LSR37

Vishay BCcomponents

High Voltage Surge Metal Glaze Leaded Resistor

FEATURES

• High pulse-loading (10 kV as specified)

capability (flashes)

• Good replacement for carbon-composite

resistors

• Lead (Pb)-free solder contacts

• Pure Tin plating provides compatibility with lead (Pb)-free

and lead containing soldering processes

A metal glazed film is deposited on a high grade ceramic

body. After that caps are applied to the rods and tinned

electrolytic copper wires are welded to these end caps.

The resistors are coated with a light-blue lacquer which

provides electrical, mechanical and climatic protection.

The encapsulation is resistant to all cleaning solvents

according to IEC 60068-2-45.

• Compliant to RoHS directive 2002/95/EC

APPLICATIONS

• Application in overload and high voltage pulse hazard

circuits (TV-sets, monitors), high power electronic ballasts

TECHNICAL SPECIFICATIONS

DESCRIPTION

VALUE

220 Ω to 910 Ω

Resistance Range (1)

Resistance Tolerance and Series

1 kΩ to 10 kΩ

± 10 %; ± 20 %; E12 series

Rated Dissipation, P70

0.5 W

Thermal Resistance, Rth

120 K/W

Temperature Coefficient

Voltage Coefficient

Maximum Permissible Voltage Umax.

0 ppm/K to + 600 ppm/K

- 600 ppm/K to + 200 ppm/K

0 to + 350 ppm/V

± 50 ppm/V

Pn x R

V=

Dielectric Withstanding Voltage of the Insulation for 1 Min

Basic Specifications

700 V

IEC 60115-1

Climatic Category (IEC 60068-1)

55/155/56

Stability After:

Load (1000 h, P70)

ΔR max.: ± (3.0 % R + 0.10 Ω)

Long Term Damp Heat Test (56 Days)

ΔR max.: ± (3.0 % R + 0.10 Ω)

Soldering (10 s, 260 °C)

ΔR max.: ± (1.0 % R + 0.10 Ω)

High Voltage Test for R-Value > 3.3 kΩ, 10 kV; 1 nF; 50 x 12/Min

ΔR/R max.: ± 20 %

(typical value ± 10 %)

ESD Contact Discharge 12 kV; 100 Pulses

ΔR/R max.: ± 20 %

(typical value: ± 10 %)

Note

(1) R values below 220 Ω are available on request

www.vishay.com

190

For technical questions, contact: filmresistorsleaded@vishay.com

Document Number: 28735

Revision: 19-Oct-09

�LSR37

High Voltage Surge Metal Glaze

Leaded Resistor

Vishay BCcomponents

PART NUMBER

PART NUMBER: LSR3700001002KA100

L

S

R

3

7

0

0

0

0

1

0

0

2

K

A

1

0

0

MODEL/SIZE

VARIANT

TCR/MATERIAL

VALUE

TOLERANCE

PACKAGING (1)

SPECIAL

LSR3700

0 = Neutral

0 = Standard

3 digit value

1 digit multiplier

MULTIPLIER

9 = *10-1

0 = *100

1 = *101

2 = *102

K = ± 10 %

M = ± 20 %

A1

R5

The 2 digits

are used for all

special parts.

Z = Value overflow

(Special)

00 = Standard

PRODUCT DESCRIPTION: LSR37 10 % A1 10K

LSR37

10 %

A1

10K

MODEL/SIZE

TOLERANCE

PACKAGING (1)

RESISTANCE VALUE

LSR37

± 10 %

± 20 %

A1

R5

220R = 220 Ω

1K2 = 1.2 kΩ

Notes

(1) Please refer to table PACKAGING

• The PART NUMBER is shown to facilitate the introduction of a unified part numbering system for ordering products

PACKAGING

AMMO PACK

MODEL

REEL

TAPING

LSR37

Axial, 52 mm

PIECES

CODE

PIECES

CODE

1000

A1

5000

R5

DIMENSIONS

L1

Ø d

Ø D

L2

Outline

DIMENSIONS - resistor type and relevant physical dimensions

TYPE

Ø Dmax.

L1 max.

L2 max.

Ød

LSR37

4.0

9.0

10.0

0.7 ± 0.03

Document Number: 28735

Revision: 19-Oct-09

For technical questions, contact: filmresistorsleaded@vishay.com

www.vishay.com

191

�LSR37

High Voltage Surge Metal Glaze

Leaded Resistor

Vishay BCcomponents

MARKING

MASS PER UNIT

TYPE

MASS

(mg)

LSR37

457

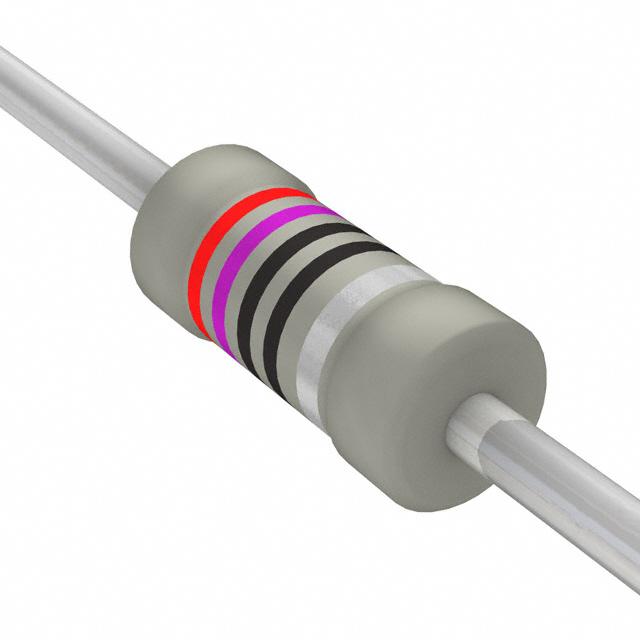

The nominal resistance and tolerance are marked on the

resistor using colored bands in accordance with IEC 60062,

marking codes for resistors and capacitors.

Three bands are used for 20 % tolerance with no indication

for the tolerance. Four bands are used for 10 % tolerance.

Grey is used instead of silver for 10 % because metal

particles in the lacquer could affect high-voltage properties.

OUTLINES

The length of the body (L1) is measured by inserting the

leads into holes of two identical gauge plates and moving

these plates parallel to each other until the resistor body is

clamped without deformation (IEC 60294).

FUNCTIONAL PERFORMANCE

PRODUCT CHARACTERIZATION

Standard values of rated resistance (nominal resistance) are taken from the E12 series with a tolerance of 10 % or 20 %. The

values of the E12 series are in accordance with IEC 60063.

The limiting voltage DC is not applicable, because the maximum rated voltage for the maximum Rn-value of 10 kΩ at Pn = 0.5 W

is only 70.7 V.

LIMITING VALUES

TYPE

LSR37

MAXIMUM PERMISSIBLE VOLTAGE Umax. (1)

(V)

V=

RATED DISSIPATION, P70

(W)

Pn x R

0.5

Notes

(1) The maximum voltage that may be continuously applied to the resistor element, see IEC 60115-1

• The maximum permissible hot-spot temperature is 155 °C

www.vishay.com

192

For technical questions, contact: filmresistorsleaded@vishay.com

Document Number: 28735

Revision: 19-Oct-09

�LSR37

High Voltage Surge Metal Glaze

Leaded Resistor

Vishay BCcomponents

Pmax.

(% P rated)

100

50

The power that the resistor can dissipate depends on the operating

temperature.

0

- 55

0

50

70

100

155

T amb (°C)

Maximum dissipation (Pmax.) in percentage of rated power as a

function of the ambient temperature (Tamb).

Derating

104

Pˆmax.

(W)

103

102

10

1

10- 6

10- 5

10- 4

10- 3

10- 2

10- 1

t i (s)

1

Pulse on a regular basis; maximum permissible peak pulse power Pmax. as a function of pulse duration (ti) for single pulse condition

Pulse Loading Capability

The resistors with straight leads are suitable for processing on automatic insersion equipment and cutting and bending machines.

the minimum pitch for this type is 6e (15 mm). For temperature rise at soldering place see figures below.

80

50

∆T

(K)

∆T

(K)

5 mm

40

60

10 mm

30

15 mm

40

20

20

0

10

0

0

0.4

0.8

P (W)

1.2

Hot-spot temperature rise (ΔT) as a function of dissipated power

0

0.4

0.8

P (W)

1.2

Temperature rise (ΔT) at the lead end (soldering point) as a function

of dissipated power at various lead lengths after mounting

Application Information

Document Number: 28735

Revision: 19-Oct-09

For technical questions, contact: filmresistorsleaded@vishay.com

www.vishay.com

193

�LSR37

High Voltage Surge Metal Glaze

Leaded Resistor

Vishay BCcomponents

TESTS AND REQUIREMENTS

Essentially all tests are carried out in accordance with

the IEC 60115-1 specifications, category LCT/UCT/56 (rated

temperature range: Lower Category Temperature, Upper

Category Temperature; damp heat, long term, 56 days).

The tests are carried out in accordance with IEC 60068-2-xx

test method under standard atmospheric conditions

according to IEC 60068-1, 5.3.

In the Test Procedures and Requirements table the tests and

requirements are listed with reference to the relevant

clauses of IEC 60115-1 and IEC 60068-2-xx test methods. A

short description of the test procedure is also given. In some

instances deviations from the IEC recommendations were

necessary for our method of specifying.

All soldering tests are performed with mildly activated flux.

TEST PROCEDURES AND REQUIREMENTS

IEC

60068-2-xx

TEST

METHOD

TEST

21 (U)

Robustness of terminations:

4.16.2

21 (Ua1)

4.16.3

IEC

60115-1

CLAUSE

PROCEDURE

REQUIREMENTS

Tensile all samples

Ø 0.7 mm; load 10 N; 10 s

Number of failures < 10 x 10-6

21 (Ub)

Bending half number

of samples

Ø 0.7 mm; load 5 N; 4 x 90°

Number of failures < 10 x 10-6

4.16.4

21 (Uc)

Torsion other half

of samples

3 x 360° in opposite directions

No damage

ΔR max.: ± (1.0 % R + 0.10 Ω)

4.17

20 (Ta)

Solderability

2 s; 235 °C: Solder bath method;

SnPb40

3 s; 245 °C: Solder bath method;

SnAg3Cu0.5

Good tinning; no damage

4.18

20 (Tb)

Resistance to

soldering heat

Thermal shock: 10 s; 260 °C;

3 mm from body

ΔR max.: ± (1.0 % R + 0.10 Ω)

4.19

14 (Na)

Rapid change of temperature

30 min at - 55 °C and

30 min at + 155 °C; 5 cycles

ΔR max.: ± (1.0 % R + 0.10 Ω)

4.20

29 (Eb)

Bump

3 x 1500 bumps in 3 directions; 40 g

No damage

ΔR max.: ± (1.0 % R + 0.10 Ω)

4.22

6 (Fc)

Vibration

Frequency 10 Hz to 500 Hz; displacement

1.5 mm or acceleration 10 g; 3 directions;

total 6 h (3 x 2 h)

No damage

ΔR max.: ± (1.0 % R + 0.10 Ω)

4.16

4.23

Climatic sequence:

2 (Ba)

Dry heat

16 h; 155 °C

4.23.3

30 (Db)

Damp heat (accelerated) 1st

cycle

24 h; 55 °C; 90 % to 100 % RH

4.23.4

1 (Aa)

Cold

2 h; - 55 °C

4.23.5

13 (M)

Low air pressure

2 h; 8.5 kPa; 15 °C to 35 °C

4.23.6

30 (Db)

Damp heat (accelerated)

remaining cycles

5 days; 55 °C; 95 % to 100 % RH

4.24.2

78 (Cab)

Damp heat

(steady state)

56 days; 40 °C; 90 % to 95 % RH;

dissipation 0.01 P70;

limiting voltage Umax. 100 VDC

ΔR max.: ± (3.0 % R + 0.10 Ω)

Endurance

1000 h at 70 °C; P70 or Umax.

ΔR max.: ± (3.0 % R + 0.10 Ω)

4.23.2

4.25.1

Rins min.: 103 MΩ

ΔR max.: ± (3.0 % R + 0.10 Ω)

220 Ω to 910 Ω

0 to + 600 ppm/K

1 kΩ to 10 kΩ

- 600 to + 200 ppm/K

4.8

Temperature coefficient

4.7

Voltage proof on insulation

URMS = 700 V during 1 min;

V-block method

No breakdown

Insulation resistance

U = 500 VDC during 1 min;

V-block method

Rins min.: 104 MΩ

4.6.1.1

www.vishay.com

194

For technical questions, contact: filmresistorsleaded@vishay.com

Document Number: 28735

Revision: 19-Oct-09

�LSR37

High Voltage Surge Metal Glaze

Leaded Resistor

Vishay BCcomponents

TEST PROCEDURES AND REQUIREMENTS

IEC

60115-1

CLAUSE

IEC

60068-2-xx

TEST

METHOD

4.13

TEST

PROCEDURE

REQUIREMENTS

Short time overload

Room temperature; dissipation 6.25 x P70;

10 cycles;

5 s ON and 45 s OFF

ΔR max.: ± (2.5 % R + 0.10 Ω)

High voltage pulse 10 kV;

1 nF; 50 x 12/min

For Rn > 3.3 kΩ

ΔR/R max.: ± 20 %

(typical value ± 10 %)

12 kV ESD test; 100 pulses

ESD contact discharge

ΔR/R max.: ± 20 %

(typical value: ± 10 %)

4.26

Active flammability

“cheese-cloth test”

4.35

Passive flammability

“needle-flame test”

Steps of: 5/10/16/25/40 x P70 duration

5 min

Application of test flame for 20 s

No flaming of gauze cylinder

No ignition of product

no ignition of under-layer

burning time less than 30 s

12NC INFORMATION FOR HISTORICAL CODING REFERENCE

• The resistors have a 12-digit numeric code starting with

2322 245

Last Digit of 12NC Indicating Resistance Decade

RESISTANCE DECADE

LAST DIGIT

47 Ω to 82 Ω

9

• The remaining digits indicate the resistance value:

100 Ω to 820 Ω

1

- The first 2 digits indicate the resistance value

1 kΩ to 9.1 kΩ

2

- The last digit indicates the resistance decade

10 kΩ

3

• The subsequent 2 digits indicate the resistor type and

packing

12NC Example

The 12NC for a LSR37, resistor value 1.5 kΩ, 10 %

tolerance, supplied on a bandolier of 1000 units in

ammopack, is: 2322 245 12152.

12NC - Resistor type and packaging

2322 245 .....

TYPE

TOLERANCE

(%)

1000 UNITS

IN AMMOPACK

5000 UNITS

ON REEL

± 10

12...

22...

± 20

11...

21...

LSR37

Document Number: 28735

Revision: 19-Oct-09

For technical questions, contact: filmresistorsleaded@vishay.com

www.vishay.com

195

�Legal Disclaimer Notice

Vishay

Disclaimer

All product specifications and data are subject to change without notice.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf

(collectively, “Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained herein

or in any other disclosure relating to any product.

Vishay disclaims any and all liability arising out of the use or application of any product described herein or of any

information provided herein to the maximum extent permitted by law. The product specifications do not expand or

otherwise modify Vishay’s terms and conditions of purchase, including but not limited to the warranty expressed

therein, which apply to these products.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this

document or by any conduct of Vishay.

The products shown herein are not designed for use in medical, life-saving, or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay products not expressly indicated for use in such

applications do so entirely at their own risk and agree to fully indemnify Vishay for any damages arising or resulting

from such use or sale. Please contact authorized Vishay personnel to obtain written terms and conditions regarding

products designed for such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document Number: 91000

Revision: 18-Jul-08

www.vishay.com

1

�

很抱歉,暂时无法提供与“LSR3700Z02700KR500”相匹配的价格&库存,您可以联系我们找货

免费人工找货