EVALUATION BOARD

Evaluation Board for Stepper

TMC2209-EVAL Evaluation Board

Document Revision V1.0 • 2019-MAY-08

The TMC2209-EVAL allows evaluation of the TMC2209 in combination with the TRINAMIC evaluation board system, or as stand-alone-board. It uses the standard schematic and offers several

options in order to test different modes of operation.

Features

• 2-phase stepper motor up to 1.7A

coil current (2.4A peak)

• Supply Voltage 5. . . 28V DC

• UART

• 1...256 microsteps

• Step/Dir interface

• StealthChop™ silent PWM mode

• SpreadCycle™ smart mixed decay

Applications

• Compatible Design Upgrade

• 3D Printers

• Printers, POS

• Office and home automation

• Textile, Sewing Machines

• CCTV, Security

Simplified Block Diagram

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at: www.trinamic.com

Read entire documentation.

• ATM, Cash recycler

• HVAC

�2 / 11

TMC2209-EVAL Evaluation Board • Document Revision V1.0 • 2019-MAY-08

Contents

1 Getting Started

1.1 First Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

4

2 Hardware Information

2.1 Onboard Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

5

3 Evaluation Features in the TMCL-IDE

3.1 Velocity Mode . . . . . . . . . . . .

3.2 Position Mode . . . . . . . . . . . .

3.3 StallGuard2™ Tuning . . . . . . . .

3.4 CoolStep™ Tuning . . . . . . . . . .

6

6

7

8

9

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

4 Revision History

11

4.1 Document Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�3 / 11

TMC2209-EVAL Evaluation Board • Document Revision V1.0 • 2019-MAY-08

1

Getting Started

Precautions

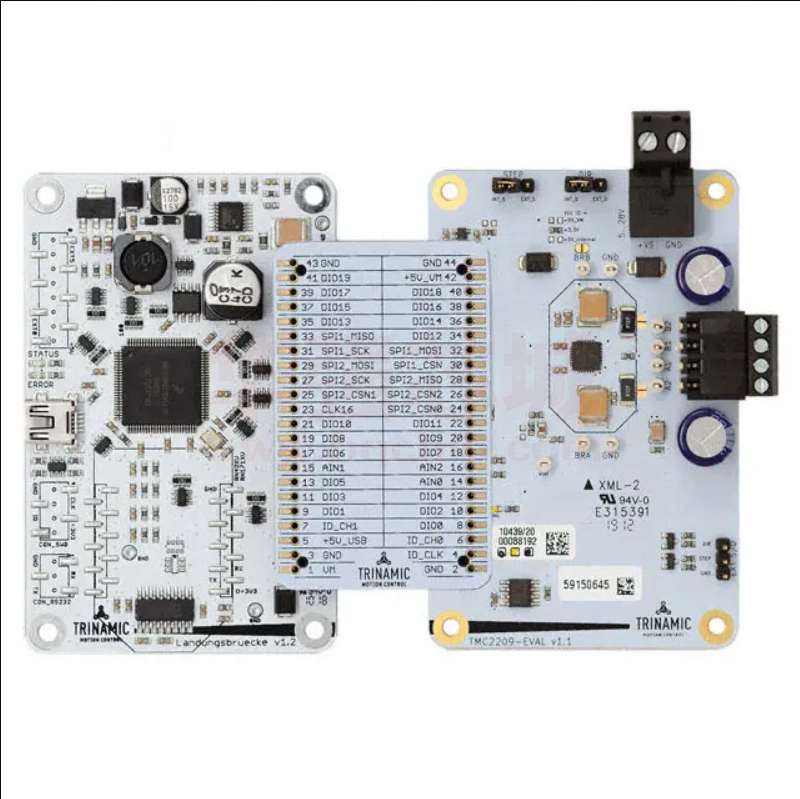

You need

• TMC2209-EVAL

• Landungsbruecke with latest firmware. (The

Startrampe does not support the UART interface.)

• Eselsbruecke bridge board

• Stepper motor (e.g. QMot line)

• USB interface

• Power Supply

• Latest TMCL-IDE V3.0 and PC

• Cables for interface, motors and power

• Do not mix up connections or short-circuit pins.

• Avoid bundling I/O wires with motor wires.

• Do not exceed the maximum rated supply supply voltage!

• Do not connect or disconnect the motor while

powered!

• START WITH POWER SUPPLY OFF!

Figure 1: Getting started

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC2209-EVAL Evaluation Board • Document Revision V1.0 • 2019-MAY-08

1.1

4 / 11

First Start-Up

1. Make sure that the latest version of the TMCL-IDE 3.0 is installed. The TMCL-IDE can be downloaded

from www.trinamic.com/support/software/tmcl-ide/.

2. Open the TMCL-IDE and connect the Landungsbruecke or Startrampe via USB to the computer. For

Windows 8 and higher is no driver needed, on Windows 7 machines the TMCL-IDE is installing the

driver automatically.

3. Verify that the Landungsbruecke or Startrampe is using the latest firmware version. The firmware

version is shown in the connected device tree.

Figure 2: Firmware Version

4. The TMCL-IDE 3.0 needs room to show all important information and to provide a good overview.

Therefore, arrange the main window related to your needs. We recommend using full screen. For

evaluation boards it is essential to have access to the registers. Therefore open up the Register

Browser (left side). For a better view click top right on the normal icon to get a maximized register

browser window.

5. The TMCL-IDE includes a dialogue for diagnostic tasks. Further, the dialogue provides an overview of

the connected motion controller and driver chips. A window pops up immediately after connecting

the evaluation kit the first time. The window shows the actual status of the connections. The second

tab of the dialogue offers the possibility to choose basic settings or to reset the module to factory

defaults.

Figure 3: Landungsbruecke Dialogue

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC2209-EVAL Evaluation Board • Document Revision V1.0 • 2019-MAY-08

2

5 / 11

Hardware Information

All design files for our evaluation boards are available for free. We offer the original ECAD files (Eagle,

Altium, or PADS), Gerber data, the BOM, and PDF copies. Please check schematics for Jumper settings and

input/output connector description.

The files can be downloaded from the evaluation boards’ website directly at out homepage: TRINAMIC Eval

Kit homepage.

Note

2.1

If files are missing on the website or something is wrong please send us a note.

Onboard Jumpers

The TMC2209-Eval board has two jumpers to select between Step/Direction source between MCU and

external pin header (lower right corner).

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC2209-EVAL Evaluation Board • Document Revision V1.0 • 2019-MAY-08

3

6 / 11

Evaluation Features in the TMCL-IDE

This chapter gives some hints and tips on using the functionality of the TMCL-IDE, e.g. how to use the

velocity mode or using the wizards.

Note

3.1

In order to achieve good settings please refer to descriptions and flowcharts

in the TMC2209-LA datasheet. The register browser of the TMCL-IDE provides

helpful information about any currently selected parameter. Beyond that, the

datasheet explains concepts and ideas which are essential for understanding

how the registers are linked together and which setting will fit for which kind of

application. For getting more familiar with the evaluation kit in the beginning

of your examinations, drive the motor using velocity mode and/or positioning

mode first. Beyond this, the direct mode function can be used. This way, TMCL

commands can be sent to the evaluation board system.

Velocity Mode

To move the motor in velocity mode, open the velocity mode tool by clicking the appropriate entry in the

tool tree. In the velocity mode tool you can enter the desired velocity and acceleration and then move the

motor using the arrow buttons. The motor can be stopped at any time by clicking the stop button. Open

the velocity graph tool to get a graphical view of the actual velocity.

Note

In order to get a more accurate graphical velocity view, close the register browser

window when using the velocity graph.

Figure 4: Driving the motor in velocity mode (TMCL-IDE provides similar view for TMC2209-EVAL)

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC2209-EVAL Evaluation Board • Document Revision V1.0 • 2019-MAY-08

3.2

7 / 11

Position Mode

To move the motor in position mode, open the position mode tool by clicking the appropriate entry in

the tool tree. In the position mode tool you can enter a target position and then start positioning by

clicking the Absolute or Relative Move button. The speed and acceleration used for positioning can also be

adjusted here.

Open the position graph tool to get a graphical view of the actual position.

Note

In order to get a more accurate graphical position view, close the register browser

window when using the position graph.

Figure 5: Driving the motor in position mode (TMCL-IDE provides similar view for TMC2209-EVAL)

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC2209-EVAL Evaluation Board • Document Revision V1.0 • 2019-MAY-08

3.3

8 / 11

StallGuard2™ Tuning

To tune StallGuard2™ properly you need to set the current for the motor first, e.g. 1A RMS. After that

you specify the velocity to run the motor with. This could be 75 rpm as in this example. You can use the

TMCL IDE to calculate the velocity with the "Parameter calculator" tool shown in the list on the left when

connecting the board.

Figure 6: TMCL IDE v3.0.20.0 Parameter calculator

In the TMCL IDE you can use the CoolStep™ & StallGuard2™ graph where the StallGuard2™value is shown

in blue. There are two parameters that need tuning for proper StallGuard2™ use. StallGuard2™ Threshold

(SGT), will need to be tuned by raising or lowering the SGT value. The goal of SGT it so have it hit 0 before a

stall occurs. If the SGT is too high, a step loss will occur and you need to lower it. In the picture you see

two regions. In the first region the SGT value was too high. It was set to 10 and with loading the motor you

can see the value does not reach 0. In the second region the SGT value was set to 4 which results in hitting

the 0 axis just short before the motor stalls.

Figure 7: CoolStep™ & StallGuard2™ window

With optimal StallGuard2™ settings you can optionally activate CoolStep™.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC2209-EVAL Evaluation Board • Document Revision V1.0 • 2019-MAY-08

3.4

9 / 11

CoolStep™ Tuning

With the TMCL IDE and the EVAL-KIT you have a powerful tool to find your CoolStep™ to run your motor

most energy efficient and cool. To tune it, please open the CoolStep™ & StallGuard2™ window you’ll find

on the left of the IDE when you have connected the EVAL board. On the CoolStep™ tab you will see below

picture by default.

Figure 8: TMCL IDE v3.0.20.0 Parameter calculator

CoolStep™ will get activated as soon as you change the "Hysteresis start" value higher than 0 and enter a

"Threshold speed" value higher than 0.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC2209-EVAL Evaluation Board • Document Revision V1.0 • 2019-MAY-08

10 / 11

Figure 9: CoolStep™ & StallGuard2™ window

The above values activate CoolStep™ but the values can be fine tuned to make CoolStep™ work reliable

and in a way as you need it in your application. For that it is important to understand what each setting is

doing.

• Current minimum: The current minimum setting will be the lowest current when CoolStep™ is

activated. With 1A RMS the current will either be reduced to a quarter or to the half of this current

when no or less force is applied to the motor shaft.

• Current down step: Current down steps defines the speed of the current to drop down after load

gets released from the motor shaft.

• Current up step: This setting defines the step height when hitting the lower StallGuard2™ threshold

(Hysteresis start).

• Hysteresis width: This setting defines the area of the StallGuard2™ threshold (Hysteresis end).

• Hysteresis start: This setting defines the switching point, related to the StallGuard2™ value, to boost

up the current by one step.

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

�TMC2209-EVAL Evaluation Board • Document Revision V1.0 • 2019-MAY-08

4

4.1

Revision History

Document Revision

Version

Date

Author

Description

1.0

2019-MAY-08

OM

Initial release.

Table 1: Document Revision

©2019 TRINAMIC Motion Control GmbH & Co. KG, Hamburg, Germany

Terms of delivery and rights to technical change reserved.

Download newest version at www.trinamic.com

11 / 11

�