ICP-10125 Datasheet

High Accuracy, Low Power, 10atm Waterproof Barometric Pressure

and Temperature Sensor IC

GENERAL INFORMATION

FEATURES

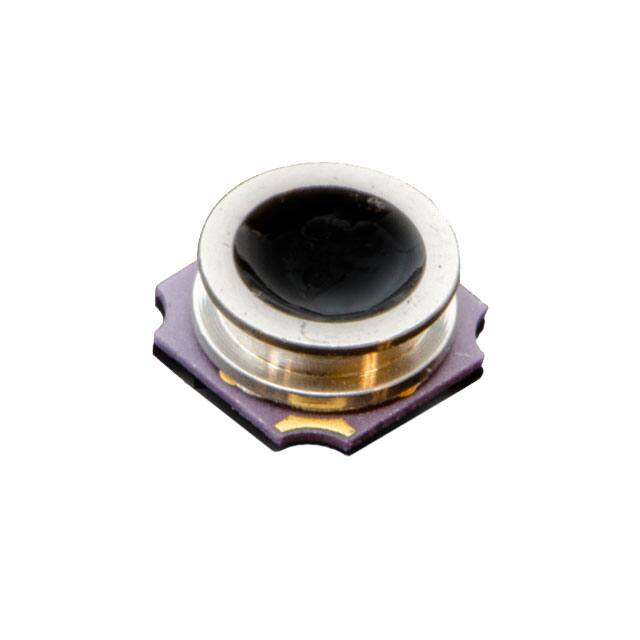

The ICP-10125 pressure sensor is based on MEMS capacitive

technology, which provides ultra-low noise at the lowest

power, enabling industry leading relative accuracy, sensor

throughput, and temperature stability. The pressure sensor

can measure pressure differences with an accuracy of ±1 Pa,

an accuracy enabling altitude measurement differentials as

small as 8.5 cm, less than the height of a single stair step.

Consuming only 1.3 µA @1 Hz, the device is available in a

small footprint 3.55 mm x 3.55 mm x 1.45 mm chimney

package with waterproofing gel providing IPx8 waterproofing

to 10 ATM. The ICP-10125 is ideally suited for wearable

fitness monitoring and battery powered IoT.

The ICP-10125 offers an industry leading temperature

coefficient offset of ±0.5 Pa/C. The combination of high

accuracy, low power, temperature stability, waterproofing in

a small footprint enables higher performance barometric

pressure sensing for sports activity identification and mobile

indoor/outdoor navigation.

DEVICE INFORMATION

PART

NUMBER

PACKAGE

LID OPENING

ICP-10125

3.55x3.55x1.45mm

HTCC-10L

Gel filled HTCC package with

machined lid; IPx8

waterproofing to 10 ATM

•

•

•

•

•

•

•

•

•

•

•

Pressure operating range: 30 to 110 kPa

Noise and current consumption

o 0.4 Pa @ 10.4 µA (ULN mode)

o 0.8 Pa @ 5.2 µA (LN mode)

o 3.2 Pa @ 1.3 µA (LP mode)

Pressure Sensor Relative Accuracy: ±1 Pa for any

10 hPa change over 950 hPa-1050 hPa at 25C

Pressure Sensor Absolute Accuracy: ±1 hPa over

950 hPa-1050 hPa, 0C to 65C

Pressure Sensor Temperature Coefficient Offset:

±0.5 Pa/C over 25C to 45C at 100 kPa

Temperature Sensor Absolute Accuracy: ±0.4C

IPx8: Waterproof to 10 ATM

Temperature operating range: -40 °C to 85 °C

Host Interface: I2C at up to 400 kHz

Single Supply voltage: 1.8V ±5%

RoHS and Green compliant

TYPICAL OPERATING CIRCUIT

Denotes RoHS and Green-Compliant Package

BLOCK DIAGRAMS

AP/HUB

I2C

ICP-10125

APPLICATIONS

•

•

•

•

•

•

Smart watches

Leisure, Sports, and Fitness Activity Monitoring for

Wearable Sensors

Altimeters and barometers for portable devices

Indoor/Outdoor Navigation (dead-reckoning,

floor/elevator/step detection)

Home and Building Automation

Weather Forecasting

InvenSense, Inc. reserves the right to change

specifications and information herein without notice

unless the product is in mass production and the

datasheet has been designated by InvenSense in writing

as subject to a specified Product / Process Change

Notification Method regulation.

InvenSense, a TDK Group Company

1745 Technology Drive, San Jose, CA 95110 U.S.A

+1(408) 988–7339

invensense.tdk.com

Document Number: DS-000329

Revision: 1.1

Release Date: 04/09/2021

�ICP-10125

TABLE OF CONTENTS

GENERAL INFORMATION ..................................................................................................................................................1

DEVICE INFORMATION .....................................................................................................................................................1

BLOCK DIAGRAMS...........................................................................................................................................................1

APPLICATIONS ................................................................................................................................................................1

FEATURES .....................................................................................................................................................................1

TYPICAL OPERATING CIRCUIT ............................................................................................................................................1

1

INTRODUCTION .............................................................................................................................................. 5

1.1

1.2

2

PRESSURE AND TEMPERATURE SENSOR SPECIFICATIONS .............................................................................. 6

2.1

2.2

2.3

2.4

2.5

3

INTERFACE SPECIFICATIONS .................................................................................................................................11

PIN OUT DIAGRAM AND SIGNAL DESCRIPTION........................................................................................................11

TYPICAL OPERATING CIRCUIT ..............................................................................................................................12

BILL OF MATERIALS FOR EXTERNAL COMPONENTS...................................................................................................13

OPERATION AND COMMUNICATION ............................................................................................................ 14

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.10

5.11

5.12

5.13

5.14

6

ELECTRICAL CHARACTERISTICS ...............................................................................................................................8

ABSOLUTE MAXIMUM RATINGS.............................................................................................................................9

SENSOR SYSTEM TIMING ......................................................................................................................................9

I2C TIMING CHARACTERIZATION ..........................................................................................................................10

APPLICATIONS INFORMATION ..................................................................................................................... 11

4.1

4.2

4.3

4.4

5

OPERATION RANGES ...........................................................................................................................................6

OPERATION MODES ............................................................................................................................................6

PRESSURE SENSOR SPECIFICATIONS ........................................................................................................................7

TEMPERATURE SENSOR SPECIFICATIONS ..................................................................................................................7

RECOMMENDED OPERATION CONDITIONS ...............................................................................................................7

ELECTRICAL SPECIFICATIONS .......................................................................................................................... 8

3.1

3.2

3.3

3.4

4

PURPOSE AND SCOPE ..........................................................................................................................................5

PRODUCT OVERVIEW...........................................................................................................................................5

POWER-UP AND COMMUNICATION START ............................................................................................................14

MEASUREMENT COMMANDS ..............................................................................................................................14

STARTING A MEASUREMENT ...............................................................................................................................14

SENSOR BEHAVIOR DURING MEASUREMENT ..........................................................................................................14

READOUT OF MEASUREMENT RESULTS .................................................................................................................15

SOFT RESET .....................................................................................................................................................15

READ-OUT OF ID REGISTER .................................................................................................................................15

CHECKSUM CALCULATION ..................................................................................................................................16

CONVERSION OF SIGNAL OUTPUT ........................................................................................................................16

READ-OUT OF CALIBRATION PARAMETERS .............................................................................................................18

SAMPLE CODE: EXAMPLE C SYNTAX .....................................................................................................................18

SAMPLE CODE: CONVERSION FORMULA (EXAMPLE PYTHON SYNTAX) ..........................................................................20

SAMPLE CODE: USING CONVERSION FORMULA (EXAMPLE PYTHON SYNTAX).................................................................21

COMMUNICATION DATA SEQUENCES....................................................................................................................22

ASSEMBLY .................................................................................................................................................... 23

6.1

IMPLEMENTATION AND USAGE RECOMMENDATIONS ...............................................................................................23

6.1.1

Soldering ..............................................................................................................................................23

Document Number: DS-000329

Revision: 1.1

Page 2 of 30

�ICP-10125

6.1.2

Chemical Exposure and Sensor Protection ...........................................................................................23

7

PACKAGE DIMENSIONS ................................................................................................................................ 24

8

TAPE AND REEL SPECIFICATION .................................................................................................................... 26

9

ORDERING GUIDE ......................................................................................................................................... 27

10

REFERENCES ............................................................................................................................................. 28

11

REVISION HISTORY ................................................................................................................................... 29

Document Number: DS-000329

Revision: 1.1

Page 3 of 30

�ICP-10125

LIST OF FIGURES

Figure 1. Digital I/O Pads Timing ................................................................................................................ 10

Figure 2. Pin Out Diagram for ICP-10125, 3.55mm x 3.55mm x 1.45mm HTCC ....................................... 11

Figure 3. ICP-10125 Application Schematic ............................................................................................... 12

Figure 4. Typical Application Circuit ............................................................................................................ 13

Figure 5. Communication Data Sequences ................................................................................................ 22

Figure 6. ICP-10125 Package Diagram ...................................................................................................... 24

Figure 7. ICP-10125 recommended PCB land pattern ............................................................................... 25

Figure 8. ICP-10125 Artwork....................................................................................................................... 25

Figure 9. ICP-10125 Tape Dimensions ................................................................................................... 26

Figure 10. Tape and Reel Orientation ......................................................................................................... 26

LIST OF TABLES

Table 1. Operation Ranges ........................................................................................................................... 6

Table 2. Operation Modes............................................................................................................................. 6

Table 3. Pressure Sensor Specifications ...................................................................................................... 7

Table 4. Temperature Sensor Specifications ................................................................................................ 7

Table 5. Electrical Specifications .................................................................................................................. 8

Table 6. Absolute Maximum Ratings ............................................................................................................ 9

Table 7. System Timing Specifications ......................................................................................................... 9

Table 8. I2C Parameters Specification ........................................................................................................ 10

Table 9. Signal Descriptions ....................................................................................................................... 11

Table 10. Bill of Materials ............................................................................................................................ 13

Table 11. ICP-10125 I2C Device Address ................................................................................................... 14

Table 12. Measurement Commands ........................................................................................................... 14

Table 13. Soft Reset Command .................................................................................................................. 15

Table 14. Read-Out Command of ID Register ............................................................................................ 15

Table 15. 16-bit ID Structure ....................................................................................................................... 16

Table 16. ICP-10125 I2C CRC Properties ................................................................................................... 16

Document Number: DS-000329

Revision: 1.1

Page 4 of 30

�ICP-10125

1 INTRODUCTION

1.1

PURPOSE AND SCOPE

This document is a preliminary product specification, providing a description, specifications, and design related

information for the ICP-10125 Pressure Sensor.

Specifications are subject to change without notice. Final specifications will be updated based upon

characterization of production silicon.

1.2

PRODUCT OVERVIEW

The ICP-10125 is an ultra-low power, low noise, digital output barometric pressure and temperature sensor IC. It is

based on an innovative MEMS capacitive pressure sensor technology that can measure pressure differences with

an accuracy of ±1 Pa at the industry’s lowest power. The high accuracy MEMS capacitive pressure sensor is capable

of measuring altitude differentials down to 8.5 cm without the penalty of increased power consumption or

reduced sensor throughput.

The capacitive pressure sensor has a ±1 hPa absolute accuracy over its full range of 300 hPa -1100 hPa. The

pressure sensor has an embedded temperature sensor and 400 kHz I2C bus for communication. For power-critical

applications, the ICP-10125 features a low power mode of 1.3 µA at a noise of 3.2 Pa or for high performance

applications, it features a low noise mode of 0.8 Pa while only consuming 5.2 µA.

The device is available in a small footprint 3.55 mm x 3.55 mm x 1.45 mm chimney package with waterproofing gel

providing IPx8 waterproofing to 10 ATM.

The ICP-10125 also offers industry leading temperature stability of the pressure sensor with a temperature

coefficient offset of ±0.5 Pa/C. The high accuracy, temperature stability, and market leading low power

consumption of 1.3 µA @1 Hz offered by ICP-10125 makes it ideally suited for applications such as mobile phones,

drone flight control and stabilization, indoor/outdoor navigation (elevator, floor, and stair step detection), sports

and fitness activity monitoring, and battery-powered IoT.

Document Number: DS-000329

Revision: 1.1

Page 5 of 30

�ICP-10125

2 PRESSURE AND TEMPERATURE SENSOR SPECIFICATIONS

2.1

OPERATION RANGES

The sensor shows best performance when operated within the recommended temperature and pressure range

(hereafter called normal conditions) of 0°C – 45°C and 95 kPa – 105 kPa, respectively. The following ranges are

defined for the device:

OPERATION RANGE

PRESSURE (KPA)

TEMPERATURE (C)

Normal

95 to 105

0 to 45

Extended

30 to 110

-20 to 65

Maximum

25 to 115

-40 to 85

Table 1. Operation Ranges

2.2

OPERATION MODES

The sensor can be operated in up to four different measurement modes to satisfy different requirements for

power consumption vs. noise, accuracy, and measurement frequency. An overview of the operation modes is given

in Table 2.

PARAMETER

Conversion Time

Current

Consumption

Pressure RMS

Noise

CONDITIONS

Time between sending last bit

of measurement command,

and sensor data ready for

measurement

1 Hz ODR

Valid for P = 100 kPa, T = 25°C,

and U = 1.8V

SENSOR MODE

Low Power (LP)

Normal (N)

TYP

1.6

5.6

MAX

1.8

6.3

UNITS

NOTES

1

1

Low Noise (LN)

Ultra Low Noise

(ULN)

Low Power (LP)

Normal (N)

Low Noise (LN)

Ultra Low Noise

(ULN)

Low Power (LP)

Normal

Low Noise (LN)

Ultra Low Noise

(ULN)

20.8

23.8

ms

1

83.2

94.5

1.3

2.6

5.2

1

µA

10.4

3.2

1.6

0.8

Pa

0.4

Table 2. Operation Modes

Notes:

1.

Guaranteed by design.

Low Power modes supports ODR greater than 500 Hz while the Low Noise mode provides industry leading RMS

noise at a fast 40 Hz ODR. Further decrease in noise may be achieved by software oversampling and filtering

through customer’s software implementation or custom TDK InvenSense operation modes available upon request.

Document Number: DS-000329

Revision: 1.1

Page 6 of 30

�ICP-10125

2.3

PRESSURE SENSOR SPECIFICATIONS

Pressure sensor specifications are given in Table 3. Default conditions of 25 °C and 1.8V supply voltage apply, unless

otherwise stated.

PARAMETER

Absolute Accuracy

Relative Accuracy

Long-term drift

During 1 year

Solder drift

CONDITIONS

Normal range

Extended range

Any step ≤ 1 kPa, 25 °C

Any step ≤ 10 kPa, 25 °C

TYP

±1

±1.5

±1

±3

Normal range

Extended range

±35

±40

1.5

P = 100 kPa

25°C … 45°C

Maximum range

Temperature coefficient offset

Resolution

UNITS

NOTES

hPa

1

Pa

Pa/y

hPa

±0.5

Pa/°C

0.01

Pa

1, 2

Table 3. Pressure Sensor Specifications

Notes:

1.

2.

2.4

Absolute accuracy may be improved through One Point Calibration

Sensor accuracy post Solder reflow may be improved through One Point Calibration

TEMPERATURE SENSOR SPECIFICATIONS

Specifications of the temperature sensor are shown in Table 4.

PARAMETER

Absolute Accuracy

Repeatability

Resolution

Long-term drift

CONDITIONS

Extended range

Extended range

Maximum range

Normal range

TYP

±0.4

±0.1

0.01

600kPa

Table 6. Absolute Maximum Ratings

3.3

SENSOR SYSTEM TIMING

Default conditions of 25°C and 1.8V supply voltage apply to typ. values listed in Table 7, unless otherwise stated.

Max. values apply over the specified operating range of VDD and over the operating temperature range.

PARAMETER

SYMBOL

CONDITIONS

MIN

TYP

MAX

UNITS

COMMENTS

Power-up time

tPU

After hard reset, VDD ≥ VPOR

-

170

-

µs

Time between VDD reaching VPU

and sensor entering idle state

Soft reset time

tSR

After soft reset

-

170

-

µs

Time between ACK of soft reset

command and sensor entering

idle state

LN Mode

-

20.8

23.8

ms

Duration for a pressure and

temperature measurement

Measurement duration

tMEAS

Table 7. System Timing Specifications

Document Number: DS-000329

Revision: 1.1

Page 9 of 30

�ICP-10125

3.4

I2C TIMING CHARACTERIZATION

Default conditions of 25°C and 1.8V supply voltage apply to values in Table 8, unless otherwise stated.

PARAMETER

SYMBOL

SCL clock frequency

CONDITIONS

fSCL

Hold time (repeated) START condition

After this period, the first

clock pulse is generated

tHD;STA

MIN

TYP

MAX

UNITS

0

-

400

kHz

0.6

-

-

µs

LOW period of the SCL clock

tLOW

1.3

-

-

µs

HIGH period of the SCL clock

tHIGH

0.6

-

-

µs

Set-up time for a repeated START

condition

tSU;STA

0.6

-

-

µs

SDA hold time

tHD;DAT

0

-

-

µs

SDA set-up time

tSU;DAT

100

-

-

ns

SCL/SDA rise time

tR

20

-

300

ns

SCL/SDA fall time

tF

-

-

300

ns

SDA valid time

tVD;DAT

-

-

0.9

µs

Set-up time for STOP condition

tSU;STO

0.6

-

-

µs

CB

-

-

400

pF

Capacitive load on bus line

Table 8. I2C Parameters Specification

1/fSC

tHIGH

L

tLOW

tR

tF

70

%

30

%

SCL

tSU;D

DATA IN

AT

tHD;DA

T

70

%

30

%

SDA

tVD;DAT

tF

tR

DATA OUT

SDA

Figure 1. Digital I/O Pads Timing

Document Number: DS-000329

Revision: 1.1

Page 10 of 30

70

%

30

%

�ICP-10125

4 APPLICATIONS INFORMATION

4.1

INTERFACE SPECIFICATIONS

The ICP-10125 supports I2C fast mode, SCL clock frequency from 0 to 400 kHz.

4.2

PIN OUT DIAGRAM AND SIGNAL DESCRIPTION

PIN NUMBER

1

2

3

4

5

6

7

8

9

10

PIN NAME

RESV

SCL

RESV

SDA

VDD

RESV

RESV

RESV

VSS

RESV

DESCRIPTION

No Connect (NC) or Connect to GND

I2C Serial Clock

Connect to Ground

I2C Serial Data

Power Supply VDD

No Connect (NC) or Connect to GND

No Connect (NC) or Connect to GND

Connect to Ground

Connect to Ground

No Connect (NC) or Connect to GND

Table 9. Signal Descriptions

8

9

10

RESV

VSS

RESV

Pin 1 Indicator

7

1

RESV

RESV

BOTTOM

VIEW

6

2

RESV

SCL

5

4

3

VDD

SDA

RESV

Figure 2. Pin Out Diagram for ICP-10125, 3.55mm x 3.55mm x 1.45mm HTCC

Document Number: DS-000329

Revision: 1.1

Page 11 of 30

�ICP-10125

4.3

TYPICAL OPERATING CIRCUIT

GND

GND

GND

Pin 1 Indicator

GND

GND

GND

SCL

VDD

C1, 100nF

SDA

GND

GND

Figure 3. ICP-10125 Application Schematic

Power supply pins supply voltage (VDD) and ground (VSS) must be decoupled with a 100 nF capacitor that shall be

placed as close to the sensor as possible. Connections shown as dashed lines are recommended for mechanical

stability of the sensor (see Figure 4).

Document Number: DS-000329

Revision: 1.1

Page 12 of 30

�ICP-10125

Connections shown as dashed lines are recommended for mechanical stability of the sensor

Figure 4. Typical Application Circuit

SCL is used to synchronize the communication between the microcontroller and the sensor. The master must keep

the clock frequency within 0 to 400 kHz as specified in Table 8.

The SDA pin is used to transfer data in and out of the sensor. For safe communication, the timing specifications

defined in the I2C manual must be met.

To avoid signal contention, the microcontroller must only drive SDA and SCL low. External pull-up resistors (i.e.

10 kΩ) are required to pull the signal high. For dimensioning resistor sizes, user should also consider bus capacity

requirements. It should be noted that pull-up resistors may be included in I/O circuits of microcontrollers.

4.4

BILL OF MATERIALS FOR EXTERNAL COMPONENTS

COMPONENT

VDD Bypass Capacitor

LABEL

SPECIFICATION

QUANTITY

C1

Ceramic, X7R, 100 nF ±10%

1

Table 10. Bill of Materials

Document Number: DS-000329

Revision: 1.1

Page 13 of 30

�ICP-10125

5 OPERATION AND COMMUNICATION

All commands and memory locations of the ICP-10125 are mapped to a 16-bit address space which can be accessed

via the I2C protocol.

ICP-10125

BINARY

DECIMAL

HEXADECIMAL

I2C address

110’0011

99

0x63

Table 11. ICP-10125 I2C Device Address

5.1

POWER-UP AND COMMUNICATION START

When VDD reaches the power-up voltage level VPOR, the ICP-10125 enters idle state after a duration of tPU. In idle

state, the ICP-10125 is ready to receive commands from the master (microcontroller).

Each transmission sequence begins with START condition (S) and ends with an (optional) STOP condition (P) as

described in the I2C-bus specification. Whenever the sensor is powered up, but not performing a measurement or

communicating, it automatically enters idle state for energy saving.

5.2

MEASUREMENT COMMANDS

The ICP-10125 provides the possibility to define the sensor behavior during measurement as well as the

transmission sequence of measurement results. These characteristics are defined by the appropriate

measurement command.

Each measurement command triggers both a temperature and a pressure measurement.

OPERATION MODE

Low Power (LP)

Normal (N)

Low Noise (LN)

Ultra-Low Noise (ULN)

TRANSMIT T FIRST

0x609C

0x6825

0x70DF

0x7866

TRANSMIT P FIRST

0x401A

0x48A3

0x5059

0x58E0

Table 12. Measurement Commands

5.3

STARTING A MEASUREMENT

A measurement communication sequence consists of a START condition followed by the I2C header with the 7-bit

I2C device address and a write bit (write W: ‘0’, 8-bit word including I2C header: 0xC6). The sensor indicates the

proper reception of a byte by pulling the SDA pin low (ACK bit) after the falling edge of the 8th SCL clock. Then the

sensor is ready to receive a 16-bit measurement command. Again, the ICP-10125 acknowledges the proper

reception of each byte with ACK condition. A complete measurement cycle is presented in Figure 5.

With the acknowledgement of the measurement command, the ICP-10125 starts measuring pressure and

temperature.

5.4

SENSOR BEHAVIOR DURING MEASUREMENT

In general, the sensor does not respond to any I2C activity during measurement, i.e. I2C read and write headers are

not acknowledged (NACK).

Document Number: DS-000329

Revision: 1.1

Page 14 of 30

�ICP-10125

5.5

READOUT OF MEASUREMENT RESULTS

After a measurement command has been issued and the sensor has completed the measurement, the master can

read the measurement results by sending a START condition followed by an I2C read header (8-bit word including

I2C header: 0xC7). The sensor will acknowledge the reception of the read header and send the measured data in

the specified order to the master. The MSB of the corresponding data is always transmitted first. Temperature

data is transmitted in two 8-bit words and pressure data is transmitted in four 8-bit words. Regarding the pressure

data, only the first three words MMSB, MLSB and LMSB contain information about the ADC pressure value p_dout.

Therefore, for retrieving the ADC pressure value, LLSB must be disregarded:

p_dout = MMSB ≪ 16 | MLSB ≪ 8| LMSB.

Two bytes of data are always followed by one byte CRC checksum, for calculation see section 5.8. Each byte must

be acknowledged by the microcontroller with an ACK condition for the sensor to continue sending data. If the ICP10125 does not receive an ACK from the master after any byte of data, it will not continue sending data.

Whether the sensor sends out pressure or temperature data first depends on the measurement command that

was sent to the sensor to initiate the measurement (see Table 12).

The I2C master can abort the read transfer with a NACK condition after any data byte if it is not interested in

subsequent data, e.g. the CRC byte or the second measurement result, to save time.

5.6

SOFT RESET

The ICP-10125 provides a soft reset mechanism that forces the system into a well-defined state without removing

the power supply. If the system is in idle state (i.e. if no measurement is in progress) the soft reset command will

be accepted by ICP-10125. This triggers the sensor to reset all internal state machines and reload calibration data

from the memory.

COMMAND

HEXADECIMAL CODE

BINARY CODE

Soft reset

0x805D

1000’0000’0101’1101

Table 13. Soft Reset Command

5.7

READ-OUT OF ID REGISTER

The ICP-10125 has an ID register which contains a specific product code. The read-out of the ID register can be

used to verify the presence of the sensor and proper communication. The command to read the ID register is

shown in Table 14.

COMMAND

HEXADECIMAL CODE

BINARY CODE

Read ID register

0xEFC8

1110’1111’1100’1000

Table 14. Read-Out Command of ID Register

It needs to be sent to the ICP-10125 after an I2C write header. After the ICP-10125 has acknowledged the proper

reception of the command, the master can send an I2C read header and the ICP-10125 will submit the 16-bit ID

followed by 8 bits of CRC. The structure of the ID is described in Table 15. Bits 15:6 of the ID contain unspecified

information (marked as “x”), which may vary from sensor to sensor, while bits 5:0 contain the ICP-10125 specific

product code.

Document Number: DS-000329

Revision: 1.1

Page 15 of 30

�ICP-10125

16-bit ID

xxxx'xxxx’xx 00’1000

bits 5 to 0: ICP-10125-specific product code

bits 15 to 6: unspecified information

Table 15. 16-bit ID Structure

5.8

CHECKSUM CALCULATION

The 8-bit CRC checksum transmitted after each data word is generated by a CRC algorithm with the properties

displayed in Table 16. The CRC covers the contents of the two previously transmitted data bytes.

PROPERTY

VALUE

Name

CRC-8

Width

8 bits

Polynomial

0x31 (x8 + x5 + x4 + 1)

Initialization

0xFF

Reflect input

false

Reflect output

false

Final XOR

0x00

Examples

CRC(0x00) = 0xAC

CRC(0xBEEF) = 0x92

Table 16. ICP-10125 I2C CRC Properties

5.9

CONVERSION OF SIGNAL OUTPUT

Pressure measurement data is always transferred as 4 8-bit words; temperature measurement data is always

transferred as two 8-bit words. Please see section 5.5 for more details.

Temperature measurement values t_dout are linearized by the ICP-10125 and must be calculated to °C by the user

via the following formula:

T = - 45°C +

175°C

216

× t_dout.

For retrieving physical pressure values in Pa the following conversion formula has to be used:

P=A+

B

,

C + pdout

where p_dout is the sensor’s raw pressure output. The converted output is compensated for temperature effects

via the temperature dependent functions A, B and C. Besides the raw temperature output t_dout, the calculation

of A, B and C requires to access calibration parameters OTP0, OTP1, OTP2, OTP3 stored in the OTP of the sensor.

Read-out of OTP parameters is described in section 5.10.

Document Number: DS-000329

Revision: 1.1

Page 16 of 30

�ICP-10125

Full sample code for calculating physical pressure values is given in section 5.11. The general workflow of the

conversion is done by:

1) Import class

Invensense_pressure_conversion

2) Read out values OTP0, …, OTP3 and save to c1, …, c4

3) Create object name for an individual sensor with parameter values c1, …, c4

name = Invensense_pressure_conversion

([c1,c2,c3,c4])

4) Get raw pressure p_dout and temperature t_dout data from the sensor as described in chapter 5.5.

5) Call function get_pressure:

name.get_pressure(p_dout, t_dout)

The sample code from section 5.13 gives an example of this workflow.

Document Number: DS-000329

Revision: 1.1

Page 17 of 30

�ICP-10125

5.10 READ-OUT OF CALIBRATION PARAMETERS

For converting raw pressure data to physical values, four calibration parameters have to be retrieved from the OTP

of the sensor.

Set up of OTP read:

1) Send I2C write header 0xC6

2) Send command 0xC595 (move pointer in address register)

3) Send address parameter together with its CRC 0x00669C

Steps 1) – 3) can be executed on many platforms by a single I2C write of the value 0xC59500669C.

Read out parameters:

Repeat the following procedure 4 times:

Send I2C write header 0xC6

a)

b) Send command 0xC7F7 (incremental read-out of OTP)

Send I2C read header 0xC7

c)

d) Read 3B (2B of data and 1B of CRC)

e)

Decode data as 16bit big endian signed integer and store result into n-th calibration parameter cn.

Steps a) to d) can be executed on many platforms by a single write 0xC7F7 to the chip address followed by a single

read of 3 B from the chip address.

5.11 SAMPLE CODE: EXAMPLE C SYNTAX

/* data structure to hold pressure sensor related parameters */

typedef struct inv_invpres

{

struct inv_invpres_serif serif;

uint32_t min_delay_us;

uint8_t pressure_en;

uint8_t temperature_en;

float sensor_constants[4]; // OTP values

float p_Pa_calib[3];

float LUT_lower;

float LUT_upper;

float quadr_factor;

float offst_factor;

} inv_invpres_t;

int inv_invpres_init(struct inv_invpres * s)

{

short otp[4];

read_otp_from_i2c(s, otp);

init_base(s, otp);

return 0;

}

int read_otp_from_i2c(struct inv_invpres * s, short *out)

{

unsigned char data_write[10];

unsigned char data_read[10] = {0};

int status;

int i;

// OTP Read mode

Document Number: DS-000329

Revision: 1.1

Page 18 of 30

�ICP-10125

data_write[0] = 0xC5;

data_write[1] = 0x95;

data_write[2] = 0x00;

data_write[3] = 0x66;

data_write[4] = 0x9C;

status = inv_invpres_serif_write_reg(&s->serif, ICC_ADDR_PRS, data_write, 5);

if (status)

return status;

// Read OTP values

for (i = 0; i < 4; i++) {

data_write[0] = 0xC7;

data_write[1] = 0xF7;

status = inv_invpres_serif_write_reg(&s->serif, ICC_ADDR_PRS, data_write, 2);

if (status)

return status;

status = inv_invpres_serif_read_reg(&s->serif, ICC_ADDR_PRS, data_read, 3);

if (status)

return status;

out[i] = data_read[0]p_Pa_calib[0] = 45000.0;

s->p_Pa_calib[1] = 80000.0;

s->p_Pa_calib[2] = 105000.0;

s->LUT_lower = 3.5 * (1LUT_lower + (float)(s->sensor_constants[0] * t * t) * s->quadr_factor;

s2 = s->offst_factor * s->sensor_constants[3] + (float)(s->sensor_constants[1] * t * t) * s->quadr_factor;

s3 = s->LUT_upper + (float)(s->sensor_constants[2] * t * t) * s->quadr_factor;

in[0] = s1;

in[1] = s2;

in[2] = s3;

calculate_conversion_constants(s, s->p_Pa_calib, in, out);

A = out[0];

B = out[1];

C = out[2];

*pressure = A + B / (C + p_LSB);

*temperature = -45.f + 175.f/65536.f * T_LSB;

return 0;

}

// p_Pa -- List of 3 values corresponding to applied pressure in Pa

// p_LUT -- List of 3 values corresponding to the measured p_LUT values at the applied pressures.

void calculate_conversion_constants(struct inv_invpres * s, float *p_Pa,

float *p_LUT, float *out)

Document Number: DS-000329

Revision: 1.1

Page 19 of 30

�ICP-10125

{

float A,B,C;

C = (p_LUT[0] * p_LUT[1] * (p_Pa[0] - p_Pa[1]) +

p_LUT[1] * p_LUT[2] * (p_Pa[1] - p_Pa[2]) +

p_LUT[2] * p_LUT[0] * (p_Pa[2] - p_Pa[0])) /

(p_LUT[2] * (p_Pa[0] - p_Pa[1]) +

p_LUT[0] * (p_Pa[1] - p_Pa[2]) +

p_LUT[1] * (p_Pa[2] - p_Pa[0]));

A = (p_Pa[0] * p_LUT[0] - p_Pa[1] * p_LUT[1] - (p_Pa[1] - p_Pa[0]) * C) / (p_LUT[0] - p_LUT[1]);

B = (p_Pa[0] - A) * (p_LUT[0] + C);

out[0] = A;

out[1] = B;

out[2] = C;

}

5.12 SAMPLE CODE: CONVERSION FORMULA (EXAMPLE PYTHON SYNTAX)

class

InvensensePressureConversion:

""" Class for conversion of the pressure and temperature output of the Invensense sensor"""

def __init__(self, sensor_constants):

""" Initialize customer formula

Arguments:

sensor_constants -- list of 4 integers: [c1, c2, c3, c4]

"""

self.sensor_constants = sensor_constants

# configuration for ICP-10125 Samples

self.p_Pa_calib = [45000.0, 80000.0, 105000.0]

self.LUT_lower = 3.5 * (2**20)

self.LUT_upper = 11.5 * (2**20)

self.quadr_factor = 1 / 16777216.0

self.offst_factor = 2048.0

def calculate_conversion_constants(self, p_Pa, p_LUT):

""" calculate temperature dependent constants

Arguments:

p_Pa -- List of 3 values corresponding to applied pressure in Pa

p_LUT -- List of 3 values corresponding to the measured p_LUT values at the applied pressures.

"""

C = (p_LUT[0] * p_LUT[1] * (p_Pa[0] - p_Pa[1]) +

p_LUT[1] * p_LUT[2] * (p_Pa[1] - p_Pa[2]) +

p_LUT[2] * p_LUT[0] * (p_Pa[2] - p_Pa[0])) / \

(p_LUT[2] * (p_Pa[0] - p_Pa[1]) +

p_LUT[0] * (p_Pa[1] - p_Pa[2]) +

p_LUT[1] * (p_Pa[2] - p_Pa[0]))

A = (p_Pa[0] * p_LUT[0] - p_Pa[1] * p_LUT[1] - (p_Pa[1] - p_Pa[0]) * C) / (p_LUT[0] - p_LUT[1])

Document Number: DS-000329

Revision: 1.1

Page 20 of 30

�ICP-10125

B = (p_Pa[0] - A) * (p_LUT[0] + C)

return [A, B, C]

def get_pressure(self, p_LSB, T_LSB):

""" Convert an output from a calibrated sensor to a pressure in Pa.

Arguments:

p_LSB -- Raw pressure data from sensor

T_LSB -- Raw temperature data from sensor

"""

t = T_LSB - 32768.0

s1 = self.LUT_lower + float(self.sensor_constants[0] * t * t) * self.quadr_factor

s2 = self.offst_factor * self.sensor_constants[3] + float(self.sensor_constants[1] * t * t) * self.quadr_factor

s3 = self.LUT_upper + float(self.sensor_constants[2] * t * t) * self.quadr_factor

A, B, C = self.calculate_conversion_constants(self.p_Pa_calib, [s1, s2, s3])

return A + B / (C + p_LSB)

[end of the pseudocode]

5.13 SAMPLE CODE: USING CONVERSION FORMULA (EXAMPLE PYTHON SYNTAX)

def read_otp_from_i2c():

# TODO: implement read from I2C

# refer to data sheet for I2C commands to read OTP

return 1000, 2000, 3000, 4000

def read_raw_pressure_temp_from_i2c():

# TODO: implement read from I2C

# refer to data sheet for I2C commands to read pressure and temperature

return 8000000, 32000

# Sample code to read

from

Invensense_pressure_conversion import

Invensense_pressure_conversion

# -- initialization

c1, c2, c3, c4 = read_otp_from_i2c()

conversion =

Invensense_pressure_conversion([c1, c2, c3, c4])

# -- read raw pressure and temp data, calculate pressure

p, T = read_raw_pressure_temp_from_i2c()

pressure = conversion.get_pressure(p, T)

print 'Pressure: %f' % pressure

[end of the pseudocode]

Document Number: DS-000329

Revision: 1.1

Page 21 of 30

�ICP-10125

5

6

7

8

S 1 1 0 0 0 1 1 0

I2C address + write

9

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

0 1 0 1 0 0 0 0

Measurement command

MSB

0 1 0 1 1 0 0 1

Measurement command

LSB

S 1 1 0 0 0 1 1 1

NACK

29 30 31 32 33 34 35 36 37 38 39

repeated I2C address +

read while meas. is in

prog. (polling)

P

ICP-10125

measuring

measurement

cont’d

measurement

completed

0 0 0 1 1 1 0 0

Pressure CRC

checksum

Pressure MLSB

Pressure LMSB

0 0 0 1 1 1 0 0

ACK

0 0 1 1 0 0 1 1

ACK

ACK

77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103

1 0 1 0 0 0 0 1

Pressure CRC

checksum

Pressure LLSB

Temperature MSB

Temperature LSB

1 1 0 0 0 1 1 1

NACK

1 0 0 0 1 0 1 1

ACK

ACK

104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131

0 1 1 0 0 1 0 0

P

Temperature CRC

checksum

Figure 5. Communication Data Sequences

Document Number: DS-000329

Revision: 1.1

Measurement in progress

ICP-10125 in

S

idle state

ACK

ACK

ACK

Pressure MMSB

0 0 1 1 0 0 1 1

ICP-10125 measuring

40 41 42 43 44 45 46 47 48 49

50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76

1 0 1 0 0 0 0 1

P

Page 22 of 30

1 1 0 0 0 1 1 1

I2C address + read

ACK

4

ACK

3

ACK

1 2

ACK

5.14 COMMUNICATION DATA SEQUENCES

�ICP-10125

6 ASSEMBLY

This section provides general guidelines for assembling TDK-InvenSense Micro Electro-Mechanical Systems (MEMS)

pressure sensors.

6.1

IMPLEMENTATION AND USAGE RECOMMENDATIONS

6.1.1 Soldering

When soldering, use the standard soldering profile IPC/JEDEC J-STD-020 with peak temperatures of 260°C. ICP10125 may exhibit a pressure offset after soldering, some settling time may be required depending on soldering

properties, PCB properties, and ambient conditions.

The ICP-10125 package consists of a chimney port that opens to the sensing element. Special care must be taken

during soldering process to avoid contaminating the sensor through the open chimney.

1.

Solder the sensor as a second soldering operation, after other components have been soldered

2.

Use No-Clean solder paste

3.

Sensor must not be subjected to board washing of any kind (critical)

6.1.2 Chemical Exposure and Sensor Protection

The ICP-10125 must not be exposed to particulates or liquids. If any type of protective coating must be applied to

the circuit board, the sensor must be protected during the coating process.

For further information on assembly, please refer to AN-000140 TDK-InvenSense Pressure Sensor PCB

Design Guidelines.

Document Number: DS-000329

Revision: 1.1

Page 23 of 30

�ICP-10125

7 PACKAGE DIMENSIONS

Package dimensions for the ICP-10125:

Top View

Side & Bottom View

Figure 6. ICP-10125 Package Diagram

Document Number: DS-000329

Revision: 1.1

Page 24 of 30

�ICP-10125

Recommended PCB land pattern for the ICP-10125:

3.6mm

1.4mm

10

9

8

1

7

0.7mm

0.45mm

2

3.6mm

Pin 1 Indicator

6

3

4

5

0.75mm

0.6mm R

0.95mm

Top View

Figure 7. ICP-10125 recommended PCB land pattern

Product artwork for the ICP-10125:

Pin 1 Indicator

Pin 1 corner marking (front view)

Front View

Back View

Figure 8. ICP-10125 Artwork

Document Number: DS-000329

Revision: 1.1

Page 25 of 30

Side View

�ICP-10125

8 TAPE AND REEL SPECIFICATION

Figure 9. ICP-10125 Tape Dimensions

Figure 10. Tape and Reel Orientation

Document Number: DS-000329

Revision: 1.1

Page 26 of 30

�ICP-10125

9 ORDERING GUIDE

PART

TEMP RANGE

PACKAGE BODY

QUANTITY

PACKAGING

ICP-10125†

−40°C to +85°C

3.55x3.55x1.45mm HTCC-10L

3000

13” Tape and Reel

†Denotes RoHS and Green-Compliant Package

Document Number: DS-000329

Revision: 1.1

Page 27 of 30

�ICP-10125

10 REFERENCES

Please refer to “InvenSense MEMS Handling Application Note (AN-IVS-0002A-00)” for the following information:

• Manufacturing Recommendations

o Assembly Guidelines and Recommendations

o PCB Design Guidelines and Recommendations

o MEMS Handling Instructions

o ESD Considerations

o Reflow Specification

o Storage Specifications

o Package Marking Specification

o Tape & Reel Specification

o Reel & Pizza Box Label

o Packaging

o Representative Shipping Carton Label

• Compliance

o Environmental Compliance

o DRC Compliance

o Compliance Declaration Disclaimer

Document Number: DS-000329

Revision: 1.1

Page 28 of 30

�ICP-10125

11 REVISION HISTORY

REVISION DATE

REVISION

DESCRIPTION

09/04/2020

1.0

Initial Release

04/09/2021

1.1

Formatting Updates; Updated Pressure Sensor Specs (Table 3); Added Tape and Reel

Specification (Section 8)

Document Number: DS-000329

Revision: 1.1

Page 29 of 30

�ICP-10125

This information furnished by InvenSense or its affiliates (“TDK InvenSense”) is believed to be accurate and reliable. However, no responsibility is assumed by TDK

InvenSense for its use, or for any infringements of patents or other rights of third parties that may result from its use. Specifications are subject to change without

notice. TDK InvenSense reserves the right to make changes to this product, including its circuits and software, in order to improve its design and/or performance,

without prior notice. TDK InvenSense makes no warranties, neither expressed nor implied, regarding the information and specifications contained in this document.

TDK InvenSense assumes no responsibility for any claims or damages arising from information contained in this document, or from the use of products and services

detailed therein. This includes, but is not limited to, claims or damages based on the infringement of patents, copyrights, mask work and/or other intellectual

property rights.

Certain intellectual property owned by InvenSense and described in this document is patent protected. No license is granted by implication or otherwise under any

patent or patent rights of InvenSense. This publication supersedes and replaces all information previously supplied. Trademarks that are registered trademarks are

the property of their respective companies. TDK InvenSense sensors should not be used or sold in the development, storage, production or utilization of any

conventional or mass-destructive weapons or for any other weapons or life threatening applications, as well as in any other life critical applications such as medical

equipment, transportation, aerospace and nuclear instruments, undersea equipment, power plant equipment, disaster prevention and crime prevention equipment.

©2020—2021 InvenSense. All rights reserved. InvenSense, MotionTracking, MotionProcessing, MotionProcessor, MotionFusion, MotionApps, DMP, AAR, and the

InvenSense logo are trademarks of InvenSense, Inc. The TDK logo is a trademark of TDK Corporation. Other company and product names may be trademarks of the

respective companies with which they are associated.

©2020—2021 InvenSense. All rights reserved.

Document Number: DS-000329

Revision: 1.1

Page 30 of 30

�