Te m p e r a t u r e P r o t e c t i o n D e v i c e s

December 2021

Temperature protection device

Chip NTC thermistor

Automotive grade, for conductive glue

NTCSP series

NTCSP10

NTCSP16

JIS 1005 [EIA 0402]

JIS 1608 [EIA 0603]

�(2/12)

Temperature Protection Devices

REMINDERS FOR USING THESE PRODUCTS

Before using these products, be sure to request the delivery specifications.

SAFETY REMINDERS

Please pay sufficient attention to the warnings for safe designing when using this products.

Incorrect usage may cause smoke or fire.

REMINDERS

Please use them within the ranges of the ratings and performance provided in the catalog and delivery specifications upon confirming the environments where they are to be used and installed.

Do not use them outside the operating temperature range.

Do not use them with the ratings or maximum permissible power levels exceeded.

Do not quickly apply 5mW or more of load with the constant-voltage power supply as this may lead to staying in thermal runaway mode or the redshorting of chips.

Please be cautious of the applied voltage in thermistors as instruments may malfunction with the lowering of resistance due to self heating.

With instruments that consumers can touch the thermistors with their hands, please carefully warn them not to touch the thermistors.

Store them in locations where the temperature is 10°C to +40°C and the relative humidity is 75% or below, avoid environments where there are sudden changes in temperatures, direct sunlight, corrosive gas, grit, or dust, and keep them packed in a manner where no loading stress is applied in

order to avoid deterioration and damage.

(Please use within 6 months after delivery.)

If the storage period is exceeded, the surface of the terminal electrode may be oxidized or sulfided and the resistance value may shift.

When sealing thermistors, please do so upon first considering the type, quantity, hardening conditions, and adhesiveness of the sealing material and

confirming its reliability.

Avoid powerful vibrations, impact (such as by dropping), pressure, etc. on thermistors that exceed the prescribed levels.

Do not use them for long periods of time in environments with a relative humidity of over 85%. (this excludes cases where countermeasures have

been taken.)

Do not use them in the following environments. (this excludes cases where countermeasures have been taken.)

・Corrosive gases (Cl2, NH3, SOx, NOx, etc.)

・Environments with highly conductive substances (electrolytes, water, saltwater, etc.)

・Environments with acid, alkali, or organic solvents

・Dusty areas

When using an alumina substrate, do a reliability test beforehand certainly, and please confirm that it's no problem (Cracks don't occur to a product.)

Please observe the following precautions when attaching them to substrates as failure to do so may result in destruction or malfunction.

・Do not let the substrates get warped or twisted at any time during mounting.

・The landing size must be even on both the left and right sides.

・Do not use items that have been dropped or detached.

・The conductive paste is used in an appropriate amount.

Please use a substance such as resin that does not generate hydrogen (H2) when forming insulation film over chips.

The products listed on this specification sheet are intended for use in general electronic equipment (AV equipment, telecommunications equipment,

home appliances, amusement equipment, computer equipment, personal equipment, office equipment, measurement equipment, industrial robots)

under a normal operation and use condition.

The products are not designed or warranted to meet the requirements of the applications listed below, whose performance and/or quality require a

more stringent level of safety or reliability, or whose failure, malfunction or trouble could cause serious damage to society, person or property.

Please note that you cannot take responsibility for the damage caused by the use of this specification beyond the scope and conditions of the

applications listed below or this specification sheet.

If you plan to use this product beyond the scope and conditions of the applications listed below or this specification sheet, please consult us at

advance. We will discuss the contents of the warranty in accordance with your use.

(1) Aerospace/aviation equipment

(2) Transportation equipment (electric trains, ships, etc.)

(3) Medical equipment

(4) Power-generation control equipment

(5) Atomic energy-related equipment

(6) Seabed equipment

(7) Transportation control equipment

(8) Public information-processing equipment

(9) Military equipment

(10) Electric heating apparatus, burning equipment

(11) Disaster prevention/crime prevention equipment

(12) Safety equipment

(13) Other applications that are not considered general-purpose

applications

When designing your equipment even for general-purpose applications, you are kindly requested to take into consideration securing protection circuit/device or providing backup circuits in your equipment.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�(3/12)

Temperature Protection Devices

Product compatible with RoHS directive

Corresponding to conductive glue

Chip NTC thermistor

Automotive grade, for conductive glue

Overview of the NTCSP series

CHARACTERISTICS OF NTC THERMISTORS

NTC(Negative Temperature Coefficient) thermistors are

manufactured from sintered metal oxides. Each thermistor

consists of a combination of two to four of the following materials:

manganese, nickel, cobalt and copper. NTC thermistors are

semiconductor resistors that exhibit decreasing resistance

characteristics with increasing temperature. TDK thermistors have

low thermal time constants which result in extremely high rates of

resistance change to accurately track the temperature.

Fig.1 R-T Curve : 10kohm@25°C

FEATURES OF NTCG SERIES

Conductive glue can mount.

The line-up corresponding to 150 °C.

AEC-Q200 compliant.

Fig.2 Internal structure of the multilayer chip Thermistors

Plated terminal type

Conductive epoxy type

1000

Resistance (kΩ)

100

Sn

Ni

Ag

AgPd

10

APPLICATIONS

For only conductive glue mounting, not for solder mounting.

ABS, transmission, engine sensors, etc.

1

0.1

–100

–50

0

50

100

Temperature (°C)

150

200

RoHS Directive Compliant Product: See the following for more details.https://product.tdk.com/info/en/environment/rohs/index.html

Please be sure to request delivery specifications that provide further details on the features and specifications of the products for proper and safe use.

Please note that the contents may change without any prior notice due to reasons such as upgrading.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�(4/12)

Temperature Protection Devices

Product compatible with RoHS directive

Corresponding to conductive glue

Chip NTC thermistor

Automotive grade, for conductive glue

Overview of the NTCSP series

PART NUMBER CONSTRUCTION

NTC

SP

○○

3J

□

Series

name

Structural

classification

shapes and

dimensions

Code

(mm)

B

constant

B constant

tolerance

(%)

NTC

thermistor

SP

Corresponding to

conductive glue

10

1005

16

1608

F

±1

103

□

T

□□□

Nominal

resistance

Nominal

resistance

tolerance

(%)

Packaging

style

TDK internal code

F

T

Taping

1S

B

Bulk

1SX

()

103

473

104

B

10,000

(10k)

47,000

(47k)

100,000

(100k)

±1

150°C vehicle response

B constant: 25/85°C

150°C vehicle response

B constant: 25/50°C

constant

B constant(K)

2000 to 2050

2051 to 2100

2101 to 2150

2201 to 2250

2251 to 2300

2401 to 2450

2451 to 2500

2501 to 2550

2601 to 2650

2701 to 2750

2801 to 2850

2A

2B

2C

2E

2F

2J

2K

2L

2N

2Q

2S

3A

3B

3C

3E

3F

3J

3K

3L

3N

3Q

3S

3000 to 3050

3051 to 3100

3101 to 3150

3201 to 3250

3251 to 3300

3401 to 3450

3451 to 3500

3501 to 3550

3601 to 3650

3701 to 3750

3801 to 3850

4A

4B

4C

4E

4F

4J

4K

4L

4N

4Q

4S

4000 to 4050

4051 to 4100

4101 to 4150

4201 to 4250

4251 to 4300

4401 to 4450

4451 to 4500

4501 to 4550

4601 to 4650

4701 to 4750

4801 to 4850

B constant calculation formula

B=

InR1–InR2

(1/T1)–(1/T2)

Shape symbol (JIS)

1005

1608

B: B constant (K)

T1:Arbitrary temperature (K)

T2:Arbitrary temperature different from T1 (K)

R1:Zero-load resistance value at temperature T1()

R2:Zero-load resistance value at temperature T2()

Each temperature is measured in absolute temperature. 0°C=273.15K

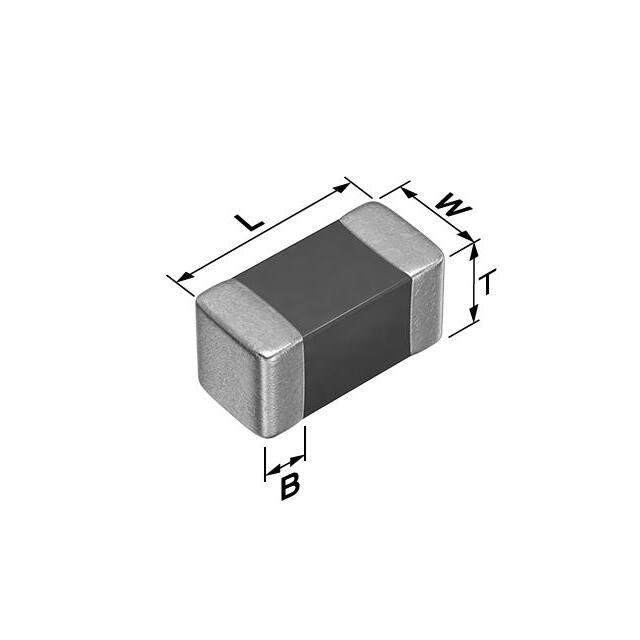

L

1.00±0.05

1.60±0.10

W

0.50±0.05

0.80±0.10

T

0.50±0.05

0.80±0.10

Dimensions in mm

B

0.1min

0.2min

COMPATIBLE WITH CONDUCTIVE GLUE

mm

1005

1608

Size

Maximum rated power (25°C)Asteris1 mW

125

125

Dissipation factors (25°C) 2

mW/°C | mW/K

1

1

1 Maximum rated power: Maximum power: at rated temperature (25°C), maximum power that can be applied continuously

2 Dissipation factors: powered that it is equivalent that be increased in self-heating by load power thermistor at 1°C temperature

Please be sure to request delivery specifications that provide further details on the features and specifications of the products for proper and safe use.

Please note that the contents may change without any prior notice due to reasons such as upgrading.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�(5/12)

Temperature Protection Devices

Product compatible with RoHS directive

Corresponding to conductive glue

Chip NTC thermistor

Automotive grade, for conductive glue

NTCSP series 1005 type

SHAPE & DIMENSIONS

RECOMMENDED LAND PATTERN

0.5±0.05

0.5 to 0.7

1±0.05

0.35 to 0.45

0.6min.

0.35 to 0.45

0.5±0.05

0.1 min.

Electrode material

Internal:Pd

External:Ag/Pg

Dimensions in mm

COMPATIBLE WITH CONDUCTIVE GLUE (OPERATING TEMPERATURE RANGE:–55 to 150°C)

Part No.

Resistance

[25°C]

()

NTCSP103JF103FT1S

10,000

NTCSP104BF473FT1SX

47,000

100,000

NTCSP104KF104FT1S

Resistance

tolerance

B constant

[25/50°C]

(K)

B constant

[25/75°C]

(K)

B constant

[25/85°C]

(K)

B constant

[25/100°C]

(K)

B constant

tolerance

±1%

±1%

±1%

3380

4050

4419

3422

4098

4468

3435

4114

4485

3453

4137

4509

±1%

±1%

±1%

Permissible

operating

current

[25°C]

(mA)

0.31

0.14

0.10

Please be sure to request delivery specifications that provide further details on the features and specifications of the products for proper and safe use.

Please note that the contents may change without any prior notice due to reasons such as upgrading.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�(6/12)

Temperature Protection Devices

Product compatible with RoHS directive

Corresponding to conductive glue

Chip NTC thermistor

Automotive grade, for conductive glue

NTCSP series 1608 type

SHAPE & DIMENSIONS

RECOMMENDED LAND PATTERN

0.8±0.1

1.1 to 1.3

1.6±0.1

0.6 to 0.8

0.9min.

0.6 to 0.8

0.8±0.1

0.2 min.

Electrode material

Internal:Pd

External:Ag/Pd

Dimensions in mm

COMPATIBLE WITH CONDUCTIVE GLUE (OPERATING TEMPERATURE RANGE:–55 to 150°C)

Part No.

Resistance

[25°C]

()

NTCSP163JF103FT1S

10,000

NTCSP164BF473FT1SX

47,000

100,000

NTCSP164KF104FT1S

Resistance

tolerance

B constant

[25/50°C]

(K)

B constant

[25/75°C]

(K)

B constant

[25/85°C]

(K)

B constant

[25/100°C]

(K)

B constant

tolerance

±1%

±1%

±1%

3380

4050

4419

3422

4098

4468

3435

4114

4485

3453

4137

4509

±1%

±1%

±1%

Permissible

operating

current

[25°C]

(mA)

0.31

0.14

0.10

Please be sure to request delivery specifications that provide further details on the features and specifications of the products for proper and safe use.

Please note that the contents may change without any prior notice due to reasons such as upgrading.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�(7/12)

Temperature Protection Devices

Product compatible with RoHS directive

Corresponding to conductive glue

Chip NTC thermistor

Automotive grade, for conductive glue

NTCSP series RT table

R-T TABLE ACQUISITION PROCEDURE

1. Access the top page of the TDK chip NTC thermistor (protective device)

https://product.tdk.com/info/en/products/protection/temperature/chip-ntc-thermistor/index.html

2. Click [Search by Part No.]

https://product.tdk.com/en/search/protection/temperature/chip-ntc-thermistor/part_no/

3. Enter the product name you want in the RT table in the box and click the Search button.

( Example: NTCG103JF103FT1 )

Wildcard and Multiple Part number.

NTCG103JF103FT1

Question mark (?) and asterisk (*) can be used as wildcard characters.

Search

The question mark (?) matches any single character, and the asterisk (*)

matches any sequence of characters.

Enable the real time search

Enter only one part number per line. Up to 50 part numbers can be

searched simultaneously.

A part number search is normally performed using a prefix search. If you

wish to use a suffix search, enter an exclamation mark (!) at the end of

the Part No.

4. Click the displayed product name.

( Example: NTCG103JF103FT1 )

Catalog /

Check Data

Images

Sheet

Part No.

NTCG103JF103FT1

New

NTCG103JF103FT1S

Distributor

Inventory

Brand

Buy Now

TDK

Buy Now

TDK

Apps.

Feature

125°C

UL

150°C

AEC-Q200

5. Individual pages are displayed and click the RT table in the "Document" on the right side bar.

Documents

Catalog

RoHS Certificate

SVHC/REACH Certificate

Selection Guide

RT Sheet

6. You can download the csv file in the 1°C step of the RT table for the product.

Please be sure to request delivery specifications that provide further details on the features and specifications of the products for proper and safe use.

Please note that the contents may change without any prior notice due to reasons such as upgrading.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�(8/12)

Temperature Protection Devices

Product compatible with RoHS directive

Corresponding to conductive glue

Chip NTC thermistor

Automotive grade, for conductive glue

Attention in the board design

BOARD DESIGN

Amount of conductive glue

When attached to NTC substrate thermistor, amount of conductive

glue has direct impact on NTC thermistor after mounting. Thus,

sufficient consideration is necessary.

Excessive amount of conductive glue during mounting can cause

electrical path formation under the chip (between the lands).

In addition, when the amount of conductive glue is excessive, the

terminal electrode sticking force is insufficient, causing chip falling

off, which may affect the reliability of the circuit. A typical example

of the amount of conductive glue is shown below.

Set of land dimensions

As the stress rises in the NTC thermistor owing to the increase in

silver, breakage and cracks will occur. Cause including crack, as

caution on board land design, configure the shape and dimensions

so that the amount of conductive glue is appropriate.

Excess adhesive forms a

conductive path under the

chip.

Conductive glue

overload

C

B

Shape symbol

1005

1608

Conductive glue

volume

A

Symbol

A

0.6min.

0.9min.

B

0.35 to 0.45

0.60 to 0.80

C

0.50 to 0.70

1.10 to 1.30

The sticking force is weak,

the connection is bad, and

there is a risk of falling off.

Conductive glue

deficit

Attention on the mounting

APPLICATION TO BOARD

Mounting head pressure

Under suction nozzle if dead point too, during implementation,

excessive force joins of NTC thermistor low, as cause causes of

crack, please use with reference to something about following.

1) The bottom dead center of the suction nozzle is set on the upper

surface of the substrate to adjust the excessive load to the

substrate.

2) Nozzle pressure at implementation is 1N−3N in static load,

please.

Cases to avoid

Recommended case

Crack

Single-sided

mounting

Support pin

Double-sided

mounting

Peeling

Crack

Support pin

Please be sure to request delivery specifications that provide further details on the features and specifications of the products for proper and safe use.

Please note that the contents may change without any prior notice due to reasons such as upgrading.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�(9/12)

Temperature Protection Devices

Chip NTC thermistor

Product compatible with RoHS directive

Corresponding to conductive glue

Automotive grade, for conductive glue

Single-part component handling

(1) To drop impact, as there is possibility that breakage and crack is

entered, do not NTC thermistor that(1) NTC thermistor falls.

Crack

Floor

(2) At stacking storage after implementation and treatment of

substrate, corner of boards is regarded as NTC thermistor. Please

be careful, as there is the possibility that breakage and cracks will

occur on impact.

Crack

Board

Please be sure to request delivery specifications that provide further details on the features and specifications of the products for proper and safe use.

Please note that the contents may change without any prior notice due to reasons such as upgrading.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�(10/12)

Temperature Protection Devices

Product compatible with RoHS directive

Corresponding to conductive glue

Chip NTC thermistor

Automotive grade, for conductive glue

Packaging style

REEL DIMENSIONS

PACKAGE QUANTITY, PRODUCT WEIGHT

Type

2.0±0.5

Individual weight

(mg)

1.3

5.0

ø60min.

NTCSP10

NTCSP16

Package quantity

(pieces/reel)

10,000

4,000

0.8

ø13±0.2

9.0max.

ø21±0.8

14.0max.

ø180±2.0

Dimensions in mm

2.0±0.05

4.0±0.1

A

8.0±0.3

B

3.5±0.05

1.5 +0.1

0

1.75±0.1

TAPE DIMENSIONS

T

P1

Dimensions in mm

Type

1005

1608

A

0.65+0.05/-0.1

1.1±0.2

160min.

Drawing direction

Taping

B

1.15+0.05/-0.1

1.9±0.2

P1

2±0.05

4.0±0.1

T

0.65max.

1.1max.

200min.

200min.

Dimensions in mm

Please be sure to request delivery specifications that provide further details on the features and specifications of the products for proper and safe use.

Please note that the contents may change without any prior notice due to reasons such as upgrading.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�(11/12)

Temperature Protection Devices

Chip NTC thermistor

Product compatible with RoHS directive

Corresponding to conductive glue

Automotive grade, for conductive glue

Description and definition of terms

INITIAL RESISTANCE

Thermistor resistance is a function of absolute temperature as indicated by the following relationship:

1

1 ............................................................ (1)

–

R=R0 • expB

T

T0

(

)

Here R0, R(k) are the respective resistance values when the surrounding temperature is T0, T(K). B is the thermistor constant(B constant below).

B CONSTANT

The B constant is found from the following equation:

B=

2.3026(logR–logR0)

1 – 1

T T0

....................................................... (2)

This B characteristic is indicated by the slope of the linear plot of log R-1/T inverse absolute temperature.

The B constant value is generally in the vicinity of 2500K to 5000K. B constant values of 3000K to 4000K are frequently used for measurements.

Resistance-temperature characteristics (Fig.1)

450 400 350 300

Temperature(˚C)

250

200

150

100

100

20kΩ /200˚C

Resistance (kΩ)

10

3.3kΩ/100˚C

1

1.4

1.6

1.8

2

2.2

1 × 10 3 (K)

T

2.4

2.6

2.8

3

TEMPERATURE COEFFICIENT

The relationship between temperature coefficient and B becomes:

B

1 dR

= •

= – 2 100(%/°C) ............................................. (3)

T

R dT

The negative sign of the temperature coefficient indicates that the temperature coefficient decreases as both thermistor resistance and

temperature rise. If B is taken as 3400K, the temperature coefficient found at 20°C (293.15K) becomes –4%/°C.

HEAT DISSIPATION COEFFICIENT

Temperature rises due to thermal energy formed as electrical current flows through the thermistor. The thermistor temperature T0 is then

related to the surrounding temperature Ta and the electrical input W:

W=k(T0–Ta)=V•I(mW) ............................................................ (4)

k=

W

(mW/°C) .............................................................. (5)

T0 –Ta

This k value is the heat dissipation coefficient, which represents the additional electrical power (mW/°C) needed to raise the thermistor

temperature by 1°C. This heat dissipation coefficient varies with changes in the measurement and environmental conditions. When a

thermistor is used for temperature measurement, it is naturally important to lower the applied electrical current as much as possible in

order to reduce measurement error resulting from self heating.

Please be sure to request delivery specifications that provide further details on the features and specifications of the products for proper and safe use.

Please note that the contents may change without any prior notice due to reasons such as upgrading.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�(12/12)

Temperature Protection Devices

Product compatible with RoHS directive

Corresponding to conductive glue

Chip NTC thermistor

Automotive grade, for conductive glue

Description and definition of terms

VOLTAGE - CURRENT CHARACTERISTIC

The voltage - current characteristic indicates the drop in voltage as electrical current through the thermistor is gradually increased.

Voltage-current characteristics (Fig.2)

100

5

4

10

3

Voltage (V)

2

1

1

0.1

Ta=25˚C (in still air)

No.1 5kΩ

2 10kΩ

3 20kΩ

4 50kΩ

5 100kΩ

10

100

1

Current (mA)

HEATING TIME CONSTANT

The time period required to heat up a thermistor from a certain temperature T0 over a target temperature rise is called the heating time

constant. Various types of heating time constants are indicated by the symbols shown in Table 1 as determined by the percent change

from T0 toward the target temperature. The standard change is typically taken to be 63.2%.

Thermal time constants (Fig.3)

70

Table 1 Heating time constant and temperature change ratio

Heating

Code

2

3

4

5

6

7

Th

40

Tc

30

20

(T0 –Ta)

×0.368

Temperature (˚C)

50

T0

(T0 –Ta)

×0.632

60

Room temperature Ta

Cooling

Rate of change (%) for T0 -Ta

63.2

86.5

95.0

98.2

99.4

99.8

99.9

10

0

τ

2τ

3τ

4τ

5τ

6τ

7τ

PERMISSIBLE OPERATING CURRENT

This is the maximum load current limit below 1°C temperature rise due to thermistor self-heating.

It's possible to express it in the following system.

Maximum allowed current [mA] = √(Heat dissipation constant[mW/°C] ÷ Resistance[]

Please be sure to request delivery specifications that provide further details on the features and specifications of the products for proper and safe use.

Please note that the contents may change without any prior notice due to reasons such as upgrading.

20211201 / tpd_automotive_ntc-thermistor_ntcsp_en.fm

�