline

7.1 Si5357 5x5 mm 32-QFN Package Diagram

The figure below illustrates the package details for the Si5357 32-QFN option. The table below lists the values for the dimensions

shown in the illustration.

Figure 7.1. 32-Pin Quad Flat No-Lead (QFN)

21

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

21

�Si5357 Data Sheet • Package Outline

Table 7.1. Package Dimensions

Dimension

MIN

NOM

MAX

A

0.80

0.85

0.90

A1

0.00

0.02

0.05

A3

0.20 REF

b

0.18

0.25

0.30

D/E

4.90

5.00

5.10

D2/E2

3.40

3.50

3.60

E

0.50 BSC

L

0.30

0.40

0.50

K

0.20

---

---

R

0.09

---

0.14

aaa

0.15

bbb

0.10

ccc

0.10

ddd

0.05

eee

0.08

fff

0.10

Notes:

1. All dimensions shown are in millimeters (mm) unless otherwise noted.

2. Dimensioning and Tolerancing per ANSI Y14.5M-1994.

3. This drawing conforms to the JEDEC Solid State Outline MO-220, Variation VKKD-4.

4. Recommended card reflow profile is per the JEDEC/IPC J-STD-020 specification for Small Body Components.

22

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

22

�Si5357 Data Sheet • PCB Land Pattern

8. PCB Land Pattern

The figure below illustrates the PCB land pattern details for the Si5357 in the 32-QFN package. The table below lists the values for the

dimensions shown in the illustration.

Figure 8.1. PCB Land Pattern

Table 8.1. PCB Land Pattern Dimensions

23

Dimension

mm

C1

4.90

C2

4.90

e

0.50

X1

0.30

Y1

0.85

X2

3.60

Y2

3.60

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

23

�Si5357 Data Sheet • PCB Land Pattern

Dimension

mm

Notes:

General

1. All dimensions shown are in millimeters (mm) unless otherwise noted.

2. This Land Pattern Design is based on the IPC-7351 guidelines.

Solder Mask Design

1. All metal pads are to be non-solder mask defined (NSMD). Clearance between the solder mask and the metal pad is to be 60 mm

minimum, all the way around the pad

Stencil Design

1. A stainless steel, laser-cut and electro-polished stencil with trapezoidal walls should be used to assure good solder paste release.

2. The stencil thickness should be 0.125mm (5 mils).

3. The ratio of stencil aperture to land pad size can be 1:1 for all perimeter pads.

4. A 3x3 array of 0.85mm square openings on a 1.00mm pitch can be used for the center ground pad.

Card Assembly

1. A No-Clean, Type-3 solder paste is recommended.

2. The recommended card reflow profile is per the JEDEC/IPC J-STD-020 specification for Small Body Components.

24

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

24

�Si5357 Data Sheet • Top Marking

9. Top Marking

Figure 9.1. Si5357 Top Marking

Table 9.1. Top Marking Explanation

Line

Characters

Description

1

Si5357g

Base part number and device grade

g = Device Grade

2

Rxxxxx

R = Produce revision (see ordering guide for current revision)

xxxxx = Customer specific NVM sequence number assigned by ClockBuilder Pro

25

3

TTTTTT

Manufacturing trace code.

4

YYWW

Year (YY) and work week (WW) of package assembly

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

25

�Si5357 Data Sheet • Document Change List

10. Document Change List

Revision 1.0

August 2018

• Updated Si5332 5x5 mm 32-QFN package diagram for external crystal versions

• Updated Si5332 32-QFN land pattern

• Updated supply current and rise/fall time specifications

Revision 0.7

September 2017

• Initial release.

26

Skyworks Solutions, Inc. • Phone [781] 376-3000 • Fax [781] 376-3100 • sales@skyworksinc.com • www.skyworksinc.com

Rev. 1.0 • Skyworks Proprietary Information • Products and Product Information are Subject to Change Without Notice • December 3, 2021

26

�ClockBuilder Pro

Customize Skyworks clock generators,

jitter attenuators and network

synchronizers with a single tool. With

CBPro you can control evaluation

boards, access documentation, request

a custom part number, export for

in-system programming and more!

www.skyworksinc.com/CBPro

Portfolio

SW/HW

Quality

Support & Resources

www.skyworksinc.com/ia/timing

www.skyworksinc.com/CBPro

www.skyworksinc.com/quality

www.skyworksinc.com/support

Copyright © 2021 Skyworks Solutions, Inc. All Rights Reserved.

Information in this document is provided in connection with Skyworks Solutions, Inc. (“Skyworks”) products or services. These materials, including the

information contained herein, are provided by Skyworks as a service to its customers and may be used for informational purposes only by the customer.

Skyworks assumes no responsibility for errors or omissions in these materials or the information contained herein. Skyworks may change its documentation,

products, services, specifications or product descriptions at any time, without notice. Skyworks makes no commitment to update the materials or

information and shall have no responsibility whatsoever for conflicts, incompatibilities, or other difficulties arising from any future changes.

No license, whether express, implied, by estoppel or otherwise, is granted to any intellectual property rights by this document. Skyworks assumes no liability

for any materials, products or information provided hereunder, including the sale, distribution, reproduction or use of Skyworks products, information or

materials, except as may be provided in Skyworks’ Terms and Conditions of Sale.

THE MATERIALS, PRODUCTS AND INFORMATION ARE PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND, WHETHER EXPRESS, IMPLIED, STATUTORY, OR

OTHERWISE, INCLUDING FITNESS FOR A PARTICULAR PURPOSE OR USE, MERCHANTABILITY, PERFORMANCE, QUALITY OR NON-INFRINGEMENT OF ANY

INTELLECTUAL PROPERTY RIGHT; ALL SUCH WARRANTIES ARE HEREBY EXPRESSLY DISCLAIMED. SKYWORKS DOES NOT WARRANT THE ACCURACY OR

COMPLETENESS OF THE INFORMATION, TEXT, GRAPHICS OR OTHER ITEMS CONTAINED WITHIN THESE MATERIALS. SKYWORKS SHALL NOT BE LIABLE FOR

ANY DAMAGES, INCLUDING BUT NOT LIMITED TO ANY SPECIAL, INDIRECT, INCIDENTAL, STATUTORY, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT

LIMITATION, LOST REVENUES OR LOST PROFITS THAT MAY RESULT FROM THE USE OF THE MATERIALS OR INFORMATION, WHETHER OR NOT THE RECIPIENT

OF MATERIALS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Skyworks products are not intended for use in medical, lifesaving or life-sustaining applications, or other equipment in which the failure of the Skyworks

products could lead to personal injury, death, physical or environmental damage. Skyworks customers using or selling Skyworks products for use in such

applications do so at their own risk and agree to fully indemnify Skyworks for any damages resulting from such improper use or sale.

Customers are responsible for their products and applications using Skyworks products, which may deviate from published specifications as a result of

design defects, errors, or operation of products outside of published parameters or design specifications. Customers should include design and operating

safeguards to minimize these and other risks. Skyworks assumes no liability for applications assistance, customer product design, or damage to any

equipment resulting from the use of Skyworks products outside of Skyworks’ published specifications or parameters.

Skyworks, the Skyworks symbol, Sky5®, SkyOne®, SkyBlue™, Skyworks Green™, Clockbuilder®, DSPLL®, ISOmodem®, ProSLIC®, and SiPHY® are trademarks or

registered trademarks of Skyworks Solutions, Inc. or its subsidiaries in the United States and other countries. Third-party brands and names are for

identification purposes only and are the property of their respective owners. Additional information, including relevant terms and conditions, posted at

www.skyworksinc.com, are incorporated by reference.

Skyworks Solutions, Inc. | Nasdaq: SWKS | sales@skyworksinc.com | www.skyworksinc.com

USA: 781-376-3000 | Asia: 886-2-2735 0399 | Europe: 33 (0)1 43548540 |

�