SL28773

EProClock® Generator for Intel Calpella Chipset

Features

• 100MHz Differential SATA clocks

• Intel CK505 Clock Revision 1.0 Compliant

• Hybrid Video Support - Simultaneous DOT96,

27MHz_SS and 27MHz_NSS video clocks

• 96MHz Differential DOT clock

• 27MHz Video clock

• 48MHz USB clock

• PCI-Express Gen 2 Compliant

• Buffered Reference Clock 14.318MHz

• Low power push-pull type differential output buffers

• PC EProClock® Programmable Technology

• Integrated voltage regulator

• I2C support with readback capabilities

• Integrated resistors on differential clocks

• Triangular Spread Spectrum profile for maximum

electromagnetic interference (EMI) reduction

CPU

SRC

x2

x1

x1

x1

x1

x1

x2

CKPWRGD/ PD#

VSS_REF

XTAL_OUT

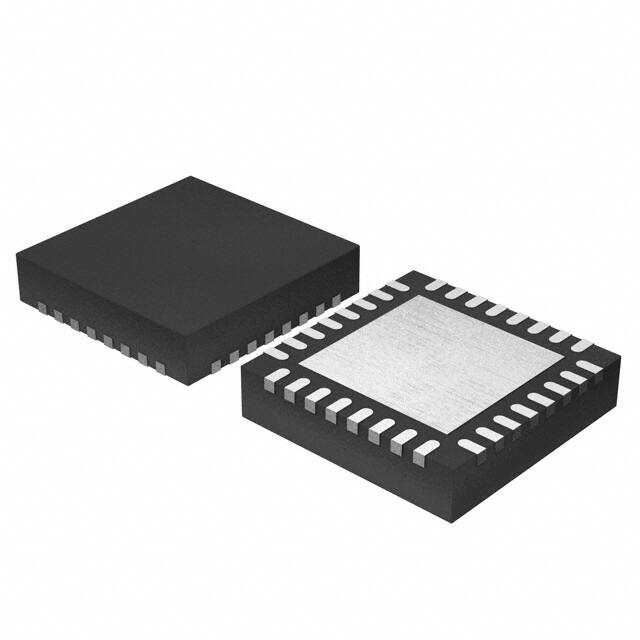

Pin Configuration

SCLK

Block Diagram

SATA DOT96 USB_48 REF 27M

XTAL_IN

• 100MHz Differential SRC clocks

• 32-pin QFN package

VDD_REF

• Differential CPU clocks with selectable frequency

• 3.3V Power supply

REF0/ FS**

• Wireless friendly 3-bits slew rate control on

single-ended clocks.

SDATA

• Scalable low voltage VDD_IO (3.3V to 1.05V)

32 31 30 29 28 27 26 25

24 VDD_CPU

VDD_DOT 1

VSS_DOT 2

23 CPU0

22 CPU#0

DOT96 3

DOT96# 4

21 VSS_CPU

SL28773

USB_48 5

VDD_27 6

20 CPU1

19 CPU#1

18 VDD_CPU_IO

27_NSS 7

27_SS 8

17 VDD_SRC

CPU_STP#

VDD_SRC_IO

SRC#1

SRC1

VSS_SRC

SRC0# / SATA#

VSS_27

SRC0 / SATA

9 10 11 12 13 14 15 16

** Internal 100K-ohm Pull-Down Resistor

........................ Document #: 001-08400 Rev ** Page 1 of 21

400 West Cesar Chavez, Austin, TX 78701

1+(512) 416-8500

1+(512) 416-9669

www.silabs.com

�SL28773

32-QFN Pin Definitions

Pin No.

1

Name

VDD_DOT

Type

PWR

Description

3.3V Power supply for outputs and PLL

2

VSS_DOT

3

DOT96

O, DIF Fixed true 96MHz clock output

GND

Ground for outputs

4

DOT96#

O, DIF Fixed complement 96MHz clock output

5

USB_48

O,SE

6

VDD_27

PWR

3.3V Power supply for 27MHz PLL

7

27M_NSS

O,SE

Non-spread 27MHz video clock output

8

27M_SS

O, SE Spread 27MHz video clock output

9

VSS_27

GND

Non-spread 48MHz video clock output

Ground for 27MHz PLL

10

SRC0 / SATA

O, DIF 100MHz True differential serial reference clock

11

SRC0# / SATA#

O, DIF 100MHz Complement differential serial reference clock

12

VSS_SRC

13

SRC1

O, DIF 100MHz True differential serial reference clock

GND

14

SRC1#

O, DIF 100MHz Complement differential serial reference clock

15

VDD_SRC_IO

16

CPU_STP#

I

17

VDD_SRC

PWR

3.3V Power supply for PLL

18

VDD_CPU_IO

PWR

Scalable 3.3V to 1.05V power supply for output buffer

19

CPU1#

O, DIF Complement differential CPU clock output

20

CPU1

O, DIF True differential CPU clock output

21

VSS_CPU

22

CPU0#

O, DIF Complement differential CPU clock output

23

CPU0

O, DIF True differential CPU clock output

24

VDD_CPU

25

CKPWRGD/PD#

PWR

GND

PWR

I

Ground for PLL

Scalable 3.3V to 1.05V power supply for output buffer

3.3V tolerance input to stop the CPU clock

Ground for PLL

3.3V Power supply for CPU PLL

3.3V LVTTL input. This pin is a level sensitive strobe used to latch the FS.

After CKPWRGD (active HIGH) assertion, this pin becomes a real-time input for

asserting power down (active LOW)

26

VSS_REF

GND

27

XOUT

O, SE 14.318MHz Crystal output

28

XIN

29

VDD_REF

30

REF/FS**

I

PWR

Ground for outputs

14.318MHz Crystal input

3.3V Power supply for outputs and also maintains SMBUS registers during

power-down

PD, I/O 3.3V tolerant input for Graphic clock selection/fixed 14.318MHz clock output.

(Internal 100K-ohm pull-down resistor on FS pin)

Refer to DC Electrical Specifications table for Vil_FS and Vih_FS specifications

31

SDATA

I/O

32

SCLK

I

SMBus compatible SDATA

SMBus compatible SCLOCK

........................Document #: 001-08400 Rev ** Page 2 of 21

�SL28773

PC EProClock® Programmable Technology

PC EProClock® is the world’s first non-volatile programmable

PC clock. The PC EProClock® technology allows board

designer to promptly achieve optimum compliance and clock

signal integrity; historically, attainable typically through device

and/or board redesigns.

PC EProClock® technology can be configured through SMBus

or hard coded.

- Differential skew control on true or compliment or both

- Differential duty cycle control on true or compliment or both

- Differential amplitude control

- Differential and single-ended slew rate control

Features:

- Program Internal or External series resistor on single-ended

clocks

- > 4000 bits of configurations

- Program different spread profiles

- Can be configured through SMBus or hard coded

- Program different spread modulation rate

- Custom frequency sets

- For more information: Please refer to Application Note #25

Frequency Select Pin (FS)

FS

CPU

Power On

0

133MHz

Default

1

100MHz

SRC

SATA

DOT96

USB_48

27MHz

REF

100MHz

100MHz

96MHz

48MHz

27MHz

14.318MHz

Frequency Select Pin FS

Apply the appropriate logic levels to FS inputs before

CKPWRGD assertion to achieve host clock frequency

selection. When the clock chip sampled HIGH on CKPWRGD

and indicates that VTT voltage is stable then FS input values

are sampled. This process employs a one-shot functionality

and once the CKPWRGD sampled a valid HIGH, all other FS,

and CKPWRGD transitions are ignored except in test mode.

Serial Data Interface

To enhance the flexibility and function of the clock synthesizer,

a two-signal serial interface is provided. Through the Serial

Data Interface, various device functions, such as individual

clock output buffers are individually enabled or disabled. The

registers associated with the Serial Data Interface initialize to

their default setting at power-up. The use of this interface is

optional. Clock device register changes are normally made at

system initialization, if any are required. The interface cannot

be used during system operation for power management

functions.

Data Protocol

The clock driver serial protocol accepts byte write, byte read,

block write, and block read operations from the controller. For

block write/read operation, access the bytes in sequential

order from lowest to highest (most significant bit first) with the

ability to stop after any complete byte is transferred. For byte

write and byte read operations, the system controller can

access individually indexed bytes. The offset of the indexed

byte is encoded in the command code described in Table 1.

The block write and block read protocol is outlined in Table 2

while Table 3 outlines byte write and byte read protocol. The

slave receiver address is 11010010 (D2h).

.

Table 1. Command Code Definition

Bit

7

Description

0 = Block read or block write operation, 1 = Byte read or byte write operation

(6:0)

Byte offset for byte read or byte write operation. For block read or block write operations, these bits should be '0000000'

Table 2. Block Read and Block Write Protocol

Block Write Protocol

Bit

1

8:2

9

10

18:11

19

27:20

28

Description

Start

Slave address–7 bits

Write

Acknowledge from slave

Command Code–8 bits

Block Read Protocol

Bit

1

8:2

9

10

18:11

Description

Start

Slave address–7 bits

Write

Acknowledge from slave

Command Code–8 bits

Acknowledge from slave

19

Acknowledge from slave

Byte Count–8 bits

20

Repeat start

Acknowledge from slave

........................Document #: 001-08400 Rev ** Page 3 of 21

27:21

Slave address–7 bits

�SL28773

Table 2. Block Read and Block Write Protocol (continued)

Block Write Protocol

Bit

36:29

37

45:38

Description

Data byte 1–8 bits

Acknowledge from slave

Data byte 2–8 bits

Block Read Protocol

Bit

Read = 1

29

Acknowledge from slave

37:30

46

Acknowledge from slave

....

Data Byte /Slave Acknowledges

....

Data Byte N–8 bits

....

Acknowledge from slave

....

Stop

Description

28

38

46:39

47

55:48

Byte Count from slave–8 bits

Acknowledge

Data byte 1 from slave–8 bits

Acknowledge

Data byte 2 from slave–8 bits

56

Acknowledge

....

Data bytes from slave / Acknowledge

....

Data Byte N from slave–8 bits

....

NOT Acknowledge

....

Stop

Table 3. Byte Read and Byte Write Protocol

Byte Write Protocol

Bit

1

8:2

9

10

18:11

19

27:20

Description

Start

Slave address–7 bits

Write

Acknowledge from slave

Command Code–8 bits

Byte Read Protocol

Bit

1

8:2

9

10

18:11

Description

Start

Slave address–7 bits

Write

Acknowledge from slave

Command Code–8 bits

Acknowledge from slave

19

Acknowledge from slave

Data byte–8 bits

20

Repeated start

28

Acknowledge from slave

29

Stop

27:21

28

29

37:30

........................Document #: 001-08400 Rev ** Page 4 of 21

Slave address–7 bits

Read

Acknowledge from slave

Data from slave–8 bits

38

NOT Acknowledge

39

Stop

�SL28773

Control Registers

Byte 0: Control Register 0

Bit

@Pup

Name

Description

7

HW

FS

6

0

RESERVED

RESERVED

5

1

RESERVED

RESERVED

4

0

iAMT_EN

3

0

RESERVED

2

0

SRC_Main_SEL

1

0

SATA_SEL

Select source of SATA clock

0 = SATA = SRC_MAIN, 1= SATA = PLL4

0

1

PD_Restore

Save configuration when PD# is asserted

0 = Config. cleared, 1 = Config. saved

CPU Frequency Select Bit, set by HW

0 = 133MHz, 1= 100MHz

iAMT Enable

0 = Legacy Mode, 1 = iAMT Enabled

RESERVED

Select source for SRC clock

0 = SRC_MAIN = PLL1, PLL3_CFG Table applies

1 = SRC_MAIN = PLL3, PLL3_CFG Table does not apply

Byte 1: Control Register 1

Bit

@Pup

Name

7

1

RESERVED

6

0

PLL1_SS_DC

Select for down or center SS

0 = Down spread, 1 = Center spread

5

0

PLL3_SS_DC

Select for down or center SS

0 = Down spread, 1 = Center spread

4

0

PLL3_CFB3

3

0

PLL3_CFB2

2

1

PLL3_CFB1

1

0

PLL3_CFB0

0

1

RESERVED

Description

RESERVED

CFB Bit [4:1] only applies when SRC_Main_SEL = 0 (Byte 0, bit 2 =0)

See Table 4 on page 9 for Configuration.

RESERVED

Byte 2: Control Register 2

Bit

@Pup

Name

7

1

REF_OE

Output enable for REF

0 = Output Disabled, 1 = Output Enabled

Description

6

1

USB_48_OE

Output enable for USB_48

0 = Output Disabled, 1 = Output Enabled

5

1

RESERVED

RESERVED

4

1

RESERVED

RESERVED

3

1

RESERVED

RESERVED

2

1

RESERVED

RESERVED

1

1

RESERVED

RESERVED

0

1

RESERVED

RESERVED

Byte 3: Control Register 3

Bit

@Pup

Name

7

1

RESERVED

RESERVED

Description

6

1

RESERVED

RESERVED

........................Document #: 001-08400 Rev ** Page 5 of 21

�SL28773

Byte 3: Control Register 3

5

1

RESERVED

RESERVED

4

1

RESERVED

RESERVED

3

1

RESERVED

RESERVED

2

1

RESERVED

RESERVED

1

1

RESERVED

RESERVED

0

1

RESERVED

RESERVED

Byte 4: Control Register 4

Bit

@Pup

Name

7

1

RESERVED

Description

6

1

SATA_OE

Output enable for SATA

0 = Output Disabled, 1 = Output Enabled

5

1

SRC_OE

Output enable for SRC

0 = Output Disabled, 1 = Output Enabled

4

1

DOT96_OE

Output enable for DOT96

0 = Output Disabled, 1 = Output Enabled

3

1

CPU1_OE

Output enable for CPU1

0 = Output Disabled, 1 = Output Enabled

2

1

CPU0_OE

Output enable for CPU0

0 = Output Disabled, 1 = Output Enabled

1

1

PLL1_SS_EN

Enable PLL1s spread modulation,

0 = Spread Disabled, 1 = Spread Enabled

0

1

PLL3_SS_EN

Enable PLL3s spread modulation

0 = Spread Disabled, 1 = Spread Enabled

RESERVED

Byte 5: Control Register 5

Bit

@Pup

Name

7

0

RESERVED

RESERVED

Description

6

0

RESERVED

RESERVED

5

0

RESERVED

RESERVED

4

0

RESERVED

RESERVED

3

0

RESERVED

RESERVED

2

0

RESERVED

RESERVED

1

0

RESERVED

RESERVED

0

0

RESERVED

RESERVED

Byte 6: Control Register 6

Bit

@Pup

Name

7

0

RESERVED

RESERVED

Description

6

0

RESERVED

RESERVED

5

0

REF Bit1

4

0

RESERVED

RESERVED

3

0

27MHz Bit 1

27MHz slew rate control (see Byte 13 for Slew Rate Bit 0 and Bit 2)

0 = High, 1 = Low

2

0

RESERVED

RESERVED

1

0

RESERVED

RESERVED

REF slew rate control (see Byte 13 for Slew Rate Bit 0 and Bit 2)

0 = High, 1 = Low

........................Document #: 001-08400 Rev ** Page 6 of 21

�SL28773

Byte 6: Control Register 6

0

0

RESERVED

RESERVED

Byte 7: Vendor ID

Bit

@Pup

Name

Description

7

0

Rev Code Bit 3

Revision Code Bit 3

6

1

Rev Code Bit 2

Revision Code Bit 2

5

0

Rev Code Bit 1

Revision Code Bit 1

4

0

Rev Code Bit 0

Revision Code Bit 0

3

1

Vendor ID bit 3

Vendor ID Bit 3

2

0

Vendor ID bit 2

Vendor ID Bit 2

1

0

Vendor ID bit 1

Vendor ID Bit 1

0

0

Vendor ID bit 0

Vendor ID Bit 0

Byte 8: Control Register 8

Bit

@Pup

Name

7

1

Device_ID3

RESERVED

Description

6

0

Device_ID2

RESERVED

5

0

Device_ID1

RESERVED

4

0

Device_ID0

RESERVED

3

0

RESERVED

RESERVED

2

0

RESERVED

RESERVED

1

1

27M_non-SS_OE

Output enable for 27M_non-SS

0 = Output Disabled, 1 = Output Enabled

0

1

27M_SS_OE

Output enable for 27M_SS

0 = Output Disabled, 1 = Output Enabled

Byte 9: Control Register 9

Bit

@Pup

Name

7

0

RESERVED

RESERVED

Description

6

0

RESERVED

RESERVED

5

1

RESERVED

RESERVED

4

0

TEST _MODE_SEL

Test mode select either REF/N or tri-state

0 = All outputs tri-state, 1 = All output REF/N

3

0

TEST_MODE_ENTRY

Allows entry into test mode

0 = Normal Operation, 1 = Enter test mode(s)

2

1

I2C_VOUT

1

0

I2C_VOUT

0

1

I2C_VOUT

Amplitude configurations differential clocks

I2C_VOUT[2:0]

000 = 0.30V

001 = 0.40V

010 = 0.50V

011 = 0.60V

100 = 0.70V

101 = 0.80V (default)

110 = 0.90V

111 = 1.00V

........................Document #: 001-08400 Rev ** Page 7 of 21

�SL28773

Byte 10: Control Register 10

Bit

@Pup

Name

Description

7

0

RESERVED

RESERVED

6

0

RESERVED

RESERVED

5

0

RESERVED

RESERVED

4

0

RESERVED

RESERVED

3

0

RESERVED

RESERVED

2

0

RESERVED

RESERVED

1

1

CPU1_STP_CTRL

Enable CPU_STP# control of CPU1

0 = Free running, 1= Stoppable

0

1

CPU0_STP_CTRL

Enable CPU_STP# control of CPU0

0 = Free running, 1= Stoppable

Byte 11: Control Register 11

Bit

@Pup

Name

Description

7

0

RESERVED

RESERVED

6

0

RESERVED

RESERVED

5

0

RESERVED

RESERVED

4

0

RESERVED

RESERVED

3

0

RESERVED

2

1

CPU1_iAMT_EN

1

1

PCI-e_GEN2

PCI-e_Gen2 Compliant

0 = non Gen2, 1= Gen2 Compliant

0

1

RESERVED

RESERVED

RESERVED

CPU1 iAMT Clock Enabled

0 = Disabled, 1 = Enabled

Byte 12: Byte Count

Bit

@Pup

Name

7

0

BC7

6

0

BC6

5

0

BC5

4

0

BC4

3

1

BC3

2

1

BC2

1

1

BC1

0

1

BC0

Description

Byte count register for block read operation.

The default value for Byte count is 15.

In order to read beyond Byte 15, the user should change the byte count

limit.to or beyond the byte that is desired to be read.

Byte 13: Control Register 13

Bit

@Pup

Name

........................Document #: 001-08400 Rev ** Page 8 of 21

Description

�SL28773

7

1

REF_Bit2

Drive Strength Control - Bit[2:0], Note: See Byte 6 Bit 5 for REF Slew Rate Bit 1 and

6

1

REF_Bit0

Byte 6 Bit 3 for 27MHz Slew Rate Bit 1

5

1

27MHz_NSS_Bit2

4

1

27MHz_NSS_Bit0

3

1

27MHz_SS_Bit2

2

1

27MHz_SS_Bit0

1

0

RESERVED

0

0

Wireless Friendly mode

Normal mode default ‘101’

Wireless Friendly Mode default to ‘111’

RESERVED

Wireless Friendly Mode

0 = Disabled, Default all single-ended clocks slew rate config bits to ‘101’

1 = Enabled, Default all single-ended clocks slew rate config bits to ‘111’

Byte 14: Control Register 14

Bit

@Pup

Name

Description

7

1

USB_48_Bit2

Drive Strength Control - Bit[2:0] , Note: REF Bit 1is located in Byte 6 Bit 5 and 27MHz

6

0

USB_48_Bit1

5

1

USB_48_Bit0

4

0

OTP_4

3

0

OTP_3

2

0

OTP_2

1

0

OTP_1

0

0

OTP_0

Bit 1 is located in Byte 6 Bit 3

Normal mode default ‘101’

Wireless Friendly Mode default to ‘111’

OTP_ID

Identification for programmed device

Table 4. Pin 6 and 7 Configuration Table

B1b4

B1b3

B1b2

B1b1

Pin7

Pin 8

Spread

(%)

0

0

0

0

N/A

N/A

N/A

0

0

0

1

N/A

N/A

N/A

0

0

1

0

27M_NSS

27M_SS

-0.5%

0

0

1

1

27M_NSS

27M_SS

-1%

0

1

0

0

27M_NSS

27M_SS

-1.5%

0

1

0

1

27M_NSS

27M_SS

-2%

0

1

1

0

27M_NSS

27M_SS

-0.75V

0

1

1

1

27M_NSS

27M_SS

-1.25%

........................Document #: 001-08400 Rev ** Page 9 of 21

�SL28773

B1b4

B1b3

B1b2

B1b1

Pin7

Pin 8

Spread

(%)

1

0

0

0

27M_NSS

27M_SS

-1.75%

1

0

0

1

27M_NSS

27M_SS

+/-0.5%

1

0

1

0

27M_NSS

27M_SS

+/-0.75%

1

0

1

1

N/A

N/A

N/A

1

1

0

0

N/A

N/A

N/A

1

1

0

1

N/A

N/A

N/A

1

1

1

0

N/A

N/A

N/A

1

1

1

1

N/A

N/A

N/A

.

.

Table 5. Output Driver Status during CPU_STP#

CPU_STP# Asserted

Single-ended Clocks Stoppable

Differential Clocks

SMBus OE Disabled

Running

Driven low

Non stoppable

Running

Stoppable

Clock driven high

Clock driven low

Clock# driven low

Non stoppable

Running

Table 6. Output Driver Status

All Single-ended Clocks

All Differential Clocks

w/o Strap

w/ Strap

Clock

Clock#

Low

Hi-z

Low

Low

PD# = 0 (Power down)

Table 7. Crystal Recommendations

Frequency

(Fund)

Cut

Loading Load Cap

Drive

(max.)

Shunt Cap

(max.)

Motional

(max.)

Tolerance

(max.)

Stability

(max.)

Aging

(max.)

14.31818 MHz

AT

Parallel

0.1 mW

5 pF

0.016 pF

35 ppm

30 ppm

5 ppm

20 pF

The SL28773 requires a Parallel Resonance Crystal. Substituting a series resonance crystal causes the SL28773 to

operate at the wrong frequency and violates the ppm specification. For most applications there is a 300-ppm frequency

shift between series and parallel crystals due to incorrect

loading.

Crystal Loading

Crystal loading plays a critical role in achieving low ppm performance. To realize low ppm performance, use the total capacitance the crystal sees to calculate the appropriate capacitive

loading (CL).

Figure 1 shows a typical crystal configuration using the two

trim capacitors. It is important that the trim capacitors are in

series with the crystal. It is not true that load capacitors are in

parallel with the crystal and are approximately equal to the

load capacitance of the crystal.

......................Document #: 001-08400 Rev ** Page 10 of 21

Figure 1. Crystal Capacitive Clarification

Calculating Load Capacitors

In addition to the standard external trim capacitors, consider

the trace capacitance and pin capacitance to calculate the

crystal loading correctly. Again, the capacitance on each side

is in series with the crystal. The total capacitance on both side

is twice the specified crystal load capacitance (CL). Trim

capacitors are calculated to provide equal capacitive loading

on both sides.

�SL28773

PD# (Power down) Clarification

The CKPWRGD/PD# pin is a dual-function pin. During initial

power up, the pin functions as CKPWRGD. Once CKPWRGD

has been sampled HIGH by the clock chip, the pin assumes

PD# functionality. The PD# pin is an asynchronous active

LOW input used to shut off all clocks cleanly before shutting

off power to the device. This signal is synchronized internally

to the device before powering down the clock synthesizer. PD#

is also an asynchronous input for powering up the system.

When PD# is asserted LOW, clocks are driven to a LOW value

and held before turning off the VCOs and the crystal oscillator.

PD# (Power down) Assertion

Figure 2. Crystal Loading Example

,

Use the following formulas to calculate the trim capacitor

values for Ce1 and Ce2.

Load Capacitance (each side)

Ce = 2 * CL – (Cs + Ci)

PD# Deassertion

Total Capacitance (as seen by the crystal)

CLe

=

1

1

( Ce1 + Cs1

+ Ci1 +

1

Ce2 + Cs2 + Ci2

When PD# is sampled LOW by two consecutive rising edges

of CPU clocks, all single-ended outputs will be held LOW on

their next HIGH-to-LOW transition and differential clocks must

held LOW. When PD# mode is desired as the initial power on

state, PD# must be asserted LOW in less than 10 s after

asserting CKPWRGD.

)

CL ................................................... Crystal load capacitance

CLe .........................................Actual loading seen by crystal

using standard value trim capacitors

The power up latency is less than 1.8 ms. This is the time from

the deassertion of the PD# pin or the ramping of the power

supply until the time that stable clocks are generated from the

clock chip. All differential outputs stopped in a three-state

condition, resulting from are driven high in less than 300 s of

PD# deassertion to a voltage greater than 200 mV. After the

clock chip’s internal PLL is powered up and locked, all outputs

are enabled within a few clock cycles of each clock. Figure 4

is an example showing the relationship of clocks coming up.

Ce .....................................................External trim capacitors

Cs ............................................. Stray capacitance (terraced)

Ci .......................................................... Internal capacitance

(lead frame, bond wires, etc.)

Figure 3. Power Down Assertion Timing Waveform

......................Document #: 001-08400 Rev ** Page 11 of 21

�SL28773

Figure 4. Power Down Deassertion Timing Waveform

Figure 5. CKPWRGD Timing Diagram

CPU_STP# Assertion

CPU_STP# Deassertion

The CPU_STP# signal is an active LOW input used for

synchronous stopping and starting the CPU output clocks

while the rest of the clock generator continues to function.

When the CPU_STP# pin is asserted, all CPU outputs that are

set with the SMBus configuration to be stoppable are stopped

within two to six CPU clock periods after sampled by two rising

edges of the internal CPUC clock. The final states of the

stopped CPU signals are CPUT = HIGH and CPUC = LOW.

The deassertion of the CPU_STP# signal causes all stopped

CPU outputs to resume normal operation in a synchronous

manner. No short or stretched clock pulses are produced when

the clock resumes. The maximum latency from the

deassertion to active outputs is no more than two CPU clock

cycles.

CPU_STP#

CPUT

CPUC

Figure 6. CPU_STP# Assertion Waveform

......................Document #: 001-08400 Rev ** Page 12 of 21

�SL28773

CPU_STP#

CPUT

CPUC

CPUT Internal

CPUC Internal

Tdrive_CPU_STP#,10 ns>200 mV

Figure 7. CPU_STP# Deassertion Waveform

......................Document #: 001-08400 Rev ** Page 13 of 21

�SL28773

Absolute Maximum Conditions

Parameter

Description

VDD_3.3V

Main Supply Voltage

VDD_IO

IO Supply Voltage

Condition

Min.

Max.

Unit

–

4.6

V

3.465

V

VIN

Input Voltage

Relative to VSS

–0.5

4.6

VDC

TS

Temperature, Storage

Non-functional

–65

150

°C

TA

Temperature, Operating

Ambient

Functional

0

85

°C

TJ

Temperature, Junction

Functional

–

150

°C

ØJC

Dissipation, Junction to Case

MIL-STD-883E Method 1012.1

–

20

°C/

W

ØJA

Dissipation, Junction to Ambient JEDEC (JESD 51)

–

60

°C/

W

ESDHBM

ESD Protection (Human Body

Model)

MIL-STD-883, Method 3015

2000

–

V

UL-94

Flammability Rating

At 1/8 in.

Max.

Unit

3.135

3.465

V

2.0

VDD + 0.3

V

VSS – 0.3

0.8

V

2.2

–

V

V–0

Multiple Supplies: The Voltage on any input or I/O pin cannot exceed the power pin during power-up. Power supply sequencing is NOT required.

DC Electrical Specifications

Parameter

Description

VDD core

3.3V Operating Voltage

VIH

3.3V Input High Voltage (SE)

Condition

3.3 ± 5%

VIL

3.3V Input Low Voltage (SE)

VIHI2C

Input High Voltage

SDATA, SCLK

VILI2C

Input Low Voltage

SDATA, SCLK

VIH_FS

FS Input High Voltage

VIL_FS

FS Input Low Voltage

IIH

Input High Leakage Current

Except internal pull-down resistors, 0 < VIN < VDD

IIL

Input Low Leakage Current

Except internal pull-up resistors, 0 < VIN < VDD

VOH

VOL

3.3V Output High Voltage (SE) IOH = –1 mA

3.3V Output Low Voltage (SE) IOL = 1 mA

VDD IO

Low Voltage IO Supply Voltage

IOZ

Min.

–

1.0

V

0.7

VDD+0.3

V

VSS – 0.3

0.35

V

–

5

A

–5

–

A

2.4

–

V

–

0.4

V

1

3.465

V

High-impedance Output

Current

–10

10

A

CIN

Input Pin Capacitance

1.5

5

pF

COUT

Output Pin Capacitance

6

pF

LIN

Pin Inductance

–

7

nH

VXIH

Xin High Voltage

0.7VDD

VDD

V

VXIL

Xin Low Voltage

0

0.3VDD

V

IDD_PD

Power Down Current

–

1

mA

IDD_3.3V

Dynamic Supply Current

All outputs enabled. SE clocks with 8” traces.

Differential clocks with 7” traces. Loading per

CK505 spec.

–

65

mA

IDD_VDD_IO

Dynamic Supply Current

All outputs enabled. SE clocks with 8” traces.

Differential clocks with 7” traces. Loading per

CK505 spec.

–

25

mA

......................Document #: 001-08400 Rev ** Page 14 of 21

�SL28773

AC Electrical Specifications

Parameter

Description

Condition

Min.

Max.

Unit

47.5

52.5

%

69.841

71.0

ns

Crystal

TDC

XIN Duty Cycle

The device operates reliably with input

duty cycles up to 30/70 but the REF clock

duty cycle will not be within specification

TPERIOD

XIN Period

When XIN is driven from an external

clock source

TR/TF

XIN Rise and Fall Times

Measured between 0.3VDD and 0.7VDD

–

10.0

ns

TCCJ

XIN Cycle to Cycle Jitter

As an average over 1-s duration

–

500

ps

TDC

CPUT and CPUC Duty Cycle

Measured at 0V differential

45

55

%

TPERIOD

100 MHz CPUT and CPUC Period

Measured at 0V differential at 0.1s

9.99900

10.00100

ns

TPERIOD

133 MHz CPUT and CPUC Period

Measured at 0V differential at 0.1s

7.49925

7.50075

ns

TPERIODSS

100 MHz CPUT and CPUC Period, SSC Measured at 0V differential at 0.1s

10.02406

10.02607

ns

TPERIODSS

133 MHz CPUT and CPUC Period, SSC Measured at 0V differential at 0.1s

7.51804

7.51955

ns

TPERIODAbs

100 MHz CPUT and CPUC Absolute

period

Measured at 0V differential at 1 clock

9.91400

10.0860

ns

TPERIODAbs

133 MHz CPUT and CPUC Absolute

period

Measured at 0V differential at 1 clock

7.41425

7.58575

ns

TPERIODSSAbs 100 MHz CPUT and CPUC Absolute

period, SSC

Measured at 0V differential at1 clock

9.914063

10.1362

ns

TPERIODSSAbs 133 MHz CPUT and CPUC Absolute

period, SSC

Measured at 0V differential at1 clock

7.41430

7.62340

ns

–

85

ps

CPU at 0.7V

TCCJ

CPU Cycle to Cycle Jitter

Measured at 0V differential

Skew

CPU0 to CPU1 skew

Measured at 0V differential

–

100

ps

LACC

Long-term Accuracy

Measured at 0V differential

–

100

ppm

T R / TF

CPU Rising/Falling Slew rate

Measured differentially from ±150 mV

2.5

8

V/ns

TRFM

Rise/Fall Matching

Measured single-endedly from ±75 mV

–

20

%

VHIGH

Voltage High

1.15

V

VLOW

Voltage Low

–0.3

–

V

VOX

Crossing Point Voltage at 0.7V Swing

300

550

mV

SRC at 0.7V

TDC

SRC Duty Cycle

Measured at 0V differential

45

55

%

TPERIOD

100 MHz SRC Period

Measured at 0V differential at 0.1s

9.99900

10.0010

ns

TPERIODSS

100 MHz SRC Period, SSC

Measured at 0V differential at 0.1s

10.02406

10.02607

ns

TPERIODAbs

100 MHz SRC Absolute Period

Measured at 0V differential at 1 clock

9.87400

10.1260

ns

Measured at 0V differential at 1 clock

9.87406

10.1762

ns

–

3.0

ns

–

125

ps

TPERIODSSAbs 100 MHz SRC Absolute Period, SSC

TSKEW(window) Any SRC Clock Skew from the earliest Measured at 0V differential

bank to the latest bank

TCCJ

SRC Cycle to Cycle Jitter

Measured at 0V differential

LACC

SRC Long Term Accuracy

Measured at 0V differential

–

100

ppm

T R / TF

SRC Rising/Falling Slew Rate

Measured differentially from ±150 mV

2.5

8

V/ns

TRFM

Rise/Fall Matching

Measured single-endedly from ±75 mV

–

20

%

VHIGH

Voltage High

1.15

V

VLOW

Voltage Low

–0.3

–

V

VOX

Crossing Point Voltage at 0.7V Swing

300

550

mV

DOT96 at 0.7V

......................Document #: 001-08400 Rev ** Page 15 of 21

�SL28773

AC Electrical Specifications (continued)

Parameter

Description

Condition

TDC

DOT96 Duty Cycle

Measured at 0V differential

Min.

Max.

Unit

45

55

%

10.4177

ns

ns

TPERIOD

DOT96 Period

Measured at 0V differential at 0.1s

10.4156

TPERIODAbs

DOT96 Absolute Period

Measured at 0V differential at 0.1s

10.1656

10.6677

TCCJ

DOT96 Cycle to Cycle Jitter

Measured at 0V differential at 1 clock

–

250

ps

LACC

DOT96 Long Term Accuracy

Measured at 0V differential at 1 clock

–

100

ppm

T R / TF

DOT96 Rising/Falling Slew Rate

Measured differentially from ±150 mV

2.5

8

V/ns

TRFM

Rise/Fall Matching

Measured single-endedly from ±75 mV

–

20

%

VHIGH

Voltage High

1.15

V

VLOW

Voltage Low

–0.3

–

V

VOX

Crossing Point Voltage at 0.7V Swing

300

550

mV

USB_48 at 3.3V

TDC

Duty Cycle

Measurement at 1.5V

45

55

%

TPERIOD

Period

Measurement at 1.5V

20.83125

20.83542

ns

TPERIODAbs

Absolute Period

Measurement at 1.5V

20.48125

21.18542

ns

THIGH

48_M High time

Measurement at 2V

8.216563

11.15198

ns

TLOW

48_M Low time

Measurement at 0.8V

7.816563

10.95198

ns

T R / TF

Rising and Falling Edge Rate

Measured between 0.8V and 2.0V

1.0

2.0

V/ns

TCCJ

Cycle to Cycle Jitter

Measurement at 1.5V

–

350

ps

LACC

48M Long Term Accuracy

Measurement at 1.5V

–

100

ppm

Measurement at 1.5V

45

55

%

27M_NSS/27_SS at 3.3V

TDC

Duty Cycle

TPERIOD

Spread 27M Period

Measurement at 1.5V

37.03594

37.03813

ns

Spread Enabled 27M Period

Measurement at 1.5V

37.12986

37.13172

ns

T R / TF

Rising and Falling Edge Rate

Measured between 0.8V and 2.0V

1.0

4.0

V/ns

TCCJ

Cycle to Cycle Jitter

Measurement at 1.5V

–

300

ps

LACC

27_M Long Term Accuracy

Measured at crossing point VOX

–

50

ppm

REF

TDC

REF Duty Cycle

Measurement at 1.5V

45

55

%

TPERIOD

REF Period

Measurement at 1.5V

69.82033

69.86224

ns

TPERIODAbs

REF Absolute Period

Measurement at 1.5V

68.83429

70.84826

ns

THIGH

REF High time

Measurement at 2V

29.97543

38.46654

ns

TLOW

REF Low time

Measurement at 0.8V

29.57543

38.26654

ns

T R / TF

REF Rising and Falling Edge Rate

Measured between 0.8V and 2.0V

1.0

4.0

V/ns

TSKEW

REF Clock to REF Clock

Measurement at 1.5V

–

500

ps

TCCJ

REF Cycle to Cycle Jitter

Measurement at 1.5V

–

1000

ps

LACC

Long Term Accuracy

Measurement at 1.5V

–

100

ppm

–

1.8

ms

10.0

–

ns

ENABLE/DISABLE and SET-UP

TSTABLE

Clock Stabilization from Power-up

TSS

Stopclock Set-up Time

......................Document #: 001-08400 Rev ** Page 16 of 21

�SL28773

Test and Measurement Set-up

For USB_48 and REF clocks

The following diagram shows the test load configurations for

the single-ended USB_48 and REF output signals.

Figure 8. Single-ended USB_48 Clock Double Load Configuration

.

Figure 9. Single-ended REF Triple Load Configuration

Figure 10. Single-ended Output Signals (for AC Parameters Measurement)

......................Document #: 001-08400 Rev ** Page 17 of 21

�SL28773

For Differential Clock Signals

This diagram shows the test load configuration for the differential clock signals

Figure 11. 0.7V Differential Load Configuration

Figure 12. Differential Measurement for Differential Output Signals (for AC Parameters Measurement)

......................Document #: 001-08400 Rev ** Page 18 of 21

�SL28773

Figure 13. Single-ended Measurement for Differential Output Signals (for AC Parameters Measurement)

......................Document #: 001-08400 Rev ** Page 19 of 21

�SL28773

Ordering Information

Part Number

Package Type

Product Flow

Lead-free

SL28773ELC

32-pin QFN

Commercial, 0 to 85C

SL28773ELCT

32-pin QFN–Tape and Reel

Commercial, 0 to 85C

SL 28 773 ELC - T

Packaging Designator for Tape and Reel

Temperature Designator

Package Designator

L : QFN

Revision Number

A = 1st Silicon

Generic Part Number

Designated Family Number

Company Initials

This device is Pb free and RoHS compliant.

Package Diagrams

32-Lead QFN 5x 5mm (Saw Version)

......................Document #: 001-08400 Rev ** Page 20 of 21

�SL28773

Document History Page

Document Title: SL28773 PC EProClock® Generator for Intel Calpella Chipset

REV.

Issue Date

Orig. of

Change

1.0

10/9/08

JMA

Initial Release

1.1

10/23/08

JMA

1. Changed operating temperature to 0-85C

2. Re-aligned ordering part number description

1.2

1/27/09

JMA

1. Updated Rev. ID

2. Uddated definition of Byte 6 bit 5 and 3

3. Updated Byte 13 and single-ended slew rate table

4. Udated Byte 14

5. Updated Feature description

6. Added less than symbol in power consumption value

7. Updated ordering part number

8. Changed package information

9. Changed Wireless Friendly Mode to 111

1.3

3/16/09

JMA

1. Added PC EProClock® Programmed Technology in Feature section

2. Updated Block Diagram

3. Updated 27MHz slew rate measurement window

4. Updated power consumption

1.4

3/25/09

JMA

1. Updated Package information removed punch version with saw version

2. Updated TPeriod at 100MHz for CPU clocks

3. Updated Revision ID

4. Added Power down Spec

5. Added PC EProClock® Technology description

6. Added CPU Skew

7. Removed 3-bit differential slew rate

8. Change SATA PLL from PLL2 to PLL4.

1.5

9/8/09

JMA

1. Removed Preliminary word

1.6

01/05/10

JMA

1. Added Note in package diagram

2. Updated text content

3. Added information on trace length in Figure 8

4. Removed CPU Driven Figures

5. Updated VDD_IO spec to 4.6V maximum value

6. Edited CK_PWRGD to CKPWRGD

Description of Change

......................Document #: 001-08400 Rev ** Page 21 of 21

�ClockBuilder Pro

One-click access to Timing tools,

documentation, software, source

code libraries & more. Available for

Windows and iOS (CBGo only).

www.silabs.com/CBPro

Timing Portfolio

www.silabs.com/timing

SW/HW

www.silabs.com/CBPro

Quality

www.silabs.com/quality

Support and Community

community.silabs.com

Disclaimer

Silicon Laboratories intends to provide customers with the latest, accurate, and in-depth documentation of all peripherals and modules available for system and software implementers using

or intending to use the Silicon Laboratories products. Characterization data, available modules and peripherals, memory sizes and memory addresses refer to each specific device, and

"Typical" parameters provided can and do vary in different applications. Application examples described herein are for illustrative purposes only. Silicon Laboratories reserves the right to

make changes without further notice and limitation to product information, specifications, and descriptions herein, and does not give warranties as to the accuracy or completeness of the

included information. Silicon Laboratories shall have no liability for the consequences of use of the information supplied herein. This document does not imply or express copyright licenses

granted hereunder to design or fabricate any integrated circuits. The products are not designed or authorized to be used within any Life Support System without the specific written consent

of Silicon Laboratories. A "Life Support System" is any product or system intended to support or sustain life and/or health, which, if it fails, can be reasonably expected to result in significant

personal injury or death. Silicon Laboratories products are not designed or authorized for military applications. Silicon Laboratories products shall under no circumstances be used in

weapons of mass destruction including (but not limited to) nuclear, biological or chemical weapons, or missiles capable of delivering such weapons.

Trademark Information

Silicon Laboratories Inc.® , Silicon Laboratories®, Silicon Labs®, SiLabs® and the Silicon Labs logo®, Bluegiga®, Bluegiga Logo®, Clockbuilder®, CMEMS®, DSPLL®, EFM®, EFM32®,

EFR, Ember®, Energy Micro, Energy Micro logo and combinations thereof, "the world’s most energy friendly microcontrollers", Ember®, EZLink®, EZRadio®, EZRadioPRO®, Gecko®,

ISOmodem®, Precision32®, ProSLIC®, Simplicity Studio®, SiPHY®, Telegesis, the Telegesis Logo®, USBXpress® and others are trademarks or registered trademarks of Silicon Laboratories Inc. ARM, CORTEX, Cortex-M3 and THUMB are trademarks or registered trademarks of ARM Holdings. Keil is a registered trademark of ARM Limited. All other products or brand

names mentioned herein are trademarks of their respective holders.

Silicon Laboratories Inc.

400 West Cesar Chavez

Austin, TX 78701

USA

http://www.silabs.com

�