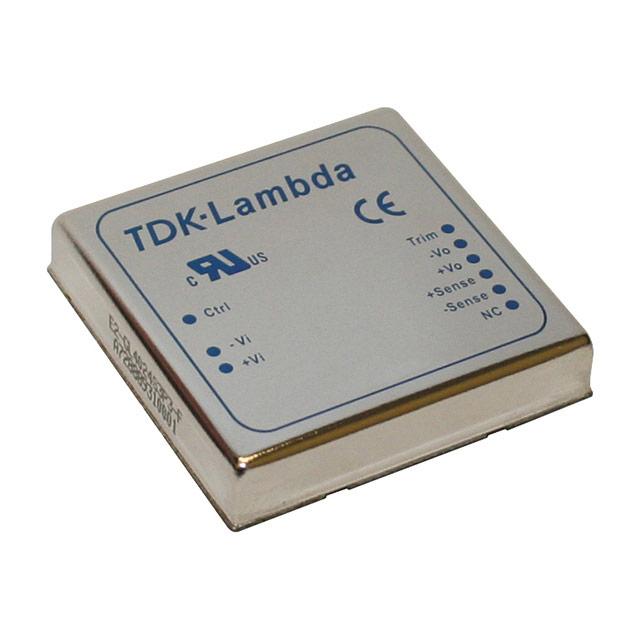

PXF40-xxWDxx Dual Output DC/DC Converter

9 to 36 Vdc and 18 to 75 Vdc input, ±12 to ±15 Vdc Dual Output, 40W

Features

Dual output current up to ±1.667A

40 watts maximum output power

4:1 ultra wide input voltage range of 9-36 and 18-75VDC

Six-sided continuous shield

Case grounding

High efficiency up to 86%

Low profile:2.002.000.40 inch (50.850.810.2 mm )

Fixed switching frequency

RoHS directive compliant

Input to output isolation: 1600Vdc,min

Over-temperature protection

Input under-voltage protection

Output over-voltage protection

Over-current protection, auto-recovery

Output short circuit protection, auto-recovery

Applications

Wireless Network

Telecom/Datacom

Industry Control System

Measurement Equipment

Semiconductor Equipment

Remote ON/OFF

Options

Heat sinks available for extended operation

Remote ON/OFF logic configuration

General Description

The PXF40-xxWDxx dual output converters offer 40 watts of output power from a 2.00 x 2.00 x 0.4 inch

package. This series with a 4:1 ultra wide input voltage of 9-36VDC and 18-75VDC, features 1600VDC of

isolation, short-circuit, over-voltage and over-temperature protection, as well as six sided shielding. All models

are particularly suited for telecommunications, industrial, mobile telecom and test equipment applications.

Table of contents

Absolute Maximum Ratings

Output Specification

Input Specification

General Specification

Characteristic Curves

Test Configurations

EMC Considerations

Input Source Impedance

Output Over Current Protection

Output Over Voltage Protection

Thermal Consideration

P2

P2

P3

P4

P5

P13

P14

P16

P16

P16

P16

Heat Sink Consideration

Remote ON/OFF Control

Mechanical Data

Recommended Pad Layout

Output Voltage Adjustment

Soldering Consideration

Packaging Information

Part Number Structure

Safety and Installation Instructions

MTBF and Reliability

P17

P18

P19

P19

P20

P21

P21

P22

P22

P22

�DataSheet

40W, Dual Output

Absolute Maximum Rating

Parameter

Model

Input Voltage

Continuous

Transient (100ms)

Operating Ambient Temperature (with derating)

Operating Case Temperature

Storage Temperature

24WDxx

48WDxx

24WDxx

48WDxx

All

All

All

Min

Max

Unit

36

75

50

100

105

105

125

-40

-55

VDC

°C

°C

°C

Output Specification

Parameter

Output Voltage

(Vin = Vin(nom) ; Full Load ; TA=25°C)

Model

Min

Typ

Max

xxWD12

11.88

12

12.12

xxWD15

14.85

15

15.15

All

-0.2

+0.2

-1.0

+1.0

-5.0

+5.0

Unit

VDC

Output Regulation

Line (Vin(min) to Vin(max) at Full Load)

Load (Min. to 100% of Full Load)

Cross Regulation

Asymmetrical Load 25% / 100% of Full Load

Output Ripple & Noise

Peak-to-Peak (20MHz bandwidth)

Temperature Coefficient

Output Voltage Overshoot

(Vin(min) to Vin(max); Full Load; TA=25°C)

All

xxWD12

120

xxWD15

150

All

-0.02

All

%

%

mVp-p

+0.02

%/°C

3

% VOUT

Dynamic Load Response

(Vin = Vin(nom) ; TA=25°C)

Load step change from

75% to 100% or 100 to 75% of Full Load

Peak Deviation

Setting Time (VOUT<10% peak deviation)

Output Current

Output Over Voltage Protection

(Zener diode clamp)

All

200

mV

All

250

μS

xxWD12

±65

±1667

xxWD15

±50

±1333

xxWD12

15

xxWD15

18

Output Over Current Protection

All

Output Short Circuit Protection

All

mA

VDC

150

% FL.

Hiccup, automatic recovery

VER:00 Page 2 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Input Specification

Parameter

Operating Input Voltage

Input Current

(Maximum value at Vin = Vin(nom); Full Load)

Input Standby Current

(Typical value at Vin = Vin(nom); No Load)

Under Voltage Lockout Turn-on Threshold

Under Voltage Lockout Turn-off Threshold

Input Reflected Ripple Current

(5 to 20MHz, 12μH Source Impedance)

Model

Min

Typ

Max

24WDxx

9

24

36

48WDxx

18

48

75

24WD12

2032

24WD15

2032

48WD12

1016

48WD15

1016

24WD12

60

24WD15

70

48WD12

30

48WD15

30

9

48WDxx

18

8

48WDxx

16

All

20

VDC

mA

mA

24WDxx

24WDxx

Unit

VDC

VDC

mAp-p

Start Up Time

(Vin = Vin(nom) and constant resistive load)

Power up

20

All

Remote ON/OFF

mS

20

Remote ON/OFF Control

(The ON/OFF pin voltage is referenced to -VIN)

Negative Logic DC-DC ON(Short)

DC-DC OFF(Open)

Positive Logic

All

0

1.2

3

12

DC-DC ON(Open)

3

12

DC-DC OFF(Short)

0

1.2

Remote Off Input Current

Input Current of Remote Control Pin

24WDxx

10

48WDxx

5

All

-0.5

VDC

mA

0.5

mA

VER:00 Page 3 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

General Specification

Parameter

Efficiency

(Vin = Vin(nom) ; Full Load ; TA=25°C)

Model

Min

Typ

24WD12

86

24WD15

86

48WD12

86

48WD15

86

Max

Unit

%

Isolation Voltage

Input to Output

All

Input (Output) to Case

VDC

1600

1600

Isolation Resistance

All

1

GΩ

Isolation Capacitance

All

Switching Frequency

All

300

kHz

Weight

All

60

g

All

1.105×106

2500

pF

MTBF

Bellcore TR-NWT-000332, TC=40°C

1.511×105

MIL-HDBK-217F

Over Temperature Protection

All

110

hours

°C

VER:00 Page 4 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Characteristic Curves

All test conditions are at 25°C.The figures are for PXF40-24WD12

Efficiency Versus Output Current

Efficiency Versus Input Voltage. Full Load

Power Dissipation Versus Output Current

Derating OutputCurrentVersusAmbientTemperature and

Airflow Vin = Vin(nom)

Derating OutputCurrentVersusAmbientTemperature with Heat-Sink

andAirflow ,Vin = Vin(nom)

VER:00 Page 5 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Characteristic Curves (Continued)

All test conditions are at 25°C.The figures are for PXF40-24WD12

Typical Output Ripple and Noise.

Transient Response to Dynamic Load Change from

Vin = Vin(nom), Full Load

100% to 75% to 100% of Full Load ; Vin = Vin(nom)

Typical Input Start-Up and Output Rise Characteristic

Using ON/OFF Voltage Start-Up and Vo Rise Characteristic

Vin = Vin(nom), Full Load

Vin = Vin(nom), Full Load

Conduction Emission of EN55022 Class A

Conduction Emission of EN55022 Class B

Vin = Vin(nom), Full Load

Vin = Vin(nom), Full Load

VER:00 Page 6 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Characteristic Curves (Continued)

All test conditions are at 25°C. The figures are for PXF40-24WD15

Efficiency Versus Output Current

Efficiency Versus Input Voltage. Full Load

Power Dissipation Versus Output Current

Derating OutputCurrentVersusAmbientTemperature and

Airflow Vin = Vin(nom)

Derating OutputCurrentVersusAmbientTemperature with Heat-Sink

andAirflow ,Vin = Vin(nom)

VER:00 Page 7 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Characteristic Curves (Continued)

All test conditions are at 25°C.The figures are for PXF40-24WD15

Typical Output Ripple and Noise.

Transient Response to Dynamic Load Change from

Vin = Vin(nom), Full Load

100% to 75% to 100% of Full Load ; Vin = Vin(nom)

Typical Input Start-Up and Output Rise Characteristic

Using ON/OFF Voltage Start-Up and Vo Rise Characteristic

Vin = Vin(nom), Full Load

Vin = Vin(nom), Full Load

Conduction Emission of EN55022 Class A

Conduction Emission of EN55022 Class B

Vin = Vin(nom), Full Load

Vin = Vin(nom), Full Load

VER:00 Page 8 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Characteristic Curves (Continued)

All test conditions are at 25°C.The figures are for PXF40-48WD12

Efficiency Versus Output Current

Efficiency Versus Input Voltage. Full Load

Power Dissipation Versus Output Current

Derating OutputCurrentVersusAmbientTemperature and

Airflow Vin = Vin(nom)

Derating OutputCurrentVersusAmbientTemperature with Heat-Sink

andAirflow ,Vin = Vin(nom)

VER:00 Page 9 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Characteristic Curves (Continued)

All test conditions are at 25°C.The figures are for PXF40-48WD12

Typical Output Ripple and Noise.

Transient Response to Dynamic Load Change from

Vin = Vin(nom), Full Load

100% to 75% to 100% of Full Load ; Vin = Vin(nom)

Typical Input Start-Up and Output Rise Characteristic

Using ON/OFF Voltage Start-Up and Vo Rise Characteristic

Vin = Vin(nom), Full Load

Vin = Vin(nom), Full Load

Conduction Emission of EN55022 Class A

Conduction Emission of EN55022 Class B

Vin = Vin(nom), Full Load

Vin = Vin(nom), Full Load

VER:00 Page 10 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Characteristic Curves (Continued)

All test conditions are at 25°C. The figures are for PXF40-48WD15

Efficiency Versus Output Current

Efficiency Versus Input Voltage. Full Load

Power Dissipation Versus Output Current

Derating OutputCurrentVersusAmbientTemperature and

Airflow Vin = Vin(nom)

Derating OutputCurrentVersusAmbientTemperature with Heat-Sink

andAirflow ,Vin = Vin(nom)

VER:00 Page 11 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Characteristic Curves (Continued)

All test conditions are at 25°C.The figures are for PXF40-48WD15

Typical Output Ripple and Noise.

Transient Response to Dynamic Load Change from

Vin = Vin(nom), Full Load

100% to 75% to 100% of Full Load ; Vin = Vin(nom)

Typical Input Start-Up and Output Rise Characteristic

Using ON/OFF Voltage Start-Up and Vo Rise Characteristic

Vin = Vin(nom), Full Load

Vin = Vin(nom), Full Load

Conduction Emission of EN55022 Class A

Conduction Emission of EN55022 Class B

Vin = Vin(nom), Full Load

Vin = Vin(nom), Full Load

VER:00 Page 12 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Test Configurations

Input reflected-ripple current measurement test:

Component

L

C

Value

12μH

47μF

Voltage

---100V

Reference

---Aluminum Electrolytic Capacitor

Peak-to-peak output ripple & noise measurement test:

Output voltage and efficiency measurement test:

Note:All measurements are taken at the module terminals.

V Io

100%

Efficiency o

Vin I in

VER:00 Page 13 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

EMC Considerations

Suggested Schematic for EN55022 Conducted Emissions Class A Limits

Recommended Layout with Input Filter

To meet conducted emissions EN55022 CLASS A needed the following components:

Value

PXF40-24WDxx

Voltage

Component

C1,C2

C3,C4

----

----

1000pF

2KV

Component

C1,C2

C3,C4

Value

2.2uF

1000pF

Reference

----

1206 MLCC

PXF40-48WDxx

Voltage

Reference

100V

1812 MLCC

2KV

1206 MLCC

VER:00 Page 14 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

EMC Considerations (Continued)

Suggested Schematic for EN55022 Conducted Emissions Class B Limits

Recommended Layout with Input Filter

To meet conducted emissions EN55022 CLASS B needed the following components:

Component

C1,C3

C5,C6

L1

Value

4.7uF

1000pF

450uH

PXF40-24WDxx

Voltage

Reference

50V

1812 MLCC

2KV

1206 MLCC

---Common Choke

PXF40-48WDxx

Component

Value

Voltage

Reference

C1,C2

2.2uF

100V

1812 MLCC

C3,C4

2.2uF

100V

1812 MLCC

C5,C6

1000pF

2KV

1206 MLCC

L1

830uH

---Common Choke

This Common Choke L1 is defined as follows:

■

L: 450μH±35% / DCR: 25mΩ, max

A height:9.8 mm, Max

■

L: 830μH±35% / DCR: 31mΩ, max

A height: 8.8 mm, Max

■ Test condition: 100KHz / 100mV

■ Recommended through hole; Φ0.8mm

■ All dimensions in millimeters

VER:00 Page 15 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Input Source Impedance

The converter should be connected to a low impedance input source. Highly inductive source impedance can

affect the stability of the converter. Input external L-C filter is recommended to minimize input reflected ripple current.

The inductor has a simulated source impedance of 12μH and the capacitor is Nippon chemi-con KZE series

47μF/100V. The capacitor must located as close as possible to the input terminals of the converter for lower

impedance.

Output Over Current Protection

When excessive output currents occur in the system, circuit protection is required on all converters. Normally,

overload current is maintained at approximately150 percent of rated current for PXF40-xxWDxx series.

Hiccup-mode is a method of operation in the converter whose purpose is to protect the converter from being

damaged during an over-current fault condition. It also enables the converter to restart when the fault is removed.

One of the problems resulting from over current is that excessive heat may be generated in power devices;

especially MOSFET and Schottky diodes and the temperature of those devices may exceed their specified limits. A

protection mechanism has to be used to prevent those power devices from being damaged.

Output Over Voltage Protection

The output over-voltage protection consists of an output Zener diode that monitors the voltage on the output

terminals. If the voltage on the output terminals exceeds the over-voltage protection threshold, then the Zener diode

clamps the output voltage.

Thermal Consideration

The converter operates in a variety of thermal environments. However, sufficient cooling should be provided to help

ensure reliable operation of the unit. Heat is removed by conduction, convection, and radiation to the surrounding

environment. Proper cooling can be verified by measuring the point as shown in the figure below. The temperature at

this location should not exceed 105°C. When operating, adequate cooling must be provided to maintain the test point

temperature at or below 105°C . Although the maximum point temperature of the converter is 105°C, limiting this

temperature to a lower value will increase the reliability of the unit.

VER:00 Page 16 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

VER:00 Page 17 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Heat Sink Consideration

Use heat-sink (7G-0026A) for lowering temperature; thus increasing the reliability of the converter.

All dimensions in millimeters

VER:00 Page 18 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Remote ON/OFF Control

The Remote ON/OFF Pin is used to turn the converter on and off. The user must use a switch to control the logic

voltage (high or low level) of the pin referenced to Vi (-). The switch can be an open collector transistor, FET or

Opto-Coupler. The switch must be capable of sinking up to 0.5 mA at low-level logic voltage. Using High-level logic, the

maximum allowable leakage current of the switch at 12V is 0.5 mA.

Remote ON/OFF Implementation Circuits

Isolated-Closure Remote ON/OFF

Level Control Using TTL Output

Level Control Using Line Voltage

There are two remote control options available, positive logic and negative logic.

a. Positive logic:

Module is turned off using Low-level

Module is turned on using High-level

logic

logic

Module is turned on using Low-level

Module is turned off using High-level

logic

logic

b. Negative logic:

VER:00 Page 19 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Mechanical Data

2.00 (50.8)

DIA. 0.04(1.0)

1.10 (27.9)

0.400 (10.16)

3

2

1

6 5

1.800 (45.72)

2.00 (50.8)

BOTTOM

VIEW

8 7

4

0.10 (2.5)

0.100 (2.54)

0.300 (7.62)

0.600 (15.24)

0.800 (20.32)

PIN CONNECTION

PIN

1

2

3

4

5

6

7

8

0.40(10.2)

0.200 (5.08)

FUNCTION

+INPUT

-INPUT

CTRL

+OUTPUT

COM

COM

-OUTPUT

TRIM

0.200 (5.08)

0.22 (5.6)

1. All dimensions in Inches (mm)

Tolerance: X.XX±0.02 (X.X±0.5)

X.XXX±0.01 (X.XX±0.25)

2. Pin pitch tolerance ±0.01(0.25)

3. Pin dimension tolerance ±0.004 (0.1)

EXTERNAL OUTPUT TRIMMING

Output can be externally trimmed by

using the method shown below.

TRIM UP

TRIM DOWN

7

8

RU

8

RD

4

Recommended Pad Layout

VER:00 Page 20 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Output Voltage Adjustment

Output voltage set point adjustment allows the user to increase or decrease the output voltage set point of a

converter. This is accomplished by connecting an external resistor between the TRIM pin and either the Vo(+) or Vo(-)

pins. With an external resistor between the TRIM and Vo(-) pin, the output voltage set point increases. With an external

resistor between the TRIM and Vo(+) pin, the output voltage set point decreases.

TRIM UP

TRIM DOWN

7

8

RU

RD

4

8

TRIM TABLE

PXF40-xxWD12

Trim up (%)

1

2

3

4

5

6

7

8

9

10

VOUT (Volts)=

±12.12

±12.24

±12.36

RU (K Ohms)=

218.21

98.105

58.07

±12.48

±12.6

±12.72

±12.84

±12.96

±13.08

±13.2

38.052

26.042

18.035

12.316

8.026

4.69

2.021

Trim down (%)

1

2

3

4

5

6

7

8

9

10

VOUT (Volts)=

±11.88

±11.76

±11.64

±11.52

±11.4

±11.28

±11.16

±11.04

±10.92

±10.8

RD (K Ohms)=

273.44

123.02

72.874

47.803

32.76

22.732

15.568

10.196

6.017

2.675

Trim up (%)

1

2

3

4

5

6

7

8

9

10

VOUT (Volts)=

±15.15

±15.3

±15.45

±15.6

±15.75

±15.9

±16.05

±16.2

±16.35

±16.5

RU (K Ohms)=

268.29

120.64

71.429

46.822

32.058

22.215

15.184

9.911

5.81

2.529

PXF40-xxWD15

Trim down (%)

1

2

3

4

5

6

7

8

9

10

VOUT (Volts)=

±14.85

±14.7

±14.55

±14.4

±14.25

±14.1

±13.95

±13.8

±13.65

±13.5

RD (K Ohms)=

337.71

152.02

90.126

59.178

40.609

28.23

19.387

12.756

7.598

3.471

VER:00 Page 21 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Soldering Consideration

Lead free wave solder profile for PXF40-xxWDxx -SERIES

Zone

Preheat zone

Reference Parameter

Rise temp. speed : 3°C / sec max.

Preheat temp. : 100~130°C

Actual heating

Peak temp. : 250~260°C

Peak time (T1+T2 time) : 4~6 sec

Reference Solder:Sn-Ag-Cu/Sn-Cu

Hand Welding: Soldering iron: Power 90W

Welding Time: 2-4 sec

Temp. 380-400 °C

Packaging Information

10 PCS per TUBE

VER:00 Page 22 of 22 Issued Date:2009/03/02

�DataSheet

40W, Dual Output

Part Number Structure

PXF40 – 48 WD 12 – N

Max. Output Power

40Watts

Negative Logic

Output Voltage

12 : 12V

15 : 15V

Input Voltage Range

24 : 9 ~ 36V

48 : 18 ~ 75V

Dual Output

Model

Number

Input

Range

Output

Voltage

±12 VDC

PXF40-24WD12

9 – 36 VDC

±15 VDC

PXF40-24WD15

9 – 36 VDC

±12 VDC

PXF40-48WD12

18 – 75 VDC

±15 VDC

PXF40-48WD15

18 – 75 VDC

Note 1. Maximum value at nominal input voltage and full load

Note 2. Typical value at nominal input voltage and full load.

Output Current

Input Current

(2)

Full load

Full Load

Eff

(%)

± 1667mA

± 1333mA

± 1667mA

± 1333mA

2032mA

2032mA

1016mA

1016mA

86

86

86

86

(1)

Safety and Installation Instruction

Fusing Consideration

Caution: This power module is not internally fused. An input line fuse must always be used.

This encapsulated converter can be used in a wide variety of applications, ranging from simple stand-alone

operation to an integrated part of a sophisticated power architecture. For maximum flexibility, internal fusing is not

included; however, to achieve maximum safety and system protection, always use an input line fuse. The safety

agencies require a slow-blow fuse with maximum rating of 8A for PXF40-24WDxx modules and 5A for

PXF40-48WDxx modules. Based on the information provided in this data sheet on Inrush energy and maximum DC

input current; the same type of fuse with lower rating can be used. Refer to the fuse manufacturer’s data for further

information.

MTBF and Reliability

The MTBF of PXF40-xxWDxx series of DC/DC converters has been calculated using:

Bellcore TR-NWT-000332 Case I: 50% stress, Operating Temperature at 40°C (Ground fixed and controlled

6

environment ). The resulting figure for MTBF is 1.105×10 hours.

MIL-HDBK 217F NOTICE 2 FULL LOAD, Operating Temperature at 25°C ℃. The resulting figure for MTBF is1.511×

5

10 hours.

VER:00 Page 23 of 22 Issued Date:2009/03/02

�