MODULE FOR STEPPER MOTORS

MODULE

Firmware Version V1.29

TMCL™ FIRMWARE MANUAL

+

+

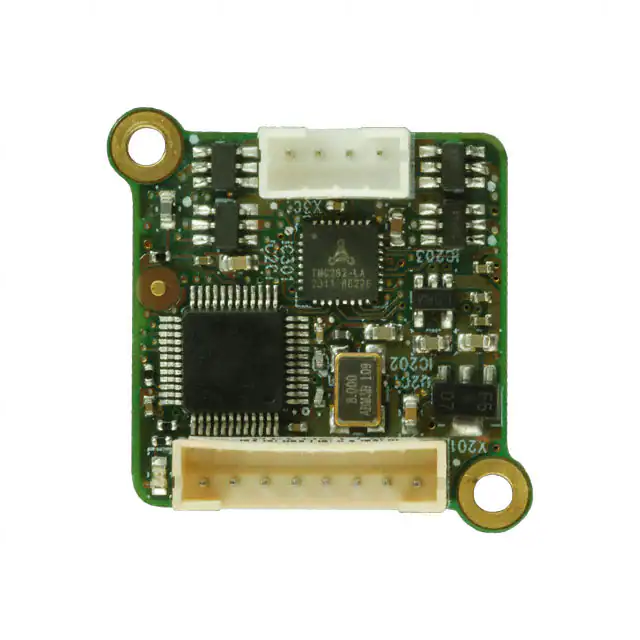

TMCM-1021

1-Axis Stepper

Controller / Driver

24V DC

up-to 0.7A RMS / 1.4A RMS

RS485 Interface

sensOstep™ Encoder

+

UNIQUE FEATURES:

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

www.trinamic.com

+

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

Table of Contents

1

2

Features........................................................................................................................................................................... 4

Putting the Module into Operation ........................................................................................................................ 6

2.1

Basic Set-Up .......................................................................................................................................................... 6

2.1.1 Connecting the Module ............................................................................................................................... 6

2.1.2 Start the TMCL-IDE Software Development Environment ................................................................. 7

2.2

Using TMCL Direct Mode .................................................................................................................................... 8

2.2.1 Important Motor Settings ........................................................................................................................... 9

2.3

Testing with a Simple TMCL Program ......................................................................................................... 10

3

TMCL and the TMCL-IDE: Introduction ................................................................................................................. 11

3.1

Binary Command Format ................................................................................................................................ 11

3.2

Reply Format ....................................................................................................................................................... 12

3.2.1 Status Codes ................................................................................................................................................. 13

3.3

Standalone Applications .................................................................................................................................. 13

3.4

TMCL Command Overview .............................................................................................................................. 13

3.4.1 TMCL Commands ......................................................................................................................................... 13

3.4.2 Commands Listed According to Subject Area .................................................................................... 14

3.5

Commands ........................................................................................................................................................... 18

3.5.1 ROR (rotate right) ........................................................................................................................................ 18

3.5.2 ROL (rotate left) ........................................................................................................................................... 19

3.5.3 MST (motor stop)......................................................................................................................................... 20

3.5.4 MVP (move to position) ............................................................................................................................ 21

3.5.5 SAP (set axis parameter) ........................................................................................................................... 23

3.5.6 GAP (get axis parameter) .......................................................................................................................... 24

3.5.7 STAP (store axis parameter) ..................................................................................................................... 25

3.5.8 RSAP (restore axis parameter) ................................................................................................................. 26

3.5.9 SGP (set global parameter) ...................................................................................................................... 27

3.5.10 GGP (get global parameter)...................................................................................................................... 28

3.5.11 STGP (store global parameter) ................................................................................................................ 29

3.5.12 RSGP (restore global parameter) ............................................................................................................ 30

3.5.13 RFS (reference search) ................................................................................................................................ 31

3.5.14 SIO (set output) ........................................................................................................................................... 32

3.5.15 GIO (get input/output) ............................................................................................................................... 34

3.5.16 CALC (calculate) ............................................................................................................................................ 36

3.5.17 COMP (compare)........................................................................................................................................... 37

3.5.18 JC (jump conditional) ................................................................................................................................. 38

3.5.19 JA (jump always) ......................................................................................................................................... 39

3.5.20 CSUB (call subroutine) ............................................................................................................................... 40

3.5.21 RSUB (return from subroutine) ................................................................................................................ 41

3.5.22 WAIT (wait for an event to occur) ......................................................................................................... 42

3.5.23 STOP (stop TMCL program execution) ................................................................................................... 43

3.5.24 SCO (set coordinate) ................................................................................................................................... 44

3.5.25 GCO (get coordinate) .................................................................................................................................. 45

3.5.26 CCO (capture coordinate) .......................................................................................................................... 46

3.5.27 ACO .................................................................................................................................................................. 47

3.5.28 CALCX (calculate using the X register) .................................................................................................. 48

3.5.29 AAP (accumulator to axis parameter) .................................................................................................... 49

3.5.30 AGP (accumulator to global parameter) ............................................................................................... 50

3.5.31 CLE (clear error flags) ................................................................................................................................. 51

3.5.32 VECT (set interrupt vector) ........................................................................................................................ 52

3.5.33 EI (enable interrupt) ................................................................................................................................... 53

3.5.34 DI (disable interrupt) .................................................................................................................................. 54

3.5.35 RETI (return from interrupt) ..................................................................................................................... 55

3.5.36 Customer Specific TMCL Command Extension (UF0… UF7/user function) ................................... 56

3.5.37 Request Target Position Reached Event ............................................................................................... 57

3.5.38 TMCL Control Functions ............................................................................................................................. 58

4

Axis Parameters .......................................................................................................................................................... 60

www.trinamic.com

2

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

4.1

Velocity Calculation ........................................................................................................................................... 66

4.2

stallGuard2 ........................................................................................................................................................... 67

4.3

coolStep Related Axis Parameters ................................................................................................................ 67

5

Global parameters ...................................................................................................................................................... 69

5.1

Bank 0 ................................................................................................................................................................... 69

5.2

Bank 1 ................................................................................................................................................................... 71

5.3

Bank 2 ................................................................................................................................................................... 72

5.4

Bank 3 ................................................................................................................................................................... 73

6

Hints and Tips ............................................................................................................................................................. 74

6.1

Reference Search ............................................................................................................................................... 74

6.2

Changing the Prescaler Value of an Encoder ............................................................................................ 77

6.3

Using the RS485 Interface .............................................................................................................................. 77

7

TMCL Programming Techniques and Structure ................................................................................................. 78

7.1

Initialization ........................................................................................................................................................ 78

7.2

Main Loop ............................................................................................................................................................ 78

7.3

Using Symbolic Constants .............................................................................................................................. 78

7.4

Using Variables .................................................................................................................................................. 79

7.5

Using Subroutines ............................................................................................................................................. 79

7.6

Mixing Direct Mode and Standalone Mode ................................................................................................ 80

8

Life Support Policy ..................................................................................................................................................... 81

9

Revision History .......................................................................................................................................................... 82

9.1

Document Revision ........................................................................................................................................... 82

9.2

Firmware Revision ............................................................................................................................................ 82

10 References .................................................................................................................................................................... 83

www.trinamic.com

3

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

1 Features

The TMCM-1021 is a single axis controller/driver module for 2-phase bipolar stepper motors with state of

the art feature set. It is highly integrated, offers a convenient handling and can be used in many

decentralized applications. The module can be mounted on the back of NEMA11 (28mm flange size) and

has been designed for coil currents up to 0.7A RMS (low current range, programmable) or 1.4A RMS (high

current range, programmable, new additional range since hardware version 1.4) and 24V DC supply

voltage. With its high energy efficiency from TRINAMIC’s coolStep™ technology cost for power consumption is

kept down. The TMCL™ firmware supports remote control (direct mode) and standalone operation (with

TMCL program being executed on the TMCM-1021 itself).

MAIN CHARACTERISTICS

Highlights

Motion profile calculation in real-time

On the fly alteration of motor parameters (e.g. position, velocity, acceleration)

High performance microcontroller for overall system control and serial communication protocol

handling

For position movement applications, where larger motors do not fit and higher torques are not

required

Bipolar stepper motor driver

Up to 256 microsteps per full step

High-efficient operation, low power dissipation

Dynamic current control

Integrated protection

stallGuard2 feature for stall detection

coolStep feature for reduced power consumption and heat dissipation

Encoder

sensOstep magnetic encoder (max. 1024 increments per rotation) e.g. for step-loss detection under

all operating conditions and positioning supervision

Interfaces

Up to 4 multi-purpose inputs (2 shared with general purpose outputs)

2 general purpose outputs

RS485 2-wire communication interface

Software

TMCL: standalone operation or remote controlled operation,

program memory (non volatile) for up to 876 TMCL commands, and

PC-based application development software TMCL-IDE available for free.

Electrical and mechanical data

Supply voltage: +24V DC nominal (9… 28V DC max.)

Motor current: up to 0.7A RMS (low current range, programmable) or 1.4A RMS (high current range,

programmable, new additional range since hardware version 1.4)

Refer to separate Hardware Manual, too.

www.trinamic.com

4

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

5

TRINAMICS UNIQUE FEATURES – EASY TO USE WITH TMCL

stallGuard2™

stallGuard2 is a high-precision sensorless load measurement using the back EMF on the

coils. It can be used for stall detection as well as other uses at loads below those which

stall the motor. The stallGuard2 measurement value changes linearly over a wide range

of load, velocity, and current settings. At maximum motor load, the value goes to zero or

near to zero. This is the most energy-efficient point of operation for the motor.

Load

[Nm]

stallGuard2

Initial stallGuard2

(SG) value: 100%

Max. load

stallGuard2 (SG) value: 0

Maximum load reached.

Motor close to stall.

Motor stalls

Figure 1.1 stallGuard2 load measurement SG as a function of load

coolStep™

coolStep is a load-adaptive automatic current scaling based on the load measurement via

stallGuard2 adapting the required current to the load. Energy consumption can be

reduced by as much as 75%. coolStep allows substantial energy savings, especially for

motors which see varying loads or operate at a high duty cycle. Because a stepper motor

application needs to work with a torque reserve of 30% to 50%, even a constant-load

application allows significant energy savings because coolStep automatically enables

torque reserve when required. Reducing power consumption keeps the system cooler,

increases motor life, and allows reducing cost.

0,9

Efficiency with coolStep

0,8

Efficiency with 50% torque reserve

0,7

0,6

0,5

Efficiency

0,4

0,3

0,2

0,1

0

0

50

100

150

200

250

300

350

Velocity [RPM]

Figure 1.2 Energy efficiency example with coolStep

www.trinamic.com

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

2 Putting the Module into Operation

Here you can find basic information for putting your TMCM-1021 into operation. If you are already

common with TRINAMICs modules you may skip this chapter.

The things you need:

TMCM-1021 with fitting motor

RS485 interface converter with cables

Nominal supply voltage +24V DC for your module

TMCL-IDE program and PC

PRECAUTIONS

Do not connect or disconnect the TMCM-1021 while powered!

Do not connect or disconnect the motor while powered!

Do not exceed the maximum power supply voltage of 28V DC!

Note, that the module is not protected against reverse polarity!

START WITH POWER SUPPLY OFF!

2.1 Basic Set-Up

The following paragraph will guide you through the steps of connecting the unit and making first

movements with the motor.

2.1.1

Connecting the Module

1.

Pin

1

2

Converter

3

e.g. USB-2-485

RS485

Pin 1 GND

Pin 3 RS485+

Pin 4 RS485Note, that the

GND pin has to be

used for the

power supply and

for the RS485

interface.

Power Supply

Pin 1 GND

Pin 2 9… 28V DC

4

5

6

1

7

1

Pin

Pin

Pin

Pin

Stepper

Motor

Figure 2.1: Starting up

www.trinamic.com

1

2

3

4

B2

B1

A2

A1

8

Connect RS485 interface and power supply.

Label

GND

VDD

Description

GND

VDD (+9V…+28V)

RS485 interface, diff. signal (nonRS485+

inverting)

RS485RS485 interface, diff. signal (inverting)

Digital input (+24V compatible)

Alternate function 1: step input

IN_0

Alternate function 2: left stop switch

Digital input (+24V compatible)

Alternate function 1: direction input

IN_1

Alternate function 2: right stop switch

Open drain output with freewheeling

diode (max. 100mA)

OUT_0 / IN_2 Alternate function 1:

digital input (+24V compatible)

Alternate function 2:home switch

Open drain output with freewheeling

diode (max. 100mA)

OUT_1 / IN_3 Alternate function 1: digital input

(+24V compatible)

Alternate function 2: analog input

6

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

2.

Connect motor

Pin

1

2

3

4

3.

Label

OB2

OB1

OA2

OA1

Description

Pin 2 of motor

Pin 1 of motor

Pin 2 of motor

Pin 1 of motor

coil

coil

coil

coil

B

B

A

A

Switch ON the power supply

Turn power ON. The green LED for power lights up slowly and the motor is powered but in

standstill now.

If this does not occur, switch power OFF and check your connections as well as the power

supply.

2.1.2

Start the TMCL-IDE Software Development Environment

The TMCL-IDE is available on www.trinamic.com.

Installing the TMCL-IDE:

Make sure the COM port you intend to use is not blocked by another program.

Open TMCL-IDE by clicking TMCL.exe.

Choose Setup and Options and thereafter the Connection tab.

Choose COM port and type with the parameters shown in Figure 2.2 (baud rate 9600). Click OK.

Figure 2.2 Setup dialogue and connection tab of the TMCL-IDE.

Please refer to the TMCL-IDE User Manual for more information (see www.TRINAMIC.com).

www.trinamic.com

7

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

2.2 Using TMCL Direct Mode

1.

Start TMCL Direct Mode.

Direct Mode

2.

If the communication is established the TMCM-1021 is automatically detected. If the module is

not detected, please check all points above (cables, interface, power supply, COM port, baud

rate).

3.

Issue a command by choosing Instruction, Type (if necessary), Motor, and Value and click

Execute to send it to the module.

Examples:

ROR rotate right, motor 0, value 10000

MST motor stop, motor 0

-> Click Execute. The first motor is rotating now.

-> Click Execute. The first motor stops now.

Top right of the TMCL Direct Mode window is the button Copy to editor. Click here to copy the chosen

command and create your own TMCL program. The command will be shown immediately on the editor.

NOTE

Please mind chapter 7 (programming techniques) of the TMCL-IDE User Manual on www.trinamic.com.

Here you will find information about creating general structures of TMCL programs. In particular

initialization, main loop, symbolic constants, variables, and subroutines are described there. Further you

can learn how to mix direct mode and stand alone mode.

Chapter 4.3 of this manual includes a diagram which points out the coolStep related axis parameters and

their functions. This can help you configuring your module to meet your needs.

www.trinamic.com

8

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

2.2.1

9

Important Motor Settings

There are some axis parameters which have to be adjusted right in the beginning after installing your

module. Please set the upper limiting values for the speed (axis parameter 4), the acceleration (axis

parameter 5), and the current (axis parameter 6). Further set the standby current (axis parameter 7) and

choose your microstep resolution with axis parameter 140. Please use the SAP (Set Axis Parameter)

command for adjusting these values. The SAP command is described in paragraph 3.5.5. You can use the

TMCM-IDE direct mode for easily configuring your module.

ATTENTION

The most important motor setting is the absolute maximum motor current setting, since too high values

might cause motor damage!

IMPORTANT AXIS PARAMETERS FOR MOTOR SETTING

Number Axis Parameter Description

4

Maximum

Maximum feasible positioning speed. Has to be

positioning

adapted to motor and application

speed

5

Maximum

Limit for acceleration and deceleration. Has to be

acceleration

adapted to motor and application.

6

Absolute max.

The maximum value is 255. This value means 100% of

current

maximum programmable current of the selected

(CS / Current

motor current range (see axis parameter 179). Current

Scale)

can be adjusted / scaled down by specifying a lower

value between 0 and 255. This value is transformed

into 32 different internal current settings supported by

the hardware (see hardware manual for more details

and complete table with possible current settings).

Range [Unit]

0… +268.435.454

[pps/s]

1… +33554431

[pps/s]

0… 255

Low current range scaling

(axis parameter 179 set to

1):

Please note: high current range is available for hardware

version V1.4, only!

High current range

scaling (axis parameter

179 set to 0):

7

Standby current

140

Microstep

resolution

www.trinamic.com

The current limit two seconds after the motor has 0… 255

stopped.

0

1

2

3

4

5

6

7

8

full step

half step

4 microsteps

8 microsteps

16 microsteps

32 microsteps

64 microsteps

128 microsteps

256 microsteps

0… 8

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

Number

179

Axis Parameter

VSENSE

Description

sense resistor voltage based current scaling

0: high current range up-to 1.4A RMS / 2A peak

1: low current range up-to 0.7A RMS / 1A peak

(default value)

Please note: this parameter should not and cannot

be changed for hardware V1.2! The high current

range is available for hardware V1.4, only!

10

Range [Unit]

0/1

2.3 Testing with a Simple TMCL Program

Type in the following program:

Loop:

ROL 0, 50000

WAIT TICKS, 0, 500

MST 0

ROR 0, 50000

WAIT TICKS, 0, 500

MST 0

//Rotate motor 0 with speed 50000

SAP 4, 0, 50000

SAP 5, 0, 50000

MVP ABS, 0, 100000

WAIT POS, 0, 0

MVP ABS, 0, -100000

WAIT POS, 0, 0

JA Loop

//Set max. Velocity

//Set max. Acceleration

//Move to Position 100000

//Wait until position reached

//Move to Position -100000

//Wait until position reached

//Infinite Loop

//Rotate motor 0 with 50000

Assemble

Stop

Download

1.

2.

3.

4.

Run

Click the Assemble icon to convert the TMCL into machine code.

Then download the program to the TMCM-1021 module by clicking the Download icon.

Press icon Run. The desired program will be executed.

Click the Stop button to stop the program.

www.trinamic.com

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

11

3 TMCL and the TMCL-IDE: Introduction

As with most TRINAMIC modules the software running on the microprocessor of the TMCM-1061 consists

of two parts, a boot loader and the firmware itself. Whereas the boot loader is installed during

production and testing at TRINAMIC and remains untouched throughout the whole lifetime, the firmware

can be updated by the user. New versions can be downloaded free of charge from the TRINAMIC website

(http://www.trinamic.com).

The TMCM-1021 supports TMCL direct mode (binary commands) and standalone TMCL program execution.

You can store up to 876 TMCL instructions on it.

In direct mode and most cases the TMCL communication over RS485 follows a strict master/slave

relationship. That is, a host computer (e.g. PC/PLC) acting as the interface bus master will send a

command to the TMCL-1021. The TMCL interpreter on the module will then interpret this command, do

the initialization of the motion controller, read inputs and write outputs or whatever is necessary

according to the specified command. As soon as this step has been done, the module will send a reply

back over RS485 to the bus master. Only then should the master transfer the next command. Normally,

the module will just switch to transmission and occupy the bus for a reply, otherwise it will stay in

receive mode. It will not send any data over the interface without receiving a command first. This way,

any collision on the bus will be avoided when there are more than two nodes connected to a single bus.

The Trinamic Motion Control Language [TMCL] provides a set of structured motion control commands.

Every motion control command can be given by a host computer or can be stored in an EEPROM on the

TMCM module to form programs that run standalone on the module. For this purpose there are not only

motion control commands but also commands to control the program structure (like conditional jumps,

compare and calculating).

Every command has a binary representation and a mnemonic. The binary format is used to send

commands from the host to a module in direct mode, whereas the mnemonic format is used for easy

usage of the commands when developing standalone TMCL applications using the TMCL-IDE (IDE means

Integrated Development Environment).

There is also a set of configuration variables for the axis and for global parameters which allow

individual configuration of nearly every function of a module. This manual gives a detailed description of

all TMCL commands and their usage.

3.1 Binary Command Format

Every command has a mnemonic and a binary representation. When commands are sent from a host to a

module, the binary format has to be used. Every command consists of a one-byte command field, a onebyte type field, a one-byte motor/bank field and a four-byte value field. So the binary representation of a

command always has seven bytes. When a command is to be sent via RS485 interface, it has to be

enclosed by an address byte at the beginning and a checksum byte at the end. In this case it consists of

nine bytes.

The binary command format for RS485 is as follows:

Bytes

1

1

1

1

4

1

Meaning

Module address

Command number

Type number

Motor or Bank number

Value (MSB first!)

Checksum

The checksum is calculated by adding up all the other bytes using an 8-bit addition.

www.trinamic.com

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

12

Checksum calculation

As mentioned above, the checksum is calculated by adding up all bytes (including the module address

byte) using 8-bit addition. Here are two examples to show how to do this:

in C:

unsigned char i, Checksum;

unsigned char Command[9];

//Set the “Command” array to the desired command

Checksum = Command[0];

for(i=1; i run infinitely

7.3 Using Symbolic Constants

To make your program better readable and understandable, symbolic constants should be taken for all

important numerical values that are used in the program. The TMCL-IDE provides an include file with

symbolic names for all important axis parameters and global parameters.

Example:

//Define some constants

#include TMCLParam.tmc

MaxSpeed = 500

MaxAcc = 100

Position0 = 0

Position1 = 5000

//Initialization

SAP APMaxPositioningSpeed, Motor0, MaxSpeed

SAP APMaxAcceleration, Motor0, MaxAcc

MainLoop:

MVP ABS, Motor0, Position1

WAIT POS, Motor0, 0

MVP ABS, Motor0, Position0

WAIT POS, Motor0, 0

JA MainLoop

www.trinamic.com

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

79

Just have a look at the file TMCLParam.tmc provided with the TMCL-IDE. It contains symbolic constants

that define all important parameter numbers.

Using constants for other values makes it easier to change them when they are used more than once in

a program. You can change the definition of the constant and do not have to change all occurrences of it

in your program.

7.4 Using Variables

The User Variables can be used if variables are needed in your program. They can store temporary values.

The commands SGP, GGP and AGP are used to work with user variables:

SGP is used to set a variable to a constant value (e.g. during initialization phase).

GGP is used to read the contents of a user variable and to copy it to the accumulator register for further

usage.

AGP can be used to copy the contents of the accumulator register to a user variable, e.g. to store the

result of a calculation.

Example:

MyVariable = 42

//Use a symbolic name for the user variable

//(This makes the program better readable and understandable.)

SGP MyVariable, 2, 1234

...

...

GGP MyVariable, 2

accumulator register

CALC MUL, 2

AAP MyVariable, 2

variable

...

...

//Initialize the variable with the value 1234

//Copy the contents of the variable to the

//Multiply accumulator register with two

//Store contents of the accumulator register to the

Furthermore, these variables can provide a powerful way of communication between a TMCL program

running on a module and a host. The host can change a variable by issuing a direct mode SGP command

(remember that while a TMCL program is running direct mode commands can still be executed, without

interfering with the running program). If the TMCL program polls this variable regularly it can react on

such changes of its contents.

The host can also poll a variable using GGP in direct mode and see if it has been changed by the TMCL

program.

7.5 Using Subroutines

The CSUB and RSUB commands provide a mechanism for using subroutines. The CSUB command

branches to the given label. When an RSUB command is executed the control goes back to the command

that follows the CSUB command that called the subroutine.

This mechanism can also be nested. From a subroutine called by a CSUB command other subroutines can

be called. In the current version of TMCL eight levels of nested subroutine calls are allowed.

www.trinamic.com

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

80

7.6 Mixing Direct Mode and Standalone Mode

Direct mode and standalone mode can also

standalone mode, direct mode commands are

program running in standalone mode). So, it

motor in direct mode while a TMCL program is

be mixed. When a TMCL program is being executed in

also processed (and they do not disturb the flow of the

is also possible to query e.g. the actual position of the

running.

Communication between a program running in standalone mode and a host can be done using the TMCL

user variables. The host can then change the value of a user variable (using a direct mode SGP

command) which is regularly polled by the TMCL program (e.g. in its main loop) and so the TMCL™

program can react on such changes. Vice versa, a TMCL program can change a user variable that is polled

by the host (using a direct mode GGP command).

A TMCL program can be started by the host using the run command in direct mode. This way, also a set

of TMCL routines can be defined that are called by a host. In this case it is recommended to place JA

commands at the beginning of the TMCL program that jump to the specific routines. This assures that

the entry addresses of the routines will not change even when the TMCL routines are changed (so when

changing the TMCL routines the host program does not have to be changed).

Example:

//Jump commands to the TMCL™ routines

Func1:

JA Func1Start

Func2:

JA Func2Start

Func3:

JA Func3Start

Func1Start: MVP ABS, 0, 1000

WAIT POS, 0, 0

MVP ABS, 0, 0

WAIT POS, 0, 0

STOP

Func2Start: ROL 0, 500

WAIT TICKS, 0, 100

MST 0

STOP

Func3Start:

ROR 0, 1000

WAIT TICKS, 0, 700

MST 0

STOP

This example provides three very simple TMCL routines. They can be called from a host by issuing a run

command with address 0 to call the first function, or a run command with address 1 to call the second

function, or a run command with address 2 to call the third function. You can see the addresses of the

TMCL labels (that are needed for the run commands) by using the Generate symbol file function of the

TMCL-IDE.

Please refer to the TMCL-IDE User Manual for further information about the TMCL-IDE.

www.trinamic.com

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

8 Life Support Policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent of

TRINAMIC Motion Control GmbH & Co. KG.

Life support systems are equipment intended to support

or sustain life, and whose failure to perform, when

properly used in accordance with instructions provided,

can be reasonably expected to result in personal injury

or death.

© TRINAMIC Motion Control GmbH & Co. KG 2014

Information given in this data sheet is believed to be

accurate and reliable. However neither responsibility is

assumed for the consequences of its use nor for any

infringement of patents or other rights of third parties,

which may result from its use.

Specifications are subject to change without notice.

www.trinamic.com

81

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

82

9 Revision History

9.1 Document Revision

Version

0.90

Date

2011-AUG-25

Author

SD

0.91

2011-AUG-31

GE

1.00

2012-MAR-09

SD

1.01

1.02

1.03

1.04

1.05

2012-MAR-13

2012-MAY-20

2012-MAY-31

2012-JUL-30

2013-APR-12

SD

SD

SD

SD

JP

1.06

2014-APR-14

SD

1.07

2014-SEP-30

GE

Description

Preliminary version

Table with axis and global parameters now centralized in

dedicated chapters

RFS function added

First complete version.

Axis parameters 130 and 200 added.

Axis parameter 254 updated

Axis parameter 254 corrected

Minor changes

JC instruction: type corrected

Global parameter 79 added

Firmware revisions updated

- Axis parameter 87 added.

- Axis parameter 197 added.

- Axis parameter 193 updated: reference mode moving

directions can be inverted now.

- Firmware revisions updated.

- Chapter 7 added.

- Axis parameter 179 added for hardware version V1.4

Figure 8.1 Document revision

9.2 Firmware Revision

Version

1.09

1.10

1.15

1.19

1.20

Date

2011-AUG-08

2011-AUG-23

2012-MAR-09

2012-JUL-25

2012-OCT-04

Author

OK

OK

OK

OK

OK

1.21

2012-DEC-07

OK

1.22

2013-FEB-23

OK

1.25

1.26

2013-MAR-13

2013-APR-04

OK

OK

1.27

1.28

1.29

2013-AUG-30

2013-SEP-24

2014-JAN-14

OK

OK

OK

Figure 8.2 Firmware revision

www.trinamic.com

Description

First version

Several enhancements

Several enhancements

Global parameter 79 added

Second Address available for RS232/RS485 (global parameter 87).

Answer suppressed for messages to 2nd address.

- Bug fix: stored axis parameter 140 correctly loaded at startup.

- Bug fix: oscillations around target position at minimum

velocity >0 (parameter 130) fixed.

- Axis parameter 193 updated: add 64 in order to invert the

reference mode moving direction.

- Bug fix (reference modes 7 and 8 / axis parameter 193): end

switches are generally deactivated.

Not deployed for TMCM-1021

Internal clock frequency increased to enable RS485 bit rates

between 9600 and 115200.

Error correction related to magnetic encoder. Update rate increased.

Not deployed for TMCM-1021

- Firmware version 1.29 is intended for TMCM-1021 module

versions from 1.0 to 1.4. Earlier firmware versions are not

compatible with TMCM-1021 V1.4. boards!

- Axis parameter 197 added.

�TMCM-1021 TMCL Firmware V1.29 Manual (Rev. 1.07 / 2014-SEP-30)

10 References

[TMC262]

[TMCL-IDE]

[QSH2818]

Please refer to www.trinamic.com.

www.trinamic.com

TMC262 Datasheet

TMCL-IDE User Manual

QSH2818 Manual

83

�