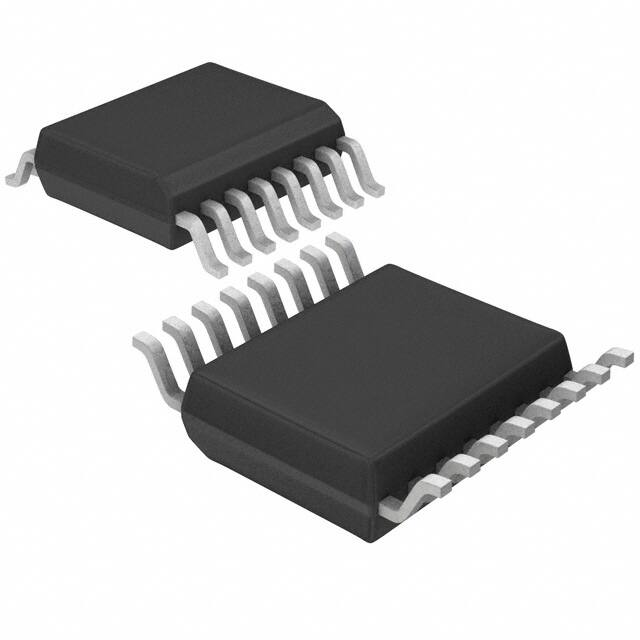

SP3221E

Intelligent +3.0V to +5.5V RS-232 Transceiver

FEATURES

• Meets true EIA/TIA-232-F Standards

from a +3.0V to +5.5V power supply

• Interoperable with EIA/TIA-232 and adheres

to EIA/TIA-562 down to a +2.7V power

source

• AUTO ON-LINE® circuitry automatically

wakes up from a 1µA typical shutdown

• Minimum 250kbps data rate under load

• Regulated charge pump yields stable

RS-232 outputs regardless of VCC variations

• ESD specifications:

+15KV Human Body Model

+15KV IEC61000-4-2 Air Discharge

+8KV IEC61000-4-2 Contact Discharge

EN

16 SHDN

1

C1+ 2

15 VCC

V+ 3

C1-

4

14 GND

SP3221E

C2+ 5

13 T1OUT

12 ONLINE

C2-

6

11 T1IN

V-

7

10

R1IN

8

9

STATUS

R1OUT

DESCRIPTION

The SP3221E is an RS-232 transceiver solution intended for portable applications such as

notebook and hand held computers. This device uses an internal high-efficiency, charge-pump

power supply that requires only 0.1µF capacitors in 3.3V operation. This charge pump and

Exar's driver architecture allow the SP3221E to deliver compliant RS-232 performance from

a single power supply ranging from +3.0V to +5.5V. The SP3221E is a 1-driver/1-receiver

device ideal for laptop/notebook computer and PDA applications. The SP3221E is offered

in 16 pin TSSOP and SSOP packages.

The AUTO ON-LINE® feature allows the device to automatically "wake-up" during a shutdown state when an RS-232 cable is connected and a connected peripheral is turned on.

Otherwise, the device automatically shuts itself down drawing less than 1µA.

SELECTION TABLE

Device

Power

Supplies

RS- 232

Drivers

RS-232

Receivers

AUTO ON-LINE ®

TTL

3-state

Data Rate

(kbps)

SP3221E

+3.0V to +5.5V

1

1

YES

YES

250

SP3221E_201_031920

1

�ABSOLUTE MAXIMUM RATINGS

Output Voltages

TxOUT.............................................................+13.2V

RxOUT, STATUS.......................-0.3V to (VCC + 0.3V)

Short-Circuit Duration

TxOUT.....................................................Continuous

Storage Temperature......................-65°C to +150°C

These are stress ratings only and functional operation

of the device at these ratings or any other above those

indicated in the operation sections of the specifications

below is not implied. Exposure to absolute maximum

rating conditions for extended periods of time may

affect reliability and cause permanent damage to the

device.

VCC.......................................................-0.3V to +6.0V

V+ (NOTE 1).......................................-0.3V to +7.0V

V- (NOTE 1)........................................+0.3V to -7.0V

V+ + |V-| (NOTE 1)...........................................+13V

ICC (DC VCC or GND current).........................+100mA

Input Voltages

TxIN, ONLINE,

SHUTDOWN, EN......................-0.3V to VCC + 0.3V

RxIN...................................................................+15V

Power Dissipation per package

16-pin TSSOP

Theta-JA.................................................100.4°C/W

Theta-JC.................................................19°C/W

16-pin SSOP

Theta-JA.................................................87°C/W

Theta-JC.................................................26°C/W

NOTE 1: V+ and V- can have maximum magnitudes of 7V, but their absolute difference cannot exceed 13V.

ELECTRICAL CHARACTERISTICS

Unless otherwise noted, the following specifications apply for VCC = +3.0V to +5.5V with TAMB = TMIN to TMAX.

Typical values apply at VCC = +3.3V or +5.0V and TAMB = 25°C (Note 2).

PARAMETER

MIN.

TYP.

MAX.

UNITS

CONDITIONS

Supply Current,

AUTO ON-LINE®

1.0

10

µA

RxIN open, ONLINE = GND,

SHUTDOWN = Vcc, TxIN = Vcc or

GND, Vcc = +3.3V, TAMB = +25ºC

Supply Current, Shutdown

1.0

10

µA

SHUTDOWN = GND,

TxIN = Vcc or GND, Vcc = +3.3V,

TAMB = +25ºC

Supply Current,

AUTO ON-LINE® Disabled

0.3

1.0

mA

ONLINE = SHUTDOWN = Vcc, No

Load, Vcc = +3.3V, TAMB = +25ºC

0.8

V

DC CHARACTERISTICS

LOGIC INPUTS AND RECEIVER OUTPUT

Input Logic Threshold

LOW

HIGH

2.0

Vcc = 3.3V or 5.0V,

TxIN, EN, SHUTDOWN, ONLINE

Input Leakage Current

+/-0.01

+/-1.0

µA

TxIN, EN, ONLINE, SHUTDOWN,

TAMB = +25ºC, Vin = 0V to Vcc

Output Leakage Current

+/-0.05

+/-10

µA

Receiver disabled,

Vout = 0V to Vcc

0.4

V

IOUT = 1.6mA

V

IOUT = -1.0mA

Output Voltage LOW

Output Voltage HIGH

Vcc - 0.6

Vcc - 0.1

NOTE 2: C1 - C4 = 0.1µF, tested at 3.3V ±10%.

C1 = 0.047µF, C2-C4 = 0.33µF, tested at 5V±10%.

SP3221E_201_031920

2

�ELECTRICAL CHARACTERISTICS

Unless otherwise noted, the following specifications apply for VCC = +3.0V to +5.5V with TAMB = TMIN to TMAX.

Typical values apply at VCC = +3.3V or +5.0V and TAMB = 25°C (Note 2).

PARAMETER

MIN.

TYP.

+/-5.0

+/-5.4

MAX.

UNITS

CONDITIONS

DRIVER OUTPUT

Output Voltage Swing

Output Resistance

300

V

Driver output loaded with 3kΩ to

GND, TAMB = +25ºC

Ω

Vcc = V+ = V- = 0V, Vout = +/-2V

Output Short-Circuit Current

+/-60

mA

Vout = 0V

Output Leakage Current

+/-25

µA

Vcc = 0V or 3.0V to 5.5V,

Vout = +/-12V, Driver disabled

+15

V

RECEIVER INPUT

Input Voltage Range

-15

Input Threshold LOW

0.6

Input Threshold LOW

0.8

1.2

Vcc = 3.3V

V

Vcc = 5.0V

Input Threshold HIGH

1.5

2.4

V

Vcc = 3.3V

Input Threshold HIGH

1.8

2.4

V

Vcc = 5.0V

Input Hysteresis

0.3

Input Resistance

3

1.5

V

V

5

7

kΩ

AUTO ON-LINE® CIRCUITRY CHARACTERISTICS (ONLINE = GND, SHUTDOWN = Vcc)

STATUS Output Voltage LOW

STATUS Output Voltage HIGH

0.4

Vcc - 0.6

V

IOUT = 1.6mA

V

IOUT = -1.0mA

Receiver Threshold to Driver

Enabled (tONLINE)

100

µs

Figure 13

Receiver Positive or Negative

Threshold to STATUS HIGH

(tSTSH)

0.5

µs

Figure 13

Receiver Positive or Negative

Threshold to STATUS LOW

(tSTSL)

20

µs

Figure 13

NOTE 2: C1 - C4 = 0.1µF, tested at 3.3V ±10%.

C1 = 0.047µF, C2-C4 = 0.33µF, tested at 5V±10%.

SP3221E_201_031920

3

�TIMING CHARACTERISTICS

Unless otherwise noted, the following specifications apply for VCC = +3.0V to +5.5V with TAMB = TMIN to TMAX.

Typical values apply at VCC = +3.3V or +5.0V and TAMB = 25°C.

PARAMETER

MIN.

TYP.

MAX.

UNITS

CONDITIONS

AC CHARACTERISTICS

Data Rate

250

kbps

RL = 3kΩ, CL = 1000pF,

Receiver Propagation Delay

tPHL and tPLH

0.15

µs

Receiver input to Receiver output,

CL = 150pF

Receiver Output Enable Time

200

ns

Normal Operation

Receiver Output Disable Time

200

ns

Normal Operation

Driver Skew

350

800

ns

│tPHL - tPLH│, RL = 3kΩ,

CL = 1000pF

Receiver Skew

50

800

ns

│tPHL - tPLH│, CL = 150pF

30

V/µs

Transition-Region Slew Rate

6

Vcc = 3.3V, RL = 3kΩ, CL = 150pF

to 1000pF, TAMB = 25°C, measurements taken from -3.0V to +3.0V

or +3.0V to -3.0V

SP3221E_201_031920

4

�TYPICAL OPERATING CIRCUIT

Figure 1. SP3221E Typical Operating Circuit

SP3221E_201_031920

5

�TYPICAL PERFORMANCE CHARACTERISTICS

Unless otherwise noted, the following performance characteristics apply for VCC = +3.3V, 250Kbps data rate,

driver loaded with 3kΩ, 0.1µF charge pump capacitors, and TAMB = +25°C.

14

6

12

4

10

2

Ic c (m A )

8

V out

6

4

0

-2

2

0

Txout+

2.7

3.2

3.7

4.2

4.7

-4

5.2

-6

V c c (V )

2.7

3.2

3.7

4.2

4.7

5.2

TxoutVcc

Figure 3. Transmitter Output Voltage VS. Supply

Voltage

Figure 2. Supply Current VS. Supply Voltage

12

10

mA

8

6

4

2

0

0

100

200

300

kb p s

Figure 4. Supply Current VS.Data Rate

SP3221E_201_031920

6

�PIN DESCRIPTION

Name

Function

Pin #

EN

Receiver Enable, apply logic LOW for normal operation. Apply logic HIGH to

disable receiver output (high-Z state).

1

C1+

Positive terminal of the voltage doubler charge-pump capacitor

2

V+

Regulated +5.5V output generated by charge pump

3

C1-

Negative terminal of the voltage doubler charge-pump capacitor

4

C2+

Positive terminal of the inverting charge-pump capacitor

5

C2-

Negative terminal of the inverting charge-pump capacitor

6

Regulated -5.5V output generated by charge pump

7

RS-232 receiver input

8

VR1IN

R1OUT

TTL/CMOS receiver output

9

TTL/CMOS output indicating receiver signal activity

10

TTL/CMOS driver input

11

Apply logic HIGH to override AUTO ON-LINE ® circuitry keeping driver active

(SHUTDOWN must also be logic HIGH, refer to table 2)

12

RS-232 driver output

13

GND

Ground

14

Vcc

+3.0V to +5.5V supply voltage

15

Apply logic LOW to shut down drivers and charge pump. This overrides all

AUTO ON-LINE ® circuitry and ONLINE (refer to table 2).

16

STATUS

T1IN

ONLINE

T1OUT

SHUTDOWN

SP3221E_201_031920

7

�DESCRIPTION

THEORY OF OPERATION

The SP3221E is a 1-driver/1-receiver device

ideal for portable or handheld applications.

The SP3221E transceiver meets the EIA/

TIA-232 and ITU-T V.28/V.24 communication

protocols and can be implemented in batterypowered, portable, or handheld applications

such as notebook or handheld computers.

The SP3221E device features the Exar

proprietary and patented (U.S.‑‑ 5,306,954)

on-board charge pump circuitry that generates ±5.5V RS-232 voltage levels from a

single +3.0V to +5.5V power supply.

The SP3221E is made up of four basic

circuit blocks:

1. Driver, 2. Receiver, 3. The Exar proprietary charge pump, and 4. AUTO ON-LINE®

circuitry.

Driver

The driver is an inverting level transmitter that

converts TTL or CMOS logic levels to 5.0V

EIA/TIA-232 levels with an inverted sense

relative to the input logic levels. Typically,

the RS-232 output voltage swing is +5.4V

with no load and +5V minimum fully loaded.

The driver output is protected against infinite

short-circuits to ground without degradation

in reliability. This driver will comply with

the EIA-TIA-232F and all previous RS-232

versions. Unused driver inputs should be

connected to GND or VCC.

This device is an ideal choice for power sensitive designs. Featuring AUTO ON-LINE®

circuitry, the SP3221E reduces the power

supply drain to a 1µA supply current. In

many portable or handheld applications,

an RS-232 cable can be disconnected or

a connected peripheral can be turned off.

Under these conditions, the internal charge

pump and the drivers will be shut down.

Otherwise, the system automatically comes

online. This feature allows design engineers

to address power saving concerns without

major design changes.

The driver can guarantee an output data rate

of 250kbps while being fully loaded with 3kΩ

in parallel with 1000pF, ensuring compatibility

with PC-to-PC communication software.

The slew rate of the driver output is internally

limited to a maximum of 30V/µs in order

to meet the EIA standards (EIA RS-232D

2.1.7, Paragraph 5). The transition of the

loaded output from HIGH to LOW also

meets the monotonicity requirements of

the standard.

VCC

C5

C1

C2

+

+

+

2 C1+

0.1µF

0.1µF

TTL/CMOS OUTPUT

V+

SP3221E

C3

C4

T1OUT 13

11 T1IN

R1IN

9 R1OUT

1

16

12

+

0.1µF

V- 7

6 C2-

5KΩ

VCC

3

4 C15 C2+

TTL/CMOS INPUT

UART

or

Serial µC

15

VCC

0.1µF

8

+

0.1µF

Figure 6 shows a loopback test circuit used

to test the RS-232 Driver. Figure 8 shows

the test results where the driver was active at

250kbps and loaded with an RS-232 receiver

in parallel with a 1000pF capacitor. RS-232

data transmission rate of 250kbps provides

compatibility with designs in personal computer peripherals and LAN applications.

RS-232

OUTPUT

RS-232

INPUT

EN

SHUTDOWN

ONLINE

10 STATUS

GND

14

RESET

µP

Supervisor

IC

VIN

Figure 5. Interface Circuitry Controlled by Microprocessor Supervisory Circuit

SP3221E_201_031920

8

�Receiver

The receiver converts ±5.0V EIA/TIA-232

levels to TTL or CMOS logic output levels.

The receiver has an inverting output that can

be disabled by using the EN pin.

The receiver is active when the AUTO ONLINE® circuitry is enabled or when in shutdown. During the shutdown, the receiver will

continue to be active. If there is no activity

present at the receiver for a period longer

than 20µs or when SHUTDOWN is enabled,

the device goes into a standby mode where

the circuit draws 1µA. Driving EN to a logic

HIGH forces the output of the receiver into

high-impedance. The truth table logic of the

SP3221E driver and receiver outputs can be

found in Table 2.

Since receiver input is usually from a transmission line where long cable lengths and

system interference can degrade the signal,

the inputs have a typical hysteresis margin

of 300mV. This ensures that the receiver

is virtually immune to noisy transmission

lines. Should an input be left unconnected,

an internal 5kΩ pull-down resistor to ground

will commit the output of the receiver to a

HIGH state.

Figure 6. Loopback Test Circuit for RS-232 Driver

Data Transmission Rates

Figure 7. Loopback Test Circuit result at 250Kbps

(Driver Fully Loaded)

Device: SP3221E

SHUTDOWN

EN

TXOUT

RXOUT

0

0

High Z

Active

0

1

High Z

High Z

1

0

Active

Active

1

1

Active

High Z

Table 2. SHUTDOWN and EN Truth Tables

Note: In AUTO ON-LINE® Mode where ONLINE = GND

and SHUTDOWN = VCC, the device will shut down if

there is no activity present at the Receiver inputs.

SP3221E_201_031920

9

�Charge Pump

Phase 3

— VDD charge storage — The third phase of

the clock is identical to the first phase — the

charge transferred in C1 produces –VCC in

the negative terminal of C1, which is applied

to the negative side of capacitor C2. Since

C2+ is at VCC, the voltage potential across C2

is 2 times VCC.

The charge pump uses a unique approach

compared to older less–efficient designs.

The charge pump still requires four external

capacitors, but uses a four–phase voltage

shifting technique to attain symmetrical

5.5V power supplies. The internal power

supply consists of a regulated dual charge

pump that provides output voltages of

+/-5.5V regardless of input voltage (VCC)

over the +3.0V to +5.5V range. This

is important to maintain compliant RS232 levels regardless of power supply

fluctuations.

Phase 4

— VDD transfer — The fourth phase of

the clock connects the negative terminal

of C2 to GND, and transfers this positive

generated voltage across C2 to C4, the

VDD storage capacitor. This voltage is

regulated to +5.5V. At this voltage, the internal oscillator is disabled. Simultaneous

with the transfer of the voltage to C4, the

positive side of capacitor C1 is switched to VCC

and the negative side is switched to GND, allowing the charge pump cycle to begin again.

The charge pump cycle will continue as long

as the operational conditions for the internal

oscillator are present.

The charge pump operates in a discontinuous mode using an internal oscillator. If the

output voltages are less than a magnitude

of 5.5V, the charge pump is enabled. If the

output voltages exceed a magnitude of 5.5V,

the charge pump is disabled. This oscillator

controls the four phases of the voltage shifting. A description of each phase follows.

Since both V+ and V– are separately generated from VCC, in a no–load condition V+

and V– will be symmetrical. Older charge

pump approaches that generate V– from

V+ will show a decrease in the magnitude

of V– compared to V+ due to the inherent

inefficiencies in the design.

Phase 1

— VSS charge storage — During this phase

of the clock cycle, the positive side of capacitors C1 and C2 are initially charged to VCC.

Cl+ is then switched to GND and the charge

in C1– is transferred to C2–. Since C2+ is connected to VCC, the voltage potential across

capacitor C2 is now 2 times VCC.

Phase 2

— VSS transfer — Phase two of the clock

connects the negative terminal of C2 to the VSS

storage capacitor and the positive terminal of

C2 to GND. This transfers a negative generated voltage to C3. This generated voltage is

regulated to a minimum voltage of -5.5V.

Simultaneous with the transfer of the voltage to C3, the positive side of capacitor C1

is switched to VCC and the negative side is

connected to GND.

SP3221E_201_031920

10

�VCC = +5V

C4

+5V

+

C1

C2

–

–5V

+

–

+

–

–

+

VDD Storage Capacitor

VSS Storage Capacitor

C3

–5V

Figure 8. Charge Pump - Phase 1

VCC = +5V

C4

C1

+

C2

–

+

–

+

–

–

+

VDD Storage Capacitor

VSS Storage Capacitor

C3

–10V

Figure 9. Charge Pump - Phase 2

[

T

]

+6V

a) C2+

T

1

2

0V

2

0V

b) C2-

T

Ch1 2.00V Ch2 2.00V M 1.00ms Ch1 1.96V

-6V

Figure 10. Charge Pump Waveforms

VCC = +5V

C4

+5V

C1

+

–

C2

–5V

+

+

–

–

+

–

VDD Storage Capacitor

VSS Storage Capacitor

C3

–5V

Figure 11. Charge Pump - Phase 3

VCC = +5V

+10V

C1

+

–

C2

C4

+

+

–

–

–

+

VDD Storage Capacitor

VSS Storage Capacitor

C3

Figure 12. Charge Pump - Phase 4

SP3221E_201_031920

11

�Charge Pump Capacitor selection

The Exar charge pump is designed to

operate reliably with a range of low cost

capacitors.Either polarized or non polarized capacitors may be used. If polarized

capacitors are used they should be oriented

as shown in the Typical Operating Circuit.

The V+ capacitor may be connected to either

ground or Vcc (polarity reversed.)

on the transmitter outputs and may slightly

reduce power consumption. C2, C3, and

C4 can be increased without changing

C1’s value

For best charge pump efficiency locate the

charge pump and bypass capacitors as

close as possible to the IC. Surface mount

capacitors are best for this purpose. Using

capacitors with lower equivalent series resistance (ESR) and self-inductance, along

with minimizing parasitic PCB trace inductance will optimize charge pump operation.

Designers are also advised to consider that

capacitor values may shift over time and

operating temperature.

The charge pump operates with 0.1µF capacitors for 3.3V operation. For other supply

voltages, see the table for required capacitor

values. Do not use values smaller than those

listed. Increasing the capacitor values (e.g.,

by doubling in value) reduces ripple

Minimum recommended charge pump capacitor value

Input Voltage VCC

Charge pump capacitor value

3.0V to 3.6V

C1 - C4 = 0.1µF

4.5V to 5.5V

C1 = 0.047µF, C2-C4 = 0.33µF

3.0V to 5.5V

C1 - C4 = 0.22µF

Table 4. Capacitor selection table

SP3221E_201_031920

12

�The second stage of the AUTO ON-LINE®

circuitry, shown in Figure 15, processes the

receiver's RXINACT signal with an accumulated delay that disables the device to

a 1µA typical supply current. The STATUS

pin goes to a logic LOW when the cable

is disconnected. The typical accumulated

delay is around 20µs. When the SP3221E

driver and internal charge pump are disabled,

the supply current is reduced to 1µA typical.

This can commonly occur in handheld or

portable applications where the RS-232

cable is disconnected or the RS-232 driver

of the connected peripheral are truned off.

AUTO ON-LINE Circuitry

®

The SP3221E device has AUTO ON-LINE®

circuitry on board that saves power in applications such as laptop computers, PDA's,

and other portable systems.

The SP3221E device incorporates an AUTO

ON-LINE® circuit that automatically enables

itself when the external transmitter is enabled

and the cable is connected. Conversely,

the AUTO ON-LINE® circuit also disables

most of the internal circuitry when the device

is not being used and goes into a standby

mode where the device typically draws 1µA.

This function is externally controlled by the

ONLINE pin. When this pin is tied to a logic

LOW, the AUTO ON-LINE® function is active. Once active, the device is enabled until

there is no activity on the receiver input. The

receiver input typically sees at least ±3V,

which are generated from the transmitter

at the other end of the cable with a ±5V

minimum. When the external transmitter

is disabled or the cable is disconnected,

the receiver input will be pulled down by its

internal 5kΩ resistor to ground. When this

occurs over a period of time, the internal

transmitter will be disabled and the device

goes into a shutdown or standby mode.

When the ONLINE pin is HIGH, the AUTO

ON-LINE® mode is disabled.

The AUTO ON-LINE® mode can be disabled

by the SHUTDOWN pin. If this pin is a logic

LOW, the AUTO ON-LINE® function will not

operate regardless of the logic state of the

ONLINE pin. Table 3 summarizes the logic

of the AUTO ON-LINE® operating modes.

The truth table logic of the SP3221E driver

and receiver outputs can be found in Table 2.

When the SP3221E device is shutdown,

the charge pumps are turned off. V+ charge

pump output decays to VCC,the V- output

decays to GND. The decay time will depend

on the size of capacitors used for the charge

pump. Once in shutdown, the time required

to exit the shut down state and have valid

V+ and V- levels is typically 200µs.

For easy programming, the STATUS can

be used to indicate DTR or a Ring Indicator

signal. Tying ONLINE and SHUTDOWN

together will bypass the AUTO ON-LINE®

circuitry so this connection acts like a shutdown input pin

The AUTO ON-LINE ® circuit has two

stages:

1) Inactive Detection

2) Accumulated Delay

The first stage, shown in Figure 14, detects

an inactive input. A logic HIGH is asserted

on RXINACT if the cable is disconnected or

the external transmitters are disabled. Otherwise, RXINACT will be at a logic LOW.

SP3221E_201_031920

13

�RS-232 SIGNAL

AT RECEIVER

INPUT

SHUTDOWN

ONLINE

STATUS

TRANSCEIVER STATUS

YES

HIGH

LOW

HIGH

Normal Operation

(AUTO ON-LINE©)

YES

HIGH

HIGH

HIGH

Normal Operation

NO

HIGH

HIGH

LOW

Normal Operation

NO

HIGH

LOW

LOW

Shutdown (AUTO ON-LINE©)

YES

LOW

HIGH/LOW

HIGH

Shutdown

NO

LOW

HIGH/LOW

LOW

Shutdown

Table 3. AUTO ON-LINE® Logic

S

H

U

T

RECEIVER +2.7V

0V

RS-232 INPUT

VOLTAGES -2.7V

D

O

W

N

VCC

STATUS

0V

tSTSL

tSTSH

tONLINE

DRIVER

RS-232 OUTPUT

VOLTAGES

+5V

0V

-5V

Figure 13. AUTO ON-LINE® Timing Waveforms

Inactive Detection Block

RXIN

RS-232

Receiver Block

RX INACT

RXOUT

Figure 14. Stage I of AUTO ON-LINE® Circuitry

SP3221E_201_031920

14

�ESD TOLERANCE

The SP3221E device incorporates

ruggedized ESD cells on the driver output

and receiver input pins. The ESD structure is

improved over our previous family for more

rugged applications and environments

sensitive to electro-static discharges and

associated transients. The improved ESD

tolerance is at least +15kV without damage

nor latch-up.

ESD is applied to points and surfaces of the

equipment that are accessible to personnel

during normal usage. The transceiver IC

receives most of the ESD current when the

ESD source is applied to the connector pins.

The test circuit for IEC61000-4-2 is shown

on Figure 16. There are two methods within

IEC61000-4-2, the Air Discharge method and

the Contact Discharge method. With the Air

Discharge Method, an ESD voltage is applied

to the equipment under test (EUT) through

air. This simulates an electrically charged

person ready to connect a cable onto the

rear of the system only to find an unpleasant

zap just before the person touches the back

panel. The high energy potential on the

person discharges through an arcing path

to the rear panel of the system before he or

she even touches the system. This energy,

whether discharged directly or through air,

is predominantly a function of the discharge

current rather than the discharge voltage.

Variables with an air discharge such as

approach speed of the object carrying the

ESD potential to the system and humidity

will tend to change the discharge current.

For example, the rise time of the discharge

current varies with the approach speed.

The Contact Discharge Method applies the

ESD current directly to the EUT. This method

was devised to reduce the unpredictability

of the ESD arc. The discharge current rise

time is constant since the energy is directly

transferred without the air-gap arc. In situations such as hand held systems, the ESD

charge can be directly discharged to the

equipment from a person already holding

the equipment. The current is transferred

on to the keypad or the serial port of the

equipment directly and then travels through

the PCB and finally to the IC.

There are different methods of ESD testing

applied:

a) MIL-STD-883, Method 3015.7

b) IEC61000-4-2 Air-Discharge

c) IEC61000-4-2 Direct Contact

The Human Body Model has been the

generally accepted ESD testing method

for semiconductors. This method is also

specified in MIL-STD-883, Method 3015.7

for ESD testing. The premise of this ESD test

is to simulate the human body’s potential to

store electro-static energy and discharge it

to an integrated circuit. The simulation is

performed by using a test model as shown

in Figure 15. This method will test the IC’s

capability to withstand an ESD transient

during normal handling such as in manufacturing areas where the IC's tend to be

handled frequently.

The IEC-61000-4-2, formerly IEC801-2, is

generally used for testing ESD on equipment

and systems. For system manufacturers,

they must guarantee a certain amount of

ESD protection since the system itself is

exposed to the outside environment and

human presence. The premise with IEC61000-4-2 is that the system is required to

withstand an amount of static electricity when

Figure15. ESD Test Circuit for Human Body Model

SP3221E_201_031920

15

�Figure 16. ESD Test Circuit for IEC61000-4-2

i→

The circuit model in Figures 15 and 16 represent the typical ESD testing circuit used for

all three methods. The CS is initially charged

with the DC power supply when the first

switch (SW1) is on. Now that the capacitor

is charged, the second switch (SW2) is on

while SW1 switches off. The voltage stored

in the capacitor is then applied through RS,

the current limiting resistor, onto the device

under test (DUT). In ESD tests, the SW2

switch is pulsed so that the device under

test receives a duration of voltage.

30A

15A

0A

For the Human Body Model, the current

limiting resistor (RS) and the source capacitor

(CS) are 1.5kΩ an 100pF, respectively. For

IEC-61000-4-2, the current limiting resistor

(RS) and the source capacitor (CS) are 330Ω

an 150pF, respectively.

t=0ns

t→

t=30ns

Figure 17. ESD Test Waveform for IEC61000-4-2

The higher CS value and lower RS value in

the IEC-61000-4-2 model are more stringent

than the Human Body Model. The larger

storage capacitor injects a higher voltage

to the test point when SW2 is switched on.

The lower current limiting resistor increases

the current charge onto the test point.

DEVICE PIN

TESTED

Driver Output

Receiver Input

HUMAN BODY

MODEL

Air Discharge

±15kV

±15kV

±15kV

±15kV

IEC61000-4-2

Direct Contact

±8kV

±8kV

Level

4

4

Table 5. Transceiver ESD Tolerance Levels

SP3221E_201_031920

16

�PACKAGE: 16 Pin TSSOP

SP3221E_201_031920

17

�PACKAGE: 16 Pin SSOP

SP3221E_201_031920

18

�ORDERING INFORMATION(1)

Part Number

Temperature

Range

Package

Packaging

Method

Lead-Free(2)

SP3221EEA-L/TR

-40°C to +85°C

16-pin SSOP

Tape and Reel

Yes

SP3221EEY-L/TR

-40°C to +85°C

16-pin TSSOP

Tape and Reel

Yes

NOTES:

1. Refer to www.maxlinear.com/SP3221E for most up-to-date Ordering Information.

2. Visit www.maxlinear.com for additional information on Environmental Rating.

SP3221E_201_031920

19

�REVISION HISTORY

DATE

REVISION

DESCRIPTION

Nov 2012

1.0.0

Production release

Dec 2012

1.0.1

Remove reference to SSOP package

Sept 2014

1.0.2

Add SSOP package option, update package thermal information

ECN 1414-04 Oct 2014

Aug 2016

2.0.0

Update Auto On-Line Circuitry section and Logic table

Mar 2020

2.0.1

Update to MaxLinear logo. Update Ordering Information.

MaxLinear, Inc.

5966 La Place Court, Suite 100

Carlsbad, CA 92008

760.692.0711 p.

760.444.8598 f.

www.maxlinear.com

The content of this document is furnished for informational use only, is subject to change without notice, and should not be construed as a commitment by MaxLinear, Inc. MaxLinear, Inc. assumes no responsibility or liability for any errors or inaccuracies that may appear in the informational content contained in this guide. Complying with all applicable copyright laws is the responsibility of the user. Without limiting the rights under copyright, no

part of this document may be reproduced into, stored in, or introduced into a retrieval system, or transmitted in any form or by any means (electronic,

mechanical, photocopying, recording, or otherwise), or for any purpose, without the express written permission of MaxLinear, Inc.

Maxlinear, Inc. does not recommend the use of any of its products in life support applications where the failure or malfunction of the product can

reasonably be expected to cause failure of the life support system or to significantly affect its safety or effectiveness. Products are not authorized

for use in such applications unless MaxLinear, Inc. receives, in writing, assurances to its satisfaction that: (a) the risk of injury or damage has been

minimized; (b) the user assumes all such risks; (c) potential liability of MaxLinear, Inc. is adequately protected under the circumstances.

MaxLinear, Inc. may have patents, patent applications, trademarks, copyrights, or other intellectual property rights covering subject matter in this

document. Except as expressly provided in any written license agreement from MaxLinear, Inc., the furnishing of this document does not give you any

license to these patents, trademarks, copyrights, or other intellectual property.

MaxLinear, the MaxLinear logo, and any MaxLinear trademarks, MxL, Full-Spectrum Capture, FSC, G.now, AirPHY and the MaxLinear logo are all on

the products sold, are all trademarks of MaxLinear, Inc. or one of MaxLinear’s subsidiaries in the U.S.A. and other countries. All rights reserved. Other

company trademarks and product names appearing herein are the property of their respective owners.

© 2012 - 2020 MaxLinear, Inc. All rights reserved.

SP3221E_201_031920

20

�