ST1S15

500 mA, 6 MHz synchronous step-down converter

Datasheet - production data

Description

Features

85% typical efficiency

500 mA output current capability

45 µA typical quiescent current

PFM or PWM operation for best efficiency

over whole load range

Ultra-fast load and line transient

Short-circuit and thermal protection

Small external components

Auto or forced PWM selection with

dedicated pin

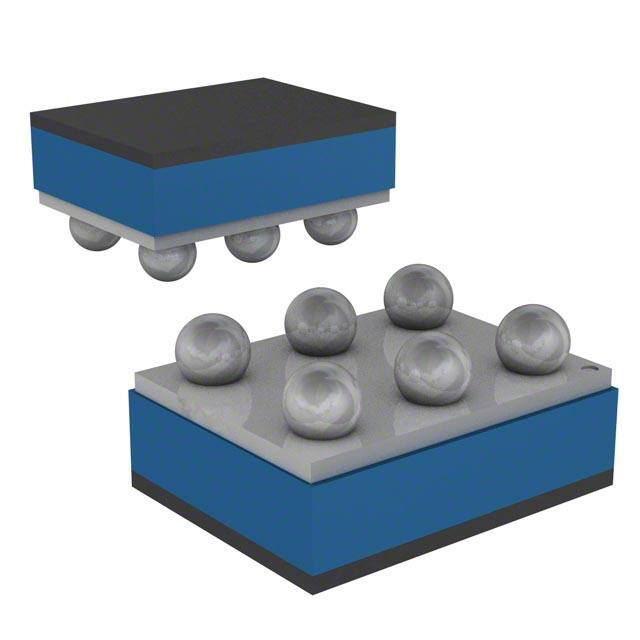

Available in Flip Chip 6 package

The ST1S15 is a high efficiency miniaturized

step-down converter able to provide 500 mA

output current from an input voltage from 2.3 V to

5.5 V. This converter is specifically designed for

applications where high efficiency and small

application area are the key factors. Thanks to

6 MHz switching frequency, the ST1S15 can use

470 nH nominal values for the inductor and

4.7 µF for the output capacitor providing, at the

same time, very good performance in terms of

load and line transients. A PFM mode can be

selected for high efficiency under light load

conditions or PWM mode for tight regulation and

best dynamic performance. Short-circuit and

thermal protection are also included.

Table 1: Device summary

Order code

Output

voltage (V)

Package

ST1S15J18R

1.82

Flip Chip 6

Applications

DSP and multimedia processor core supply

Cell phones

PDAs

February 2015

DocID023280 Rev 4

This is information on a product in full production.

1/27

www.st.com

�Contents

ST1S15

Contents

1

Application schematic .................................................................... 5

2

Pin configuration ............................................................................. 6

3

Maximum ratings ............................................................................. 7

4

5

Electrical characteristics ................................................................ 8

Typical performance characteristics ........................................... 10

6

Block schematic ............................................................................ 13

7

Detailed description ...................................................................... 14

8

7.1

General description ......................................................................... 14

7.2

Mode transition................................................................................ 14

7.3

Soft-start ......................................................................................... 15

7.4

Short-circuit protection .................................................................... 15

7.5

Undervoltage lockout (UVLO) ......................................................... 15

7.6

Thermal protection .......................................................................... 16

7.7

Overcurrent protection .................................................................... 16

7.8

Enable function ............................................................................... 16

Application information ................................................................ 17

8.1

Input and output capacitors ............................................................. 17

8.2

Inductor ........................................................................................... 17

8.3

Layout guidelines ............................................................................ 18

9

Different output voltage versions of the ST1S15 available on

request .................................................................................................... 19

10

11

2/27

Package information ..................................................................... 20

10.1

Flip Chip 6 package information ...................................................... 21

10.2

Packing information ......................................................................... 24

Revision history ............................................................................ 26

DocID023280 Rev 4

�ST1S15

List of tables

List of tables

Table 1: Device summary ........................................................................................................................... 1

Table 2: Typical external components ........................................................................................................ 5

Table 3: Pin description .............................................................................................................................. 6

Table 4: Absolute maximum ratings ........................................................................................................... 7

Table 5: Thermal data ................................................................................................................................. 7

Table 6: ESD performance ......................................................................................................................... 7

Table 7: Electrical characteristics ............................................................................................................... 8

Table 8: Inductors ..................................................................................................................................... 17

Table 9: Flip Chip 6 mechanical data ....................................................................................................... 22

Table 10: Tape and reel mechanical data ................................................................................................ 25

Table 11: Document revision history ........................................................................................................ 26

DocID023280 Rev 4

3/27

�List of figures

ST1S15

List of figures

Figure 1: ST1S15 application schematic .................................................................................................... 5

Figure 2: Pin connections (top view) ........................................................................................................... 6

Figure 3: Efficiency vs. output current ...................................................................................................... 10

Figure 4: Output voltage vs. input voltage ................................................................................................ 10

Figure 5: Supply current vs. input voltage in auto mode .......................................................................... 10

Figure 6: Supply current vs. input voltage in PWM mode ......................................................................... 10

Figure 7: Output voltage vs. output current .............................................................................................. 10

Figure 8: Frequency vs. input voltage ....................................................................................................... 10

Figure 9: Output voltage vs. output current VIN=3.6 V .............................................................................. 11

Figure 10: Mode transition vs. input voltage ............................................................................................. 11

Figure 11: Mode transition PFM to PWM.................................................................................................. 11

Figure 12: Output voltage ripple (no-load) ................................................................................................ 11

Figure 13: Output voltage ripple ............................................................................................................... 11

Figure 14: Line transient ........................................................................................................................... 11

Figure 15: Load transient IOUT = 50 to 250 mA ......................................................................................... 12

Figure 16: Load transient IOUT = 250 to 50 mA ......................................................................................... 12

Figure 17: Enable startup ......................................................................................................................... 12

Figure 18: VIN startup ................................................................................................................................ 12

Figure 19: Block schematic ....................................................................................................................... 13

Figure 20: PFM to PWM transition ............................................................................................................ 14

Figure 21: PWM to PFM transition ............................................................................................................ 15

Figure 22: Flip Chip layout recommended (not in scale) .......................................................................... 18

Figure 23: Flip Chip 6 package outline ..................................................................................................... 21

Figure 24: Flip Chip 6 footprint recommended data (mm) ........................................................................ 23

Figure 25: Tape and reel outline ............................................................................................................... 24

4/27

DocID023280 Rev 4

�ST1S15

1

Application schematic

Application schematic

Figure 1: ST1S15 application schematic

Table 2: Typical external components

Component

Manufacturer

CIN

Part number

Size

4.7 µF

0402

470 nH

2.0 x 1.25 x 0.5 mm

GRM155R60J475ME87

GRM155R60G475ME87

COUT

Value

Murata

(1)

GRM155R60J475ME87

L

LQM21PNR47MC0D

Notes:

(1)

VOUT ≤ 1.82 V

All the above components refer to a typical application. The ST1S15 operation is

not limited to the choice of these external components.

DocID023280 Rev 4

5/27

�Pin configuration

2

ST1S15

Pin configuration

Figure 2: Pin connections (top view)

MARKING VIEW

BUMP VIEW

A1

A2

A2

A1

B1

B2

B2

B1

C1

C2

C2

C1

GIPG0901151142LM

Table 3: Pin description

Pin

Flip Chip

VIN

A2

High-side switch connection and IC supply.

EN

B2

ENABLE pin with positive logic. The IC shuts down if pulled

low. Do not leave this pin floating.

GND

C2

Power and IC supply ground.

FB

C1

Feedback input.

SW

B1

Inductor connection to internal PFET and NFET.

A1

Operation mode selection:

LOW = automatic operation PFM or PWM according to

output load.

HIGH = forced PWM operation.

Do not leave this pin floating.

MODE

6/27

Description

DocID023280 Rev 4

�ST1S15

3

Maximum ratings

Maximum ratings

Table 4: Absolute maximum ratings

Symbol

Parameter

Value

Unit

VIN

Power and signal supply voltage

- 0.3 to + 6.0

V

Logic input pins

- 0.3 to + 6.0

V

-0.3 to VIN + 0.3

V

Operating ambient temperature

- 40 to 85

°C

Junction temperature

- 40 to 150

°C

EN, MODE

FB, SW

TAMB

TJ

Feedback and switching pins

Absolute maximum ratings are those values beyond which damage to the device

may occur. Functional operation under these conditions is not implied.

Table 5: Thermal data

Symbol

Parameter

Flip Chip

Unit

RthJA

Thermal resistance junction-ambient

130

°C/W

Flip Chip

Unit

Table 6: ESD performance

Symbol

ESD

Parameter

Human body model

±2000

Machine model

±100

DocID023280 Rev 4

V

7/27

�Electrical characteristics

4

ST1S15

Electrical characteristics

- 40 °C < TA < 85 °C, CIN = 4.7 µF nominal, COUT = 4.7 µF nominal, L = 470 nH, typical

values are at TA = 25 °C, VEN = VIN unless otherwise specified.

Table 7: Electrical characteristics

Symbol

Parameter

Test conditions

Min.

Typ.

Max.

Unit

5.5

V

General section

VIN

VUVLO

IQ

Operating input voltage range

Undervoltage lockout

threshold

VIN rising

PFM mode quiescent current

No load

45

PWM mode quiescent current

No load

15

Shutdown current

VEN = 0

VIN falling

fSW

Switching frequency

IOUT

Continuous output current

ISC

IPFM-PWM

h

tON

TSHDN

2.3

Short-circuit current

2.1

1.8

5.4

(1)

VIN ≥ VOUT + 0.40 V

2.2

1.9

60

mA

5

µA

6

6.6

MHz

500

mA

1200

200

VIN = 3.6 V, VOUT = 1.82 V

PWM to PFM transition

µA

0.5

(2)

PFM to PWM transition

V

mA

mA

100

IOUT = 10 mA PFM mode

80

IOUT = 150 mA

83

VEN from low to high,

VIN = 3.6 V, VOUT = 1.82 V

260

µs

Thermal shutdown

125

°C

Hysteresis

30

°C

Efficiency

(VIN = 3.6 V, VOUT = 1.82 V)

Start-up time

%

Output voltage

Accuracy (ST1S15J18)

VOUT

ILKFB

8/27

Peak-to-peak output voltage

ripple

FB pin leakage current

1.78

2.3 ≤ VIN ≤ 5.5 V,

IOUT= 10 mA, PFM mode,

-40 ≤ TA ≤ 85 °C

1.78

2.3 ≤ VIN ≤ 5.5 V,

VOUT=1.82 V, IOUT = 0 to

500 mA, PWM mode,

-40 ≤ TA ≤ 85 °C

Load regulation

VOUT_Ripple

2.3 ≤ VIN ≤ 5.5 V,

IOUT= 10 mA, PWM mode,

-40 ≤ TA ≤ 85 °C

1.82

1.86

V

1.82

1.86

-1.5

%

PWM mode,

IOUT = 150 mA, VIN = 3.6 V,

VOUT = 1.82 V

10

mV

PFM mode,

IOUT = 150 mA, VIN = 3.6 V,

VOUT = 1.82 V

30

mV

VFB = 5.5 V

DocID023280 Rev 4

9

µA

�ST1S15

Electrical characteristics

Symbol

Parameter

Test conditions

VIN_TR

Line transient response.

Output voltage variation over

the nominal DC level

tR = tF = 10 µs

case 1: VIN = 2.5 to 3.1 V

case 2: VIN = 3.9 to 4.5 V

IOUT_TR

Load transient response

tR= tF= 0.1 µs

case 1: VIN = 2.5 V

case 2: VIN = 3.6 V

case 3: VIN = 4.5 V

Min.

Typ.

Max.

Unit

IOUT = 50 mA,

VOUT = 1.82 V

±50

IOUT = 250 mA,

VOUT = 1.82 V

IOUT = 0 to 150 mA,

VOUT = 1.82 V

±50

IOUT = 50 to 250 mA,

VOUT = 1.82 V

±70

IOUT = 150 to 400 mA,

VOUT = 1.82 V

±70

mV

mV

Logic inputs

VIL

Low-level input voltage

(EN, MODE pins)

VIH

High-level input voltage

(EN, MODE pins)

ILK-I

Input leakage current

(EN, MODE pins)

0.4

V

1.2

VEN = VMODE = 5.5 V

V

0.01

1

µA

P-channel MOSFET

on-resistance

300

400

N-channel MOSFET

on-resistance

350

450

1000

1200

mA

Power switches

RDS(on)

mΩ

ILPEAK

P-channel peak current limit

Over the input voltage

range

ILKG-P

P-channel leakage current

VIN = 5.5 V, VEN= 0

1

µA

ILKG-N

N-channel leakage current

VSW = 5.5 V, VEN= 0

1

µA

900

Notes:

(1)

(2)

Not tested in production. This value is guaranteed by correlation with RDS(on), peak current limit and operating input voltage.

Not tested in production. This parameter is guaranteed by peak current limit.

DocID023280 Rev 4

9/27

�Typical performance characteristics

5

ST1S15

Typical performance characteristics

Figure 3: Efficiency vs. output current

(VOUT = 1.82 V)

Figure 4: Output voltage vs. input voltage

Figure 5: Supply current vs. input voltage in auto

mode

Figure 6: Supply current vs. input voltage in PWM

mode

Figure 7: Output voltage vs. output current

Figure 8: Frequency vs. input voltage

10/27

DocID023280 Rev 4

�ST1S15

Typical performance characteristics

Figure 10: Mode transition vs. input voltage

Figure 9: Output voltage vs. output current VIN=3.6 V

Figure 11: Mode transition PFM to PWM

Figure 12: Output voltage ripple (no-load)

Figure 13: Output voltage ripple

Figure 14: Line transient

DocID023280 Rev 4

11/27

�Typical performance characteristics

ST1S15

Figure 15: Load transient IOUT = 50 to 250 mA

Figure 16: Load transient IOUT = 250 to 50 mA

Figure 17: Enable startup

Figure 18: VIN startup

12/27

DocID023280 Rev 4

�ST1S15

6

Block schematic

Block schematic

Figure 19: Block schematic

EN

Enable and

soft-start

V - I reference

and

prereg + UVLO

VIN

Current limit and short protection

MODE

PFM- analog timing

PFM - PWM

Switch control logic

Oscillator

and

sawtooth

Driver

and

anti X - cond

SW

Thermal protection

Vref_PFM

FB

PW M comparator

R1

GND

Error amp and comp.

R2

Vref_PW M

GIPG1401151127LM

DocID023280 Rev 4

13/27

�Detailed description

ST1S15

7

Detailed description

7.1

General description

The ST1S15 is a fixed voltage mode PWM step-down DC-DC converter, which operates

with typically 6 MHz fixed frequency pulse width modulation (PWM) at moderate and heavy

load currents. At light load currents the converter can automatically enter PFM (pulse

frequency mode) mode.

Few components are required: an inductor and two capacitors. It can work properly with

X5R or X7R SMD ceramic capacitors both at the input and at the output. These kinds of

capacitors, thanks to their very low series resistance (ESR), minimize the output voltage

ripple. In addition, the chosen inductor must not saturate at the peak current level.

7.2

Mode transition

The ST1S15 can work in PWM mode or in PFM mode according to the different operating

conditions. If the MODE pin is pulled high, the device works in PWM mode only even at

light or no-load. If the MODE pin is low, the operation changes according to the average

input current handled by the device. At low output current the device works in PFM mode

so to obtain very low power consumption and very good efficiency. When the output current

increases, the device automatically switches to PWM mode in order to deliver the power

needed by the load.

The ST1S15 passes from PFM to PWM when 3 consecutive PFM pulses occur. This

means that the PFM has reached its maximum current capability and the device needs to

go into PWM mode. The whole PWM circuitry starts after a transition time. During this time

the duration of the PFM pulses rises about 350 ns so to provide higher current capability.

After the PWM circuitry startup, the ST1S15 switches to PWM operation.

Figure 20: PFM to PWM transition

14/27

DocID023280 Rev 4

�ST1S15

Detailed description

The transition from PWM to PFM mode occurs when the load current decreases and the

coil current becomes negative. After the zero-crossing output goes up for 127 consecutive

times the device switches to PFM mode.

Figure 21: PWM to PFM transition

7.3

Soft-start

The internal soft-start is enabled after VIN reaches the UVLO threshold and the EN pin is

high or for startup after enable. An overtemperature shutdown event or over short-circuit

event also activates the soft-start sequence.

It eliminates the in-rush current problem during the start-up phase. During the soft-start the

device always works in PWM regardless of the status of the MODE pin.

7.4

Short-circuit protection

The short-circuit protection begins when there is a short between the device output and

ground. In this case the output voltage value is lower than the voltage reference and the

overcurrent protection comparator output is high.

When this happens the power stage (P-channel and N-channel) turns off and a soft-start

phase starts. The device repeats the soft-start sequence during the short-circuit condition.

7.5

Undervoltage lockout (UVLO)

The UVLO circuit prevents the device from malfunctioning when the input voltage is not

high enough. The device is in shutdown mode, when the input voltage is below the UVLO

threshold. The hysteresis of 200 mV prevents unstable operation when the input voltage is

close to the UVLO threshold.

DocID023280 Rev 4

15/27

�Detailed description

7.6

ST1S15

Thermal protection

The device also has thermal shutdown protection, which is active when the junction

temperature reaches 125 °C. In this case both the high and low-side MOSFETs turn off.

Once the junction temperature goes back below 95 °C, the device resumes normal

operation.

7.7

Overcurrent protection

The overcurrent protection limits the maximum inductor current. This current, flowing

through the P-channel of the power stage, causes a voltage drop, across its R DS(on), at the

switching node. A comparator compares the switching node voltage with a reference

voltage VR. To generate the VR voltage a current generator is used, which causes a drop

across a P-channel of the same kind as the power stage. When the switching node voltage

is lower than VR, the comparator output goes high and the power P-channel turns off.

7.8

Enable function

The ST1S15 features an enable function (B2). When the EN voltage is higher than 1.2 V

the device is ON, and if it is lower than 0.4 V the device is OFF. In shutdown mode the

consumption is lower than 5 µA. The EN pin does not have an internal pull-up, which

means that the EN pin cannot be left floating. If the enable function is not used, the EN pin

must be connected to VIN.

16/27

DocID023280 Rev 4

�ST1S15

Application information

8

Application information

8.1

Input and output capacitors

Ceramic capacitors with X5R or X7R dielectric and low ESR should be used. The input

capacitor filters any disturbance present in the input line so to obtain a stable operation.

The output capacitor satisfies the output voltage ripple requirement. The output voltage

ripple (VOUT_RIPPLE), in continuous mode, is calculated as follows:

Equation 1

VOUT_RIPPLE = IL

VIN ESL

1

ESR + ---------------------------------------- + --------------------------8 C OUT f SW

L

where ΔIL is the ripple current and fSW is the switching frequency. The use of ceramic

capacitors with voltage ratings higher than 1.5 times the maximum input or output voltage

is recommended.

8.2

Inductor

The inductor is the key passive component for switching converters. The internal

compensation is optimized to operate with an output filter of L=0.47 µH and COUT=4.7 µF.

In addition to the inductance value, in order to avoid saturation, the maximum saturation

current of the inductor must be higher than IPEAK.

The peak current of the inductor has to be calculated as follows:

Equation 2

IPEAK = I

V OUT V IN_MAX – V OUT

OUT + --------------------------------------------------------------------2 V IN_MAX fSW L

The following inductor part numbers from different suppliers have been tested in the

ST1S15 converters.

Table 8: Inductors

Manufacturer

Murata

TDK

Part numbers

Dimension (mm)

LQM21PNR47MC0D

2.0 x 1.25 x 0.5

LQM21PNR54MG0D

2.0 x 1.25 x 0.5

LQH32PNR47NN0L

3.2 x 2.7 x 1.55

MLP2012SR47T

2.0 x 1.25 x 0.5

VLS2010ET-1R0N

2.0 x 2.0 x 1.0

DocID023280 Rev 4

17/27

�Application information

8.3

ST1S15

Layout guidelines

Due to the high switching frequency and peak current, the layout is an important design

step for all switching power supplies. If the layout is not fulfilled carefully, important

parameters such as: stability, efficiency, line and load regulation and output voltage ripple

may be compromised. Short, wide traces must be implemented for main current and for

power ground paths. The input capacitor must be placed as close as possible to the device

pin as well as the inductor and output capacitor. The feedback pin (FB) is a high

impedance node, so the interference can be minimized by placing the routing of the

feedback node as far as possible from the high current paths. A common ground node

minimizes ground noise.

Figure 22: Flip Chip layout recommended (not in scale)

VOUT

EN

GND

COUT

CIN

L

VIN

MODE

GIPG1401151337LM

18/27

DocID023280 Rev 4

�ST1S15

9

Different output voltage versions of the ST1S15

available on request

Different output voltage versions of the ST1S15

available on request

Options available on request:

0.8 V

1V

1.05 V

1.2 V

1.25 V

1.5 V

1.8 V

1.85 V

1.875 V

2.5 V

2.8 V

3.0 V

3.3 V

DocID023280 Rev 4

19/27

�Package information

10

ST1S15

Package information

In order to meet environmental requirements, ST offers these devices in different grades of

®

®

ECOPACK packages, depending on their level of environmental compliance. ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

®

ECOPACK is an ST trademark.

20/27

DocID023280 Rev 4

�ST1S15

10.1

Package information

Flip Chip 6 package information

Figure 23: Flip Chip 6 package outline

1

2

A B C

GIPG2301151335LM

DocID023280 Rev 4

21/27

�Package information

ST1S15

Table 9: Flip Chip 6 mechanical data

mm

Dim.

Min.

Typ.

Max.

A

0.52

0.56

0.6

A1

0.17

0.20

0.23

A2

0.35

0.36

0.37

b

0.23

0.25

0.29

D

1.16

1.19

1.22

D1

0.8

e

0.4

E

0.905

0.935

E1

0.4

fD

0.267

fE

0.195

SE

0.2

ccc

0.075

0.965

The terminal A1 on the bump side is identified by a distinguishing feature (for

instance by a circular "clear area" typically 0.1 mm diameter) and/or a missing

bump. The terminal A1 on the backside of the product is identified by a

distinguishing feature (for instance by a circular "clear area" typically 0.5 mm

diameter).

22/27

DocID023280 Rev 4

�ST1S15

Package information

Figure 24: Flip Chip 6 footprint recommended data (mm)

DocID023280 Rev 4

23/27

�Package information

10.2

ST1S15

Packing information

Figure 25: Tape and reel outline

Drawing not in scale

24/27

DocID023280 Rev 4

�ST1S15

Package information

Table 10: Tape and reel mechanical data

mm

Dim.

Min.

Typ.

A

Max.

180

C

12.8

D

20.2

N

60

13.2

T

14.4

Ao

1.01

1.06

1.11

Bo

1.26

1.31

1.36

Ko

0.61

0.66

0.71

Po

3.9

4.1

P

3.9

4.1

DocID023280 Rev 4

25/27

�Revision history

11

ST1S15

Revision history

Table 11: Document revision history

26/27

Date

Revision

Changes

07-Jun-2012

1

Initial release.

4-Mar-2013

2

Modified: D1 and E1 values in table 9.

27-Aug-2013

3

Updated: table 1, table 7, section 9 and Package

mechanical data.

24-Feb-2015

4

Deleted DFN package.

DocID023280 Rev 4

�ST1S15

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and

improvements to ST products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST

products before placing orders. ST products are sold pursuant to ST’s terms and conditions of sale in place at the time of order

acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the

design of Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. All other product or service names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2015 STMicroelectronics – All rights reserved

DocID023280 Rev 4

27/27

�