STTH15RQ06-Y

Datasheet

Automotive turbo 2 ultrafast high voltage rectifier

Features

A

K

K

K

K A

NC

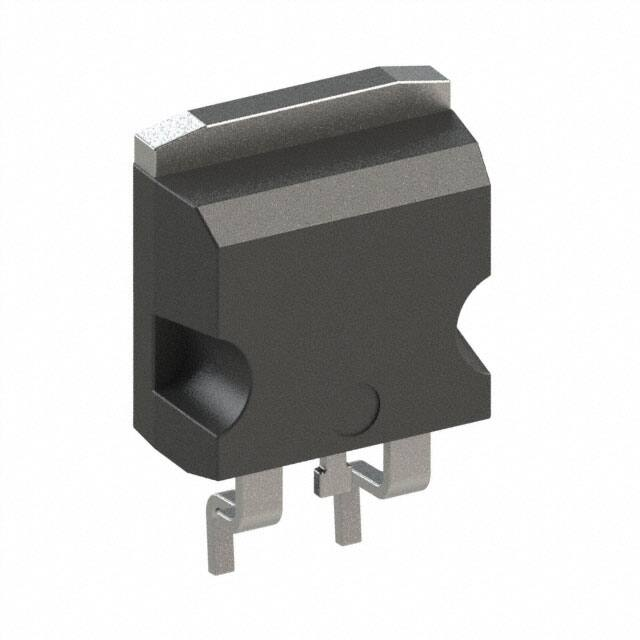

D²PAK

D²PAK HV

A A

NC

K

A

K

A

DO-247

K

•

•

•

•

•

•

•

•

•

AEC-Q101 qualified

High junction temperature capability

Ultrafast with soft recovery behavior

Low reverse current

Low thermal resistance

Reduce switching and conduction losses

PPAP capable

D²PAK HV creepage distance (anode to cathode) = 5.38 mm min. (with top

coating)

VRRM guaranteed from -40 °C to 175 °C

•

ECOPACK®2 compliant (DO-247, TO-220AC)

TO-220AC

Applications

•

•

•

•

•

Output rectification

PFC

UPS

Air conditioning

Charging station

Product status link

Description

STTH15RQ06-Y

Product summary

IF(AV)

15 A

VRRM

600 V

VF (max.)

1.45 V

trr (max.)

25 ns

Tj

-40 °C to 175 °C

The STTH15RQ06-Y has been developed to be used in application requiring a highvoltage secondary rectification for LLC Full Bridge topology.

It is also suited for use in switching power supplies and automotive applications,

industrial applications, as rectification, freewheeling and clamping diode.

DS12163 - Rev 2 - November 2018

For further information contact your local STMicroelectronics sales office.

www.st.com

�STTH15RQ06-Y

Characteristics

1

Characteristics

Table 1. Absolute ratings (limiting values, at 25 °C, unless otherwise specified)

Symbol

Parameter

VRRM

Repetitive peak reverse voltage

IF(RMS)

Forward rms current

Tj = -40 °C to +175 °C

Value

Unit

600

V

50

A

IF(AV)

Average forward current δ = 0.5, square wave

TC = 115 °C

15

A

IFSM

Surge non repetitive forward current

tp = 10 ms sinusoidal

120

A

Tstg

Storage temperature range

-65 to +175

°C

Operating junction temperature range

-40 to +175

°C

Tj

Table 2. Thermal parameters

Symbol

Rth(j-c)

Parameter

Max. value

Unit

1.5

°C/W

Junction to case

Table 3. Static electrical characteristics

Symbol

IR (1)

Parameter

Test conditions

Tj = 25 °C

Reverse leakage current

Tj = 150 °C

Tj = 25 °C

VF (2)

Tj = 150 °C

Forward voltage drop

Tj = 25 °C

Tj = 150 °C

VR = VRRM

IF = 7.5 A

IF = 15 A

Min.

Typ.

Max.

-

20

40

2.45

1.15

1.45

-

µA

400

-

Unit

V

2.95

1.45

1.85

1. Pulse test: tp = 5 ms, δ < 2%

2. Pulse test: tp = 380 µs, δ < 2%

To evaluate the conduction losses, use the following equation:

P = 1.05 x IF(AV) + 0.053 x IF 2 (RMS)

Table 4. Dynamic electrical characteristics

Symbol Parameter

trr

Reverse recovery time

IRM

Reverse recovery current

QRR

Reverse recovery charge

trr

Reverse recovery time

Tj = 25 °C

Tj = 125 °C

Test conditions

Min.

IF = 0.5 A, IR = 1 A, Irr = 0.25 A

-

IF = 1 A, VR = 30 V, dlF/dt = -50 A/µs

-

35

50

-

6

8

-

250

nC

-

70

ns

IF = 15 A, VR = 400 V, dlF/dt = -200 A/µs

Typ.

Max.

25

Unit

ns

A

For more information, please refer to the following application notes related to the power losses:

DS12163 - Rev 2

page 2/17

�STTH15RQ06-Y

Characteristics (curves)

•

•

1.1

AN604: Calculation of conduction losses in a power rectifier

AN4021: Calculation of reverse losses in a power diode

Characteristic (curves)

Figure 1. Average forward power dissipation versus

average forward current (square waveform)

Figure 2. Average forward power dissipation versus

average forward current (sinusoidal waveform)

PF( AV )(W)

PF( AV )(W)

50

δ = 0.05

60

δ = 0.2

δ = 0.1

δ = 0.5

δ= 1

δ = 0.1 δ = 0.2

δ = 0.05

50

40

δ = 0.5

δ= 1

40

30

30

20

20

T

10

10

IF( AV ) (A)

δ=tp/T

0

0

4

8

12

IF( AV ) (A)

tp

16

0

20

Figure 3. Forward voltage drop versus forward current

(typical values)

100.0

IF(A)

0

10.0

20

24

TjJ=150°C

= 175°C

3.0

TjJ=150°C

= -40 °C

1.0

VF (V)

2.0

TjJ=150°C

= 25°C

10.0

TjJ=150°C

= -40 °C

1.0

DS12163 - Rev 2

16

TJj =150°C

= 150°C

= 25°C

TjJ=150°C

1.0

12

IF (A)

TJj =150°C

= 150°C

0.1

0.0

8

Figure 4. Forward voltage drop versus forward current

(maximum values)

100.0

TjJ=150°C

= 175°C

4

4.0

5.0

0.1

0.0

VF (V)

1.0

2.0

3.0

4.0

5.0

6.0

page 3/17

�STTH15RQ06-Y

Characteristics (curves)

Figure 5. Relative variation of thermal impedance junction

to case versus pulse duration

1.0

Figure 6. Peak reverse recovery current versus dIF/dt

(typical values)

IRM(A)

Zth (j-c)/Rt h(j-c)

15

0.9

VR = 400 V

Tj = 125°C

Single pulse

0.8

0.7

10

0.6

IF = IF(AV)

0.5

0.4

IF = IF(AV) / 2

5

0.3

IF = IF(AV) / 4

0.2

0.1

t p( s )

0.0

1.E-04

dI F/dt(A/µs)

0

0

1.E-03

1.E-02

1.E-01

50

100

150

200

250

300

350

400

450

500

1.E+00

Figure 7. Reverse recovery time versus dIF/dt (typical

values)

Figure 8. Reverse recovery charges versus dIF/dt (typical

values)

QRR(nC)

tRR(ns)

500

160

VR = 400 V

Tj = 125°C

VR = 400 V

Tj = 125°C

400

120

IF = IF(AV)

IF = IF(AV)

300

IF = IF(AV) / 2

80

200

IF = IF(AV) / 2

40

IF = IF(AV) / 4

100

IF = IF(AV) / 4

dI F /dt(A/µs)

0

0

50

100

150

200

250

300

350

400

450

dI F /dt(A/µs)

0

0

500

Figure 9. Reverse recovery softness factor versus dIF/dt

(typical values)

Sfactor

50

100

150

200

250

400

450

500

IF = IF(AV)

VR = 400 V

Reference :Tj = 125 °C

VR = 400 V

Tj = 125°C

1.6

350

Figure 10. Relative variations of dynamic parameters

versus junction temperature

1.6

2.0

300

1.2

1.2

0.8

SFACTOR

0.8

0.4

IRM

0.4

QRR

dI F /dt(A/µs)

0.0

0

50

DS12163 - Rev 2

100

150

200

250

300

Tj(°C)

0.0

350

400

450

500

25

50

75

100

125

page 4/17

�STTH15RQ06-Y

Characteristics (curves)

Figure 11. Junction capacitance versus reverse voltage

applied (typical values)

1000

C(pF)

Figure 12. Thermal resistance junction to ambient versus

copper surface under tab (D²PAK and D²PAK HV)

Rth(j-a) (°C/W)

80

F=1MHz

VOSC=30mVRMS

Tj=25°C

70

60

50

40

100

30

20

10

SCu (cm²)

VR(V)

10

1

10

0

100

1000

Figure 13. Relative variation of non-repetitive peak surge

forward current versus pulse duration (sinusoidal

waveform)

4.0

IFSM(tp) / IFSM(10 ms)

0

1.2

1.0

3.0

0.8

2.5

0.6

2.0

0.4

1.5

0.2

tp(ms)

0.1

DS12163 - Rev 2

1.0

10

15

25

30

35

40

IFSM(Tj) / IFSM(25 °C)

Tj(°C)

0.0

10.0

20

Figure 14. Relative variation of non-repetitive peak surge

forward current versus initial junction temperature

(sinusoidal waveform)

3.5

1.0

5

25

50

75

100

125

150

175

page 5/17

�STTH15RQ06-Y

Package information

2

Package information

In order to meet environmental requirements, ST offers these devices in different grades of ECOPACK®

packages, depending on their level of environmental compliance. ECOPACK® specifications, grade definitions

and product status are available at: www.st.com. ECOPACK® is an ST trademark.

2.1

DO-247 package information

•

•

•

•

Epoxy meets UL94, V0

Cooling method: by conduction (C)

Recommended torque value: 0.8 N·m (DO-247)

Maximum torque value: 1.0 N·m (DO-247)

Figure 15. DO-247 package outline

V

Dia

V

A

H

0.10

L5

L

L2

L4

F2

L1

F3

L3

D

V2

F

G

DS12163 - Rev 2

M

E

page 6/17

�STTH15RQ06-Y

DO-247 package information

Table 5. DO-247 package mechanical data

Dimensions

Ref.

Millimeters

Min.

Max.

Min.

Max.

A

4.85

5.15

0.191

0.203

D

2.20

2.60

0.086

0.102

E

0.40

0.80

0.015

0.031

F

1.00

1.40

0.039

0.055

F2

F3

2.00 typ.

2.00

G

0.078 typ.

2.40

0.078

10.90 typ.

0.094

0.429 typ.

H

15.45

15.75

0.608

0.620

L

19.85

20.15

0.781

0.793

L1

3.70

4.30

0.145

0.169

L2

L3

18.50 typ.

14.20

0.728 typ.

14.80

0.559

0.582

L4

34.60 typ.

1.362 typ.

L5

5.50 typ.

0.216 typ.

M

2.00

3.00

0.078

0.118

V

5°

5°

V2

60°

60°

Dia.

DS12163 - Rev 2

Inches

3.55

3.65

0.139

0.143

page 7/17

�STTH15RQ06-Y

D²PAK package information

2.2

D²PAK package information

•

•

Epoxy meets UL94, V0.

Cooling method: by conduction (C)

Figure 16. D²PAK package outline

DS12163 - Rev 2

page 8/17

�STTH15RQ06-Y

D²PAK package information

Table 6. D²PAK package mechanical data

Dimensions

Ref.

Millimeters

Min.

Typ.

Inches (for reference only)

Max.

Min.

Typ.

Max.

A

4.40

4.60

0.173

0.181

A1

0.03

0.23

0.001

0.009

b

0.70

0.93

0.028

0.037

b2

1.14

1.70

0.045

0.067

c

0.45

0.60

0.018

0.024

c2

1.23

1.36

0.048

0.053

D

8.95

9.35

0.352

0.368

D1

7.50

7.75

8.00

0.295

0.305

0.315

D2

1.10

1.30

1.50

0.043

0.051

0.060

E

10.00

10.40

0.394

E1

8.30

8.50

8.70

0.335

0.343

0.346

E2

6.85

7.05

7.25

0.266

0.278

0.282

e

0.409

2.54

0.100

e1

4.88

5.28

0.190

0.205

H

15.00

15.85

0.591

0.624

J1

2.49

2.69

0.097

0.106

L

2.29

2.79

0.090

0.110

L1

1.27

1.40

0.049

0.055

L2

1.30

1.75

0.050

0.069

R

V2

0.40

0°

0.015

8°

0°

8°

Figure 17. D²PAK recommended footprint (dimensions are in mm)

Footprint

DS12163 - Rev 2

page 9/17

�STTH15RQ06-Y

TO-220AC package information

2.3

TO-220AC package information

•

•

•

•

Epoxy meets UL 94,V0

Cooling method: by conduction (C)

Recommended torque value: 0.55 N·m

Maximum torque value: 0.70 N·m

Figure 18. TO-220AC package outline

A

H2

ØI

C

L5

L7

L6

L2

F1

D

L9

L4

F

M

E

G

DS12163 - Rev 2

page 10/17

�STTH15RQ06-Y

TO-220AC package information

Table 7. TO-220AC package mechanical data

Dimensions

Ref.

Millimeters

Min.

Max.

Min.

Max.

A

4.40

4.60

0.173

0.181

C

1.23

1.32

0.048

0.051

D

2.40

2.72

0.094

0.107

E

0.49

0.70

0.019

0.027

F

0.61

0.88

0.024

0.034

F1

1.14

1.70

0.044

0.066

G

4.95

5.15

0.194

0.202

H2

10.00

10.40

0.393

0.409

L2

16.40 typ.

0.645 typ.

L4

13.00

14.00

0.511

0.551

L5

2.65

2.95

0.104

0.116

L6

15.25

15.75

0.600

0.620

L7

6.20

6.60

0.244

0.259

L9

3.50

3.93

0.137

0.154

M

ØI

DS12163 - Rev 2

Inches

2.6 typ.

3.75

0.102 typ.

3.85

0.147

0.151

page 11/17

�STTH15RQ06-Y

D²PAK high voltage package information

2.4

D²PAK HV package information

Figure 19. D²PAK high voltage package outline

A

H

C

L1

L

R

L4

R

M

L2

0.25 gauge plane

F (x2)

E

e

H1

L3

A1

V

DS12163 - Rev 2

page 12/17

�STTH15RQ06-Y

D²PAK high voltage package information

Table 8. D²PAK high voltage package mechanical data

Ref.

Dimensions

Min.

Typ.

Max.

A

4.30

4.70

A1

0.03

0.20

C

1.17

1.37

e

4.98

5.18

E

0.50

0.90

F

0.78

0.85

H

10.00

10.40

H1

7.40

7.80

L

15.30

15.80

L1

1.27

1.40

L2

4.93

5.23

L3

6.85

7.25

L4

1.5

1.7

M

2.6

2.9

R

0.20

0.60

V

0°

8°

Figure 20. D²PAK High Voltage footprint in mm

10,58

7,46

15,95

5,10

3,40

1,20

5,08

DS12163 - Rev 2

page 13/17

�STTH15RQ06-Y

D²PAK high voltage package information

2.4.1

Creepage distance between anode and cathode

Table 9. Creepage distance between anode and cathode

Symbol

Note:

Parameter

CdA-K1

Minimum creepage distance between A and K1 (with top coating)

CdA-K2

Minimum creepage distance between A and K2 (without top coating)

Value

D²PAK HV

5.38

3.48

Unit

mm

D²PAK HV creepage distance (anode to cathode) = 5.38 mm min. (refer to IEC 60664-1)

Figure 21. Creepage with top coating

Figure 22. Creepage without top coating

DS12163 - Rev 2

page 14/17

�STTH15RQ06-Y

Ordering information

3

Ordering information

Table 10. Ordering information

DS12163 - Rev 2

Order code

Marking

Package

Weight

Base qty.

Delivery mode

STTH15RQ06GY-TR

STTH15RQ06GY

D²PAK

1.48 g

1000

Tape and reel

STTH15RQ06DY

STTH15RQ06DY

TO-220AC

1.86 g

50

Tube

STTH15RQ06WY

STTH15RQ06WY

DO-247

4.40 g

30

Tube

STTH15RQ06G2Y-TR

TH15RQ06G2Y

D²PAK HV

1.48 g

1000

Tape and reel

page 15/17

�STTH15RQ06-Y

Revision history

Table 11. Document revision history

DS12163 - Rev 2

Date

Revision

Changes

12-Jun-2017

1

Initial release.

22-Nov-2018

2

Added D²PAK HV package.

page 16/17

�STTH15RQ06-Y

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. All other product or service names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2018 STMicroelectronics – All rights reserved

DS12163 - Rev 2

page 17/17

�

很抱歉,暂时无法提供与“STTH15RQ06G2Y-TR”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格 香港价格

- 1+14.759401+1.76450

- 10+10.9379110+1.30764

- 100+8.86340100+1.05963

- 500+7.32211500+0.87537

- 国内价格

- 1+10.60301

- 10+9.34503

- 30+8.60372

- 100+7.17164

- 500+6.82344

- 1000+6.66620

- 国内价格 香港价格

- 1000+7.199041000+0.86065

- 2000+6.677532000+0.79831

- 3000+6.411893000+0.76655

- 5000+6.317205000+0.75523