S P6137

Wide Input, 900kHz Synchronous PWM Step Down

Controller

January 2009

Rev. 2.0.0

GENERAL DESCRIPTION

APPLICATIONS

The SP6137 is a 900kHz constant frequency,

voltage mode, synchronous PWM step down

controller optimized for high efficiency.

• 12V DPA

• Communications Systems

• Graphics Cards

The SP6137 is adequately suited for split plane

applications utilizing a low power 5V rail to

power the controller circuitry, minimizing

power dissipation. Its wide input voltage range

of 3V to 15V allows for conversions from the

standard 3.3V, 5V, 9.6V and 12V power rails

to an output voltage adjustable down to 0.8V.

Developed around a wide bandwidth internal

amplifier, the SP6137 can accommodate type

II and type III compensation schemes.

FEATURES

• 2.5V to 20V Step Down Achieved Using

Dual Input

• On-Board 1.5Ω sink (2Ω source) NFET

Drivers

• Up to 10A Output Capability

• UVLO Detects Both VCC and VIN

Protection features include a programmable

UVLO, thermal shutdown and output short

circuit protection.

• Short-Circuit Protection with AutoRestart

The SP6137 is part of a larger family of step

down

controllers

operating

at

various

switching frequencies up to 1300kHz and input

voltages up to 28V. Refer to Exar’s SP6132,

SP6132H, SP6134, SP6134H and SP6139 for

complete details.

• Supports Type II or III Compensation

• Programmable Soft Start

• Fast Transient Response

• High Efficiency: Greater than 94%

• Non-synchronous Start-Up

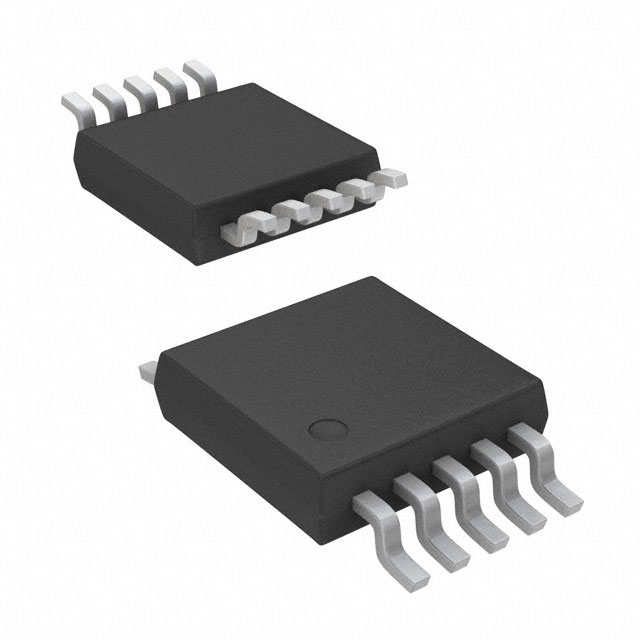

The SP6137 is available in lead free, RoHS

compliant,

space

saving

10-pin

MSOP

package.

• Small 10-Pin MSOP Package

• U.S. Patent #6,922,041

TYPICAL APPLICATION DIAGRAM

VIN

2.5V -20V

C1

22μF

16V

8 7 6 5

C2

22μF

16V

VCC = 5V @ 30mA

FDS6676S

14.5A, 6mΩ

QT

4

RLF

3.0,5%

GND

C1, C2

Ceramic

1210

X5R

1 2 3

CBST

0.1μF

U1

DBST

MBR0530

1

R3

221k, 1%

CVCC

10μF

6.3V

GND 3

2

3

4

0.8V

5

UVIN

R4

100k, 1%

CVCC

Ceramic

8050

X5R

VCC

GL

BST 10

SP6137

R5

Bead

SWN 8

VFB

SS 7

COMP

UVIN 6

CZ2

RZ2

L1 SC5018-2R7M

2.7μH @ 12A

DCR=4.30mΩ

GH 9

GND

8 7 6 5

QB

4

SS

CSS

47nF

C3

47μF

6.3V

C4

47μF

6.3V

1 2 3

CZ3

220pF

VOUT≤VIN

3.3V @ 10A

R1

68.1k, 1%

FDS6676S

14.5A, 6.0mΩ

GND2

820pF 40.2k, 1%

CP1

CF1

100pF

RZ3

4.64k, 1%

C3, C4

Ceramic

1210

X5R

56pF

R2

21.5k, 1%

Fig. 1: SP6137 Application Diagram

Exar Corporation

48720 Kato Road, Fremont CA 94538, USA

www.exar.com

Tel. +1 510 668-7000 – Fax. +1 510 668-7001

�S P6137

Wide Input, 900kHz Synchronous PWM Step Down

Controller

ABSOLUTE MAXIMUM RATINGS

These are stress ratings only and functional operation of

the device at these ratings or any other above those

indicated in the operation sections of the specifications

below is not implied. Exposure to absolute maximum

rating conditions for extended periods of time may affect

reliability.

GH, GL peak output current > Cp1 and R1 >> Rz3

Output Load Resistance >> Resr and Rdc

Bode Plot of Type III Error Amplifier Compensation.

© 2008 Exar Corporation

12/15

Rev. 2.0.0

�S P6137

Wide Input, 900kHz Synchronous PWM Step Down

Controller

TYPICAL APPLICATION DIAGRAM

VIN

2.5V -20V

C1

22μF

16V

8 7 6 5

C2

22μF

16V

VCC = 5V @ 30mA

FDS6676S

14.5A, 6mΩ

QT

4

RLF

3.0,5%

GND

C1, C2

Ceramic

1210

X5R

1 2 3

CBST

0.1μF

U1

DBST

MBR0530

1

R3

221k, 1%

CVCC

10μF

6.3V

GND 3

2

3

4

0.8V

5

UVIN

R4

100k, 1%

CVCC

Ceramic

8050

X5R

VCC

GL

BST 10

SP6137

SWN 8

VFB

SS 7

CZ2

L1 SC5018-2R7M

2.7μH @ 12A

QB

4

SS

UVIN 6

RZ2

8 7 6 5

DCR=4.30mΩ

GH 9

GND

COMP

R5

Bead

CSS

47nF

C3

47μF

6.3V

C4

47μF

6.3V

1 2 3

CZ3

220pF

VOUT≤VIN

3.3V @ 10A

R1

68.1k, 1%

FDS6676S

14.5A, 6.0mΩ

GND2

820pF 40.2k, 1%

CP1

CF1

100pF

RZ3

4.64k, 1%

C3, C4

Ceramic

1210

X5R

56pF

R2

21.5k, 1%

Note: Components highlighted in bold are those used on the SP6137 Evaluation Board.

Table 1. Input and Output Stage Components Selection Charts.

© 2008 Exar Corporation

13/15

Rev. 2.0.0

�S P6137

Wide Input, 900kHz Synchronous PWM Step Down

Controller

PACKAGE SPECIFICATION

© 2008 Exar Corporation

MSOP-10

14/15

Rev. 2.0.0

�S P6137

Wide Input, 900kHz Synchronous PWM Step Down

Controller

REVISION HISTORY – TO BE DELETED PRIOR TO PUBLICATION Revision

2.0.0

Date

1/20/2009

Description

Complete re-formatting

Changes from PCN #09-0120-01

FOR FURTHER ASSISTANCE

Email:

customersupport@exar.com

Exar Technical Documentation:

http://www.exar.com/TechDoc/default.aspx?

EXAR CORPORATION

HEADQUARTERS AND SALES OFFICES

48720 Kato Road

Fremont, CA 94538 – USA

Tel.: +1 (510) 668-7000

Fax: +1 (510) 668-7030

www.exar.com

NOTICE

EXAR Corporation reserves the right to make changes to the products contained in this publication in order to improve

design, performance or reliability. EXAR Corporation assumes no responsibility for the use of any circuits described herein,

conveys no license under any patent or other right, and makes no representation that the circuits are free of patent

infringement. Charts and schedules contained here in are only for illustration purposes and may vary depending upon a

user’s specific application. While the information in this publication has been carefully checked; no responsibility, however,

is assumed for inaccuracies.

EXAR Corporation does not recommend the use of any of its products in life support applications where the failure

malfunction of the product can reasonably be expected to cause failure of the life support system or to significantly affect

safety or effectiveness. Products are not authorized for use in such applications unless EXAR Corporation receives,

writing, assurances to its satisfaction that: (a) the risk of injury or damage has been minimized; (b) the user assumes

such risks; (c) potential liability of EXAR Corporation is adequately protected under the circumstances.

or

its

in

all

Reproduction, in part or whole, without the prior written consent of EXAR Corporation is prohibited.

© 2008 Exar Corporation

15/15

Rev. 2.0.0

�