S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

March 2009

Rev. 2.0.0

GENERAL DESCRIPTION

APPLICATIONS

The SP7600 is a non-synchronous voltage

mode PWM step down converter with

integrated high side FET optimized to drive

high power LEDs at up to 2A of continuous

current. A wide 4.5V to 29V input voltage

range allows for single supply operations from

industry standard 5, 12 or 24V power rails.

A 1.2MHz constant operating frequency allows

for small external components selection while

an internal type II control loop compensation

reduces the overall component count and

solution footprint. A low 200mV feedback

reference voltage minimizes power dissipation

in the system while efficiency is mazimized via

a 100% duty cycle capability. Dimming and

shutdown mode is provided via an enable

function when required. An adjustable over

current and under voltage lock out protection

insures safe operations under abnormal

operating conditions.

The SP7600 is pin compatible with Exar’s

XRP7603 and XRP7604, non synchronous buck

high power led drivers respectively rated at

500mA and 1A.

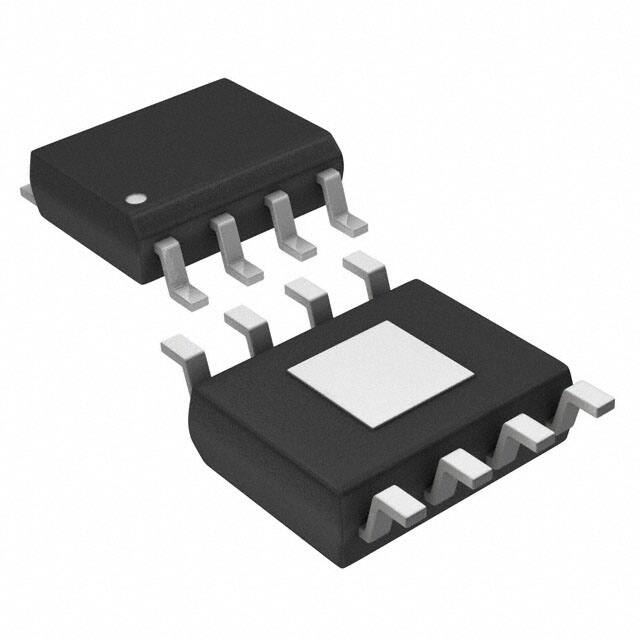

The SP7600 is offered in a compact thermally

enhanced lead free RoHS compliant 8-pin SO

package.

• General Lighting and Displays

• Architectural and Accent Lighting

• Medical and Industrial Instrumentation

• Video Projectors

FEATURES

• 2A Continous Output Current Capable

• 4.5V to 29V Single Rail Input Voltage

• 1.2MHz Constant Switching Frequency

• Internal Control Loop Compensation

• 0.2V Feedback Reference Voltage

• 2.5% Output Voltage Accuracy

• Built-in Soft Start

• PWM & Analog Dimming Capability

• Adjustable Over-Current Protection

• Pin Compatible with 500mA rated

XRP7603 & 1A rated XRP7604

• Thermally Enhanced Package

• Lead Free RoHS Compliant 8-pin SO

Package

TYPICAL APPLICATION DIAGRAM

Fig. 1: SP7600 Application Diagram

Exar Corporation

48720 Kato Road, Fremont CA 94538, USA

www.exar.com

Tel. +1 510 668-7000 – Fax. +1 510 668-7001

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

ABSOLUTE MAXIMUM RATINGS

OPERATING RATINGS

These are stress ratings only and functional operation of

the device at these ratings or any other above those

indicated in the operation sections of the specifications

below is not implied. Exposure to absolute maximum

rating conditions for extended periods of time may affect

reliability.

Input Voltage Range VIN ................................4.5V to 29V

Junction Temperature Range ....................-40°C to 125°C

Thermal Resistance θJA ...................................... 59°C/W

Input Voltage ............................................. -0.3V to 30V

Lx................................................................-2V to 30V

FB .....................................................-0.3V to VIN+0.3V

Storage Temperature .............................. -65°C to 150°C

Power Dissipation (Note 1) ................... Internally Limited

Lead Temperature (Soldering, 10 sec) ................... 300°C

ESD Rating (Lx, ISET) ....................................1KV - HBM

ESD Rating (All other pins) .............................2KV - HBM

ELECTRICAL SPECIFICATIONS

Specifications with standard type are for an Operating Junction Temperature of TJ = 25°C only; limits applying over the full

Operating Junction Temperature range are denoted by a “•”. Minimum and Maximum limits are guaranteed through test,

design, or statistical correlation. Typical values represent the most likely parametric norm at TJ = 25°C, and are provided for

reference purposes only. Unless otherwise indicated, VIN = 4.5V to 29V, CIN = 1µF, TJ = –40°C to 125°C.

Parameter

Min.

Typ.

Max.

Units

UVLO Turn-On Threshold

4.0

4.2

4.5

V

0°C ≤ TJ ≤ 125°C

UVLO Turn-Off Threshold

3.8

4.0

4.3

V

0°C ≤ TJ ≤ 125°C

UVLO Hysteresis

0.2

V

Operating Input Voltage Range

4.5

29

V

Operating Input Voltage Range

7

29

V

Operating VCC Current

Conditions

0°C ≤ TJ ≤ 125°C

•

2

3

mA

VFB=0.1V, not switching

Standby VCC Current

0.6

1

mA

VFB=1.2V, not switching

Reference Voltage

200

mV

Reference Voltage

186

200

214

mV

Switching Frequency

960

1200

1440

kHz

40

100

ns

0

%

Minimum On-Pulse Duration

Minimum Duty Cycle

Maximum Duty Cycle

100

VDR Voltage

4.5

Over-Current Threshold

300

ISET Pin Input Current

25

OFF Interval During Hiccup

SHDN Threshold

SHDN Threshold Hysteresis

Switch On Resistance

Switch Leakage

•

%

5.5

V

350

400

mV

33

40

µA

100

0.8

•

1.0

Measure VIN-VDR

VIN > 7V

Measure VIN-Lx

•

VIN=VLx

•

Apply voltage to FB

ms

1.2

100

V

mV

95

3

•

mΩ

5

µA

Note 1: All parameters tested at TA=25°C. Specifications over temperature are guaranteed by design.

© 2009 Exar Corporation

2/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

BLOCK DIAGRAM

Fig. 2: SP7600 Block Diagram

PIN ASSIGNEMENT

Fig. 3: SP7600 Pin Assignement

© 2009 Exar Corporation

3/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

PIN DESCRIPTION

Name

Pin Number

Description

FB

1

Regulator feedback input. A current setting resistor is connected to LED’s cathode and

FB on one side and to ground on the other side. This pin can be also used for dimming

control. By connecting a diode between this pin and a >2V signal the LED can be pulsed

at up to 1kHz

GND

2

Ground pin

VDR

3

Power supply for the internal driver. This voltage is internally regulated to about 5V

below VIN. Place a 0.1uF decoupling capacitor between VDR and Vin as close as

possible to the IC.

PVIN

4,5

SVIN

6

Input power supply for the regulator. Place input decoupling capacitor as close as

possible to this pin. This is the Vin connection for the regulator and is not tied to the

high-side FET.

LX

7

Connect to the output inductor. This is the P-Channel FET Drain

ISET

8

This pin is used as a current limit input for the internal current limit comparator.

Connect to LX through an optional resistor. Internal threshold is pre-set to 350mV

nominal and can be decreased by changing the external resistor based on the following

formula: VTRSHLD = 350mV – 33uA * R

Power PAD

9

Can be connected to inductor LX node for a thermal PAD – see Layout suggestions

section.

Connection to the FET source

ORDERING INFORMATION

Temperature

Range

Marking

Package

Packing

Quantity

SP7600EN2-L

-40°C≤TJ≤+125°C

SP7600E

YYWWL

X..X

HSOICN-8

Exp. PAD

Bulk

SP7600EN2-L/TR

-40°C≤TJ≤+125°C

SP7600E

YYWWL

X..X

HSOICN-8

Exp. PAD

Part Number

SP7600EB

Note 1

Note 2

Lead Free

2.5K/Tape & Reel Lead Free

SP7600 Evaluation Board

“YY” = Year – “WW” = Work Week – “L” = Lead Free designator – “X” = Lot Number

© 2009 Exar Corporation

4/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

TYPICAL PERFORMANCE CHARACTERISTICS

The typical performance characteristics follow and begin with an illustration of the efficiencies that

can be obtained with the SP7600 driving 1 or 6 white LEDs in series for up to 2A output current.

For the 6 LED applications with a 24V input, the duty cycle is high and an efficiency of 94% can be

obtained. For 12V input and 1 LED at 2A output, the duty cycle is much lower, but the efficiency is

still over 80%. Note: to improve line regulation a small 22pF ceramic capacitor C6 should be placed

from VFB to GND to filter out any noise obtained on the sensitive FB pin.

Scope photos of output ripple are shown for the typical application circuit for 6V input at 150mVpp

ripple and at 29V input with over 400mVpp output ripple, both shown with no output capacitor. For

comparison, an output ripple scope photo is shown with only 70mVpp when a 1uF capacitor is used

at the output. For applications sensitive to output ripple, adding this relatively small 1206 sized 1uF

50V ceramic capacitor to the output provides a very good reduction in output ripple but since the

value is only 1uF the circuit will still provide good PWM output response.

Vin startup scope photos are shown for 6V, 12V and 29V input with no problems in startup as

shown in the Vout, VFB and especially the inductor current signal ILX.

The last scope photos are for the output short circuit which causes a hiccup mode. The output can

be shorted which causes a controlled automatic reset or hiccup mode of about 50 to 100msec

period.

All data taken at VIN = 12V, TA = 25°C, unless otherwise specified - Schematic and BOM from Application Information

section of this datasheet.

Fig. 5: Output Current vs Input Voltage

Fig. 4: Efficiency vs Input Voltage

© 2009 Exar Corporation

5/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

Ch1: Lx

Ch2: Vout(AC)

Ch4: ILx 2A/div

Fig. 6: Feedback Voltage vs Input Voltage

Fig. 7: No Cout, Output Ripple=150mVpp, Vin=6V

2 LEDs in parallel, Vf=3.6V @ 2A

Ch1: Lx

Ch2: Vout(AC)

Ch4: ILx 2A/div

Fig. 8: No Cout, Output Ripple=440mVpp, Vin=29V

2 LEDs in parallel, Vf=3.6V @ 2A

Ch1:

Ch2:

Ch3:

Ch4:

Fig. 9: Cout=1uF, Output Ripple=70mVpp, Vin=29V

2 LEDs in parallel, Vf=3.6V @ 2A

Vin

Vout

VFB

ILx 2A/div

Ch1:

Ch2:

Ch3:

Ch4:

Vin

Vout

VFB

ILx 2A/div

Fig. 11: 12V Vin Startup

2 LED in parallel, Vf=3.6V @ 2A

Fig. 10: 5V Vin Startup

2 LED in parallel, Vf=3.6V @ 2A

© 2009 Exar Corporation

Ch1: Lx

Ch2: Vout(AC)

Ch4: ILx 2A/div

6/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

Ch1:

Ch2:

Ch3:

Ch4:

Lx

Vout(AC)

VFB

ILx 2A/div

Fig. 13: Output Short Circuit

Hiccup mode with Vin=29V

Fig. 12: 29V Vin Startup

2 LED in parallel, Vf=3.6V @ 2A

Ch1:

Ch2:

Ch3:

Ch4:

Ch1:

Ch2:

Ch3:

Ch4:

Vin

Vout

VFB

ILx 2A/div

Lx

Vout

VFB

Ilx 2A/div

Fig. 14: OutputShort Circuit

Zoomed in on hiccup mode with Vin=29V

© 2009 Exar Corporation

7/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

DIM = L. The DIM signal needs to be greater

than 600mV minimum to turn-off the SP7600

and less than 200mV to fully turn-on the

SP7600. It is recommended to use a signal

with DIM = 1V or more for OFF and 0V for ON.

The user should note that the logic is reversed

relative to many other PWM controlled LED

drivers. In other words a logic level high at

20% duty cycle will result in approximately an

80% duty cycle for the LED. Recommended

modulation frequencies are from 100Hz to

200Hz with 10 – 90% duty cycle, 500Hz with

10 – 80% duty cycle, and 1000Hz with 10 70% duty cycle. Figures 15 & 16 show the

output response at the maximum PWM DIM

signal of 1000Hz. See figure 17 for 100Hz to

1000Hz duty cycle response for two Luxeon K2

LEDs in parallel at 2A total current.

THEORY OF OPERATION

The SP7600 is a fixed frequency, Voltagemode, non-synchronous buck PWM regulator

optimized for driving LEDs. Constant LED

current is achieved using resistor RFB as

shown in the page 1 schematic. A low 0.2V

reference voltage minimizes power dissipation

in RFB. A tight reference voltage tolerance of

±3%, over full operating conditions, helps

accurately program the LED current. High

switching frequency of 1.2MHz (nominal)

reduces the size of passive components.

Dimming and power sequencing is achieved

using a logic-level PWM signal applied to FB

pin via a diode. Overcurrent protection (OCP)

is based on high-side MOSFET’s Rds(on) and is

programmable via a resistor placed at LX

node.

PROGRAMMING THE LED CURRENT

Use the following equation to program the LED

current:

Equ.1: RFB =

0.2V

I LED

The output voltage will adjust as needed to

ensure average ILED is supplied. For example if

the output current has to be set at 0.35A then

RFB=0.57 Ohm. If the output LED has a

corresponding Vf of 3.5V then SP7600 will step

down the VIN to 3.5V. If two of these LEDs are

placed in series then SP7600 will step down

the voltage to 7V. Superimposed on ILED there

is a current ripple that is equal in magnitude

to inductor current ripple. Current ripple will

be nominally set to 10% of ILED by proper

sizing of inductor. Note that throughout this

and

IO

will

be

used

datasheet

ILED

interchangeably.

Ch1: DIM Signal

Ch2: VFB - 2A IOUT/div

Fig. 15: 1.1KHz, 10% Duty Cycle Dimming Signal

Dimming Signal is ~70% LED Duty Cycle

Ch1: DIM Signal

Ch2: VFB - 2A IOUT/div

DIMMING SIGNAL

A logic-level PWM signal applied through a

small-signal diode to the feed-back (FB) pin

can be used for dimming control of the LED.

This external signal we call DIM turns the

MOSFET gate drive on/off, thereby modulating

the average current delivered to the LED. The

DIM signal connects to the VFB pin through a

1N4148 diode and will shutdown the SP7600

when DIM = H and turn-on the SP7600 when

© 2009 Exar Corporation

Fig. 16: 1KHz, 70% Duty Cycle

Dimming Signal is ~10% LED Duty Cycle

8/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

Another benefit of using power sequencing for

power up is that it ensures all internal circuitry

is alive and fully operational before the device

is required to regulate the current through the

LEDs. Since the regulator was “Off” before

power was applied, it is unlikely the LED is

under any type of thermal stress. EXAR does

not recommend using the SP7600 in

applications where dimming of the LED is

achieved by PWM’ing the actual input power as

is

common

in

automotive

dimming

applications.

BUCK OPERATION WITHOUT OUTPUT

CAPACITOR

Fig. 17: LED Duty Cycle vs (1-D) DIM pin Duty Cycle

Vin=12V, 2 Luxeon K2 in Parallel with 2A total

In order to be able to apply the

aforementioned dimming signal to the LED,

the output filter capacitor that is normally

used with a buck converter has to be removed

from the circuit. Thus the LED current ripple

equals the inductor current ripple. As a rule of

thumb current ripple should be limited to 30%

of ILED. Allowing for a higher current ripple,

up to 30%, while staying within LED

manufacturer ripple guidelines, will reduce

inductance and possibly inductor size.

MODULATOR OPERATION AND POWER

SEQUENCING

The SP7600 has a unique modulator design

which improves the device’s ability to operate

at very high duty cycle. While seamless in

operation as the duty cycle is increasing (input

voltage falling), when the duty cycle is

decreased (input voltage rising), the user will

observe the switching frequency increasing in

distinct fractions of the switching frequency. If

the device is operating at 100% duty cycle, a

unique advantage of using a p-channel pass

device, and then the input voltage is

increased, the frequency will start at 300kHz,

then 600kHz, and then finally 1.2MHz. The

frequency will tend to increase to the next

higher fraction once the duty cycle reaches 75

to 65 percent. This is the normal operation of

the device and should be expected. There is

no impact on the LED current accuracy. If

PWM dimming is being used as the input

voltage is increased, one will see the

frequency increasing when the duty cycle is <

90%. When power is initially applied the

device will begin operating as if the input

voltage is increasing and may start operation

at one of the fractional operating frequencies.

Many users will prefer to have the device start

operating at the nominal operating frequency,

thus it is recommended that Vin be applied

after FB is set at the high state (>1.2V). The

regulator is now in standby and once Vin has

reached steady-state then FB is transitioned

from a high to a low state. The regulator then

starts operating at nominal frequency.

© 2009 Exar Corporation

OVERCURRENT PROGRAMMING

Resistor Rs can be used to program

Overcurrent Protection (OCP). Use the

following equation for calculating the Rs value.

Equ.2: Rs =

0.35V − (1.5 × 1.05 × I OCP × Rds (on))

33μA

Where Iocp is the programmed overcurrent

and is generally set 50% above nominal

output current, and Rds(on) = 95mohms.

Maximum value of Rs that can be used for

programming OCP is 3k.

INDUCTOR SELECTION

Select the inductor L1 for inductance, Irms

and Isat. Calculate inductance from

Equ.3: L =

Vo × (Vin − Vo)

Vin × f × ΔI L

Where Vin is converter input voltage and Vo is

converter output voltage. Since voltage across

Rset is small, Vo approximately equals Vf (for

9/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

a string of series connected LEDs Vo equals

total Vf)

Resistance

(ESR),

Equivalent

Series

inductance (ESL) and small form factor.

ΔIL is inductor current ripple (nominally set to

30% of Io)

SCHOTTKY RECTIFIER SELECTION

Inductor Isat and Irms must allow sufficient

safeguard over output current Io. As a rule of

thumb these parameters should be 50%

higher than Io. Where high efficiency is

required a low DCR inductor should be used.

Select the Schottky D1 for Voltage rating VR

and current rating If. Recommended schottky

diode voltage rating for 12V and 24V

applications is 30V and 40V respectively.

Current rating can be calculated from:

Equ.5 : If ≥ 1 −

INPUT CAPACITOR SELECTION

Select the input capacitor for capacitanceand

ripple current rating. Use the capacitances

listed in the table 1 as a starting point and if

needed increase Cin.

IO(A)

Cin (µF)

1.2

2 x 4.7

Note that in applications where duty cycle is

low, Schottky losses comprise a larger

percentage of converter losses. In order to

improve the efficiency in these applications

choose a Schottky that meets the calculated

current rating and has a lower Vf.

FEEDBACK RESISTOR RFB

Table 1: Cin Selection

R2 is part of SP7600 loop compensation

network. Use a 30k R2 for Vin of 20V and

larger. Use R2 of 60K for Vin less than 20V.

Calculate the ripple current requirement from:

Equ.4: Irip = Io ×

CAPACITOR C5

D × (1 − D)

This is the decoupling capacitor for the power

supply for the internal driver. Use a 0.1uF and

place as closely to VDR and SVIN pins as

possible.

Vo

Where D =

Vin

Ceramic capacitors are recommended for input

filtering due to their low Equivalent Series

© 2009 Exar Corporation

Vo

× Io

Vin

10/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

Schottky current rating IF

DESIGN EXAMPLE

Design a drive circuit for a 1.5A LED with a

12V input voltage. Nominal LED voltage is

3.6V.

IF ≥ 1−

Voltage rating should be 30V. B340A rated at

30V/3A or equivalent can be used for its

ample current rating and low forward voltage.

Resistor RFB calculation

RFB =

0.2V

= 0.13Ω

1.5 A

Rs calculation

A standard value of 0.12ohm 0805 is selected.

Rs =

Inductor L1 calculation

L1 =

3.3V

× 1 .5 A = 1 .3 A

12V

3.6V × (12V − 3.6V )

= 4.3μH

12V × 1.3MHz × 0.45 A

0.35V − (1.5 × 1.05 × 2.25 A × 0.095Ω)

= 424Ω

33μA

Use standard resistor value for Rs of 470Ω.

An inductor of 4.7uH, rated at 3ARMS and 3A

ISAT is selected.

Input capacitor

A 10µF CIN (C1) is needed (refer to table 1).

From Equ.4, the ripple current rating of CIN is

a fraction of 1.5A. A 10uF/16V ceramic

capacitor easily meets this requirement and

offers low ESR and ESL.

Fig. 18: Circuit for design example

copper regions to connect output capacitors to

load to minimize inductance and resistances.

LAYOUT CONSIDERATION

i) Place the bypass capacitors C4 and C5 as

close as possible to the 7600 IC. See figure 5

for details.

v) Keep other sensitive circuits and traces

away from the LX node in particular and away

from the power supply completely if possible.

ii) Create a pad under the IC that connects the

power pad (pin 9) to the inductor. Duplicate

this pad through the pcb layers if present, and

on the bottom side of the PCB. Use multiple

vias to connect these layers to aid in heat

dissipation. Do not oversize this pad - since

the LX node is subjected to very high dv/dt

voltages, the stray capacitance formed

between these islands and the surrounding

circuitry will tend to couple switching noise

For more detail on the SP7600 layout see the

SP7600EB Evaluation Board Manual available

on our web site. Each layer is shown in detail

as well as a complete bill of materials.

iii) Connect the Schottky diode cathode as

close as possible to the LX node and inductor

input side. Connect the anode to a large

diameter trace or a copper area that connects

the input ground to the output ground.

iv) The output capacitor, if used, should be

placed close to the load. Use short wide

© 2009 Exar Corporation

Fig. 19: SP7600 Eval Board

Component Side Lay

11/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

PACKAGE SPECIFICATION

8-PIN HSOICN

© 2009 Exar Corporation

12/13

Rev. 2.0.0

�S P7 6 0 0

2A 29V Non-Sync. Buck High Power LED Driver

REVISION HISTORY

Revision

Date

1.0

12/17/2007

First release of data sheet

Description

2.0.0

03/17/2009

Reformat of Datasheet

Addition of pin compatibility with Exar’s XRP7603 and XRP7604

FOR FURTHER ASSISTANCE

Email:

customersupport@exar.com

Exar Technical Documentation:

http://www.exar.com/TechDoc/default.aspx?

EXAR CORPORATION

HEADQUARTERS AND SALES OFFICES

48720 Kato Road

Fremont, CA 94538 – USA

Tel.: +1 (510) 668-7000

Fax: +1 (510) 668-7030

www.exar.com

NOTICE

EXAR Corporation reserves the right to make changes to the products contained in this publication in order to improve

design, performance or reliability. EXAR Corporation assumes no responsibility for the use of any circuits described herein,

conveys no license under any patent or other right, and makes no representation that the circuits are free of patent

infringement. Charts and schedules contained here in are only for illustration purposes and may vary depending upon a

user’s specific application. While the information in this publication has been carefully checked; no responsibility, however,

is assumed for inaccuracies.

EXAR Corporation does not recommend the use of any of its products in life support applications where the failure

malfunction of the product can reasonably be expected to cause failure of the life support system or to significantly affect

safety or effectiveness. Products are not authorized for use in such applications unless EXAR Corporation receives,

writing, assurances to its satisfaction that: (a) the risk of injury or damage has been minimized; (b) the user assumes

such risks; (c) potential liability of EXAR Corporation is adequately protected under the circumstances.

or

its

in

all

Reproduction, in part or whole, without the prior written consent of EXAR Corporation is prohibited.

© 2009 Exar Corporation

13/13

Rev. 2.0.0

�