IPS160H, IPS161H

Datasheet

60 V, 60 mΩ single high-side switches

Features

•

•

•

•

•

•

•

8 V to 60 V operating voltage range

Minimum output current limitation: 0.7 A (IPS161H) or 2.5 A (IPS160H)

Fast demagnetization of inductive load

Non-dissipative short-circuit protection (cut-off)

Programmable cut-off delay time using external capacitor

Ground disconnection protection

VCC disconnection protection

•

•

•

Thermal shutdown protection

Undervoltage lock-out

Diagnostic signalization for: open load in off-state, cut-off and junction thermal

shutdown

Designed to meet IEC 61131-2

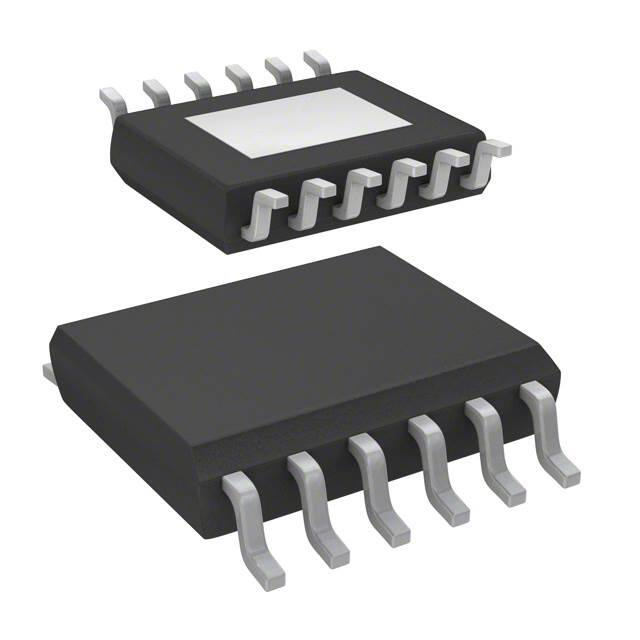

PowerSSO12 package

•

•

Applications

•

•

•

•

•

Product status

IPS160H

Description

IPS161H

The IPS160H (IOUT < 2.5 A) and IPS161H (IOUT < 0.7 A) are monolithic devices

which can drive capacitive, resistive or inductive loads with one side connected to

ground.

Product label

Product summary

Order code

Package

Packing

IPS160H

IPS160HTR

IPS161H

IPS161HTR

PowerSSO12

Tube

Programmable logic control

Industrial PC peripheral input/output

Numerical control machines

Domotics

Generic power supply switch

The 60 V operating range and Ron = 60 mΩ, combined with the extended diagnostic

(Open Load, Over Load, Overtemperature) make the IC suitable for applications

implementing the proper architectures to address higher SIL levels.

The built-in overload and thermal shutdown protections guarantee the ICs, the

application and the load against electrical and thermal overstress. Furthermore, in

order to minimize the power dissipation when the output is shorted, a low-dissipative

short-circuit protection (cut-off) is implemented to limit the output average current

value and consequent device overheating.Cut-off delay time can be set by soldering

an external capacitor or disabled by a resistor on pin 4 (CoD).

The DIAG common diagnostic open drain pin reports the open load in off-state, cutoff

(overload) and thermal shutdown.

Tape and

reel

DS10907 - Rev 11 - December 2022

For further information contact your local STMicroelectronics sales office.

www.st.com

�IPS160H, IPS161H

Block diagram

1

Block diagram

Figure 1. Block diagram

IN

DIAG

Logic interface

Undervoltage

detection

Vcc

Vcc clamp

Output clamp

Current limitation

cut -off

Open load in off-state

OUT

CoD

Junction

Overtemperature

GND

DS10907 - Rev 11

GIPG1702151307LM

page 2/24

�IPS160H, IPS161H

Pin description

2

Pin description

Figure 2. Pin connection (top view)

VCC

1

12 VCC

IN

2

11

OUT

DIAG

3

10

OUT

CoD

4

9

OUT

NC

5

8

OUT

NC

6

7

GND

TAB=Vcc

GIPG1702151321LM

Table 1. Pin configuration

Number

Name

Type

1, 12, TAB

VCC

Device supply voltage

Supply

2

IN

Channel input

Input

3

DIAG

Common diagnostic pin both for thermal shutdown, cut-off and open load

Output open

drain

4

CoD

Cut-off delay pin, cannot be left floating.

Connected to GND by 1 kΩ resistor to disable the cut-off function. Connect to a CCoD

capacitor to set the cut-off delay see Table 8. Protection and diagnostic

Input

5, 6

NC

Not connected

7

GND

Device ground

Ground

Channel power stage output

Output

8, 9, 10, 11 OUT

2.1

Function

IN

This pin drives the output stage to pin OUT. IN pin has internal weak pull-down resistors, see Table 7. Logic

inputs.

2.2

OUT

Output power transistor is in high-side configuration, with active clamp for fast demagnetization.

2.3

DIAG

This pin is used for diagnostic purpose and it is internally wired to an open drain transistor. The open drain

transistor is turned on in case of junction thermal shutdown, cut-off, or open load in off-state.

DS10907 - Rev 11

page 3/24

�IPS160H, IPS161H

CoD

2.4

CoD

This pin cannot be left floating and can be used to program the cut-off delay time tcoff, see Table 8. Protection

and diagnostic through an external capacitor (CCoD). The cut-off function can be completely disabled connecting

the CoD pin to GND through 1 kΩ resistor: in this condition the output channel remains in limitation condition,

supplying the current to the load until the input is forced LOW or the thermal shutdown threshold is triggered.

2.5

GND

IC ground.

2.6

VCC

IC supply voltage.

DS10907 - Rev 11

page 4/24

�IPS160H, IPS161H

Reverse polarity

3

Reverse polarity

Reverse polarity

The IC can be protected against reverse polarity using two different solutions:

1. Placing a resistor RGND between IC GND pin and load connection point to GND (RGND > VCC/Icc, see Table 1.

Absolute maximum rating). Note that power dissipated by RGND during reverse polarity condition is Vcc^2/RGND.

2. Placing a diode in parallel to RGND

The diode must be selected such that its VRRM > |VCC| and power dissipation capability is higher than VF*IS

(see Table 1).

In normal operation (no reverse polarity), there is a voltage drop (ΔV) between GND of the device and GND of the

module.

Using option 1, ΔV = RGND * ICC.

Using option 2, ΔV = VF@(IS).

Figure 3. Reverse polarity protection schematic

DS10907 - Rev 11

page 5/24

�IPS160H, IPS161H

Absolute maximum ratings

4

Absolute maximum ratings

Table 2. Absolute maximum ratings

Symbol

Parameter

VCC

Supply voltage

VOUT

Output channel voltage

Value

Unit

-0.3 to 65

V

Vcc-Vclamp to Vcc+0.3

V

-10 to +10

mA

IIN

Input current

VIN

IN voltage

VCC

V

VCOD

Output cut-off voltage pin

5.5

V

ICOD

Input current on cut-off pin

-1 to +10

mA

VDIAG

Fault voltage

VCC

V

IDIAG

Fault current

-5 to +10

mA

ICC (1)

Maximum DC reverse current flowing through the IC

from GND to VCC

-250

mA

IOUT

Output stage current

-IOUT (1)

EAS

(1)

Internally limited

A

Maximum DC reverse current flowing through the IC

from OUT to VCC

5

Single pulse avalanche energy (TAMB = 125 °C, VCC

= 24 V, Iload = 0.5 A)

3000

mJ

Single pulse avalanche energy (TAMB = 125 °C, VCC

= 24 V, Iload = 1.0 A)

1000

mJ

Internally limited

W

PTOT

Power dissipation at TC = 25 °C (2)

TSTG

Storage temperature range

-55 to 150

Junction temperature

-40 to 150

TJ

°C

1. Verified on STEVAL-IFP028V1 and STEVAL-IFP034V1 application board

2. (TJSD(MAX)-TC)/ Rth(JA)

Note:

Absolute maximum ratings are those values beyond which damage to the device may occur. Functional

operation under these conditions is not implied. All voltages are referenced to GND.

Table 3. Thermal data

Value

Symbol

Note:

Parameter

1s

2s2p

2s2p (with 4

thermal vias)

Rth(JC)

Thermal resistance junction-case

0.4

0.9

0.5

Rth(JA)

Thermal resistance junction-ambient

117

57

29

Unit

°C/W

Rth(JC) is intended between the die and the bottom case surface measured by cold plate as per JESD51. Rth(JA)

according JESD51-3 (1s) JESD51-5 (2s2p) and JESD51-7 (2s2p and thermal vias).

DS10907 - Rev 11

page 6/24

�IPS160H, IPS161H

Electrical characteristics

5

Electrical characteristics

(8 V < VCC < 60 V; -40 °C < TJ < 125 °C, unless otherwise specified)

Table 4. Supply

Symbol

Parameter

Test conditions

Min.

Typ.

Max.

Unit

VUVON

60

V

VCC

Supply voltage

VUVON

Undervoltage on threshold

6.9

8

V

VUVOFF

Undervoltage off threshold

6.5

7.8

V

VUVH

Undervoltage hysteresis

0.15

Supply current in off-state

IS

Supply current in on-state

ILGND

GND disconnection output current

0.5

V

VCC = 24 V

300

500

VCC = 60 V

350

600

VCC = 24 V

1

1.4

VCC = 60 V

1.4

2.1

VGND = VIN = VCC, VOUT = 0 V; TJ = 25oC

0.5

VGND = VIN = VCC, VOUT = 0 V; TJ = 125oC

0.55

μA

mA

mA

Table 5. Output stage

Symbol

Parameter

Test conditions

Min. Typ. Max. Unit

VCC = 24 V

RDS(on)

On-state resistance

60

IOUT =0.5 A (IPS161H), 1 A (IPS160H) @ TJ = 25 °C

mΩ

VCC = 24 V

120

IOUT =0.5 A (IPS161H), 1 A (IPS160H) @ TJ = 125 °C

DS10907 - Rev 11

VOUT(OFF)

Off-state output voltage

IOUT(OFF)

Off-state output current

IOUT(OFF-min)

Off-state output current

80

VIN = 0 V and IOUT = 0 A

2

VCC = 24 V, VIN = 0 V, VOUT = 0 V

3

VCC = 60 V, VIN = 0 V, VOUT = 0 V

10

VIN = 0 V, VOUT = 4 V

-35

V

μA

0

page 7/24

�IPS160H, IPS161H

Electrical characteristics

Table 6. Switching (VCC = 24 V; -40 °C < TJ < 125 °C, RLOAD = 48 Ω)

Symbol

Parameter

Test conditions

tr

Rise time

tf

Fall time

tPD(H-L)

Propagation delay time off

tPD(L-H)

Propagation delay time on

tD(VCC-ON)

Power-on delay time from

VCC rising edge

Min. Typ. Max.

IOUT = 0.5 A, Figure 4. Timing in normal operation

IOUT = 0.5 A, (see Figure 5. Propagation delay at startup)

10

20

10

20

20

35

20

35

Unit

μs

600 1200

Figure 4. Timing in normal operation

Figure 5. Propagation delay at start-up

VIN

t

VCC

VUVON

t

td(Vcc-on)

VOUT

10%

t

DS10907 - Rev 11

page 8/24

�IPS160H, IPS161H

Electrical characteristics

Table 7. Logic inputs

Symbol

Parameter

VIL

Input low level voltage

VIH

Input high level voltage

VI(HYST)

Input hysteresis voltage

IIN

Input current

Test conditions

Min.

Typ.

Max.

Unit

0.8

V

2.2

0.4

VCC = VIN = 36 V

200

VCC = VIN = 60 V

550

μA

Table 8. Protection and diagnostic

Symbol

Parameter

Test conditions

Vclamp

VCC active clamp

ICC = 10 mA

Vdemag

Demagnetization voltage

IOUT = 0.5 A; load =1 mH

VOLoff

Open load (off-state) or short to

VCC detection threshold

tBKT

Open load blanking time

VDIAG

Voltage drop on DIAG

IDIAG

DIAG pin leakage current

IPK

IPS161H

Output current limitation activation

threshold

tcoff

Typ.

Max.

65.5

68.5

71.5

2

200

μs

1

V

VCC ≤ 36 V

110

36 V ˂ VCC ≤ 60 V

180

2.1

3.0

4.6

IPS161H Output current limitation

0.7

1.7

IPS160H Output current limitation

2.5

4.2

Cut-off current delay time

Programmable by the external

capacitor on CoD pin. Cut-off is

disabled when CoD pin is connected to

GND through 1 kΩ resistor.

V

4

IDIAG = 4 mA

VCC ≤ 24 V, RLOAD ≤ 10 mΩ

Unit

VCC-71.5 VCC-68.5 VCC-65.5

1.3

IPS160H

Output current limitation activation

threshold

ILIM

Min.

50xCCOD[nf] ± 35%(1)

μA

A

μs

TJ˂ TJSD

tres

Output stage restart delay time

TJSD

Junction temperature shutdown

TJHYST

Junction temperature thermal

hysteresis

TJ˂ TJSD

32xtcoff [μs]± 40%

150

170

15

190

°C

1. The formula is guaranteed in the range 10 nF ≤ CCOD ≤ 100 nF.

DS10907 - Rev 11

page 9/24

�IPS160H, IPS161H

Output logic

6

Output logic

Table 9. Output stage truth table

Operation

Normal

Cut-off

Overtemperature

Open load

UVLO

DS10907 - Rev 11

IN

OUT

DIAG

L

L

H

H

H

H

L

L

L

H

L

L

L

L

L

H

L

L

L

H (external pull-up resistor is

used)

L (external pull-up resistor is

used)

H

H

X

L

X

X

L

X

H

page 10/24

�IPS160H, IPS161H

Protection and diagnostic

7

Protection and diagnostic

The IC integrates several protections to ease the design of a robust application.

7.1

Undervoltage lock-out

The device turns off if the supply voltage falls below the turn-off threshold (VUV(off)). Normal operation restarts

after VCC exceeds the turn-on threshold (VUV(on)). Turn-on and turn-off thresholds are defined in Table 4. Supply.

7.2

Overtemperature

The output stage turns off when its internal junction temperature (TJ) exceeds the shutdown threshold TJSD.

Normal operation restarts when TJ comes back below the reset threshold (TJSD - TJHYST), see Table 8. Protection

and diagnostic. The internal fault signal is set when the channel is off due to thermal protection and it is reset

when the junction triggers the reset threshold. This same behavior is reported on DIAG pin.

7.3

Cut-off

The IC can limit the output current at the power stage by its embedded output current limitation circuit.

This circuit continuously monitor the output current and, when load is increasing, at the triggering of its activation

threshold (3.8A TYP) it starts limiting to ILIM limitation level (See Protection and diagnostic): while current

limitation is active the IC enters an high dissipation status.

The IC implements the cut-off feature which limits the duration of the current limitation condition.

The duration of the current limitation condition (Tcoff) can be set by a capacitor (CCoD) placed between CoD and

GND pins. The design rule for CCoD is:

tcoff[us] +/- 35% = 50 x Ccod[nF]

The drift of +/-35% is guaranteed in the range of 10 nF < Ccod < 100 nF; lower capacitance than 10 nF can be

used.

If ILIM threshold is triggered, the output stage remains in the current limitation condition (IOUT = ILIM) no longer

than tcoff. If tcoff elapses, the output stage turns off and restarts after the tres restart time.

Thermal shutdown protection has higher priority than cut-off:

•

IC is forced off if TJSD is triggered before tcoff elapses

•

if TJSD is triggered, IC is maintained off even after the tres has elapsed and until the TJ decreases below

TJSD-TJHYST

Figure 6. Current limitation and cut-off

I OUT

t COFF

t res

ILIM

TJ 36 V) the cut-off

function needs activating in order to avoid IC permanent damages. The following table reports the suggested

cut-off delay for the different operating voltage.

Table 10. Minimum cut-off delay for TAMB less than -20 °C

DS10907 - Rev 11

VCC [V]

Cut-off delay [μs]

Cut-off capacitance [nF]

36-48

100

2.2

48-60

50

1

page 12/24

�IPS160H, IPS161H

Open load in off-state

7.4

Open load in off-state

The IC provides the open load detection feature which detects if the load is disconnected from the OUT pin. This

feature can be activated by a resistor (RPU) between OUT and VCC pins.

Figure 7. Open load off-state

Application board

VCC

SUPPLY RAIL

IC

VCC

EXPOSED PAD

Open load

detection signal

R PU

+

-

OUT

VOLOFF

RI

R LED

R LOAD

PGND

GROUND PLANE

In case of wire break and during the OFF state (IN = low), the output voltage VOUT rises according to the the

partitioning between the external pull-up resistor and the internal impedence of the IC (130 kΩ < RI < 360 kΩ).

The effect of the LED (if any) on the output pin has to be considered as well. In case of wire break and during the

ON state (IN = high), the output voltage VOUT is pulled up to VCC by the low resistive integrated switch. If the load

is not connected, in order to guarantee the correct open load signalization it must result:

VOUT > VOLoff(max.)

Referring to the circuit in figure 6:

therefore:

VOUT = VCC − RPU × IPU = VCC − RPU × IRI + ILED + IRL

VCC min − VOLoff max

RPU < V

VOLoff max − VLED

OLoff max

+

RLED

RI min

(1)

(2)

If the load is connected, in order to avoid any false signalization of the open load, it must result as follows:

VOUT < VOLoff(min)

By taking into account the circuit in figure 6:

so:

VOUT = VCC − RPU × IPU = VCC − RPU ×

VOUT VOUT − VLED VOUT

+ R

RI +

RLED

L

VCC max − VOLoff min

RPU > V

VOLoff min − VLED VOLoff min

OLoff min

+

+

RLED

RL

RI max

(3)

(4)

The fault condition is reported on the DIAG pin and the fault reset occurs when load is reconnected.

If the channel is switched on by IN pin, the fault condition is no longer detected.

When inductive load is driven, some ringing of the output voltage may be observed at the end of the

demagnetization. In fact, the load is completely demagnetized when ILOAD = 0 A and the OUT pin remains

floating until next turn-on. In order to avoid a fake signalization of the open load event driving inductive loads, the

open load signal is masked for tBKT. So, the open load is reported on the DIAG pin with a delay of tBKT and if the

open load event is triggered for more than tBKT.

DS10907 - Rev 11

page 13/24

�IPS160H, IPS161H

VCC disconnection protection

7.5

VCC disconnection protection

The IC is protected despite the VCC disconnection event. This event is intended as the disconnection of the

VCC wire from the application board, see figure below. When this condition happens, the IC continues working

normally until the voltage on the VCC pin is ≥ VUVOFF. Once the VUVOFF is triggered, the output channel is turned

off independently on the input status. In case of inductive load, if the VCC is disconnected while the output channel

is still active, the IC allows the discharge of the energy still stored in the inductor through the integrated power

switch.

Figure 8. VCC disconnection

APPLICATION BOARD

VCC >VUVOFF

VCC

EXPOSED

PAD

CVCC

SUPPLY RAIL

ON

DRIVING

CIRCUITRY

OUT

IC

GND

GROUND PLANE

7.6

GND disconnection protection

GND disconnection is intended as the disconnection event of the application ground, see figure below. When this

event happens, the IC continues working normally until the voltage between VCC and GND pins of the IC results ≥

VUVOFF. The voltage on GND pin of the IC rises up to the supply rail voltage level. In case of GND disconnection

event, a current (ILGND) flows through OUT pin. Table 7. Logic inputs reports IOUT = ILGND for the worst case of

GND disconnection event in case of output shorted to ground.

Figure 9. GND disconnection

APPLICATION BOARD

SUPPLY RAIL

VCC

VCC

EXPOSED

PAD

CVCC

DRIVING

CIRCUITRY

ON

OUT

IC

LOAD

GROUND PLANE

DS10907 - Rev 11

GND

page 14/24

�IPS160H, IPS161H

Active VDS clamp

8

Active VDS clamp

Active clamp is also known as fast demagnetization of inductive loads or fast current decay. When a high-side

driver turns off an inductance, an undervoltage is detected on output.

The OUT pin is pulled down to Vdemag. The conduction state is modulated by an internal circuitry in order to keep

the OUT pin voltage at about Vdemag until the load energy has been dissipated. The energy is dissipated both in

IC internal switch and in load resistance.

Figure 10. Active clamp equivalent principle schematic

APPLICATION BOARD

SUPPLY RAIL

IC

VCC

EXPOSED PAD

Clamp

circuitry

OUT

L LOAD

GROUND PLANE

GND

Figure 11. Fast demag waveforms

IOUT

tON

tDEMAG

~

ILOAD

t

VOUT

~

VCC

t

VCC-VDEMAG

VIN

~

t

The demagnetization of inductive load causes a huge electrical and thermal stress to the IC. The curve plotted

below shows the maximum demagnetization energy that the IC can support in a single demagnetization pulse

with VCC = 24 V and TAMB = 125 °C. If higher demagnetization energy is required then an external free-wheeling

Schottky diode has to be connected between OUT (cathode) and GND (anode) pins. Note that in this case the

fast demagnetization is inhibited.

DS10907 - Rev 11

page 15/24

�IPS160H, IPS161H

Active VDS clamp

Figure 12. Typical demagnetization energy (single pulse) at VCC = 24 V and TAMB = 125 °C

4000

3500

EDEMAG [mJ]

3000

2500

2000

1500

1000

500

0

500

700

900

1100

1300

ILOAD

DS10907 - Rev 11

1500

1700

1900

2100

2300

2500

[mA]

page 16/24

�IPS160H, IPS161H

Package information

9

Package information

In order to meet environmental requirements, ST offers these devices in different grades of ECOPACK packages,

depending on their level of environmental compliance. ECOPACK specifications, grade definitions and product

status are available at: www.st.com. ECOPACK is an ST trademark.

9.1

PowerSSO12 package information

Figure 13. PowerSSO12 package outline

7392413 rev. D

Table 11. PowerSSO12 package mechanical data

Dim.

mm

Min.

Max.

A

1.250

1.700

A1

0.000

0.100

A2

1.100

1.600

B

0.230

0.410

C

0.190

0.250

D

4.800

5.000

E

3.800

4.000

e

0.800

H

5.800

6.200

h

0.250

0.55

L

0.400

1.270

k

0d

8d

X

1.900

2.500

Y

3.600

4.200

ddd

DS10907 - Rev 11

Typ.

0.100

page 17/24

�IPS160H, IPS161H

PowerSSO12 package information

Note:

Dimension D doesn't include mold flash protrusions or gate burrs. Mold flash protrusions or gate burrs don't

exceed 0.15 mm in total both side.

Figure 14. PowerSSO12 recommended footprint

Figure 15. PowerSSO12 tape packing information [mm]

DS10907 - Rev 11

page 18/24

�IPS160H, IPS161H

PowerSSO12 package information

Figure 16. PowerSS012 reel packing information [mm]

DS10907 - Rev 11

page 19/24

�IPS160H, IPS161H

Revision history

Table 12. Document revision history

Date

Revision

19-Mar-2015

1

Changes

Initial release.

Minor text changes throughout the document.

04-Nov-2015

Added figure 7 titled "VCC disconnection", figure 10 titled: "Fast demag

waveforms" and figure 11 titled "Typical demagnetization energy (single pulse)

at VCC = 24 V and TAMB = 125 °C.

Updated tables titled: "Supply", "Switching (VCC = 24 V; 125 °C > TJ > -40 °C,

RLOAD = 48 Ω)" and "Protection diagnostic".

11-May-2016

3

20-May-2016

4

Document status promoted from preliminary to production data.

08-Mar-2018

5

Updated EAS value in Table 2. Absolute maximum ratings

14-Dec-2018

6

Added reel packaging information in Section 9.1 PowerSSO12 package

information

02-Dec-2019

7

Updated value in Table 4. Supply. Text change in Section 2.4 CoD. Change

to Figure 16 title.

03-Mar-2021

8

Merged IPS160H and IPS161H datasheets. Updated Section Description and

Section Applications target.

29-Mar-2021

9

Updated ILGND max value in Table 4

30-Jul-2021

10

Reviewed the feature list order in front page. Updated thermal data in Table 3

according to Jedec conditions

11

Updated Table Table 6. Switching (VCC = 24 V; -40 °C < TJ < 125 °C,

RLOAD = 48 Ω): filled column Max, added tD(VCC-ON) parameter. Added figure

Figure 5. Propagation delay at start-up. Added parameter IPK (activation

threshold of current activation feature) in table Table 8. Protection and

diagnostic. Reduced minimum and maximum values of ILIM for IPS160H in

table Table 8. Protection and diagnostic.

06-Dec-2022

DS10907 - Rev 11

2

Changed figures titled: "tPD(L-H) and tPD(H-L)" and "Current limitation and cutoff".

page 20/24

�IPS160H, IPS161H

Contents

Contents

1

Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2

Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1

IN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2

OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3

DIAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4

CoD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5

GND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.6

VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3

Reverse polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

4

Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5

Electrical characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6

Output logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

7

Protection and diagnostic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

7.1

Undervoltage lock-out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.2

Overtemperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.3

Cut-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.4

Open load in off-state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.5

VCC disconnection protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.6

GND disconnection protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8

Active clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

9

Package information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

9.1

PowerSSO12 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

DS10907 - Rev 11

page 21/24

�IPS160H, IPS161H

List of tables

List of tables

Table 1.

Table 2.

Table 3.

Table 4.

Table 5.

Table 6.

Table 7.

Table 8.

Table 9.

Table 10.

Table 11.

Table 12.

Pin configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . .

Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switching (VCC = 24 V; -40 °C < TJ < 125 °C, RLOAD = 48 Ω).

Logic inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Protection and diagnostic . . . . . . . . . . . . . . . . . . . . . . . . .

Output stage truth table . . . . . . . . . . . . . . . . . . . . . . . . . .

Minimum cut-off delay for TAMB less than -20 °C . . . . . . . . .

PowerSSO12 package mechanical data . . . . . . . . . . . . . . .

Document revision history . . . . . . . . . . . . . . . . . . . . . . . . .

DS10907 - Rev 11

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 3

. 6

. 6

. 7

. 7

. 8

. 9

. 9

10

12

17

20

page 22/24

�IPS160H, IPS161H

List of figures

List of figures

Figure 1.

Figure 2.

Figure 3.

Figure 4.

Figure 5.

Figure 6.

Figure 7.

Figure 8.

Figure 9.

Figure 10.

Figure 11.

Figure 12.

Figure 13.

Figure 14.

Figure 15.

Figure 16.

Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pin connection (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reverse polarity protection schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing in normal operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Propagation delay at start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current limitation and cut-off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open load off-state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VCC disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GND disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Active clamp equivalent principle schematic . . . . . . . . . . . . . . . . . . . . . . . . . .

Fast demag waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical demagnetization energy (single pulse) at VCC = 24 V and TAMB = 125 °C

PowerSSO12 package outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PowerSSO12 recommended footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PowerSSO12 tape packing information [mm] . . . . . . . . . . . . . . . . . . . . . . . . .

PowerSS012 reel packing information [mm] . . . . . . . . . . . . . . . . . . . . . . . . . .

DS10907 - Rev 11

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. 2

. 3

. 5

. 8

. 8

11

13

14

14

15

15

16

17

18

18

19

page 23/24

�IPS160H, IPS161H

IMPORTANT NOTICE – READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgment.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, refer to www.st.com/trademarks. All other product or service names

are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2022 STMicroelectronics – All rights reserved

DS10907 - Rev 11

page 24/24

�