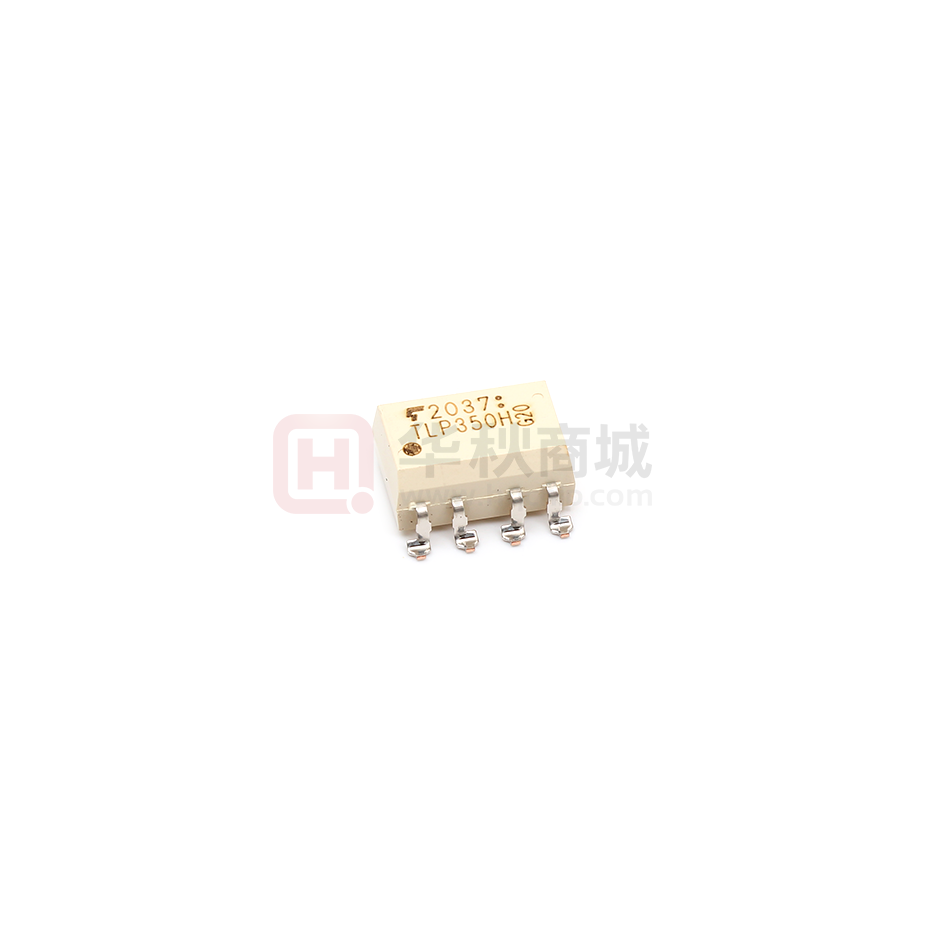

TLP350H,TLP350HF

Photocouplers

GaAℓAs Infrared LED & Photo IC

TLP350H,TLP350HF

1. Applications

•

Industrial Inverters

•

Air Conditioner Inverters

•

MOSFET Gate Drivers

•

IGBT Gate Drivers

•

Induction Cooktop and Home Appliances

2. General

The TLP350H is a photocoupler in a DIP8 package that consists of a GaAℓAs infrared light-emitting diode (LED)

optically coupled to an integrated high-gain, high-speed photodetector IC chip. It provides guaranteed performance

and specifications at temperatures up to 125 .The TLP350H has an internal Faraday shield that provides a

guaranteed Common-mode transient immunity of ±20 kV/µs. It has a totem-pole output that can both sink and

source current.

The TLP350H is ideal for IGBT of small capacity to middle capacity and power MOSFET gate drive.

3. Features

(1)

Buffer logic type (totem pole output)

(2)

Output peak current: ±2.5 A (max)

(3)

Operating temperature: -40 to 125

(4)

Supply current: 3 mA (max)

(5)

Supply voltage: 15 to 30 V

(6)

Threshold input current: 5 mA (max)

(7)

Propagation delay time: 500 ns (max)

(8)

Common-mode transient immunity: ±20 kV/µs (min)

(9)

Isolation voltage: 3750 Vrms (min)

(10) Safety standards

UL-approved: UL1577, File No.E67349

cUL-approved: CSA Component Acceptance Service No.5A File No.E67349

VDE-approved: EN60747-5-5, EN60065 or EN60950-1 (Note 1)

CQC-approved: GB4943.1, GB8898 Japan Factory

Note 1: When a VDE approved type is needed, please designate the Option (D4)

(D4).

Start of commercial production

©2016 Toshiba Corporation

1

2011-08

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

4. Packaging (Note)

TLP350H

TLP350H(LF1,TP1)

11-10C401S

11-10C4S

TLP350HF

11-10C405S

TLP350HF(LF4,TP4)

11-10C402S

Note:

TLP350H(LF5,TP5)

11-10C404S

Through-hole type: TLP350H, TLP350HF

Lead forming option: (LF1), (LF4), (LF5)

Taping option: (TP1), (TP4), (TP5)

5. Pin Assignment

1: N.C.

2: Anode

3: Cathode

4: N.C.

5: GND

6: VO (Output)

7: N.C.

8: VCC

©2016 Toshiba Corporation

2

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

6. Internal Circuit (Note)

Note:

A 0.1-µF bypass capacitor must be connected between pin 8 and pin 5.

7. Principle of Operation

7.1. Truth Table

Input

LED

M1

M2

Output

H

ON

ON

OFF

H

L

OFF

OFF

ON

L

7.2. Mechanical Parameters

7.62 mm Pitch

TLP350H

10.16 mm Pitch

TLP350HF

Unit

Creepage distances

7.0 (min)

8.0 (min)

mm

Clearance distances

7.0 (min)

8.0 (min)

Internal isolation thickness

0.4 (min)

0.4 (min)

Characteristics

©2016 Toshiba Corporation

3

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

8. Absolute Maximum Ratings (Note) (Unless otherwise specified, Ta = 25 )

Characteristics

LED

Symbol

Input forward current

Input forward current derating

(Ta ≥ 116 )

Unit

IF

20

mA

-0.6

mA/

1

A

-25

mA/

IFPT

(Ta ≥ 110 )

Rating

∆IF/∆Ta

Peak transient input forward

current

Peak transient input forward

current derating

Note

(Note 1)

∆IFPT/∆Ta

Input reverse voltage

VR

5

V

Input power dissipation

PD

40

mW

(Ta ≥ 110 )

∆PD/∆Ta

-1.0

mW/

(Ta = -40 to 125 )

IOPH

(Note 2)

-2.5

A

(Ta = -40 to 125 )

IOPL

(Note 2)

+2.5

Input power dissipation

derating

Detector Peak high-level output current

Peak low-level output current

Output voltage

VO

35

Supply voltage

VCC

35

Output power dissipation

Output power dissipation

derating

(Ta ≥ 110 )

PO

260

mW

∆PO/∆Ta

-6.5

mW/

Topr

-40 to 125

Tstg

-55 to 150

Common Operating temperature

Storage temperature

Lead soldering temperature

Isolation voltage

V

(10 s)

Tsol

(Note 3)

260

AC, 60 s,

R.H. ≤ 60 %

BVS

(Note 4)

3750

Vrms

Note:

Using continuously under heavy loads (e.g. the application of high temperature/current/voltage and the

significant change in temperature, etc.) may cause this product to decrease in the reliability significantly even

if the operating conditions (i.e. operating temperature/current/voltage, etc.) are within the absolute maximum

ratings.

Please design the appropriate reliability upon reviewing the Toshiba Semiconductor Reliability Handbook

("Handling Precautions"/"Derating Concept and Methods") and individual reliability data (i.e. reliability test

report and estimated failure rate, etc).

Note 1: Pulse width (PW) ≤ 1 µs, 300 pps

Note 2: Exponential waveform. Pulse width ≤ 0.3 µs, f ≤ 15 kHz

Note 3: ≥ 2 mm below seating plane.

Note 4: This device is considered as a two-terminal device: Pins 1, 2, 3 and 4 are shorted together, and pins 5, 6, 7

and 8 are shorted together.

9. Recommended Operating Conditions (Note)

Characteristics

Symbol

Note

Min

Typ.

Input on-state current

IF(ON)

(Note 1)

6.5

Input off-state voltage

VF(OFF)

0

15

30

-2.0

+2.0

50

Supply voltage

VCC

Peak high-level output current

IOPH

Peak low-level output current

IOPL

Operating frequency

f

(Note 2)

(Note 3)

Max

Unit

10

mA

0.8

V

A

kHz

Note:

The recommended operating conditions are given as a design guide necessary to obtain the intended

performance of the device. Each parameter is an independent value. When creating a system design using

this device, the electrical characteristics specified in this datasheet should also be considered.

Note: A ceramic capacitor (0.1 µF) should be connected between pin 8 and pin 5 to stabilize the operation of a highgain linear amplifier. Otherwise, this photocoupler may not switch properly. The bypass capacitor should be

placed within 1 cm of each pin.

Note 1: The rise and fall times of the input on-current should be less than 0.5 µs.

Note 2: Denotes the operating range, not the recommended operating condition.

Note 3: Exponential waveform. IOPH ≥ -2.0 A (≤ 0.3 µs), IOPL ≤ 2.0 A (≤ 0.3 µs), Ta = 125

©2016 Toshiba Corporation

4

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

10. Electrical Characteristics (Note)

(Unless otherwise specified, Ta = -40 to 125 )

Characteristics

Symbol

Input forward voltage

Input forward voltage

temperature coefficient

VF

∆VF/∆Ta

Input reverse current

IR

Input capacitance

Peak high-level output current

Peak low-level output current

Test

Circuit

Note

Ct

IOPH

(Note 1)

IOPL

(Note 1)

Fig.

13.1.1

Fig.

13.1.2

Test Condition

Min

Typ.

Max

IF = 10 mA, Ta = 25

1.4

1.55

1.7

V

IF = 10 mA

-2.0

mV/

VR = 5 V, Ta = 25

10

µA

V = 0 V, f = 1 MHz, Ta = 25

95

pF

IF = 5 mA, VCC = 30 V,

V8-6 = -3.5 V

-1.6

-1.0

A

IF = 5 mA, VCC = 15 V,

V8-6 = -7.0 V

-2.0

IF = 0 mA, VCC = 30 V,

V6-5 = 2.5 V

1.0

1.6

IF = 0 mA, VCC = 15 V,

V6-5 = 7.0 V

2.0

High-level output voltage

VOH

Fig.

13.1.3

IF = 5 mA, RL = 200 Ω,

VCC1 = +15 V, VEE1 = -15 V

11.0

13.7

Low-level output voltage

VOL

Fig.

13.1.4

VF = 0.8 V, RL = 200 Ω,

VCC1 = +15 V, VEE1 = -15 V

-14.9

-12.5

High-level supply current

ICCH

Fig.

13.1.5

IF = 10 mA, VCC = 30 V,

VO = Open

1.5

3.0

Low-level supply current

ICCL

Fig.

13.1.6

IF = 0 mA, VCC = 30 V,

VO = Open

1.5

3.0

Threshold input current (L/H)

IFLH

VCC = 15 V, VO > 1 V

1.0

5

Threshold input voltage (H/L)

VFHL

VCC = 15 V, VO < 1 V

0.8

VCC

Supply voltage

UVLO threshold voltage

UVLO hysteresis

15

30

VUVLO+

IF = 5 mA , VO > 2.5 V

11.0

12.5

13.5

VUVLO-

IF = 5 mA, VO < 2.5 V

9.5

11.0

12.0

1.5

UVLOHYS

Unit

V

mA

V

Note:

Note:

All typical values are at Ta = 25 .

This device is designed for low power consumption, making it more sensitive to ESD than its predecessors.

Extra care should be taken in the design of circuitry and pc board implementation to avoid ESD problems.

Note 1: IO application time ≤ 50 µs, single pulse.

11. Isolation Characteristics (Unless otherwise specified, Ta = 25 )

Characteristics

Total capacitance (input to output)

Isolation resistance

Isolation voltage

Symbol

CS

RS

BVS

Note

Test Conditions

Min

Typ.

Max

Unit

1.0

pF

1014

Ω

3750

Vrms

AC, 1 s in oil

10000

DC, 60 s in oil

10000

(Note 1) VS = 0 V, f = 1 MHz

(Note 1) VS = 500 V, R.H. ≤ 60 %

(Note 1) AC, 60 s

1×

1012

Vdc

Note 1: This device is considered as a two-terminal device: Pins 1, 2, 3 and 4 are shorted together, and pins 5, 6, 7

and 8 are shorted together.

©2016 Toshiba Corporation

5

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

12. Switching Characteristics (Note)

(Unless otherwise specified, Ta = -40 to 125 )

Characteristics

Symbol

Note

Propagation delay time

(L/H)

tpLH

(Note 1)

Propagation delay time

(H/L)

tpHL

Test

Circuit

Min

Typ.

Max

Unit

IF = 0 → 5 mA, VCC = 30 V,

Rg = 20 Ω, Cg = 10 nF

50

500

ns

(Note 1)

IF = 5 → 0 mA, VCC = 30 V,

Rg = 20 Ω, Cg = 10 nF

50

500

|tpHL-tpLH|

(Note 1)

IF = 0 ←→ 5 mA, VCC = 30 V,

Rg = 20 Ω, Cg = 10 nF

350

Rise time

tr

(Note 1)

IF = 0 → 5 mA, VCC = 30 V,

Rg = 20 Ω, Cg = 10 nF

15

Fall time

tf

(Note 1)

IF = 5 → 0 mA, VCC = 30 V,

Rg = 20 Ω, Cg = 10 nF

8

Common-mode transient

immunity at output high

CMH

(Note 2)

VCM = 1000 Vp-p, IF = 5 mA,

VCC = 30 V, Ta = 25 ,

VO(min) = 26 V

±20

±25

Common-mode transient

immunity at output low

CML

(Note 3)

VCM = 1000 Vp-p, IF = 0 mA,

VCC = 30 V, Ta = 25 ,

VO(max) = 1 V

±20

±25

Pulse width distortion

Fig.

13.1.7

Fig.

13.1.8

Test Condition

kV/µs

Note: All typical values are at Ta = 25 .

Note 1: Input signal ( f = 25 kHz, duty = 50 %, tr = tf = 5 ns or less ).

CL is approximately 15 pF which includes probe and stray wiring capacitance.

Note 2: CMH is the maximum rate of rise of the common mode voltage that can be sustained with the output voltage

in the logic high state (VO > 26 V).

Note 3: CML is the maximum rate of fall of the common mode voltage that can be sustained with the output voltage in

the logic low state (VO < 1 V).

©2016 Toshiba Corporation

6

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

13. Test Circuits and Characteristics Curves

13.1. Test Circuits

Fig. 13.1.1 IOPH Test Circuit

Fig. 13.1.2 IOPL Test Circuit

Fig. 13.1.3 VOH Test Circuit

Fig. 13.1.4 VOL Test Circuit

Fig. 13.1.5 ICCH Test Circuit

Fig. 13.1.6 ICCL Test Circuit

Fig. 13.1.7 Switching Time Test Circuit and Waveform

Fig. 13.1.8 Common-Mode Transient Immunity Test Circuit and Waveform

©2016 Toshiba Corporation

7

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

13.2. Characteristics Curves (Note)

Fig. 13.2.1 IF - VF

Fig. 13.2.2 IF - Ta

Fig. 13.2.3 PO - Ta

Fig. 13.2.4 IFLH - Ta

Fig. 13.2.5 ICCL - Ta

Fig. 13.2.6 ICCH - Ta

©2016 Toshiba Corporation

8

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

Fig. 13.2.7 VOL - Ta

Fig. 13.2.8 VOH - Ta

Fig. 13.2.9 VOL - IOPL

Fig. 13.2.10 (VOH-VCC) - IOPH

Fig. 13.2.11 VO(VUVLO) - VCC

Fig. 13.2.12 tpLH,tpHL,|tpHL-tpLH| - Ta

©2016 Toshiba Corporation

9

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

Fig. 13.2.13 tpLH,tpHL,|tpHL-tpLH| - IF

Fig. 13.2.14 tpLH,tpHL,|tpHL-tpLH| - VCC

NOTE: The above characteristics curves are presented for reference only and not guaranteed by production test,

unless otherwise noted.

©2016 Toshiba Corporation

10

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

14. Soldering and Storage

14.1. Precautions for Soldering

The soldering temperature should be controlled as closely as possible to the conditions shown below, irrespective

of whether a soldering iron or a reflow soldering method is used.

•

When using soldering reflow.

The soldering temperature profile is based on the package surface temperature.

(See the figure shown below, which is based on the package surface temperature.)

Reflow soldering must be performed once or twice.

The mounting should be completed with the interval from the first to the last mountings being 2 weeks.

Fig. 14.1.1 An example of a temperature profile

when Sn-Pb eutectic solder is used

•

Fig. 14.1.2 An example of a temperature profile

when lead(Pb)-free solder is used

When using soldering flow (Applicable to both eutectic solder and Lead(Pb)-Free solder)

Preheat the device at a temperature of 150 (package surface temperature) for 60 to 120 seconds.

Mounting condition of 260 within 10 seconds is recommended.

Flow soldering must be performed once.

•

When using soldering Iron

Complete soldering within 10 seconds for lead temperature not exceeding 260 or within 3 seconds not

exceeding 350

Heating by soldering iron must be done only once per lead.

14.2. Precautions for General Storage

•

Avoid storage locations where devices may be exposed to moisture or direct sunlight.

•

Follow the precautions printed on the packing label of the device for transportation and storage.

•

Keep the storage location temperature and humidity within a range of 5 to 35 and 45 % to 75 %,

respectively.

•

Do not store the products in locations with poisonous gases (especially corrosive gases) or in dusty

conditions.

•

Store the products in locations with minimal temperature fluctuations. Rapid temperature changes during

storage can cause condensation, resulting in lead oxidation or corrosion, which will deteriorate the

solderability of the leads.

•

When restoring devices after removal from their packing, use anti-static containers.

•

Do not allow loads to be applied directly to devices while they are in storage.

•

If devices have been stored for more than two years under normal storage conditions, it is recommended

that you check the leads for ease of soldering prior to use.

©2016 Toshiba Corporation

11

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

15. Land Pattern Dimensions (for reference only)

Unit: mm

TLP350H

TLP350HF

Fig. 15.1 Lead forming and taping option

(LF1), (TP1), (LF5), (TP5)

Fig. 15.2 Lead forming and taping option

(LF4), (TP4)

16. Marking (Note)

TLP350H

Note:

TLP350HF

A different marking is used for photocouplers that have been qualified according to option (D4) of EN60747.

See Fig.17.4 and Fig.17.5.

©2016 Toshiba Corporation

12

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

17. EN60747-5-5 Option (D4) Specification

•

Part number: TLP350H, TLP350HF (Note 1)

•

The following part naming conventions are used for the devices that have been qualified according to

option (D4) of EN60747.

Example: TLP350H(D4-TP1, F)

D4: EN60747 option

TP: Tape type

F: [[G]]/RoHS COMPATIBLE (Note 2)

Note 1: Use TOSHIBA standard type number for safety standard application.

e.g., TLP350H(D4-TP1,F) → TLP350H

Note 2: Please contact your Toshiba sales representative for details on environmental information such as the product's

RoHS compatibility.

RoHS is the Directive 2011/65/EU of the European Parliament and of the Council of 8 June 2011 on the

restriction of the use of certain hazardous substances in electrical and electronics equipment.

Fig. 17.1 EN60747 Isolation Characteristics

©2016 Toshiba Corporation

13

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

Fig. 17.2 Insulation Related Specifications (Note)

Note:

Note:

If a printed circuit is incorporated, the creepage distance and clearance may be reduced below this value. (e.

g., at a standard distance between soldering eye centers of 7.5 mm). If this is not permissible, the user shall

take suitable measures.

This photocoupler is suitable for safe electrical isolation only within the safety limit data.

Maintenance of the safety data shall be ensured by means of protective circuits.

Fig. 17.3 Marking on Packing for EN60747

Fig. 17.4 Marking Example (Note)

Note:

Fig. 17.5 Marking Example (Note)

The above marking is applied to the photocouplers that have been qualified according to option (D4) of EN60747.

©2016 Toshiba Corporation

14

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

Fig. 17.6 Measurement Procedure

©2016 Toshiba Corporation

15

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

Package Dimensions

Unit: mm

TLP350H

Weight: 0.54 g (typ.)

Package Name(s)

TOSHIBA: 11-10C4S

©2016 Toshiba Corporation

16

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

Package Dimensions

Unit: mm

TLP350H(LF1,TP1)

Weight: 0.53 g (typ.)

Package Name(s)

TOSHIBA: 11-10C401S

©2016 Toshiba Corporation

17

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

Package Dimensions

Unit: mm

TLP350H(LF5,TP5)

Weight: 0.53 g (typ.)

Package Name(s)

TOSHIBA: 11-10C405S

©2016 Toshiba Corporation

18

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

Package Dimensions

Unit: mm

TLP350HF

Weight: 0.54 g (typ.)

Package Name(s)

TOSHIBA: 11-10C402S

©2016 Toshiba Corporation

19

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

Package Dimensions

Unit: mm

TLP350HF(LF4,TP4)

Weight: 0.53 g (typ.)

Package Name(s)

TOSHIBA: 11-10C404S

©2016 Toshiba Corporation

20

2016-04-18

Rev.8.0

�TLP350H,TLP350HF

RESTRICTIONS ON PRODUCT USE

• Toshiba Corporation, and its subsidiaries and affiliates (collectively "TOSHIBA"), reserve the right to make changes to the information

in this document, and related hardware, software and systems (collectively "Product") without notice.

• This document and any information herein may not be reproduced without prior written permission from TOSHIBA. Even with TOSHIBA's

written permission, reproduction is permissible only if reproduction is without alteration/omission.

• Though TOSHIBA works continually to improve Product's quality and reliability, Product can malfunction or fail. Customers are responsible

for complying with safety standards and for providing adequate designs and safeguards for their hardware, software and systems which

minimize risk and avoid situations in which a malfunction or failure of Product could cause loss of human life, bodily injury or damage

to property, including data loss or corruption. Before customers use the Product, create designs including the Product, or incorporate

the Product into their own applications, customers must also refer to and comply with (a) the latest versions of all relevant TOSHIBA

information, including without limitation, this document, the specifications, the data sheets and application notes for Product and the

precautions and conditions set forth in the "TOSHIBA Semiconductor Reliability Handbook" and (b) the instructions for the application

with which the Product will be used with or for. Customers are solely responsible for all aspects of their own product design or applications,

including but not limited to (a) determining the appropriateness of the use of this Product in such design or applications; (b) evaluating

and determining the applicability of any information contained in this document, or in charts, diagrams, programs, algorithms, sample

application circuits, or any other referenced documents; and (c) validating all operating parameters for such designs and applications.

TOSHIBA ASSUMES NO LIABILITY FOR CUSTOMERS' PRODUCT DESIGN OR APPLICATIONS.

• PRODUCT IS NEITHER INTENDED NOR WARRANTED FOR USE IN EQUIPMENTS OR SYSTEMS THAT REQUIRE

EXTRAORDINARILY HIGH LEVELS OF QUALITY AND/OR RELIABILITY, AND/OR A MALFUNCTION OR FAILURE OF WHICH MAY

CAUSE LOSS OF HUMAN LIFE, BODILY INJURY, SERIOUS PROPERTY DAMAGE AND/OR SERIOUS PUBLIC IMPACT

("UNINTENDED USE"). Except for specific applications as expressly stated in this document, Unintended Use includes, without limitation,

equipment used in nuclear facilities, equipment used in the aerospace industry, medical equipment, equipment used for automobiles,

trains, ships and other transportation, traffic signaling equipment, equipment used to control combustions or explosions, safety devices,

elevators and escalators, devices related to electric power, and equipment used in finance-related fields. IF YOU USE PRODUCT FOR

UNINTENDED USE, TOSHIBA ASSUMES NO LIABILITY FOR PRODUCT. For details, please contact your TOSHIBA sales

representative.

• Do not disassemble, analyze, reverse-engineer, alter, modify, translate or copy Product, whether in whole or in part.

• Product shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is prohibited under any

applicable laws or regulations.

• The information contained herein is presented only as guidance for Product use. No responsibility is assumed by TOSHIBA for any

infringement of patents or any other intellectual property rights of third parties that may result from the use of Product. No license to any

intellectual property right is granted by this document, whether express or implied, by estoppel or otherwise.

• ABSENT A WRITTEN SIGNED AGREEMENT, EXCEPT AS PROVIDED IN THE RELEVANT TERMS AND CONDITIONS OF SALE

FOR PRODUCT, AND TO THE MAXIMUM EXTENT ALLOWABLE BY LAW, TOSHIBA (1) ASSUMES NO LIABILITY WHATSOEVER,

INCLUDING WITHOUT LIMITATION, INDIRECT, CONSEQUENTIAL, SPECIAL, OR INCIDENTAL DAMAGES OR LOSS, INCLUDING

WITHOUT LIMITATION, LOSS OF PROFITS, LOSS OF OPPORTUNITIES, BUSINESS INTERRUPTION AND LOSS OF DATA, AND

(2) DISCLAIMS ANY AND ALL EXPRESS OR IMPLIED WARRANTIES AND CONDITIONS RELATED TO SALE, USE OF PRODUCT,

OR INFORMATION, INCLUDING WARRANTIES OR CONDITIONS OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, ACCURACY OF INFORMATION, OR NONINFRINGEMENT.

• GaAs (Gallium Arsenide) is used in Product. GaAs is harmful to humans if consumed or absorbed, whether in the form of dust or vapor.

Handle with care and do not break, cut, crush, grind, dissolve chemically or otherwise expose GaAs in Product.

• Do not use or otherwise make available Product or related software or technology for any military purposes, including without limitation,

for the design, development, use, stockpiling or manufacturing of nuclear, chemical, or biological weapons or missile technology products

(mass destruction weapons). Product and related software and technology may be controlled under the applicable export laws and

regulations including, without limitation, the Japanese Foreign Exchange and Foreign Trade Law and the U.S. Export Administration

Regulations. Export and re-export of Product or related software or technology are strictly prohibited except in compliance with all

applicable export laws and regulations.

• Please contact your TOSHIBA sales representative for details as to environmental matters such as the RoHS compatibility of Product.

Please use Product in compliance with all applicable laws and regulations that regulate the inclusion or use of controlled substances,

including without limitation, the EU RoHS Directive. TOSHIBA ASSUMES NO LIABILITY FOR DAMAGES OR LOSSES OCCURRING

AS A RESULT OF NONCOMPLIANCE WITH APPLICABLE LAWS AND REGULATIONS.

©2016 Toshiba Corporation

21

2016-04-18

Rev.8.0

�