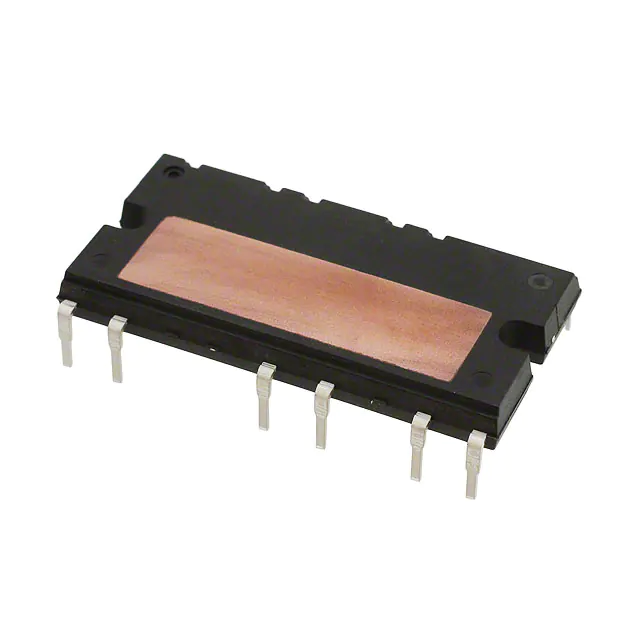

STGIPL35K120L1

SLLIMM™ (small low-loss intelligent molded module)

IPM, single phase - 35 A, 1200 V short-circuit rugged IGBT

Datasheet − preliminary data

Features

■

IPM 35 A, 1200 V single phase IGBT including

control ICs for gate driving and free-wheeling

diodes

■

Short-circuit rugged IGBTs

■

VCE(sat) negative temperature coefficient

■

Active Miller clamp feature

■

Undervoltage lockout

■

Desaturation detection

■

Fault status output

■

Input compatible with pulse transformer or

optocoupler

■

DBC substrate leading to low thermal

resistance

■

Isolation rating of 2500 Vrms/min

■

4.7 kΩ NTC for temperature control

)

s

(

ct

u

d

o

let

r

P

e

o

s

b

SDIP-18L

O

)

s

(

t

c

u

d

o

Applications

r

P

Description

e

t

e

l

o

s

b

O

■

Power inverters

This intelligent power module provides a compact,

high performance AC motor drive for a simple and

rugged design. It targets power inverters for air

conditioners. It combines ST proprietary control

ICs with the most advanced short-circuit rugged

IGBT system technology. SLLIMM™ is a

trademark of STMicroelectronics.

Table 1.

Device summary

Order code

Marking

Package

Packaging

STGIPL35K120L1

GIPL35K120L1

SDIP-18L

Tube

February 2013

Doc ID 022751 Rev 4

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to

change without notice.

1/19

www.st.com

19

�Contents

STGIPL35K120L1

Contents

1

Internal block diagram and pin configuration . . . . . . . . . . . . . . . . . . . . 3

2

Electrical ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3

2.1

Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2

Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1

3.1.1

3.2

4

)

s

(

ct

Control part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

u

d

o

NTC thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

r

P

e

Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

t

e

l

o

4.1

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2

Voltage reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3

Desaturation protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4

Active Miller clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5

Fault status output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.6

Undervoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

)

(s

s

b

O

t

c

u

d

o

r

5

Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

P

e

t

e

l

o

6

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

s

b

O

2/19

Doc ID 022751 Rev 4

�STGIPL35K120L1

1

Internal block diagram and pin configuration

Internal block diagram and pin configuration

Figure 1.

Internal block diagram

)

s

(

ct

u

d

o

r

P

e

t

e

l

o

)

(s

s

b

O

t

c

u

d

o

r

P

e

t

e

l

o

s

b

O

Doc ID 022751 Rev 4

3/19

�Internal block diagram and pin configuration

Table 2.

STGIPL35K120L1

Pin description

Pin

Symbol

1

VH-H

2

HIN

3

VREF-H

High side gate driver +5 V reference voltage

4

FAULT-H

High side gate driver fault output status

5

GND-H

High side gate driver ground

6

T1

NTC thermistor terminal 1

7

T2

NTC thermistor terminal 2

8

VH-L

9

LIN

10

VREF-L

Low side gate driver +5 V reference voltage

11

FAULT-L

Low side gate driver fault output status

12

GND-L

Low side gate driver ground

13

N

Negative DC input

14

N

Negative DC input

15

PHASE

Phase output

16

PHASE

Phase output

17

P

High side gate driver power supply

High side logic input (active low)

P

d

o

r

)

s

(

ct

Low side gate driver power supply

Low side logic input (active low)

u

d

o

r

P

e

t

e

l

o

)

(s

t

c

u

18

Figure 2.

Description

s

b

O

Positive DC input

Positive DC input

Pin layout (bottom view)

12 11 10 9

P

e

8

7

6

5

4

3

2

1

t

e

l

o

s

b

O

Marking area

13

14

15

16

17

18

AM09388v1

4/19

Doc ID 022751 Rev 4

�STGIPL35K120L1

Electrical ratings

2

Electrical ratings

2.1

Absolute maximum ratings

Table 3.

Inverter part

Symbol

Parameter

Value

Unit

1200

V

Each IGBT continuous collector current

at TC = 25°C

35

A

Each IGBT pulsed collector current

70

PTOT

Each IGBT total dissipation at TC = 25°C

100

tscw

Short circuit withstand time, VCE = 0.5 V(BR)CES

TJ = 125 °C, VH-H = 15 V, VI= 1 "logic state"

(s)

Each IGBT collector emitter voltage

VCE

± IC(1)

± ICP (2)

1. Calculated according to the iterative formula:

A

ct

du

5

W

µs

o

r

P

Tj ( max ) – TC

IC ( T C ) = ------------------------------------------------------------------------------------------------------R thj – c × V CE ( sat ) ( max ) ( T j ( max ), I C ( T C ) )

e

t

e

ol

2. Pulse width limited by max junction temperature

Table 4.

Control part

Symbol

VH

)

(s

ct

Vfault

Voltage on FAULT pin

Vother

Voltage on other pins (IN, VREF)

ete

du

o

r

P

Symbol

s

b

O

Parameter

Maximum VH-H, VH-L voltages vs. GND

Table 5.

ol

s

b

O

Value

Unit

28

V

-0.3 to VH+0.3

V

-0.3 to 7

V

Value

Unit

2500

V

Total system

Parameter

VISO

Isolation withstand voltage applied between each

pin and heatsink plate (AC voltage, t = 60 sec.)

TJ (1)

Operating junction temperature for IGBT and diode

-40 to 150

°C

Module case operation temperature

-40 to 125

°C

TC

1. The maximum junction temperature rating of the power chips integrated within the SDIP module is 150 °C

(@TC ≤ 100 °C). To ensure safe operation of the NDIP module, the average junction temperature should

be limited to TJ(avg) ≤ 125 °C (@TC ≤ 100 °C).

Doc ID 022751 Rev 4

5/19

�Electrical ratings

2.2

STGIPL35K120L1

Thermal data

Table 6.

Thermal data

Symbol

RthJC

Figure 3.

Parameter

Value

Unit

Thermal resistance junction-case single IGBT

0.9

°C/W

Thermal resistance junction-case single diode

1.4

°C/W

Transient thermal impedance IGBT/diode - inverter

AM09392v1

10

)

s

(

ct

DIODE

ZTH(J-C) [K/W]

1

0.1

t

e

l

o

0.01

1.E-05

1.E-04

od

r

P

e

)

(s

t

c

u

0.001

1.E-03

s

b

O

1.E-02

time [s]

t

e

l

o

s

b

O

6/19

u

d

o

r

P

e

IGBT

Doc ID 022751 Rev 4

1.E-01

1.E+00

1.E+01

�STGIPL35K120L1

3

Electrical characteristics

Electrical characteristics

TJ = 25 °C unless otherwise specified.

Table 7.

Inverter part

Value

Symbol

Parameter

ICES

VF

Unit

Min.

Typ.

Max.

VH-H (VH-L) = 15 V, VIN (1) = 1 "logic

state", IC = 30 A

-

2.8

3.6

VH-H (VH-L) = 15 V, VIN (1) = 1 "logic

state", IC = 30 A, TJ = 125°C

-

2.4

Collector-cut off current

(VIN (1)= 0 “logic state”)

VCE = 1200 V, VH-H (VH-L) = 15 V

-

Diode forward voltage

VIN (1) = 0 "logic state", IF = 30 A

-

u

d

o

-

720

-

-

300

-

-

880

-

-

275

-

-

520

-

-

3.7

-

-

1.9

-

-

820

-

-

350

-

-

1400

-

-

700

-

-

620

-

-

5.6

-

-

5.8

-

Collector-emitter

saturation voltage

VCE(sat)

Test conditions

V

r

P

e

Switching on/off (inductive load) (2)

ton

tc(on)

Crossover time (on)

toff

Turn-off time

tc(off)

Crossover time (off)

trr

Reverse recovery time

Eon

Turn-on switching losses

Eoff

Turn-off switching losses

ton

Turn-on time

toff

e

t

e

l

tc(off)

o

s

b

O

Pr

Turn-off time

o

s

b

VDD = 600 V,

VH-H (VH-L) = 15 V,

VIN = 1 "logic state" (see Table 9)

IC = 30 A (see Figure 4 and 5)

O

)

s

(

t

c

u

d

o

Crossover time (on)

tc(on)

trr

let

Turn-on time

Crossover time (off)

Reverse recovery time

Eon

Turn-on switching losses

Eoff

Turn-off switching losses

VDD = 600 V,

VH-H (VH-L) = 15 V,

VIN = 1 "logic state" (see Table 9)

IC = 30 A, TJ = 125 °C

(see Figure 4 and 5)

)

s

(

ct

10

mA

2.3

V

ns

mJ

ns

mJ

1. See Table 9: Truth table.

2. tON and tOFF include the propagation delay time of the internal drive. tC(ON) and tC(OFF) are the switching time of IGBT itself

under the internally given gate driving condition. Parameter values take into account a 20 nH stray inductance.

Doc ID 022751 Rev 4

7/19

�Electrical characteristics

Figure 4.

STGIPL35K120L1

Switching time test circuit

)

s

(

ct

u

d

o

r

P

e

t

e

l

o

Figure 5.

s

b

O

Switching time definition

)

(s

100% IC 100% IC

t rr

t

c

u

od

r

P

e

IC

VCE

VCE

IC

t

e

l

o

s

b

O

VIN

VIN

t ON

t OFF

t C(OFF)

t C(ON)

VIN(ON)

10% IC 90% IC 10% VCE

(a) turn-on

8/19

VIN(OFF)

10% VCE

(b) turn-off

Doc ID 022751 Rev 4

10% IC

AM09390v1

�STGIPL35K120L1

3.1

Electrical characteristics

Control part

TA = - 20 to 125 °C, VH = 16 V (unless otherwise specified).

Table 8.

Electrical characteristics

Symbol

Parameter

Test condition

Min

Typ

0.8

1.0

Max

Unit

Input

Vton

IN turn-on threshold voltage

Vtoff

IN turn-off threshold voltage

tonmin

Iinp

Minimum pulse width

100

V

4.0

4.2

V

135

220

ns

1

µA

(s)

IN input current

t

c

u

Voltage reference (1)

Vref

Voltage reference

Iref

Maximum output current

Tmin < T < Tmax

4.77

Fault output

tfault

Delay for fault detection

VFL

FAULT low voltage

UVLO top threshold

UVLOL

UVLO bottom threshold

Vhyst

)

(s

ct

UVLO hysteresis

u

d

o

Supply current

Quiescent current

Iin

e

t

e

l

so

IFLsink = 10 mA

Under voltage lockout (UVLO)

UVLOH

Pr

10

5.22

od

b

O

UVLOH-UVLOL

mA

500

ns

1

V

10

11

12

V

9

10

11

V

0.5

1

V

Output = 0 V, no load

r

P

e

V

5

mA

1. Recommended capacitor range on VREF pin is 10 nF to 100 nF.

t

e

l

o

Table 9.

bs

Truth table

Logic input (VI)

Output

Condition

LIN

HIN

Low side gate

driver output

High side gate

driver output

0 ‘’logic state”

half-bridge tri-state

H

H

L

L

1 “logic state”

low side direct driving

L

H

H

L

1 “logic state”

high side direct driving

H

L

L

H

O

Note:

X: don’t care

Doc ID 022751 Rev 4

9/19

�Electrical characteristics

3.1.1

STGIPL35K120L1

NTC thermistor

Table 10.

NTC thermistor

Symbol

Parameter

Test conditions

Min.

Typ. Max. Unit.

R25

Resistance

TC = 25°C

4.7

kΩ

R125

Resistance

TC = 125°C

160

Ω

B

B-constant

TC = 25°C

3950

K

T

Operating temperature

-40

Equation 1: resistance variation vs. temperature

150

R ( T ) = R 25 ⋅ e

Figure 6.

NTC resistance vs. temperature

100

)

(s

od

let

o

s

b

O

10/19

r

P

e

AM07843v1

s

b

O

t

c

u

10

r

P

e

u

d

o

t

e

l

o

R (kΩ)

)

s

(

ct

1

1

B ⎛ --- – ----------⎞

⎝ T 298⎠

Where T are temperatures in Kelvins

1

0.1

0.01

-50

0

50

Doc ID 022751 Rev 4

100

°C

T (°C)

�STGIPL35K120L1

3.2

Electrical characteristics

Recommendations

●

As the IPM may be used in a very noisy environment, care should be taken to decouple

the supplies. Small ceramic capacitors, connected inside the IPM as close as possible

to the gate driver pins, are used to improve noise-withstand capability.

●

The IPM is compatible with both pulse transformers or optocouplers. When using an

optocoupler, the IN input must be limited to approximately 5 V. The pull-up resistor to

VH must be between 5 kΩ and 20 kΩ, depending on optocoupler characteristics. An

optional filtering capacitor can be added in the event of a highly noisy environment,

although the IPM already includes a filtering on input signals and rejects signals

smaller than 100 ns (tONMIN specification).

●

When using a pulse transformer, a 2.5 V reference point can be built from the 5 V VREF

pin with a resistor divider. The capacitor between the VREF pin and the resistor divider

middle point provides decoupling of the 2.5 V reference, and also ensures a high level

on the IN input pin at power-up to start the IPM in OFF state. The waveform from the

pulse transformer must comply with the tONMIN and VtON / VtOFF specifications. To turn

ON the IPM outputs, the input signal must be lower than 0.8 V for at least 220 ns.

Conversely, the input signal must be higher than 4.2 V for at least 200 ns to turn OFF

the outputs. A pulse width of about 500 ns at these threshold levels is recommended. In

all cases, the input signal at the IN pin must be between 0 and 5 V.

)

s

(

ct

u

d

o

r

P

e

t

e

l

o

●

To prevent the input signals oscillation, the wiring of each input should be as short as

possible.

●

Electrolytic bus capacitors should be mounted as close to the module bus terminals as

possible. Additional high frequency ceramic capacitor mounted close to the module

pins will further improve performance.

●

When setting the maximum voltage to be applied between P-N, the internal stray

inductance and the maximum di/dt should be considered. Due to both internal and

layout stray inductances, the di/dt results in a voltage surges between the DC-link

capacitor and the switches during commutations.

)

(s

s

b

O

●

t

c

u

d

o

r

FAULT pin is externally available to provide a feedback signal about IPM status. Please

refer to undervoltage protection and desaturation fault timing diagrams for more

information. Fault output signals the undervoltage state and is reset only when

undervoltage state disappears. When a desaturation event occurs, the fault output is

pulled down and IPM outputs are low (IGBT off) until the IN input signal is released

(high level), then activated again (low level).

P

e

t

e

l

o

s

b

O

Doc ID 022751 Rev 4

11/19

�Functional description

STGIPL35K120L1

4

Functional description

4.1

Input

The input is compatible with optocouplers or pulse transformers. The input is triggered by

the signal edge and allows the use of low-sized, low-cost pulse transformer. Input is active

low (output is high when input is low) to ease the use of optocoupler. When driven by a pulse

transformer, the input pulse (positive and negative) width must be larger than the minimum

pulse width tonmin.

4.2

Voltage reference

)

s

(

ct

A voltage reference is used to create accurate timing for the two-level turn-off with external

resistor and capacitor.

4.3

u

d

o

r

P

e

Desaturation protection

t

e

l

o

The desaturation function provides a protection against over-current events. Voltage across

the IGBT is monitored, and the IGBT is turned off if the voltage threshold is reached. A

blanking time is made of an internal current source and a capacitor.

s

b

O

During operation, the DESAT capacitor is discharged when IPM output is low (IGBT off).

When the IGBT is turned on, the DESAT capacitor starts charging and desaturation

protection is effective after the blanking time (fixed by design showing a typical value of 2

µs).

)

(s

t

c

u

When a desaturation event occurs, the fault output is pulled down and IPM outputs are low

(IGBT off) until the IN input signal is released (high level), then activated again (low level).

d

o

r

Figure 7.

Desaturation 1200 V

P

e

t

e

l

o

s

b

O

12/19

Doc ID 022751 Rev 4

�STGIPL35K120L1

4.4

Functional description

Active Miller clamp

A Miller clamp allows the control of the Miller current during a high dV/dt situation and can

avoid the use of a negative supply voltage.

During turn-off, the gate voltage is monitored and the clamp output is activated when gate

voltage goes below 2 V (relative to GND). The clamp is disabled when the IN input is

triggered again.

4.5

Fault status output

Fault output is used to signal a fault event (desaturation, UVLO) to a controller. The fault pin

is designed to drive an optocoupler.

4.6

)

s

(

ct

Undervoltage protection

u

d

o

Undervoltage detection protects the application in the event of a low VH supply voltage

(during start-up or a fault situation). Fault output signals the undervoltage state and is reset

only when undervoltage state disappears.

Figure 8.

r

P

e

t

e

l

o

Undervoltage protection

bs

O

)

VH

OUT

s

(

t

c

UVH

UVL

VH-Hmin

2V

u

d

o

r

P

e

FAULT

AM17097v1

t

e

l

o

s

b

O

Doc ID 022751 Rev 4

13/19

�Package mechanical data

5

STGIPL35K120L1

Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK® packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK® is an ST trademark.

Please refer to dedicated technical note TN0107 for mounting instructions.

Table 11.

SDIP-18L package mechanical data

mm.

)

s

(

ct

Dim.

Min.

Typ.

A

49.10

49.60

A1

1.10

1.30

A2

1.40

1.60

A3

44.10

44.60

B

24.00

B1

11.25

B2

27.10

C

5.00

1.80

45.10

25.00

27.60

28.10

5.40

6.00

6.50

7.00

7.50

10.35

10.85

11.35

2.40

2.60

2.80

11.80

12.00

12.20

e2

7.10

7.30

7.50

e3

4.50

4.70

4.90

e4

5.80

6.00

6.20

e5

6.30

6.50

6.70

e6

10.40

10.60

10.80

e7

17.00

17.20

17.40

e

)

s

(

ct

u

d

o

e1

14/19

1.50

12.45

C2

s

b

O

o

s

b

Pr

u

d

o

50.10

11.85

C1

e

t

e

ol

e

t

e

l

24.50

Max.

Pr

-O

D

38.00

D1

5.70

E

11.80

E1

2.15

F

0.85

1.00

1.15

F1

0.35

0.50

0.65

R

1.55

1.75

1.95

T

0.45

0.55

0.65

V

0°

Doc ID 022751 Rev 4

6°

�STGIPL35K120L1

Figure 9.

Package mechanical data

SDIP-18L package drawing (dimensions are in mm.)

)

s

(

ct

u

d

o

r

P

e

t

e

l

o

)

(s

s

b

O

t

c

u

d

o

r

P

e

t

e

l

o

8243339_D

s

b

O

Doc ID 022751 Rev 4

15/19

�Package mechanical data

STGIPL35K120L1

Figure 10. SDIP-18L shipping tube type A (dimensions are in mm.)

)

s

(

ct

r

P

e

t

e

l

o

)

(s

s

b

O

t

c

u

d

o

r

P

e

t

e

l

o

s

b

O

16/19

Doc ID 022751 Rev 4

8147106_E

u

d

o

�STGIPL35K120L1

Package mechanical data

Figure 11. SDIP-18L shipping tube type B (dimensions are in mm.)

)

s

(

ct

u

d

o

t

e

l

o

)

(s

s

b

O

8147106_E

r

P

e

t

c

u

d

o

r

P

e

t

e

l

o

s

b

O

Doc ID 022751 Rev 4

17/19

�Revision history

6

STGIPL35K120L1

Revision history

Table 12.

Document revision history

Date

Revision

Changes

30-Jan-2012

1

Initial release.

28-Feb-2012

2

Added: VCE(sat) max. value Table 7 on page 7.

15-Oct-2012

3

Modified: VF max. value 2.3 V Table 7 on page 7.

07-Feb-2013

4

Modified: tscw parameter Table 3 on page 5.

Updated: Figure 8 on page 13.

u

d

o

)

s

(

ct

r

P

e

t

e

l

o

)

(s

s

b

O

t

c

u

d

o

r

P

e

t

e

l

o

s

b

O

18/19

Doc ID 022751 Rev 4

�STGIPL35K120L1

)

s

(

ct

Please Read Carefully:

u

d

o

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

r

P

e

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

t

e

l

o

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

)

(s

s

b

O

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

t

c

u

d

o

r

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

P

e

t

e

l

o

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

s

b

O

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2013 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 022751 Rev 4

19/19

�