298D

Vishay Sprague

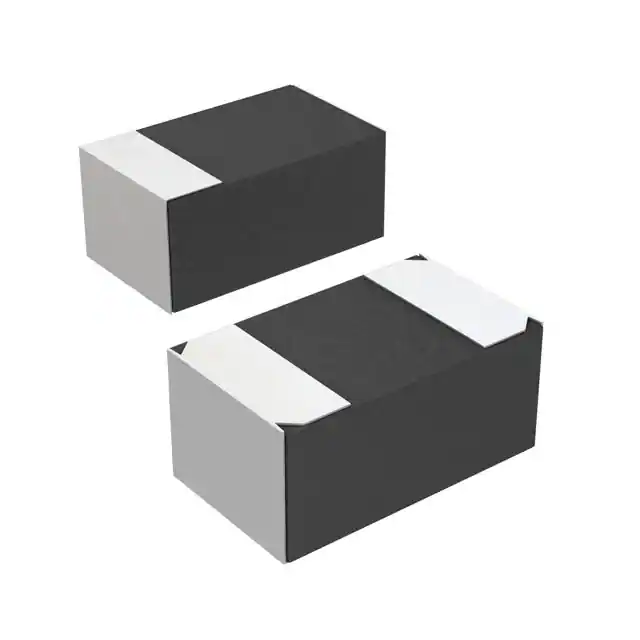

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

FEATURES

• Small sizes include 0603 and 0402 footprint

• Lead (Pb)-free L-shaped terminations

• 8 mm tape and reel packaging available per

EIA-481-1 and reeling per IEC 286-3

7" [178 mm] standard

• Compliant to RoHS directive 2002/95/EC

PERFORMANCE CHARACTERISTICS

Operating Temperature: - 55 °C to + 85 °C

(to + 125 °C voltage derating)

Capacitance Range: 1 µF to 220 µF

Capacitance Tolerance: ± 20 % standard

Voltage Range: 2.5 WVDC to 50 WVDC

ORDERING INFORMATION

298D

MODEL

106

CAPACITANCE

X0

CAPACITANCE

TOLERANCE

010

DC VOLTAGE RATING

AT + 85 °C

This is expressed in

picofarads. The first two

digits are the significant

figures. The third is the

number of zeros to

follow.

X0 = ± 20 %

X9 = ± 10 %

This is expressed in volts.

To complete the three-digit

block, zeros precede the

voltage rating. A decimal

point is indicated by an “R”

(6R3 = 6.3 V).

M

2

CASE CODE TERMINATION

T

REEL SIZE AND

PACKAGING

See Ratings

and Case

Codes table

T = Tape and reel

7" [178 mm] reel

2 = 100 % tin

4 = Gold plated

Note

• Preferred tolerance and reel size are in bold.

We reserve the right to supply higher voltage ratings and tighter capacitance tolerance capacitors in the same case size.

Voltage substitutions will be marked with the higher voltage rating

DIMENSIONS in inches [millimeters]

Anode Polarity Bar

Anode Termination

W

C

P1

P2

Cathode Termination

H

P1

L

CASE

L

W

H

P1

P2 (REF.)

C

K

0.039 + 0.008

[1.0 + 0.2]

0.02 + 0.008

[0.5 + 0.2]

0.024 max.

[0.6 max.]

0.01 ± 0.004

[0.25 ± 0.1]

0.02

[0.5]

0.015 ± 0.004

[0.38 ± 0.1]

M

0.063 ± 0.004

[1.60 ± 0.1]

0.033 ± 0.004

[0.85 ± 0.1]

0.031 ± 0.004

[0.80 ± 0.1]

0.020 ± 0.004

[0.50 ± 0.1]

0.024

[0.60]

0.024 ± 0.004

[0.60 ± 0.1]

R

0.079 ± 0.004

[2.0 ± 0.1]

0.050 ± 0.004

[1.25 ± 0.1]

0.060 max.

[1.5 max.]

0.020 ± 0.004

[0.50 ± 0.1]

0.04

[1.0]

0.035 ± 0.004

[0.90 ± 0.1]

P

0.094 ± 0.004

[2.4 ± 0.1]

0.057 ± 0.004

[1.45 ± 0.1]

0.043 ± 0.004

[1.10 ± 0.1]

0.020 ± 0.004

[0.50 ± 0.1]

0.057

[1.40]

0.035 ± 0.004

[0.90 ± 0.1]

A

0.126 ± 0.008

[3.2 ± 0.2]

0.063 ± 0.008

[1.6 ± 0.2]

0.063 ± 0.008

[1.6 ± 0.2]

0.031 ± 0.004

[0.80 ± 0.1]

0.063

[1.60]

0.047 ± 0.004

[1.20 ± 0.1]

** Please see document “Vishay Material Category Policy” (5-2008)”: www.vishay.com/doc?99902

www.vishay.com

38

For technical questions, contact: tantalum@vishay.com

Document Number: 40065

Revision: 21-Jun-10

�298D

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

Vishay Sprague

RATINGS AND CASE CODES

µF

1.0

1.5

2.2

3.3

4.7

6.8

10

15

22

33

47

100

220

2.5 V

4V

K/M

M

K*/M

K

K/M

K

M

M

M

P

P

M

6.3 V

K

K*/M

M

M

M

P

P/A*

10 V

K

M

K/M

M

M

16 V

K/M

M

M

M

P

P

R

20 V

25 V

M/R

P

P

35 V

50 V

P

M

M

P

Note

* Preliminary values, contact factory for availability.

MARKING

V

2.5

4

6.3

10

16

20

25

35

50

M-Case

Polarity Bar

Voltage Code

A

K-Case

M-CASE

CODE

e

G

J

A

C

D

E

V

T

P, R-CASE

CAP, F

CODE

0.68

w

1

A

2.2

J

3.3

N

4.7

S

6.8

W

10

α

15

e

22

j

33

n

47

s

68

w

100

A

150

E

220

J

P, R-Case

Capacitance

Voltage Code

Code

Polarity Bar

GJ

STANDARD RATINGS

CAPACITANCE

(µF)

CASE

CODE

47

220

M

P

4.7

10

10

15

22

33

47

100

220

K

K

M

K

M

M

M

P

P

Document Number: 40065

Revision: 21-Jun-10

MAX. ESR

MAX. DC

MAX. DF

AT + 25 °C

LEAKAGE

AT + 25 °C

100 kHz

AT + 25 °C

(%)

(Ω)

(µA)

2.5 WVDC AT + 85 °C, . . . 1.6 WVDC AT + 125 °C

298D476X02R5M2T

2.4

20

4.0

298D227X02R5P2T

11.0

30

3.0

4 WVDC AT + 85 °C, . . . 2.7 WVDC AT + 125 °C

298D475X0004K2T

0.5

15.0

20.0

298D106X0004K2T

4.0

50.0

20.0

298D106X0004M2T

0.5

8.0

5.0

298D156X0004K2T

10.0

50.0

20.0

298D226X0004M2T

0.9

15.0

4.0

298D336X0004M2T

2.6

30.0

4.0

298D476X0004M2T

3.8

40.0

7.5

298D107X0004P2T

4.0

30.0

2.0

298D227X0004P2T (3)

17.6

30.0

3.0

PART

NUMBER

For technical questions, contact: tantalum@vishay.com

MAX. RIPPLE

100 kHz

Irms

(A)

ΔC/C (1)

(%)

0.080

0.122

± 30

± 30

0.027

0.027

0.071

0.027

0.080

0.080

0.080

0.100

0.122

± 30

± 30

± 10

± 30

± 15

± 20

± 30

± 30

± 30

www.vishay.com

39

�298D

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

Vishay Sprague

STANDARD RATINGS

CAPACITANCE

(µF)

CASE

CODE

MAX. DC

LEAKAGE

AT + 25 °C

(µA)

PART

NUMBER

MAX. DF

AT + 25 °C

(%)

MAX. ESR

AT + 25 °C

100 kHz

(Ω)

MAX. RIPPLE

100 kHz

Irms

(A)

ΔC/C (1)

(%)

6.3 WVDC AT + 85 °C, . . . 4 WVDC AT + 125 °C

1.0

K

298D105X06R3K2T

0.5

6.0

20.0

0.027

± 30

2.2

K

298D225X06R3K2T

0.5

8.0

20.0

0.027

± 30

2.2

M

298D225X06R3M2T (3)

0.5

10.0

5.0

0.070

± 10

3.3

M

298D335X06R3M2T (3)

0.5

8.0

6.0

0.090

4.7

K

298D475X06R3K2T (2)

4.0

50.0

20.0

0.027

± 30

4.7

M

298D475X06R3M2T (2)

0.5

8.0

3.0

0.090

± 10

10

K

298D106X06R3K2T (2)

10.0

50.0

20.0

0.027

± 30

± 10

10

M

298D106X06R3M2T (3)

0.6

8.0

5.0

0.071

15

M

298D156X06R3M2T (3)

1.0

20.0

7.0

0.060

± 20

22

M

298D226X06R3M2T

2.8

20.0

5.5

0.067

± 15

33

M

298D336X06R3M2T

4.2

30.0

7.5

0.058

± 30

± 20

47

P

298D476X06R3P2T

3.0

22.0

3.0

0.122

100

A

298D107X06R3A2T(2)

6.3

20.0

1.0

0.270

± 10

100

P

298D107X06R3P2T

6.3

30.0

2.0

0.150

± 20

± 30

10 WVDC AT + 85 °C, . . . 7 WVDC AT + 125 °C

1.0

K

298D105X0010K2T

0.5

6.0

20.0

0.027

1.5

M

298D155X0010M2T (3)

0.5

6.0

14.0

0.040

2.2

K

298D225X0010K2T

0.5

8.0

15.0

0.027

± 30

± 10

2.2

M

298D225X0010M2T

0.5

10.0

10.0

0.050

3.3

M

298D335X0010M2T (3)

0.5

8.0

6.0

0.090

4.7

M

298D475X0010M2T (3)

0.5

6.0

5.0

0.071

± 15

10

M

298D106X0010M2T

1.0

20.0

7.5

0.058

± 15

15

M

298D156X0010M2T (3)

1.5

30.0

7.5

0.058

± 20

22

M

298D226X0010M2T

22.0

40.0

10.0

0.050

± 30

33

P

298D336X0010P2T (3)

3.3

16.0

2.0

0.150

± 10

47

P

298D476X0010P2T

4.7

22.0

3.0

0.122

± 20

16 WVDC AT + 85 °C, . . . 10 WVDC AT + 125 °C

1.0

K

298D105X0016K2T

3.0

10.0

20.0

0.027

± 30

1.0

M

298D105X0016M2T (3)

0.5

6.0

12.0

0.045

± 15

2.2

M

(3)

0.5

10.0

12.0

0.045

± 15

4.7

M

298D475X0016M2T

0.8

8.0

6.0

0.060

± 15

10

R

298D106X0016R2T

1.6

8.0

8.0

0.075

± 10

0.106

± 10

0.050

± 10

298D225X0016M2T

20 WVDC AT + 85 °C, . . . 13 WVDC AT + 125 °C

4.7

P

298D475X0020P2T (3)

1.0

6.0

4.0

25 WVDC AT + 85 °C, . . . 17 WVDC AT + 125 °C

1.0

M

298D105X0025M2T

1.0

R

298D105X0025R2T

4.7

P

298D475X0025P2T (3)

1.0

P

298D105X0050P2T

0.5

6.0

10.0

0.5

6.0

10.0

0.050

± 10

1.2

6.0

4.0

0.106

± 10

0.075

± 10

50 WVDC AT + 85 °C, . . . 33 WVDC AT + 125 °C

0.5

8.0

8.0

Notes

(1) See Performance Characteristics tables

(2) In development

(3) ± 10 % capacitance tolerance available

www.vishay.com

40

For technical questions, contact: tantalum@vishay.com

Document Number: 40065

Revision: 21-Jun-10

�298D

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

Vishay Sprague

CAPACITORS PERFORMANCE CHARACTERISTICS

ELECTRICAL PERFORMANCE CHARACTERISTICS

ITEM

Category Temperature Range

Capacitance Tolerance

Dissipation Factor (at 120 Hz)

ESR (100 kHz)

Leakage Current

Reverse Voltage

Temperature Derating

Operating Temperature

PERFORMANCE CHARACTERISTICS

- 55 °C to + 85 °C (to + 125 °C with voltage derating)

± 20 %, ± 10 % (at 120 Hz) 2 Vrms at + 25 °C using a capacitance bridge

Limits per Standard Ratings Table. Tested via bridge method, at 25 °C, 120 Hz.

Limits per Standard Ratings Table. Tested via bridge method, at 25 °C, 100 kHz.

After application of rated voltage applied to capacitors for 5 minutes using a steady source of power

with 1 kΩ resistor in series with the capacitor under test, leakage current at 25 °C is not more than

described in Standard Ratings Table. Note that the leakage current varies with temperature and

applied voltage. See graph below for the appropriate adjustment factor.

Capacitors are capable of withstanding peak voltages in the reverse direction equal to: 10 % of the DC

rating at + 25 °C

5 % of the DC rating at + 85 °C

Vishay does not recommend intentional or repetitive application of reverse voltage

If capacitors are to be used at temperatures above + 25 °C, the permissible rms ripple current or

voltage shall be calculated using the derating factors:

1.0 at + 25 °C

0.9 at + 85 °C

0.4 at + 125 °C

+ 85 °C RATING

+ 125 °C RATING

WORKING VOLTAGE (V) SURGE VOLTAGE (V) WORKING VOLTAGE (V) SURGE VOLTAGE (V)

4

5.2

2.7

3.4

6.3

8

4

5

10

13

7

8

16

20

10

12

20

26

13

16

25

32

17

20

35

46

23

28

50

65

33

40

TYPICAL LEAKAGE CURRENT FACTOR RANGE

LEAKAGE CURRENT FACTOR

100

+ 125 °C

+ 85 °C

10

+ 55 °C

+ 25 °C

1.0

0 °C

0.1

- 55 °C

0.01

0.001

0

10

20

30

40

50

60

70

80

90

100

PERCENT OF RATED VOLTAGE

Notes

• At + 25 °C, the leakage current shall not exceed the value listed in the Standard Ratings Table

• At + 85 °C, the leakage current shall not exceed 10 times the value listed in the Standard Ratings Table

• At + 125 °C, the leakage current shall not exceed 12 times the value listed in the Standard Ratings Table

Document Number: 40065

Revision: 21-Jun-10

For technical questions, contact: tantalum@vishay.com

www.vishay.com

41

�298D

Vishay Sprague

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

ENVIRONMENTAL PERFORMANCE CHARACTERISTICS

ITEM

CONDITION

POST TEST PERFORMANCE

Life Test at + 85 °C

1000 h application of rated voltage at

85 °C with a 3 Ω series resistance,

MIL-STD-202G Method 108A

Capacitance change

Dissipation factor

Leakage current

Refer to Standard Ratings table

Not to exceed 150 % of initial

Not to exceed 200 % of initial

Humidity Tests

At 40 °C/90 % RH 500 h, no voltage

applied. MIL-STD-202G Method 103B

Capacitance change

Dissipation factor

Leakage current

Refer to Standard Ratings table

Not to exceed 150 % of initial

Not to exceed 200 % of initial

Thermal Shock

At - 55 °C/+ 125 °C, 30 min each,

for 5 cycles. MIL-STD-202G Method 107G

Capacitance change

Dissipation factor

Leakage current

Refer to Standard Ratings table

Not to exceed 150 % of initial

Not to exceed 200 % of initial

MECHANICAL PERFORMANCE CHARACTERISTICS

TEST CONDITION

Terminal Strength

Substrate Bending

(Board flex)

Vibration

CONDITION

POST TEST PERFORMANCE

Apply a pressure load of 5 N for 10 s ± 1 s

horizontally to the center of capacitor side body.

AEC Q-200 rev. C Method 006

With parts soldered onto substrate test board,

apply force to the test board for a deflection

of 1 mm. AEC-Q200 rev. C Method 005

MIL-STD-202G, Method 204D,

10 Hz to 2000 Hz, 20 g peak

Capacitance change

Dissipation factor

Leakage current

Refer to Standard Ratings table

Initial specified value or less

Initial specified value or less

There shall be no mechanical or visual damage to capacitors

Capacitance change

Dissipation factor

Leakage current

Refer to Standard Ratings table

Initial specified value or less

Initial specified value or less

Capacitance change

Dissipation factor

Leakage current

Refer to Standard Ratings table

Initial specified value or less

Initial specified value or less

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Shock

MIL-STD-202G, Method 213B, Condition I,

100 g peak

Capacitance change

Dissipation factor

Leakage current

Refer to Standard Ratings table

Initial specified value or less

Initial specified value or less

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Resistance to Solder

Heat

At 260 °C, for 10 s, reflow

Capacitance change

Dissipation factor

Leakage current

Refer to Standard Ratings table

Not to exceed 150 % of initial

Not to exceed 200 % of initial

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Solderability

MIL-STD-202G, Method 208H, ANSI/J-STD-002,

Test B. Applies only to solder and tin plated

terminations. Does not apply to gold terminations.

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Resistance to

Solvents

MIL-STD-202, Method 215D

There shall be no mechanical or visual damage to capacitors

post-conditioning.

Flammability

Encapsulation materials meet UL 94 V-0 with an

oxygen index of 32 %.

www.vishay.com

42

For technical questions, contact: tantalum@vishay.com

Document Number: 40065

Revision: 21-Jun-10

�298D

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

Vishay Sprague

TYPICAL CURVES AT + 25 °C, IMPEDANCE AND ESR VS. FREQUENCY

“M” Case

“M” Case

100

100

IMPEDANCE

ESR

IMPEDANCE

ESR

ESR/Z, Ω

ESR/Z, Ω

10

10

47 µF - 4 V

1

22 µF - 4 V

1

0.1

1

10

FREQUENCY, kHz

100

0.1

0.1

1000

1

10

“M” Case

1000

100

1000

FREQUENCY, kHz

“M” Case

1000

IMPEDANCE

ESR

IMPEDANCE

ESR

100

ESR/Z, Ω

ESR/Z, Ω

100

10

10

4.7 µF - 10 V

1

10 µF - 6 V

1

0.1

1

10

FREQUENCY, kHz

100

0.1

0.1

1000

1

10

100

1000

FREQUENCY, kHz

“M” Case

“M” Case

1000

10 000

IMPEDANCE

ESR

IMPEDANCE

ESR

1000

ESR/Z, Ω

ESR/Z, Ω

100

10

1

Document Number: 40065

Revision: 21-Jun-10

10

FREQUENCY, kHz

100

1 µF - 16 V

10

10 µF - 10 V

1

0.1

100

1000

1

0.1

1

10

100

1000

FREQUENCY, kHz

For technical questions, contact: tantalum@vishay.com

www.vishay.com

43

�298D

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

Vishay Sprague

TYPICAL CURVES AT + 25 °C, IMPEDANCE AND ESR VS. FREQUENCY

“P” CASE

“P” CASE

100.0

1000.0

IMPEDANCE

IMPEDANCE

ESR

ESR

100.0

ESR/Z, Ω

ESR/Z, Ω

10.0

10.0

1.0

1.0

33 µF - 10 V

4.7 µF - 25 V

0.1

0.1

0.1

1

10

100

0.1

1000

1

FREQUENCY, kHz

10

100

1000

FREQUENCY, kHz

“P” CASE

“P” CASE

10.0

100.0

IMPEDANCE

ESR

IMPEDANCE

ESR

ESR/Z, Ω

ESR/Z, Ω

10.0

1.0

1.0

47 µF - 10 V

0.1

0.1

220 µF - 4 V

0.1

1

10

100

1000

0.1

1

FREQUENCY, kHz

www.vishay.com

44

For technical questions, contact: tantalum@vishay.com

10

FREQUENCY, kHz

100

1000

Document Number: 40065

Revision: 21-Jun-10

�298D

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

Vishay Sprague

PLASTIC TAPE AND REEL PACKAGING in inches [millimeters]

0.157 ± 0.004

[4.0 ± 0.10]

Tape Thickness

Deformation

Between

Embossments

0.014

[0.35]

MAX.

0.059 + 0.004 - 0.0

[1.5 + 0.10 - 0.0]

Top

Cover

Tape

B1 MAX.

(Note 6)

10 pitches cumulative

tolerance on tape

± 0.008 [0.200]

Embossment

0.069 ± 0.004

0.079 ± 0.002

[1.75 ± 0.10]

[2.0 ± 0.05]

A0

K0

0.030 [0.75]

MIN. (Note 3)

B0

Top

Cover

Tape

0.004 [0.1]

MAX.

For Tape Feeder

Reference only

including draft.

Concentric around B0

(Note 5)

Center Lines

of Ca vity

20°

F

W

Maximum

Component

Rotation

0.030 [0.75]

MIN. (Note 4)

(Side or Front Sectional Vie w)

P1

USER DIRECTION OF FEED

Maximum

Cavity Siz e

(Note 1)

D1 MIN. For Components

0.079 x 0.047 [2.0 x 1.2] and Larger

.

(Note 5)

Cathode (-)

Anode (+)

Direction of Feet

Ty pical

Component

Cavity

Center Line

B0

A0

Ty pical

Component

Center Line

(Top Vie w)

Tape and Reel Specifications: All case sizes are available on

plastic embossed tape per EIA-481-1. Tape reeling per IEC 286-3

is also available. Standard reel diameter is 7" [178 mm],

13" [330 mm] reels are available and recommended as the most

cost effective packaging method.

3.937 [100.0]

0.039 [1.0]

MAX.

20° Maximum

Component Rotation

Tape

0.039 [1.0]

MAX.

0.9843 [250.0]

The most efficient packaging quantities are full reel increments on

a given reel diameter. The quantities shown allow for the sealed

empty pockets required to be in conformance with EIA-481-1. Reel

size and packaging orientation must be specified in the Vishay

Sprague part number.

Camber

(Top View)

Allo wable Camber to be 0.039/3.937 [1/100]

Non-Cumulative Ov er 9.843 [250.0]

Note

• Metric dimensions will govern. Dimensions in inches are rounded and for reference only.

CASE

CODE

TAPE

SIZE

B1

(MAX.)

D1

(MIN.)

F

K0

(MAX.)

P1

W

8 mm

0.108

[2.75]

0.039

[1.0]

0.138 ± 0.002

[3.5 ± 0.05]

0.054

[1.37]

0.157 ± 0.004

[4.0 ± 1.0]

0.315 ± 0.0118/- 0.0039

[8.0 ± 0.30/- 0.10]

298D

P, R

Document Number: 40065

Revision: 21-Jun-10

For technical questions, contact: tantalum@vishay.com

www.vishay.com

45

�298D

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

Vishay Sprague

PAPER TAPE AND REEL PACKAGING in inches [millimeters]

T

P2

Ø D0

[10 pitches cumulative tolerance

on tape ± 0.2 mm]

E1

P0

A0

Bottom Cover

Tape

F

W

B0

E2

Top

Cover Tape

Anode

P1

Cavity Center Lines

G

Bottom Cover Tape

Cavity Size

Note 1

User Feed Direction

298D

CASE TAPE

SIZE SIZE

A0

B0

D0

P0

P1

P2

E

F

W

T

K

8 mm

0.033 ± 0.002 0.053 ± 0.002 0.06 ± 0.004 0.157 ± 0.004 0.078 ± 0.004 0.079 ± 0.002 0.069 ± 0.004 0.0138 ± 0.002 0.315 ± 0.008 0.03 ± 0.002

[0.85 ± 0.05] [1.35 ± 0.05] [1.5 ± 0.1]

[4.0 ± 0.1]

[2.0 ± 0.1]

[2.0 ± 0.05] [1.75 ± 0.1]

[3.5 ± 0.05]

[8.0 ± 0.2] [0.75 ± 0.05]

M

8 mm

0.041 ± 0.002 0.071 ± 0.002 0.06 ± 0.004 0.157 ± 0.004 0.157 ± 0.004 0.079 ± 0.002 0.069 ± 0.004 0.0138 ± 0.002 0.315 ± 0.008 0.037 ± 0.002

[1.05 ± 0.05] [1.8 ± 0.05]

[1.5 ± 0.1]

[4.0 ± 0.1]

[4.0 ± 0.1]

[2.0 ± 0.05] [1.75 ± 0.1]

[3.5 ± 0.05]

[8.0 ± 0.2] [0.95 ± 0.05]

STANDARD PACKAGING QUANTITY

SERIES

CASE CODE

298D

QUANTITY (PCS/REEL)

7" REEL

K

5000

M

4000

P

3000

R

2500

RECOMMENDED VOLTAGE DERATING GUIDELINES

STANDARD CONDITIONS: FOR EXAMPLE: OUTPUT FILTERS

Capacitor Voltage Rating

4.0

6.3

10

16

20

25

35

50

SEVERE CONDITIONS: FOR EXAMPLE: INPUT FILTERS

Capacitor Voltage Rating

4.0

6.3

10

16

20

25

35

50

www.vishay.com

46

For technical questions, contact: tantalum@vishay.com

Operating Voltage

2.5

3.6

6.0

10

12

15

24

28

Operating Voltage

2.5

3.3

5.0

8.0

10

12

15

24

Document Number: 40065

Revision: 21-Jun-10

�298D

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

Vishay Sprague

POWER DISSIPATION

MAXIMUM PERMISSIBLE

POWER DISSIPATION AT + 25 °C (W) IN FREE AIR

CASE CODE

K

298D

0.015

M

0.025

P

0.045

R

0.045

RECOMMENDED REFLOW PROFILES

Tp °C

(tp)

Temperature (°C)

TL °C

Ts MAX. °C

(tL)

Ts MAX. °C

Preheat (ts)

25 °C

t, s

All Case Codes

TYPE

298D

TP

TP

Lead (Pb)-free Sn/Pb

260 °C

TL

TL

TS MIN.

TS MIN.

TS MAX.

TS MAX.

tS

tS

Lead (Pb)-free Sn/Pb Lead (Pb)-free Sn/Pb Lead (Pb)-free Sn/Pb Lead (Pb)-free Sn/Pb

tP

225 °C 10

217 °C

183 °C

150 °C

100 °C

200 °C

150 °C

60 to 150

tL

60 to 90 60

PAD DIMENSIONS in inches [millimeters]

B

D

C

A

A

(MIN.)

B

(NOM.)

C

(NOM.)

D

(NOM.)

K

0.028 [0.70]

0.018 [0.45]

0.024 [0.60]

0.059 [1.50]

M

0.039 [1.00]

0.028 [0.70]

0.24 [0.60]

0.080 [2.00]

P

0.063 [1.60]

0.031 [0.80]

0.047 [1.20]

0.110 [2.80]

R

0.059 [1.50]

0.031 [0.80]

0.039 [1.0]

0.102 [2.60]

CASE CODE

298D

Document Number: 40065

Revision: 21-Jun-10

For technical questions, contact: tantalum@vishay.com

www.vishay.com

47

�298D

Vishay Sprague

Solid Tantalum Chip Capacitors

MICROTANTM Leadframeless Molded

GUIDE TO APPLICATION

1.

Printed Circuit Board Materials: Molded capacitors

are compatible with commonly used printed circuit

board materials (alumina substrates, FR4, FR5, G10,

PTFE-fluorocarbon and porcelanized steel).

7.

Attachment:

7.1

Solder Paste: The recommended thickness of the

solder paste after application is 0.007" ± 0.001"

[0.178 mm ± 0.025 mm]. Care should be exercised in

selecting the solder paste. The metal purity should be

as high as practical. The flux (in the paste) must be

active enough to remove the oxides formed on the

metallization prior to the exposure to soldering heat.

In practice this can be aided by extending the solder

preheat time at temperatures below the liquidous

state of the solder.

7.2

Soldering: Capacitors can be attached by

conventional soldering techniques; vapor phase,

convection reflow, infrared reflow, wave soldering

and hot plate methods. The Soldering Profile charts

show recommended time/temperature conditions for

soldering. Preheating is recommended. The

recommended maximum ramp rate is 2 °C per

second. Attachment with a soldering iron is not

recommended due to the difficulty of controlling

temperature and time at temperature. The soldering

iron must never come in contact with the capacitor.

A-C Ripple Current: The maximum allowable ripple

current shall be determined from the formula:

I rms =

where,

P=

P

---------------R ESR

Power dissipation in Watts at + 25 °C as

given in the table in paragraph number 5

(power dissipation).

The capacitor equivalent series resistance

at the specified frequency.

RESR =

2.

6.

A-C Ripple Voltage: The maximum allowable ripple

voltage shall be determined from the formula:

P

V rms = Z ---------------R ESR

or, from the formula:

V rms = I rms × Z

where,

P=

RESR =

Z=

2.1

Power dissipation in Watts at + 25 °C as

given in the table in paragraph number 5

(power dissipation).

The capacitor equivalent series resistance

at the specified frequency.

The capacitor impedance at the specified

frequency.

The sum of the peak AC voltage plus the applied DC

voltage shall not exceed the DC voltage rating of the

capacitor.

2.2

The sum of the negative peak AC voltage plus the

applied DC voltage shall not allow a voltage reversal

exceeding 10 % of the DC working voltage at + 25 °C.

3.

Reverse Voltage: These capacitors are capable of

withstanding peak voltages in the reverse direction

equal to 10 % of the DC rating at + 25 °C, 5 % of the DC

rating at + 85 °C and 1 % of the DC rating at + 125 °C.

4.

Temperature Derating: If these capacitors are to be

operated at temperatures above + 25 °C, the

permissible rms ripple current or voltage shall be

calculated using the derating factors as shown:

TEMPERATURE

+ 25 °C

+ 85 °C

+ 125 °C

5.

DERATING FACTOR

1.0

0.9

0.4

Power Dissipation: Power dissipation will be

affected by the heat sinking capability of the mounting

surface. Non-sinusoidal ripple current may produce

heating effects which differ from those shown. It is

important that the equivalent Irms value be established

when calculating permissible operating levels. (Power

Dissipation calculated using + 25 °C temperature

rise.)

www.vishay.com

48

7.2.1 Backward and Forward Compatibility: Capacitors

with SnPb or 100 % tin termination finishes can be

soldered using SnPb or lead (Pb)-free soldering

processes.

8.

Cleaning (Flux Removal) After Soldering: Molded

capacitors are compatible with all commonly used

solvents such as TES, TMS, Prelete, Chlorethane,

Terpene and aqueous cleaning media. However,

CFC/ODS products are not used in the production of

these devices and are not recommended. Solvents

containing methylene chloride or other epoxy

solvents should be avoided since these will attack the

epoxy encapsulation material.

8.1

When using ultrasonic cleaning, the board may

resonate if the output power is too high. This vibration

can cause cracking or a decrease in the adherence of

the termination. DO NOT EXCEED 9W/l at 40 kHz for

2 minutes.

9.

Recommended Mounting Pad Geometries: Proper

mounting pad geometries are essential for successful

solder connections. These dimensions are highly

process sensitive and should be designed to

minimize component rework due to unacceptable

solder joints. The dimensional configurations shown

are the recommended pad geometries for both wave

and reflow soldering techniques. These dimensions

are intended to be a starting point for circuit board

designers and may be fine tuned if necessary based

upon the peculiarities of the soldering process and/or

circuit board design.

For technical questions, contact: tantalum@vishay.com

Document Number: 40065

Revision: 21-Jun-10

�Legal Disclaimer Notice

Vishay

Disclaimer

All product specifications and data are subject to change without notice.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf

(collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained herein

or in any other disclosure relating to any product.

Vishay disclaims any and all liability arising out of the use or application of any product described herein or of any

information provided herein to the maximum extent permitted by law. The product specifications do not expand or

otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed

therein, which apply to these products.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document or by any conduct of Vishay.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay products not expressly indicated for use in such

applications do so entirely at their own risk and agree to fully indemnify Vishay for any damages arising or resulting

from such use or sale. Please contact authorized Vishay personnel to obtain written terms and conditions regarding

products designed for such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document Number: 91000

Revision: 18-Jul-08

www.vishay.com

1

�