POWER DRIVER FOR STEPPER MOTORS

INTEGRATED CIRCUITS

TMC2208/2 & TMC2224 family Datasheet

TMC2202, TMC2208, TMC2224 Step/Dir Drivers for Two-Phase Bipolar Stepper Motors up to 2A peak StealthChop™ for Quiet Movement - UART Interface Option.

APPLICATIONS

Compatible Design Upgrade

3D Printers

Printers, POS

Office and home automation

Textile, Sewing Machines

CCTV, Security

ATM, Cash recycler

HVAC

FEATURES

AND

BENEFITS

2-phase stepper motors up to 2A coil current (peak)

STEP/DIR Interface with 2, 4, 8, 16 or 32 microstep pin

setting

Smooth Running 256 microsteps by MicroPlyer™ interpolation

StealthChop2™ silent motor operation

SpreadCycle™ highly dynamic motor control chopper

Low RDSon LS 280mΩ & HS 290mΩ (typ. at 25°C)

Voltage Range 4.75… 36V DC

Automatic Standby current reduction (option)

Internal Sense Resistor option (no sense resistors required)

Passive Braking and Freewheeling

Single Wire UART & OTP for advanced configuration options

Integrated Pulse Generator for standalone motion

Full Protection & Diagnostics

Choice of QFN and wettable QFN packages for best fit

BLOCK DIAGRAM

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

DESCRIPTION

The TMC2202, TMC2208 and TMC2224 are

ultra-silent motor driver ICs for two-phase

stepper motors. Their pinning is compatible

to a number of legacy drivers. TRINAMICs

sophisticated

StealthChop2

chopper

ensures noiseless operation, maximum

efficiency and best motor torque. Its fast

current

regulation

and

optional

combination with SpreadCycle allow for

highly dynamic motion. Integrated powerMOSFETs handle motor current up to 1.4A

RMS. Protection and diagnostic features

support robust and reliable operation. A

simple to use UART interface opens up

more

tuning

and

control

options.

Application specific tuning can be stored to

OTP memory. Industries’ most advanced

STEP/DIR stepper motor driver family

upgrades designs to noiseless and most

precise operation for cost-effective and

highly competitive solutions.

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

2

APPLICATION EXAMPLES: SIMPLE SOLUTIONS – HIGHLY EFFECTIVE

The TMC22xx family scores with power density, integrated power MOSFETs, smooth and quiet

operation, and a congenial simplicity. The TMC22xx covers a wide spectrum of applications from

battery systems to embedded applications with up to 2A motor current per coil. TRINAMICs unique

chopper modes SpreadCycle and StealthChop2 optimize drive performance. StealthChop reduces motor

noise to the point of silence at low velocities. Standby current reduction keeps costs for power

dissipation and cooling down. Extensive support enables rapid design cycles and fast time-to-market

with competitive products.

STANDALONE REPLACEMENT

FOR

LEGACY STEPPER DRIVER

0A+

S/D

ERROR, INDEX

TMC22xx

S

0A-

N

0B+

0B-

UART

INTERFACE FOR

FULL DIAGNOSTICS

AND

CONTROL

0A+

S/D

High-Level

Interface

CPU

UART

TMC22xx

0A0B+

0B-

Sense Resistors may be omitted

S

N

In this example, configuration is hard

wired via pins. Software based motion

control generates STEP and DIR

(direction) signals, INDEX and ERROR

signals report back status information.

A CPU operates the driver via step and

direction signals. It accesses diagnostic

information

and

configures

the

TMC22xx via the UART interface. The

CPU manages motion control and the

TMC22xx drives the motor and smoothens and optimizes drive performance.

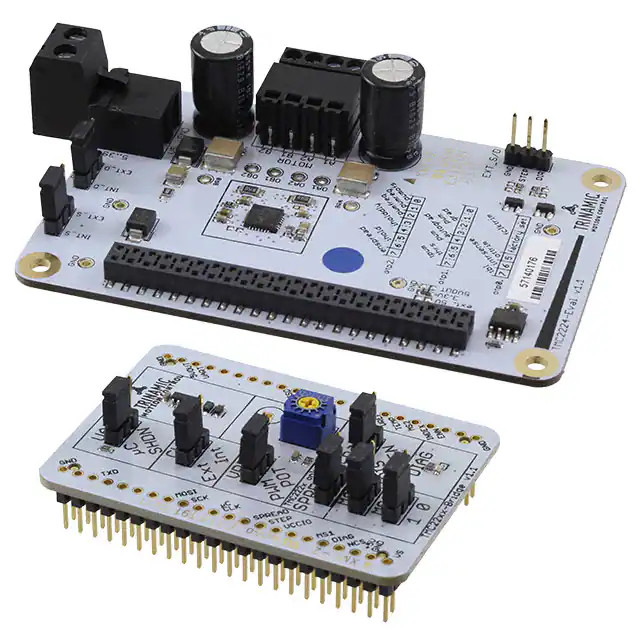

TMC2208-EVAL E VALUATION BOARD

The

TMC22xx-EVAL

is

part

of

TRINAMICs universal evaluation board

system which provides a convenient

handling of the hardware as well as a

user-friendly

software

tool

for

evaluation. The TMC22xx evaluation

board system consists of three parts:

LANDUNGSBRÜCKE

(base

board),

ESELSBRÜCKE (connector board with

test points), and TMC22xx-EVAL.

ORDER CODES

Order code

TMC2208-LA

TMC2224-LA

TMC2202-WA

TMC2208-EVAL

TMC2224-EVAL

ESELSBRÜCKE

LANDUNGSBRÜCKE

www.trinamic.com

PN

00-0150

00-0154

00-0159

40-0182

40-0183

40-0098

40-0167

Description

StealthChop driver; QFN28 (RoHS)

StealthChop driver; QFN28 (RoHS)

StealthChop driver; wettable edge QFN32 (RoHS)

Evaluation board for TMC2208 stepper motor driver

Evaluation board for TMC2224 stepper motor driver

Connector board fitting to V1.3 and future 22xx-EVAL

Baseboard for TMC2208-EVAL and further evaluation

boards

Size [mm2]

5x5

5x5

5x5

85 x 55

85 x 55

61 x 38

85 x 55

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

3

Table of Contents

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

2

GENERAL REGISTERS .....................................21

VELOCITY DEPENDENT CONTROL ...................26

SEQUENCER REGISTERS .................................27

CHOPPER CONTROL REGISTERS .....................28

STEALTHCHOP™ ..............................................34

6.1

6.2

6.3

6.4

6.5

6.6

6.7

7

DATAGRAM STRUCTURE .................................16

CRC CALCULATION .......................................18

UART SIGNALS ............................................18

ADDRESSING MULTIPLE SLAVES ....................19

REGISTER MAP .................................................20

5.1

5.2

5.3

5.4

6

STANDARD APPLICATION CIRCUIT ................12

INTERNAL RDSON SENSING..........................12

5V ONLY SUPPLY..........................................13

CONFIGURATION PINS ..................................14

HIGH MOTOR CURRENT .................................14

DRIVER PROTECTION AND EME CIRCUITRY ...15

UART SINGLE WIRE INTERFACE ................16

4.1

4.2

4.3

4.4

5

PACKAGE OUTLINE TMC2208 ........................ 8

SIGNAL DESCRIPTIONS TMC2208 .................. 8

PACKAGE OUTLINE TMC2202 ........................ 9

SIGNAL DESCRIPTIONS TMC2202 .................. 9

PACKAGE OUTLINE TMC2224 ......................10

SIGNAL DESCRIPTIONS TMC2224 ................11

SAMPLE CIRCUITS ..........................................12

3.1

3.2

3.3

3.4

3.5

3.6

4

KEY CONCEPTS ................................................ 5

CONTROL INTERFACES ..................................... 6

MOVING AND CONTROLLING THE MOTOR ........ 6

STEALTHCHOP2 & SPREADCYCLE DRIVER ....... 6

PRECISE CLOCK GENERATOR AND CLK INPUT... 7

AUTOMATIC STANDSTILL POWER DOWN......... 7

INDEX OUTPUT ................................................ 7

PIN ASSIGNMENTS ........................................... 8

2.1

2.2

2.3

2.4

2.5

2.6

3

7.1

PRINCIPLES OF OPERATION ......................... 4

AUTOMATIC TUNING .....................................34

STEALTHCHOP OPTIONS ................................37

STEALTHCHOP CURRENT REGULATOR.............37

VELOCITY BASED SCALING ............................39

COMBINING STEALTHCHOP AND SPREADCYCLE .

.....................................................................41

FLAGS IN STEALTHCHOP ...............................42

FREEWHEELING AND PASSIVE BRAKING ........43

SPREADCYCLE CHOPPER ...............................45

www.trinamic.com

SPREADCYCLE SETTINGS ............................... 46

8

SELECTING SENSE RESISTORS.................... 49

9

MOTOR CURRENT CONTROL ........................ 50

9.1

ANALOG CURRENT SCALING VREF ............... 51

10

INTERNAL SENSE RESISTORS ..................... 53

11

STEP/DIR INTERFACE .................................... 55

11.1 TIMING ......................................................... 55

11.2 CHANGING RESOLUTION ............................... 56

11.3 MICROPLYER STEP INTERPOLATOR AND STAND

STILL DETECTION ....................................................... 57

11.4 INDEX OUTPUT ............................................. 58

12

INTERNAL STEP PULSE GENERATOR ......... 59

13

DRIVER DIAGNOSTIC FLAGS ...................... 60

13.1

13.2

13.3

13.4

TEMPERATURE MEASUREMENT ....................... 60

SHORT PROTECTION ...................................... 60

OPEN LOAD DIAGNOSTICS ........................... 61

DIAGNOSTIC OUTPUT ................................... 61

14

QUICK CONFIGURATION GUIDE ................ 62

15

EXTERNAL RESET ............................................. 65

16

CLOCK OSCILLATOR AND INPUT ............... 65

17

ABSOLUTE MAXIMUM RATINGS ................. 66

18

ELECTRICAL CHARACTERISTICS ................. 66

18.1

18.2

18.3

19

LAYOUT CONSIDERATIONS ......................... 72

19.1

19.2

19.3

19.4

20

OPERATIONAL RANGE ................................... 66

DC AND TIMING CHARACTERISTICS .............. 67

THERMAL CHARACTERISTICS.......................... 71

EXPOSED DIE PAD ........................................ 72

WIRING GND .............................................. 72

SUPPLY FILTERING........................................ 72

LAYOUT EXAMPLE TMC2208 ........................ 73

PACKAGE MECHANICAL DATA .................... 74

20.1

20.2

20.3

DIMENSIONAL DRAWINGS QFN28............... 74

DIMENSIONAL DRAWINGS QFN32-WA ....... 76

PACKAGE CODES ........................................... 77

21

TABLE OF FIGURES ......................................... 78

22

REVISION HISTORY ....................................... 79

23

REFERENCES ...................................................... 79

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

1

4

Principles of Operation

The TMC22xx family of stepper drivers is intended as a drop-in upgrade for existing low cost stepper

driver applications. Its silent drive technology StealthChop enables non-bugging motion control for

home and office applications. A highly efficient power stage enables high current from a tiny package.

The TMC22xx requires just a few control pins on its tiny package. They allow selection of the most

important setting: the desired microstep resolution. A choice of 2, 4, 8, 16 or 32 microsteps adapts the

driver to the capabilities of the motion controller. Some package options also allow chopper mode

selection by pin.

STEP

DIR

5V Voltage

regulator

Step&Dir input

Analog Scaling

(only TMC222x)

PDN/UART

Configuration

Interface

B. Dwersteg, ©

TRINAMIC 2016

UART interface

+ Register Block

Driver error

Index pulse

DIAG

INDEX

(not with TMC2202)

opt. ext. clock

10-16MHz

CLK_IN

3.3V or 5V

I/O voltage

VCC_IO

100µF

VCP

CPI

Low ESR type

OA1

Full Bridge A

OA2

BRA

stealthChop2

256 Microstep

Sequencer

100n

Driver

Integrated

Rsense

N

stepper

motor

RSA

IREF

Connect directly

to GND plane

Use low inductivity SMD

type, e.g. 1206, 0.5W for

RSA and RSB

spreadCycle

Programmable

Diagnostic

Outputs

S

OB1

Full Bridge B

Trimmed

CLK oscillator/

selector

OB2

BRB

RSB

Connect directly

to GND plane

ENN

100n

GND

optional UART interface

Configuration

Memory (OTP)

100n

charge pump

IREF

Stand Still

Current

Reduction

microPlyer

MS2

SPREAD

+VM

VS

VREF

MS1

100n

16V

TMC22xx

Step Pulse

Generator

Configuration

(GND or VCC_IO)

22n

50V

DIE PAD

Step and Direction

motion control

CPO

2.2µ

6.3V

5VOUT

Place near IC with

short path to die pad

VREF Analog current

scaling or leave

open

Even at low microstepping rate, the TMC22xx offers a number of unique enhancements over

comparable products: TRINAMICs sophisticated StealthChop2 chopper plus the microstep enhancement

MicroPlyer ensure noiseless operation, maximum efficiency and best motor torque. Its fast current

regulation and optional combination with SpreadCycle allow for highly dynamic motion. Protection

and diagnostic features support robust and reliable operation. A simple-to-use 8 bit UART interface

opens up more tuning and control options. Application specific tuning can be stored to on-chip OTP

memory. Industries’ most advanced step & direction stepper motor driver family upgrades designs to

noiseless and most precise operation for cost-effective and highly competitive solutions.

opt. driver enable

Figure 1.1 TMC22xx basic application block diagram

THREE MODES OF OPERATION:

OPTION 1: Standalone STEP/DIR Driver (Legacy Mode)

A CPU (µC) generates step & direction signals synchronized to additional motors and other

components within the system. The TMC22xx operates the motor as commanded by the configuration

pins and STEP/DIR signals. Motor run current either is fixed, or set by the CPU using the analog input

VREF. The pin PDN_UART selects automatic standstill current reduction. Feedback from the driver to

the CPU is granted by the INDEX and DIAG output signals. Enable or disable the motor using the ENN

pin.

www.trinamic.com

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

5

OPTION 2: Standalone STEP/DIR Driver with OTP pre-configuration

UART

Additional options enabled by pre-programming OTP memory (label UART & OTP):

+

+

+

OTP

Tuning of the chopper to the application for application tailored performance

Cost reduction by switching the driver to internal sense resistor mode

Adapting the automatic power down level and timing for best application efficiency

0A+

S/D

High-Level

Interface

CPU

ERROR, INDEX

TMC22xx

0A-

S

N

0B+

TXD only or bit

bang UART

Other drivers

0B-

External preprogramming

Figure 1.2 Stand-alone driver with pre-configuration

To enable the additional options, either one-time program the driver’s OTP memory, or store

configuration in the CPU and transfer it to the on-chip registers following each power-up. Operation

uses the same signals as Option 1. Programming does not need to be done within the application - it

can be executed during testing of the PCB! Alternatively, use bit-banging by CPU firmware to configure

the driver. Multiple drivers can be programmed at the same time using a single TXD line.

OPTION 3: STEP/DIR Driver with Full Diagnostics and Control

UART

Similar to Option 2, but pin PDN_UART is connected to the CPU UART interface.

Additional options (label UART):

+

+

+

+

Detailed diagnostics and thermal management

Passive braking and freewheeling for flexible, lowest power stop modes

More options for microstep resolution setting (fullstep to 256 microstep)

Software controlled motor current setting and more chopper options

This mode allows replacing all control lines like ENN, DIAG, INDEX, MS1, MS2, and analog current

setting VREF by a single interface line. This way, only three signals are required for full control: STEP,

DIR and PDN_UART. Even motion without external STEP pulses is provided by an internal

programmable step pulse generator: Just set the desired motor velocity. However, no ramping is

provided by the TMC22xx. Access to multiple driver ICs is possible using an analog multiplexer IC.

1.1 Key Concepts

The TMC22xx implements advanced features which are exclusive to TRINAMIC products. These features

contribute toward greater precision, greater energy efficiency, higher reliability, smoother motion, and

cooler operation in many stepper motor applications.

StealthChop2™ No-noise, high-precision chopper algorithm for inaudible motion and inaudible

standstill of the motor. Allows faster motor acceleration and deceleration than

StealthChop™ and extends StealthChop to low stand still motor currents.

SpreadCycle™

High-precision

movements.

cycle-by-cycle

current

control

algorithm

for

highest

dynamic

MicroPlyer™

Microstep interpolator for obtaining full 256 microstep smoothness with lower

resolution step inputs starting from fullstep

In addition to these performance enhancements, TRINAMIC motor drivers offer safeguards to detect

and protect against shorted outputs, output open-circuit, overtemperature, and undervoltage

conditions for enhancing safety and recovery from equipment malfunctions.

www.trinamic.com

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

6

1.2 Control Interfaces

The TMC22xx supports both, discrete control lines for basic mode selection and a UART based single

wire interface with CRC checking. The UART interface automatically becomes enabled when correct

UART data is sent. When using UART, the pin selection may be disabled by control bits.

1.2.1

UART Interface

UART

The single wire interface allows unidirectional operation (for parameter setting only), or bi-directional

operation for full control and diagnostics. It can be driven by any standard microcontroller UART or

even by bit banging in software. Baud rates from 9600 Baud to 500k Baud or even higher (when

using an external clock) may be used. No baud rate configuration is required, as the TMC22xx

automatically adapts to the masters’ baud rate. The frame format is identical to the intelligent

TRINAMIC controller & driver ICs TMC5130 and TMC5072. A CRC checksum allows data transmission

over longer distance. For fixed initialization sequences, store the data including CRC into the µC, thus

consuming only a few 100 bytes of code for a full initialization. CRC may be ignored during read

access, if not desired. This makes CRC use an optional feature! The IC has a fixed address. Multiple

drivers can be programmed in parallel by tying together all interface pins, in case no read access is

required. An optional addressing can be provided by analog multiplexers, like 74HC4066.

From a software point of view the TMC22xx is a peripheral with a number of control and status

registers. Most of them can either be written only or are read only. Some of the registers allow both,

read and write access. In case read-modify-write access is desired for a write only register, a shadow

register can be realized in master software.

1.3 Moving and Controlling the Motor

1.3.1

STEP/DIR Interface

The motor is controlled by a step and direction input. Active edges on the STEP input can be rising

edges or both rising and falling edges as controlled by a special mode bit (DEDGE). Using both edges

cuts the toggle rate of the STEP signal in half, which is useful for communication over slow interfaces

such as optically isolated interfaces. The state sampled from the DIR input upon an active STEP edge

determines whether to step forward or back. Each step can be a fullstep or a microstep, in which

there are 2, 4, 8, 16, 32, 64, 128, or 256 microsteps per fullstep. A step impulse with a low state on

DIR increases the microstep counter and a high state decreases the counter by an amount controlled

by the microstep resolution. An internal table translates the counter value into the sine and cosine

values which control the motor current for microstepping.

1.3.2 Internal Step Pulse Generator

UART

Some applications do not require a precisely co-ordinate motion – the motor just is required to move

for a certain time and at a certain velocity. The TMC22xx comes with an internal pulse generator for

these applications: Just provide the velocity via UART interface to move the motor. The velocity sign

automatically controls the direction of the motion. However, the pulse generator does not integrate a

ramping function. Motion at higher velocities will require ramping up and ramping down the velocity

value via software.

STEP/DIR mode and internal pulse generator mode can be mixed in an application!

1.4 StealthChop2 & SpreadCycle Driver

StealthChop is a voltage chopper based principle. It especially guarantees that the motor is absolutely

quiet in standstill and in slow motion, except for noise generated by ball bearings. Unlike other

voltage mode choppers, StealthChop2 does not require any configuration. It automatically learns the

best settings during the first motion after power up and further optimizes the settings in subsequent

motions. An initial homing sequence is sufficient for learning. Optionally, initial learning parameters

can be stored to OTP. StealthChop2 allows high motor dynamics, by reacting at once to a change of

motor velocity.

www.trinamic.com

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

7

For highest velocity applications, SpreadCycle is an option to StealthChop2. It can be enabled via

input pin (TMC222x) or via UART and OTP. StealthChop2 and SpreadCycle may even be used in a

combined configuration for the best of both worlds: StealthChop2 for no-noise stand still, silent and

smooth performance, SpreadCycle at higher velocity for high dynamics and highest peak velocity at

low vibration.

SpreadCycle is an advanced cycle-by-cycle chopper mode. It offers smooth operation and good

resonance dampening over a wide range of speed and load. The SpreadCycle chopper scheme

automatically integrates and tunes fast decay cycles to guarantee smooth zero crossing performance.

Benefits of using StealthChop2:

- Significantly improved microstepping with low cost motors

- Motor runs smooth and quiet

- Absolutely no standby noise

- Reduced mechanical resonance yields improved torque

1.5 Precise clock generator and CLK input

The TMC22xx provides a factory trimmed internal clock generator for precise chopper frequency and

performance. However, an optional external clock input is available for cases, where quartz precision

is desired, or where a lower or higher frequency is required. For safety, the clock input features

timeout detection, and switches back to internal clock upon fail of the external source.

1.6 Automatic Standstill Power Down

An automatic current reduction drastically reduces application power dissipation and cooling

requirements. Per default, the stand still current reduction is enabled by pulling PDN_UART input to

GND. It reduces standstill power dissipation to less than 33% by going to slightly more than half of

the run current.

Modify stand still current, delay time and decay via UART, or pre-programmed via internal OTP.

Automatic freewheeling and passive motor braking are provided as an option for stand still. Passive

braking reduces motor standstill power consumption to zero, while still providing effective

dampening and braking!

STEP

CURRENT

IRUN

IHOLD

RMS motor current trace with pin PDN=0

TPOWERDOWN IHOLDDELAY

power down power down

ramp time

delay time

t

Figure 1.3 Automatic Motor Current Power Down

1.7 Index Output

The index output gives one pulse per electrical rotation, i.e. one pulse per each four fullsteps. It

shows the internal sequencer microstep 0 position (MSTEP near 0). This is the power on position. In

combination with a mechanical home switch, a more precise homing is enabled.

www.trinamic.com

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

2

8

Pin Assignments

The TMC22xx family comes in a number of package variants in order to fit different footprints. Please

check for availability.

VS

BRB

OB1

OA1

BRA

VS

2.1 Package Outline TMC2208

26

25

24

23

22

3

19

2

20

1

6

© B. Dwersteg,

TRINAMIC

7

Pad=GND

9

10

11

12

13

OA2

DIR

GND

VREF

STEP

VCC_IO

14

5VOUT

MS1

MS2

DIAG

INDEX

CLK

PDN_UART

8

15

16

5

17

18

TMC2208

QFN28

4

OB2

ENN

GND

CPO

CPI

VCP

-

27

21

28

Figure 2.1 TMC2208 Pinning Top View – type: QFN28, 5x5mm², 0.5mm pitch

2.2 Signal Descriptions TMC2208

Pin

OB2

Number

1

Type

ENN

2

DI

GND

CPO

CPI

VCP

3, 18

4

5

6

7, 20,

25

N.C.

5VOUT

8

MS1

MS2

DIAG

INDEX

9

10

11

12

DI (pd)

DI (pd)

DO

DO

CLK

13

DI

PDN_UART

14

DIO

VCC_IO

15

www.trinamic.com

Function

Motor coil B output 2

Enable not input. The power stage becomes switched off (all motor

outputs floating) when this pin becomes driven to a high level.

GND. Connect to GND plane near pin.

Charge pump capacitor output.

Charge pump capacitor input. Tie to CPO using 22nF 50V capacitor.

Charge pump voltage. Tie to VS using 100nF capacitor.

Unused pin, leave open or connect to GND for compatibility to future

versions.

Output of internal 5V regulator. Attach 2.2µF to 4.7µF ceramic

capacitor to GND near to pin for best performance. Provide the

shortest possible loop to the GND pad.

Microstep resolution configuration (internal pull-down resistors)

MS2, MS1: 00: 1/8, 01: 1/2, 10: 1/4 11: 1/16

Diagnostic output. Hi level upon driver error. Reset by ENN=high.

Configurable index output. Provides index pulse.

CLK input. Tie to GND using short wire for internal clock or supply

external clock.

Power down not control input (low = automatic standstill current

reduction).

Optional UART Input/Output. Power down function can be disabled

in UART mode.

3.3V to 5V IO supply voltage for all digital pins.

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

Pin

STEP

Number

16

Type

DI

VREF

17

AI

DIR

19

DI (pd)

VS

22, 28

OA2

21

BRA

23

OA1

OB1

24

26

BRB

27

Exposed

die pad

-

9

Function

STEP input

Analog reference voltage for current scaling or reference current for

use of internal sense resistors (optional mode)

DIR input (internal pull-down resistor)

Motor supply voltage. Provide filtering capacity near pin with

shortest possible loop to GND pad.

Motor coil A output 2

Sense resistor connection for coil A. Place sense resistor to GND near

pin. Tie to GND when using internal sense resistor.

Motor coil A output 1

Motor coil B output 1

Sense resistor connection for coil B. Place sense resistor to GND near

pin. Tie to GND when using internal sense resistor.

Connect the exposed die pad to a GND plane. Provide as many as

possible vias for heat transfer to GND plane. Serves as GND pin for

power drivers and analogue circuitry.

BRB

OB1

OA1

BRA

2.3 Package Outline TMC2202

30

29

28

27

26

25

3

22

2

23

1

6

19

5

20

21

TMC2202

QFN32

4

8

Pad=GND

10

11

12

13

14

15

OA2

VS

DIR

GND

VREF

STEP

16

VCP

5VOUT

MS1

MS2

DIAG

CLK

PDN_UART

VCC_IO

9

17

18

© B. Dwersteg,

TRINAMIC

7

OB2

VS

ENN

GND

CPO

CPI

31

24

32

Figure 2.2 TMC2202 Pinning Top View – type: QFN32, 5x5mm², 0.5mm pitch

2.4 Signal Descriptions TMC2202

Pin

OB2

N.C.

Number

1

2, 4, 21,

23, 26,

28, 29,

31

VS

3, 22

ENN

5

www.trinamic.com

Type

DI

Function

Motor coil B output 2

Unused pin, leave open to provide for higher creeping voltage

distances.

Motor supply voltage. Provide filtering capacity near pin with

shortest possible loop to GND pad.

Enable not input. The power stage becomes switched off (all motor

outputs floating) when this pin becomes driven to a high level.

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

Pin

GND

CPO

CPI

VCP

Number

6, 19

7

8

9

Type

5VOUT

10

MS1

MS2

DIAG

11

12

13

DI (pd)

DI (pd)

DO

CLK

14

DI

PDN_UART

15

DIO

VCC_IO

STEP

16

17

DI

VREF

18

AI

DIR

OA2

20

24

DI (pd)

BRA

25

OA1

OB1

27

30

BRB

32

Exposed

die pad

-

Function

GND. Connect to GND plane near pin.

Charge pump capacitor output.

Charge pump capacitor input. Tie to CPO using 22nF 50V capacitor.

Charge pump voltage. Tie to VS using 100nF capacitor.

Output of internal 5V regulator. Attach 2.2µF to 4.7µF ceramic

capacitor to GND near to pin for best performance. Provide the

shortest possible loop to the GND pad.

Microstep resolution configuration (internal pull-down resistors)

MS2, MS1: 00: 1/8, 01: 1/2, 10: 1/4 11: 1/16

Diagnostic output. Hi level upon driver error. Reset by ENN=high.

CLK input. Tie to GND using short wire for internal clock or supply

external clock.

Power down not control input (low = automatic standstill current

reduction).

Optional UART Input/Output. Power down function can be disabled

in UART mode.

3.3V to 5V IO supply voltage for all digital pins.

STEP input

Analog reference voltage for current scaling or reference current for

use of internal sense resistors (optional mode)

DIR input (internal pull-down resistor)

Motor coil A output 2

Sense resistor connection for coil A. Place sense resistor to GND near

pin. Tie to GND when using internal sense resistor.

Motor coil A output 1

Motor coil B output 1

Sense resistor connection for coil B. Place sense resistor to GND near

pin. Tie to GND when using internal sense resistor.

Connect the exposed die pad to a GND plane. Provide as many as

possible vias for heat transfer to GND plane. Serves as GND pin for

power drivers and analogue circuitry.

MS1

CLK

STEP

ENN

DIR

SPREAD

2.5 Package Outline TMC2224

26

25

24

23

22

3

19

2

20

1

7

© B. Dwersteg,

TRINAMIC

Pad=GND

9

10

11

12

13

DIAG

PDN_UART

VCC_IO

5VOUT

GND

TEST

VREF

14

OA2

BRA

OA1

OB1

BRB

OB2

VS

8

15

6

16

5

17

18

TMC2224

QFN28

4

MS2

INDEX

GND

CPO

CPI

VCP

VS

27

21

28

Figure 2.3 TMC2224 Pinning Top View – type: QFN28, 5x5mm², 0.5mm pitch

www.trinamic.com

10

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

11

2.6 Signal Descriptions TMC2224

Pin

MS1

MS2

INDEX

GND

CPO

CPI

VCP

Number

28

1

2

3, 17

4

5

6

VS

7, 14

OA2

8

BRA

9

OA1

OB1

10

11

BRB

12

OB2

13

VREF

15

TEST

16

5VOUT

18

VCC_IO

19

PDN_UART

20

DIO

(pd)

DIAG

SPREAD

DIR

21

22

23

DO

DI (pd)

DI (pd)

ENN

24

DI

STEP

25

DI (pd)

N.C.

26

CLK

27

Exposed

die pad

-

www.trinamic.com

Type

DI (pd)

DI (pd)

DO

AI

DI

Function

Microstep resolution configuration (internal pull-down resistors)

MS2, MS1: 00: 1/4, 01: 1/8, 10: 1/16, 11: 1/32

Configurable index output. Provides index pulse.

GND. Connect to GND plane near pin.

Charge pump capacitor output.

Charge pump capacitor input. Tie to CPO using 22nF 50V capacitor.

Charge pump voltage. Tie to VS using 100nF capacitor.

Motor supply voltage. Provide filtering capacity near pin with

shortest possible loop to GND pad.

Motor coil A output 2

Sense resistor connection for coil A. Place sense resistor to GND near

pin. Tie to GND when using internal sense resistor.

Motor coil A output 1

Motor coil B output 1

Sense resistor connection for coil B. Place sense resistor to GND near

pin. Tie to GND when using internal sense resistor.

Motor coil B output 2

Analog reference voltage for current scaling or reference current for

use of internal sense resistors (optional mode)

Connect to GND. May alternatively be left open or connected to VREF.

Output of internal 5V regulator. Attach 2.2µF to 4.7µF ceramic

capacitor to GND near to pin for best performance. Provide the

shortest possible loop to the GND pad.

3.3V to 5V IO supply voltage for all digital pins.

Power down not control input (low = automatic standstill current

reduction). (internal pull-down resistor)

Optional UART Input/Output. Power down function can be disabled

in UART mode.

Diagnostic output. Hi level upon driver error. Reset by ENN=high.

Chopper mode selection: Low=StealthChop, High=SpreadCycle

DIR input (internal pull-down resistor)

Enable not input. The power stage becomes switched off (all motor

outputs floating) when this pin becomes driven to a high level.

STEP input (internal pull-down resistor)

Unused pin, leave open or connect to GND for compatibility to future

versions.

CLK input. Tie to GND using short wire for internal clock or supply

external clock.

Connect the exposed die pad to a GND plane. Provide as many as

possible vias for heat transfer to GND plane. Serves as GND pin for

power drivers and analogue circuitry.

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

3

12

Sample Circuits

The sample circuits show the connection of external components in different operation and supply

modes. The connection of the bus interface and further digital signals is left out for clarity.

STEP

DIR

5V Voltage

regulator

Step&Dir input

Analog Scaling

(only TMC222x)

PDN/UART

B. Dwersteg, ©

TRINAMIC 2016

UART interface

+ Register Block

Driver error

Index pulse

DIAG

INDEX

(not with TMC2202)

opt. ext. clock

10-16MHz

CLK_IN

3.3V or 5V

I/O voltage

VCC_IO

100µF

VCP

CPI

Low ESR type

OA1

Full Bridge A

OA2

BRA

stealthChop2

256 Microstep

Sequencer

100n

Driver

Integrated

Rsense

N

stepper

motor

RSA

IREF

Connect directly

to GND plane

Use low inductivity SMD

type, e.g. 1206, 0.5W for

RSA and RSB

spreadCycle

Programmable

Diagnostic

Outputs

S

OB1

Full Bridge B

Trimmed

CLK oscillator/

selector

OB2

BRB

RSB

Connect directly

to GND plane

ENN

100n

GND

optional UART interface

Configuration

Interface

100n

charge pump

IREF

Stand Still

Current

Reduction

Configuration

Memory (OTP)

microPlyer

MS2

SPREAD

+VM

VS

VREF

Configuration

(GND or VCC_IO)

100n

16V

TMC22xx

Step Pulse

Generator

MS1

22n

50V

DIE PAD

Step and Direction

motion control

CPO

2.2µ

6.3V

5VOUT

Place near IC with

short path to die pad

VREF Analog current

scaling or leave

open

3.1 Standard Application Circuit

opt. driver enable

Figure 3.1 Standard application circuit

The standard application circuit uses a minimum set of additional components. Two sense resistors

set the motor coil current. See chapter 8 to choose the right sense resistors. Use low ESR capacitors

for filtering the power supply. The capacitors need to cope with the current ripple cause by chopper

operation. A minimum capacity of 100µF near the driver is recommended for best performance.

Current ripple in the supply capacitors also depends on the power supply internal resistance and

cable length. VCC_IO can be supplied from 5VOUT, or from an external source, e.g. a 3.3V regulator.

Basic layout hints

Place sense resistors and all filter capacitors as close as possible to the related IC pins. Use a solid

common GND for all GND connections, also for sense resistor GND. Connect 5VOUT filtering capacitor

directly to 5VOUT and the die pad. See layout hints for more details. Low ESR electrolytic capacitors

are recommended for VS filtering.

3.2 Internal RDSon Sensing

For cost critical or space limited applications, sense resistors can be omitted. For internal current

sensing, a reference current set by a tiny external resistor programs the output current. For calculation

of the reference resistor, refer chapter 9.1.

Attention

Be sure to switch the IC to RDSon mode, before enabling drivers: Set otp_internalRsense = 1.

www.trinamic.com

�STEP

Step and Direction

motion control

DIR

RREF

5V Voltage

regulator

Step&Dir input

Configuration

Interface

(only TMC222x)

PDN/UART

B. Dwersteg, ©

TRINAMIC 2016

UART interface

+ Register Block

DIAG

INDEX

(not with TMC2202)

opt. ext. clock

10-16MHz

CLK_IN

3.3V or 5V

I/O voltage

VCC_IO

256 Microstep

Sequencer

100n

100µF

charge pump

IREF

Low ESR type

OA1

Full Bridge A

OA2

BRA

stealthChop2

microPlyer

MS2

SPREAD

Driver error

+VM

100n

Analog Scaling

Stand Still

Current

Reduction

Configuration

Memory (OTP)

MS1

Integrated

Rsense

Driver

Programmable

Diagnostic

Outputs

S

N

stepper

motor

Connect directly

to GND plane

IREF

Attention:

Start with ENN=high!

Set GCONF.1 or OTP0.6

prior to enabling the driver!

spreadCycle

OB1

Full Bridge B

OB2

Trimmed

CLK oscillator/

selector

BRB

Connect directly

to GND plane

100n

GND

ENN

DIE PAD

Index pulse

100n

16V

VS

VREF

optional UART interface

22n

50V

TMC22xx

Step Pulse

Generator

Configuration

(GND/open or VCC_IO)

CPO

VREF

5VOUT

2.2µ

6.3V

VCP

Place near IC with

short path to die pad

13

CPI

TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

opt. driver enable

Figure 3.2 Application circuit using RDSon based sensing

3.3 5V Only Supply

STEP

DIR

5V Voltage

regulator

Step&Dir input

Configuration

Interface

PDN/UART

B. Dwersteg, ©

TRINAMIC 2016

UART interface

+ Register Block

INDEX

(not with TMC2202)

opt. ext. clock

10-16MHz

CLK_IN

3.3V or 5V

I/O voltage

VCC_IO

256 Microstep

Sequencer

100n

100µF

VCP

CPI

IREF

Low ESR type

OA1

Full Bridge A

OA2

BRA

Driver

Integrated

Rsense

N

stepper

motor

RSA

IREF

Connect directly

to GND plane

Use low inductivity SMD

type, e.g. 1206, 0.5W for

RSA and RSB

spreadCycle

Programmable

Diagnostic

Outputs

S

OB1

Full Bridge B

Trimmed

CLK oscillator/

selector

OB2

BRB

RSB

Connect directly

to GND plane

ENN

100n

GND

Driver error

100n

charge pump

stealthChop2

microPlyer

MS2

SPREAD

(only TMC222x)

Index pulse

CPO

Analog Scaling

Stand Still

Current

Reduction

Configuration

Memory (OTP)

MS1

DIAG

4.7-5.4V

VS

VREF

optional UART interface

100n

16V

TMC22xx

Step Pulse

Generator

Configuration

(GND/open or VCC_IO)

22n

50V

DIE PAD

Step and Direction

motion control

5VOUT

10µ

6.3V

VREF

10R

Optional – bridges the

internal 5V reference

Place near IC with

short path to die pad

opt. driver enable

Figure 3.3 5V only operation

While the standard application circuit is limited to roughly 5.2 V lower supply voltage, a 5 V only

application lets the IC run from a 5 V +/-5% supply. In this application, linear regulator drop must be

www.trinamic.com

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

14

minimized. Therefore, the internal 5V regulator is filtered with a higher capacitance. An optional

resistor bridges the internal 5V regulator by connecting 5VOUT to the external power supply. This RC

filter keeps chopper ripple away from 5VOUT. With this resistor, the external supply is the reference

for the absolute motor current and must not exceed 5.5V.

3.4 Configuration Pins

The TMC22xx family members provide three or four configuration pins depending on the package

option. These pins allow quick configuration for standalone operation. Several additional options can

be set by OTP programming. In UART mode, the configuration pins can be disabled in order to set a

different configuration via registers.

PDN_UART: CONFIGURATION OF STANDSTILL POWER DOWN

PDN_UART

GND

VCC_IO

UART interface

Current Setting

Enable automatic power down in standstill periods

Disable

When using the UART interface, the configuration pin should be disabled via

GCONF.pdn_disable = 1. Program IHOLD as desired for standstill periods.

OPTIONS FOR TMC220X DEVICES, ONLY:

MS1/MS2: CONFIGURATION OF MICROSTEP RESOLUTION FOR STEP INPUT (TMC220X)

MS2

GND

GND

VCC_IO

VCC_IO

MS1

GND

VCC_IO

GND

VCC_IO

Microstep Setting

8 microsteps

2 microsteps (half step)

4 microsteps (quarter step)

16 microsteps

OPTIONS FOR TMC222X DEVICES, ONLY:

SPREAD (ONLY WITH TMC222X): SELECTION OF CHOPPER MODE

SPREAD

GND or

Pin open / not

available

VCC_IO

Chopper Setting

StealthChop is selected. Automatic switching to SpreadCycle in dependence of

the step frequency can be programmed via OTP.

SpreadCycle operation.

MS1/MS2: CONFIGURATION OF MICROSTEP RESOLUTION FOR STEP INPUT (TMC222X)

MS2

GND

GND

VCC_IO

VCC_IO

MS1

GND

VCC_IO

GND

VCC_IO

Microstep Setting

4 microsteps (quarter step)

8 microsteps

16 microsteps

32 microsteps

3.5 High Motor Current

When operating at a high motor current, the driver power dissipation due to MOSFET switch onresistance significantly heats up the driver. This power dissipation will significantly heat up the PCB

cooling infrastructure, if operated at an increased duty cycle. This in turn leads to a further increase of

driver temperature. An increase of temperature by about 100°C increases MOSFET resistance by

roughly 50%. This is a typical behavior of MOSFET switches. Therefore, under high duty cycle, high

load conditions, thermal characteristics have to be carefully taken into account, especially when

increased environment temperatures are to be supported. Refer the thermal characteristics and the

layout hints for more information. As a thumb rule, thermal properties of the PCB design become

www.trinamic.com

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

15

critical for the tiny QFN 5mm x 5mm package at or above 1A RMS motor current for increased periods

of time. Keep in mind that resistive power dissipation raises with the square of the motor current. On

the other hand, this means that a small reduction of motor current significantly saves heat dissipation

and energy.

Pay special attention to good thermal properties of your PCB layout, when going for 1A RMS current

or more.

An effect which might be perceived at medium motor velocities and motor sine wave peak currents

above roughly 1.4A peak is a slight sine distortion of the current wave when using SpreadCycle. It

results from an increasing negative impact of parasitic internal diode conduction, which in turn

negatively influences the duration of the fast decay cycle of the SpreadCycle chopper. This is, because

the current measurement does not see the full coil current during this phase of the sine wave,

because an increasing part of the current flows directly from the power MOSFETs’ drain to GND and

does not flow through the sense resistor. This effect with most motors does not negatively influence

the smoothness of operation, as it does not impact the critical current zero transition. The effect does

not occur with StealthChop.

3.6 Driver Protection and EME Circuitry

Some applications have to cope with ESD events caused by motor operation or external influence.

Despite ESD circuitry within the driver chips, ESD events occurring during operation can cause a reset

or even a destruction of the motor driver, depending on their energy. Especially plastic housings and

belt drive systems tend to cause ESD events of several kV. It is best practice to avoid ESD events by

attaching all conductive parts, especially the motors themselves to PCB ground, or to apply electrically

conductive plastic parts. In addition, the driver can be protected up to a certain degree against ESD

events or live plugging / pulling the motor, which also causes high voltages and high currents into

the motor connector terminals. A simple scheme uses capacitors at the driver outputs to reduce the

dV/dt caused by ESD events. Larger capacitors will bring more benefit concerning ESD suppression,

but cause additional current flow in each chopper cycle, and thus increase driver power dissipation,

especially at high supply voltages. The values shown are example values – they may be varied

between 100pF and 1nF. The capacitors also dampen high frequency noise injected from digital parts

of the application PCB circuitry and thus reduce electromagnetic emission. A more elaborate scheme

uses LC filters to de-couple the driver outputs from the motor connector. Varistors in between of the

coil terminals eliminate coil overvoltage caused by live plugging. Optionally protect all outputs by a

varistor to GND against ESD voltage.

470pF

100V

OA1

Full Bridge A

OA1

OA2

S

N

stepper

motor

Full Bridge A

50Ohm @

100MHz

V1A

V1

OA2

50Ohm @

100MHz

470pF

100V

BRA

Driver

RSA

470pF

100V

S

N

stepper

motor

V1B

470pF

100V

Driver

100nF

16V

470pF

100V

OB1

Full Bridge B

OB1

Full Bridge B

OB2

50Ohm @

100MHz

V2A

V2

OB2

50Ohm @

100MHz

470pF

100V

BRB

RSB

100nF

16V

470pF

100V

Fit varistors to supply voltage

rating. SMD inductivities

conduct full motor coil

current.

Figure 3.4 Simple ESD enhancement and more elaborate motor output protection

www.trinamic.com

V2B

470pF

100V

Varistors V1 and V2 protect

against inductive motor coil

overvoltage.

V1A, V1B, V2A, V2B:

Optional position for varistors

in case of heavy ESD events.

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

4

16

UART Single Wire Interface

UART

The UART single wire interface allows control of the TMC22xx with any microcontroller UART. It shares

transmit and receive line like an RS485 based interface. Data transmission is secured using a cyclic

redundancy check, so that increased interface distances (e.g. over cables between two PCBs) can be

bridged without danger of wrong or missed commands even in the event of electro-magnetic

disturbance. The automatic baud rate detection makes this interface easy to use.

4.1 Datagram Structure

4.1.1

Write Access

UART WRITE ACCESS DATAGRAM STRUCTURE

each byte is LSB…MSB, highest byte transmitted first

0 … 63

8 bit slave

RW + 7 bit

sync + reserved

32 bit data

address

register addr.

56…63

63

…

CRC

56

55

…

24…55

data bytes 3, 2, 1, 0

(high to low byte)

24

1

23

…

16…23

register

address

16

4

15

3

…

2

SLAVEADDR=0

8

0

7

1

6

0

5

1

1

8…15

Reserved (don’t cares

but included in CRC)

0

0…7

CRC

A sync nibble precedes each transmission to and from the TMC22xx and is embedded into the first

transmitted byte, followed by an addressing byte (0 for TMC22xx). Each transmission allows a

synchronization of the internal baud rate divider to the master clock. The actual baud rate is adapted

and variations of the internal clock frequency are compensated. Thus, the baud rate can be freely

chosen within the valid range. Each transmitted byte starts with a start bit (logic 0, low level on

SWIOP) and ends with a stop bit (logic 1, high level on SWIOP). The bit time is calculated by

measuring the time from the beginning of start bit (1 to 0 transition) to the end of the sync frame (1

to 0 transition from bit 2 to bit 3). All data is transmitted bytewise. The 32 bit data words are

transmitted with the highest byte first.

A minimum baud rate of 9000 baud is permissible, assuming 20 MHz clock (worst case for low baud

rate). Maximum baud rate is fCLK/16 due to the required stability of the baud clock.

The slave address SLAVEADDR is always 0 for the TMC22xx.

The communication becomes reset if a pause time of longer than 63 bit times between the start bits

of two successive bytes occurs. This timing is based on the last correctly received datagram. In this

case, the transmission needs to be restarted after a failure recovery time of minimum 12 bit times of

bus idle time. This scheme allows the master to reset communication in case of transmission errors.

Any pulse on an idle data line below 16 clock cycles will be treated as a glitch and leads to a timeout

of 12 bit times, for which the data line must be idle. Other errors like wrong CRC are also treated the

same way. This allows a safe re-synchronization of the transmission after any error conditions.

Remark, that due to this mechanism an abrupt reduction of the baud rate to less than 15 percent of

the previous value is not possible.

Each accepted write datagram becomes acknowledged by the receiver by incrementing an internal

cyclic datagram counter (8 bit). Reading out the datagram counter allows the master to check the

success of an initialization sequence or single write accesses. Read accesses do not modify the

counter.

www.trinamic.com

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

17

The UART line must be logic high during idle state. Therefore, the power down function cannot be

assigned by the pin PDN_UART in between of transmissions. In an application using the UART

interface, set the desired power down function by register access and set pdn_disable in GCONF to

disable the pin function.

4.1.2

Read Access

UART READ ACCESS REQUEST DATAGRAM STRUCTURE

each byte is LSB…MSB, highest byte transmitted first

8…15

16…23

24…31

31

…

CRC

24

23

0

…

16

register address

15

…

SLAVEADDR=0

8

0

7

1

6

0

5

1

Reserved (don’t cares

but included in CRC)

4

0...7

3

CRC

2

RW + 7 bit register

address

1

8 bit slave address

0

sync + reserved

The read access request datagram structure is identical to the write access datagram structure, but

uses a lower number of user bits. Its function is the addressing of the slave and the transmission of

the desired register address for the read access. The TMC22xx responds with the same baud rate as

the master uses for the read request.

In order to ensure a clean bus transition from the master to the slave, the TMC22xx does not

immediately send the reply to a read access, but it uses a programmable delay time after which the

first reply byte becomes sent following a read request. This delay time can be set in multiples of

eight bit times using SENDDELAY time setting (default=8 bit times) according to the needs of the

master.

UART READ ACCESS REPLY DATAGRAM STRUCTURE

each byte is LSB…MSB, highest byte transmitted first

24…55

data bytes 3, 2, 1, 0

(high to low byte)

56…63

…

CRC

56

55

CRC

…

32 bit data

24

0

23

…

15

3

…

2

16…23

register

address

0xFF

8

1

reserved (0)

7

0

6

1

5

0

8…15

4

1

0

0…7

16

sync + reserved

63

0 ...... 63

8 bit master

RW + 7 bit

address

register addr.

The read response is sent to the master using address code %11111111. The transmitter becomes

switched inactive four bit times after the last bit is sent.

Address %11111111 is reserved for read access replies going to the master.

www.trinamic.com

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

18

4.2 CRC Calculation

An 8 bit CRC polynomial is used for checking both read and write access. It allows detection of up to

eight single bit errors. The CRC8-ATM polynomial with an initial value of zero is applied LSB to MSB,

including the sync- and addressing byte. The sync nibble is assumed to always be correct. The

TMC22xx responds only to correctly transmitted datagrams containing its own slave address. It

increases its datagram counter for each correctly received write access datagram.

𝐶𝑅𝐶 = 𝑥 8 + 𝑥 2 + 𝑥 1 + 𝑥 0

SERIAL CALCULATION EXAMPLE

CRC = (CRC 750Hz (roughly). TSTEP

shows filtered step time values when active.

9 test_mode

0:

Normal operation

1:

Enable analog test output on pin ENN (pull-down

resistor off), ENN treated as enabled.

IHOLD[1..0] selects the function of DCO:

0…2: T120, DAC, VDDH

Attention: Not for user, set to 0 for normal operation!

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

22

GENERAL CONFIGURATION REGISTERS (0X00…0X0F)

R/W

Addr

n

Register

R+

WC

0x01

3

GSTAT

R

0x02

8

IFCNT

W

0x03

4

SLAVECONF

W

0x04

16

OTP_PROG

R

0x05

24

OTP_READ

R

0x06

10

+

8

IOIN

www.trinamic.com

Description / bit names

Bit

GSTAT – Global status flags

(Re-Write with ‘1’ bit to clear respective flags)

0 reset

1:

Indicates that the IC has been reset since the last

read access to GSTAT. All registers have been

cleared to reset values.

1 drv_err

1:

Indicates, that the driver has been shut down

due to overtemperature or short circuit detection

since the last read access. Read DRV_STATUS for

details. The flag can only be cleared when all

error conditions are cleared.

2 uv_cp

1:

Indicates an undervoltage on the charge pump.

The driver is disabled in this case. This flag is not

latched and thus does not need to be cleared.

Interface transmission counter. This register becomes

incremented with each successful UART interface write

access. Read out to check the serial transmission for

lost data. Read accesses do not change the content.

The counter wraps around from 255 to 0.

Bit

SLAVECONF

11..8 SENDDELAY for read access (time until reply is sent):

0, 1:

8 bit times

2, 3:

3*8 bit times

4, 5:

5*8 bit times

6, 7:

7*8 bit times

8, 9:

9*8 bit times

10, 11: 11*8 bit times

12, 13: 13*8 bit times

14, 15: 15*8 bit times

Bit

OTP_PROGRAM – OTP programming

Write access programs OTP memory (one bit at a time),

Read access refreshes read data from OTP after a write

2..0 OTPBIT

Selection of OTP bit to be programmed to the selected

byte location (n=0..7: programs bit n to a logic 1)

5..4 OTPBYTE

Selection of OTP programming location (0, 1 or 2)

15..8 OTPMAGIC

Set to 0xbd to enable programming. A programming

time of minimum 10ms per bit is recommended (check

by reading OTP_READ).

Bit

OTP_READ (Access to OTP memory result and update)

See separate table!

7..0

OTP0 byte 0 read data

15..8 OTP1 byte 1 read data

23..16 OTP2 byte 2 read data

Bit

INPUT (Reads the state of all input pins available)

0 ENN (TMC220x)

1 PDN_UART (TMC222x)

2 MS1 (TMC220x), SPREAD (TMC222x)

3 MS2 (TMC220x), DIR (TMC222x)

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

23

GENERAL CONFIGURATION REGISTERS (0X00…0X0F)

R/W

RW

Addr

0x07

n

Register

5+2

FACTORY_

CONF

www.trinamic.com

Description / bit names

4 DIAG (TMC220x), ENN (TMC222x)

5 STEP (TMC222x)

6 PDN_UART (TMC220x), MS1 (TMC222x)

7 STEP (TMC220x), MS2 (TMC222x)

8 SEL_A: Driver type

1: TMC220x

0: TMC222x

9 DIR (TMC220x)

31.. VERSION: 0x20=first version of the IC

24 Identical numbers mean full digital compatibility.

4..0 FCLKTRIM (Reset default: OTP)

0…31: Lowest to highest clock frequency. Check at

charge pump output. The frequency span is not

guaranteed, but it is tested, that tuning to 12MHz

internal clock is possible. The devices come preset to

12MHz clock frequency by OTP programming.

9..8 OTTRIM

(Default: OTP)

%00:

OT=143°C, OTPW=120°C

%01:

OT=150°C, OTPW=120°C

%10:

OT=150°C, OTPW=143°C

%11:

OT=157°C, OTPW=143°C

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

5.1.1

24

OTP_READ – OTP configuration memory

The OTP memory holds power up defaults for certain registers. All OTP memory bits are cleared to 0

by default. Programming only can set bits, clearing bits is not possible. Factory tuning of the clock

frequency affects otp0.0 to otp0.4. The state of these bits therefore may differ between individual ICs.

0X05: OTP_READ – OTP MEMORY MAP

Bit

23

Name

otp2.7

Function

otp_en_SpreadCycle

22

21

otp2.6

otp2.5

OTP_IHOLD

20

19

otp2.4

otp2.3

OTP_IHOLDDELAY

18

otp2.2

otp_PWM_FREQ

17

otp2.1

otp_PWM_REG

16

otp2.0

otp_PWM_OFS

15

14

13

otp1.7

otp1.6

otp1.5

OTP_CHOPCONF8

OTP_TPWMTHRS

OTP_CHOPCONF7...5

12

otp1.4

www.trinamic.com

otp_pwm_autograd

Comment

This flag determines if the driver defaults to SpreadCycle

or to StealthChop.

0

Default: StealthChop (GCONF.en_SpreadCycle=0)

OTP 1.0 to 1.7 and 2.0 used for StealthChop

SpreadCycle settings: HEND=0; HSTART=5; TOFF=3

1

Default: SpreadCycle (GCONF.en_SpreadCycle=1)

OTP 1.0 to 1.7 and 2.0 used for SpreadCycle

StealthChop settings: PWM_GRAD=0; TPWM_THRS=0;

PWM_OFS=36; pwm_autograd=1

Reset default for standstill current IHOLD (used only if

current reduction enabled, e.g. pin PDN_UART low).

%00: IHOLD= 16

(53% of IRUN)

%01: IHOLD= 2

( 9% of IRUN)

%10: IHOLD= 8

(28% of IRUN)

%11: IHOLD= 24

(78% of IRUN)

(Reset default for run current IRUN=31)

Reset default for IHOLDDELAY

%00: IHOLDDELAY= 1

%01: IHOLDDELAY= 2

%10: IHOLDDELAY= 4

%11: IHOLDDELAY= 8

Reset default for PWM_FREQ:

0: PWM_FREQ=%01=2/683

1: PWM_FREQ=%10=2/512

Reset default for PWM_REG:

0: PWM_REG=%1000: max. 4 increments / cycle

1: PWM_REG=%0010: max. 1 increment / cycle

Depending on otp_en_SpreadCycle

0

0: PWM_OFS=36

1: PWM_OFS=00 (no feed forward scaling);

pwm_autograd=0

1

Reset default for CHOPCONF.8 (hend1)

Depending on otp_en_SpreadCycle

0

Reset default for TPWM_THRS as defined by (0..7):

0: TPWM_THRS=

0

1: TPWM_THRS= 200

2: TPWM_THRS= 300

3: TPWM_THRS= 400

4: TPWM_THRS= 500

5: TPWM_THRS= 800

6: TPWM_THRS= 1200

7: TPWM_THRS= 4000

1

Reset default for CHOPCONF.5 to CHOPCONF.7

(hstrt1, hstrt2 and hend0)

Depending on otp_en_SpreadCycle

0

0: pwm_autograd=1

1: pwm_autograd=0

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

25

0X05: OTP_READ – OTP MEMORY MAP

Bit

Name

Function

OTP_CHOPCONF4

11

10

9

8

otp1.3

otp1.2

otp1.1

otp1.0

OTP_PWM_GRAD

7

otp0.7

OTP_CHOPCONF3...0

otp_TBL

6

otp0.6

otp_internalRsense

5

otp0.5

otp_OTTRIM

4

3

2

1

0

otp0.4

otp0.3

otp0.2

otp0.1

otp0.0

OTP_FCLKTRIM

www.trinamic.com

Comment

1

Reset

default

for

CHOPCONF.4

(hstrt0);

(pwm_autograd=1)

Depending on otp_en_SpreadCycle

0

Reset default for PWM_GRAD as defined by (0..15):

0: PWM_GRAD= 14

1: PWM_GRAD= 16

2: PWM_GRAD= 18

3: PWM_GRAD= 21

4: PWM_GRAD= 24

5: PWM_GRAD= 27

6: PWM_GRAD= 31

7: PWM_GRAD= 35

8: PWM_GRAD= 40

9: PWM_GRAD= 46

10: PWM_GRAD= 52

11: PWM_GRAD= 59

12: PWM_GRAD= 67

13: PWM_GRAD= 77

14: PWM_GRAD= 88

15: PWM_GRAD= 100

1

Reset default for CHOPCONF.0 to CHOPCONF.3 (TOFF)

Reset default for TBL:

0: TBL=%10

1: TBL=%01

Reset default for GCONF.internal_Rsense

0: External sense resistors

1: Internal sense resistors

Reset default for OTTRIM:

0: OTTRIM= %00 (143°C)

1: OTTRIM= %01 (150°C)

(internal power stage temperature about 10°C above the

sensor temperature limit)

Reset default for FCLKTRIM

0: lowest frequency setting

31: highest frequency setting

Attention: This value is pre-programmed by factory clock

trimming to the default clock frequency of 12MHz and

differs between individual ICs! It should not be altered.

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

26

5.2 Velocity Dependent Control

VELOCITY DEPENDENT DRIVER FEATURE CONTROL REGISTER SET (0X10…0X1F)

R/W

Addr

n

Register

W

0x10

5

+

5

+

4

Description / bit names

Bit

IHOLD_IRUN – Driver current control

4..0 IHOLD (Reset default: OTP)

Standstill current (0=1/32 … 31=32/32)

In combination with StealthChop mode, setting

IHOLD=0 allows to choose freewheeling or coil

short circuit (passive braking) for motor stand still.

12..8 IRUN (Reset default=31)

Motor run current (0=1/32 … 31=32/32)

IHOLD_IRUN

W

0x11

8

TPOWER

DOWN

Hint: Choose sense resistors in a way, that normal

IRUN is 16 to 31 for best microstep performance.

19..16 IHOLDDELAY (Reset default: OTP)

Controls the number of clock cycles for motor

power down after standstill is detected (stst=1) and

TPOWERDOWN has expired. The smooth transition

avoids a motor jerk upon power down.

0:

instant power down

1..15:

Delay per current reduction step in multiple

of 2^18 clocks

TPOWERDOWN (Reset default=20)

Sets the delay time from stand still (stst) detection to motor

current power down. Time range is about 0 to 5.6 seconds.

0…((2^8)-1) * 2^18 tCLK

Attention: A minimum setting of 2 is required to allow

automatic tuning of StealthChop PWM_OFFS_AUTO.

Actual measured time between two 1/256 microsteps derived

from the step input frequency in units of 1/fCLK. Measured

value is (2^20)-1 in case of overflow or stand still.

R

0x12

20

TSTEP

W

0x13

20

TPWMTHRS

W

0x22

24

VACTUAL

www.trinamic.com

The TSTEP related threshold uses a hysteresis of 1/16 of the

compare value to compensate for jitter in the clock or the step

frequency: (Txxx*15/16)-1 is the lower compare value for each

TSTEP based comparison.

This means, that the lower switching velocity equals the

calculated setting, but the upper switching velocity is higher as

defined by the hysteresis setting.

Sets the upper velocity for StealthChop voltage PWM mode.

TSTEP ≥ TPWMTHRS

- StealthChop PWM mode is enabled, if configured

When the velocity exceeds the limit set by TPWMTHRS, the

driver switches to SpreadCycle.

0: Disabled

VACTUAL allows moving the motor by UART control.

It gives the motor velocity in +-(2^23)-1 [µsteps / t]

0: Normal operation. Driver reacts to STEP input.

/=0: Motor moves with the velocity given by VACTUAL. Step

pulses can be monitored via INDEX output. The motor

direction is controlled by the sign of VACTUAL.

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

27

5.3 Sequencer Registers

The sequencer registers have a pure informative character and are read-only. They help for special

cases like storing the last motor position before power off in battery powered applications.

MICROSTEPPING CONTROL REGISTER SET (0X60…0X6B)

R/W

Addr

n

Register

R

0x6A

10

MSCNT

R

0x6B

9

+

9

www.trinamic.com

MSCURACT

Description / bit names

Microstep counter. Indicates actual position

in the microstep table for CUR_A. CUR_B uses

an offset of 256 into the table. Reading out

MSCNT allows determination of the motor

position within the electrical wave.

bit 8… 0:

CUR_A (signed):

Actual microstep current for

motor phase A as read from the

internal sine wave table (not

scaled by current setting)

bit 24… 16: CUR_B (signed):

Actual microstep current for

motor phase B as read from the

internal sine wave table (not

scaled by current setting)

Range [Unit]

0…1023

+/-0...255

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

28

5.4 Chopper Control Registers

DRIVER REGISTER SET (0X6C…0X7F)

R/W

Addr

n

Register

RW

0x6C

32

CHOPCONF

R

0x6F

32

DRV_

STATUS

RW

0x70

22

PWMCONF

R

R

0x71

0x72

9+8

8+8

www.trinamic.com

PWM_SCALE

PWM_AUTO

Description / bit names

Chopper and driver configuration

See separate table!

Driver status flags and current level read

back

See separate table!

StealthChop PWM chopper configuration

See separate table!

Results of StealthChop amplitude regulator.

These values can be used to monitor

automatic PWM amplitude scaling (255=max.

voltage).

bit 7… 0

PWM_SCALE_SUM:

Actual PWM duty cycle. This

value is used for scaling the

values CUR_A and CUR_B read

from the sine wave table.

bit 24… 16 PWM_SCALE_AUTO:

9 Bit signed offset added to the

calculated PWM duty cycle. This

is the result of the automatic

amplitude regulation based on

current measurement.

These automatically generated values can be

read out in order to determine a default /

power up setting for PWM_GRAD and

PWM_OFS.

bit 7… 0

PWM_OFS_AUTO:

Automatically determined offset

value

bit 23… 16 PWM_GRAD_AUTO:

Automatically

determined

gradient value

Range [Unit]

Reset default=

0x10000053

Reset default=

0xC10D0024

0…255

signed

-255…+255

0…255

0…255

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

5.4.1

29

CHOPCONF – Chopper Configuration

0X6C: CHOPCONF – CHOPPER CONFIGURATION

Bit

31

Name

diss2vs

30

diss2g

29

dedge

28

intpol

interpolation to 256

microsteps

27

26

25

24

mres3

mres2

mres1

mres0

MRES

micro step resolution

23

22

21

20

19

18

17

-

reserved

vsense

16

15

tbl1

tbl0

sense resistor voltage

based current scaling

TBL

blank time select

14

13

12

11

10

9

8

7

-

reserved

hend3

hend2

hend1

hend0

HEND

hysteresis low value

OFFSET

sine wave offset

6

5

4

hstrt2

hstrt1

hstrt0

HSTRT

hysteresis start value

added to HEND

www.trinamic.com

Function

Low side short

protection disable

short to GND

protection disable

enable double edge

step pulses

Comment

0: Short protection low side is on

1: Short protection low side is disabled

0: Short to GND protection is on

1: Short to GND protection is disabled

1: Enable step impulse at each step edge to reduce step

frequency requirement. This mode is not compatible

with the step filtering function (multistep_filt)

1: The actual microstep resolution (MRES) becomes

extrapolated to 256 microsteps for smoothest motor

operation.

(Default: 1)

%0000:

Native 256 microstep setting.

%0001 … %1000:

128, 64, 32, 16, 8, 4, 2, FULLSTEP

Reduced microstep resolution.

The resolution gives the number of microstep entries per

sine quarter wave.

When choosing a lower microstep resolution, the driver

automatically uses microstep positions which result in a

symmetrical wave.

Number of microsteps per step pulse = 2^MRES

(Selection by pins unless disabled by GCONF.

mstep_reg_select)

set to 0

0: Low sensitivity, high sense resistor voltage

1: High sensitivity, low sense resistor voltage

%00 … %11:

Set comparator blank time to 16, 24, 32 or 40 clocks

Hint: %00 or %01 is recommended for most applications

(Default: OTP)

set to 0

%0000 … %1111:

Hysteresis is -3, -2, -1, 0, 1, …, 12

(1/512 of this setting adds to current setting)

This is the hysteresis value which becomes used for the

hysteresis chopper.

(Default: OTP, resp. 5 in StealthChop mode)

%000 … %111:

Add 1, 2, …, 8 to hysteresis low value HEND

(1/512 of this setting adds to current setting)

Attention: Effective HEND+HSTRT ≤ 16.

Hint: Hysteresis decrement is done each 16 clocks

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

0X6C: CHOPCONF – CHOPPER CONFIGURATION

Bit

Name

Function

Comment

(Default: OTP, resp. 0 in StealthChop mode)

3

2

1

0

toff3

toff2

toff1

toff0

TOFF off time

and driver enable

Off time setting controls duration of slow decay phase

NCLK= 24 + 32*TOFF

%0000: Driver disable, all bridges off

%0001: 1 – use only with TBL ≥ 2

%0010 … %1111: 2 … 15

(Default: OTP, resp. 3 in StealthChop mode)

www.trinamic.com

30

�TMC220X, TMC2224 DATASHEET (Rev. 1.09 / 2019-JUL-17)

5.4.2

31

PWMCONF – Voltage PWM Mode StealthChop

0X70: PWMCONF – VOLTAGE MODE PWM STEALTHCHOP

Bit

31

30

29

28

Name

PWM_LIM

Function

PWM automatic scale

amplitude limit when

switching on

27

26

25

24

PWM_REG

Regulation loop

gradient

23

22

21

20

freewheel1

freewheel0

reserved

reserved

Allows different

standstill modes

19

pwm_

autograd

PWM automatic

gradient adaptation

18

pwm_

autoscale

PWM automatic

amplitude scaling

17

pwm_freq1

PWM frequency

www.trinamic.com

Comment

Limit for PWM_SCALE_AUTO when switching back from

SpreadCycle to StealthChop. This value defines the upper

limit for bits 7 to 4 of the automatic current control

when switching back. It can be set to reduce the current

jerk during mode change back to StealthChop.

It does not limit PWM_GRAD or PWM_GRAD_AUTO offset.

(Default = 12)

User defined maximum PWM amplitude change per half

wave when using pwm_autoscale=1. (1…15):

1: 0.5 increments (slowest regulation)

2: 1 increment (default with OTP2.1=1)

3: 1.5 increments

4: 2 increments

…