MODULE FOR STEPPER MOTORS

MODULE

Firmware Version V1.27

TMCL™ FIRMWARE MANUAL

+

+

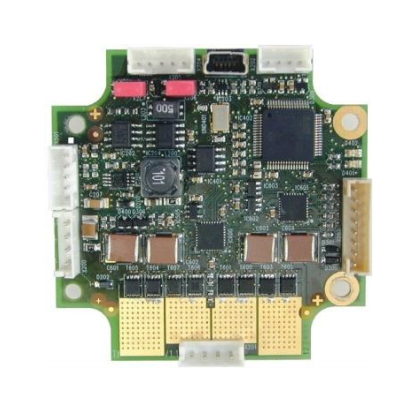

TMCM-1160

1-Axis Stepper

Controller / Driver

2.8 A / 48 V

USB, RS485, and CAN

Step/Dir Interface

sensOstep™ Encoder

+

UNIQUE FEATURES:

TRINAMIC Motion Control GmbH & Co. KG

Hamburg, Germany

www.trinamic.com

+

�TMCM-1160 TMCL Firmware V1.27 Manual (Rev. 1.04 / 2013-SEP-02)

Table of Contents

1

2

Features........................................................................................................................................................................... 4

Putting the Module into Operation ........................................................................................................................ 6

2.1

Basic Set-Up .......................................................................................................................................................... 6

2.1.1 Start the TMCL-IDE Software Development Environment ................................................................. 9

2.2

Using TMCL Direct Mode .................................................................................................................................. 10

2.2.1 Important Motor Settings ......................................................................................................................... 11

2.3

Testing with a Simple TMCL Program ......................................................................................................... 12

3

TMCL and the TMCL-IDE: Introduction ................................................................................................................. 13

3.1

Binary Command Format ................................................................................................................................ 13

3.1.1 Checksum Calculation ................................................................................................................................ 14

3.2

Reply Format ....................................................................................................................................................... 14

3.2.1 Status Codes ................................................................................................................................................. 15

3.3

Standalone Applications .................................................................................................................................. 15

3.4

TMCL Command Overview .............................................................................................................................. 16

3.4.1 TMCL Commands ......................................................................................................................................... 16

3.4.2 Commands Listed According to Subject Area .................................................................................... 17

3.5

The ASCII Interface ........................................................................................................................................... 21

3.5.1 Format of the Command Line ................................................................................................................. 21

3.5.2 Format of a Reply ....................................................................................................................................... 21

3.5.3 Configuring the ASCII Interface ............................................................................................................. 22

3.6

Commands ........................................................................................................................................................... 23

3.6.1 ROR (rotate right) ....................................................................................................................................... 23

3.6.2 ROL (rotate left) ........................................................................................................................................... 24

3.6.3 MST (motor stop)......................................................................................................................................... 25

3.6.4 MVP (move to position) ............................................................................................................................ 26

3.6.5 SAP (set axis parameter) ........................................................................................................................... 28

3.6.6 GAP (get axis parameter) .......................................................................................................................... 29

3.6.7 STAP (store axis parameter) ..................................................................................................................... 30

3.6.8 RSAP (restore axis parameter) ................................................................................................................. 31

3.6.9 SGP (set global parameter) ...................................................................................................................... 32

3.6.10 GGP (get global parameter)...................................................................................................................... 33

3.6.11 STGP (store global parameter) ................................................................................................................ 34

3.6.12 RSGP (restore global parameter) ............................................................................................................ 35

3.6.13 RFS (reference search) ................................................................................................................................ 36

3.6.14 SIO (set input / output) ............................................................................................................................. 37

3.6.15 GIO (get input /output) ............................................................................................................................. 39

3.6.16 CALC (calculate) ............................................................................................................................................ 42

3.6.17 COMP (compare)........................................................................................................................................... 43

3.6.18 JC (jump conditional) ................................................................................................................................. 44

3.6.19 JA (jump always) ......................................................................................................................................... 45

3.6.20 CSUB (call subroutine) ............................................................................................................................... 46

3.6.21 RSUB (return from subroutine) ................................................................................................................ 47

3.6.22 WAIT (wait for an event to occur) ......................................................................................................... 48

3.6.23 STOP (stop TMCL program execution) ................................................................................................... 49

3.6.24 SCO (set coordinate) ................................................................................................................................... 50

3.6.25 GCO (get coordinate) .................................................................................................................................. 51

3.6.26 CCO (capture coordinate) .......................................................................................................................... 52

3.6.27 ACO (accu to coordinate) .......................................................................................................................... 53

3.6.28 CALCX (calculate using the X register) .................................................................................................. 54

3.6.29 AAP (accumulator to axis parameter) .................................................................................................... 55

3.6.30 AGP (accumulator to global parameter) ............................................................................................... 56

3.6.31 CLE (clear error flags) ................................................................................................................................. 57

3.6.32 VECT (set interrupt vector) ........................................................................................................................ 58

3.6.33 EI (enable interrupt) ................................................................................................................................... 59

3.6.34 DI (disable interrupt) .................................................................................................................................. 60

3.6.35 RETI (return from interrupt) ..................................................................................................................... 61

www.trinamic.com

2

�TMCM-1160 TMCL Firmware V1.27 Manual (Rev. 1.04 / 2013-SEP-02)

3.6.36 Customer Specific TMCL Command Extension (UF0… UF7 / User Function) ............................... 62

3.6.37 Request Target Position Reached Event ............................................................................................... 62

3.6.38 TMCL Control Functions ............................................................................................................................. 63

4

Axis Parameters .......................................................................................................................................................... 65

4.1

stallGuard2 ........................................................................................................................................................... 72

4.2

coolStep Related Axis Parameters ................................................................................................................ 72

5

Global Parameters ...................................................................................................................................................... 74

5.1

Bank 0 ................................................................................................................................................................... 74

5.2

Bank 1 ................................................................................................................................................................... 76

5.3

Bank 2 ................................................................................................................................................................... 76

5.4

Bank 3 ................................................................................................................................................................... 77

6

Hints and Tips ............................................................................................................................................................. 78

6.1

Reference Search ............................................................................................................................................... 78

6.2

Changing the Prescaler Value of an Encoder ............................................................................................ 81

6.3

Using the RS485 Interface .............................................................................................................................. 82

7

TMCL Programming Techniques and Structure ................................................................................................. 83

7.1

Initialization ........................................................................................................................................................ 83

7.2

Main Loop ............................................................................................................................................................ 83

7.3

Using Symbolic Constants .............................................................................................................................. 83

7.4

Using Variables .................................................................................................................................................. 84

7.5

Using Subroutines ............................................................................................................................................. 84

7.6

Mixing Direct Mode and Standalone Mode ................................................................................................ 85

8

Life Support Policy ..................................................................................................................................................... 86

9

Revision History .......................................................................................................................................................... 87

9.1

Document Revision ........................................................................................................................................... 87

9.2

Firmware Revision ............................................................................................................................................ 87

10 References .................................................................................................................................................................... 88

www.trinamic.com

3

�TMCM-1160 TMCL Firmware V1.27 Manual (Rev. 1.04 / 2013-SEP-02)

4

1 Features

The TMCM-1160 is a single axis controller/driver module for 2-phase bipolar stepper motors with state of

the art feature set. It is highly integrated, offers a convenient handling and can be used in many

decentralized applications. The module can be mounted on the back of NEMA 23 (57mm flange size) or

NEMA 24 (60mm flange size) stepper motors and has been designed for coil currents up to 2.8 A RMS and

24 or 48 V DC supply voltage. With its high energy efficiency from TRINAMIC’s coolStep™ technology cost

for power consumption is kept down. The TMCL™ firmware allows for both, standalone operation and

direct mode.

MAIN CHARACTERISTICS

Motion controller

Motion profile calculation in real-time

On the fly alteration of motor parameters (e.g. position, velocity, acceleration)

High performance microcontroller for overall system control and serial communication protocol

handling

Bipolar stepper motor driver

Up to 256 microsteps per full step

High-efficient operation, low power dissipation

Dynamic current control

Integrated protection

stallGuard2 feature for stall detection

coolStep feature for reduced power consumption and heat dissipation

Encoder

sensOstep magnetic encoder (1024 increments per rotation) e.g. for step-loss detection under all

operating conditions and positioning supervision

Interface for connection of external incremental a/b/n encoder

Interfaces

- RS485 interface

- CAN (2.0B up to 1Mbit/s) interface

- USB full speed (12Mbit/s) interface

- Step/Direction interface (optically isolated)

- 3 inputs for stop switches and home switch (+24V compatible) with programmable pull-up

- 2 general purpose inputs (+24V compatible) and 2 general purpose outputs (open collector)

- Incremental a/b/n encoder interface (TTL and open-collector signals supported directly)

Safety features

- Shutdown input – driver will be disabled in hardware as long as this pin is left open or shorted to

ground

- Separate supply voltage inputs for driver and digital logic – driver supply voltage may be switched off

externally while supply for digital logic and therefore digital logic remains active

Software

TMCL:

standalone operation or remote controlled operation,

program memory (non volatile) for up to 2048 TMCL commands, and

PC-based application development software TMCL-IDE available for free.

Electrical and mechanical data

- Supply voltage: common supply voltages +12 V DC / +24 V DC / +48 V DC supported (+9 V… +51 V DC)

- Motor current: up to 2.8 A RMS (programmable)

Refer to separate Hardware Manual, too.

www.trinamic.com

�TMCM-1160 TMCL Firmware V1.27 Manual (Rev. 1.04 / 2013-SEP-02)

5

TRINAMICS UNIQUE FEATURES – EASY TO USE WITH TMCL

stallGuard2™

stallGuard2 is a high-precision sensorless load measurement using the back EMF on the

coils. It can be used for stall detection as well as other uses at loads below those which

stall the motor. The stallGuard2 measurement value changes linearly over a wide range of

load, velocity, and current settings. At maximum motor load, the value goes to zero or

near to zero. This is the most energy-efficient point of operation for the motor.

Load

[Nm]

stallGuard2

Initial stallGuard2

(SG) value: 100%

Max. load

stallGuard2 (SG) value: 0

Maximum load reached.

Motor close to stall.

Motor stalls

Figure 1.1 stallGuard2 load measurement SG as a function of load

coolStep™

coolStep is a load-adaptive automatic current scaling based on the load measurement via

stallGuard2 adapting the required current to the load. Energy consumption can be reduced

by as much as 75%. coolStep allows substantial energy savings, especially for motors

which see varying loads or operate at a high duty cycle. Because a stepper motor

application needs to work with a torque reserve of 30% to 50%, even a constant-load

application allows significant energy savings because coolStep automatically enables

torque reserve when required. Reducing power consumption keeps the system cooler,

increases motor life, and allows reducing cost.

0,9

Efficiency with coolStep

0,8

Efficiency with 50% torque reserve

0,7

0,6

0,5

Efficiency

0,4

0,3

0,2

0,1

0

0

50

100

150

200

250

300

350

Velocity [RPM]

Figure 1.2 Energy efficiency example with coolStep

www.trinamic.com

�TMCM-1160 TMCL Firmware V1.27 Manual (Rev. 1.04 / 2013-SEP-02)

6

2 Putting the Module into Operation

Here you can find basic information for putting your TMCM-1160 into operation. If you are already common

with TRINAMICs modules you may skip this chapter.

The things you need:

TMCM-1160

Interface (RS485/CAN/USB) suitable to your module with cables

Nominal supply voltage +24V DC (12 V DC / 48 V DC) for your module

TMCL-IDE program and PC

Stepper motor

PRECAUTIONS

Do not connect or disconnect the TMCM-1160 while powered!

Do not connect or disconnect the motor while powered!

Do not exceed the maximum power supply voltage of 51 V DC!

Note, that the module is not protected against reverse polarity!

START WITH POWER SUPPLY OFF!

2.1 Basic Set-Up

The following paragraph will guide you through the steps of connecting the unit and making first

movements with the motor.

CONNECTING THE MODULE

USB

Serial USB

interface

Converter

Converter

e.g. USB-2-485

CA

N

e.g. USB-2-X

CAN

Pin 2 CAN_L

Pin 1 CAN_H

Pin 3 GND

1

1

Motor

1

Motor

Figure 2.1: Starting up

www.trinamic.com

S/D

Encoder

1

USB

In/Out

POWER SUPPLY

Pin 1 VDriver

Pin 2 VLogic

Pin 3 Shutdown

Pin 4 GND

Interface

Power

RS485

Pin 5 RS485Pin 4 RS485+

Pin 3 GND

1

1

RS485

�TMCM-1160 TMCL Firmware V1.27 Manual (Rev. 1.04 / 2013-SEP-02)

1.

7

Connect power supply

Note:

- In order to enable motor driver stage connect /SHUTDOWN (pin 3) to power supply!

- In case separate power supplies for driver and logic are not used pin 2 (logic supply) and pin

3 (/SHUTDOWN input) of the power connector may be connected together in order to enable

driver stage.

Please refer to the TMCM-1160 Hardware Manual for further information about the power supply!

Pin

1

2

2.

Label

+VDriver

+VLogic

3

/SHUTDOWN

4

GND

Description

Module + driver stage power supply input

(Optional) separate digital logic power supply input

Shutdown input. Connect this input to +VDriver or +VLogic in order to activate

driver stage. Leaving this input open or connecting it to ground will disable

driver stage

Module ground (power supply and signal ground)

Choose your interface

a) Connect CAN or RS485

CAN interface will be de-activated in case USB is connected due to internal sharing of hardware

resources.

Pin

1

2

3

4

5

Label

CAN_H

CAN_L

GND

RS485+

RS485-

Description

CAN bus signal (dominant high)

CAN bus signal (dominant low)

Module ground (system and signal ground)

RS485 bus signal (non inverted)

RS485 bus signal (inverted)

b) Connect USB interface (as alternative to CAN and RS485; use a normal USB cable)

Download and install the file TMCM-1160.inf (www.trinamic.com).

Pin

1

2

3

4

5

Label

VBUS

DD+

ID

GND

www.trinamic.com

Description

+5V power

Data –

Data +

Not connected

Module ground

�TMCM-1160 TMCL Firmware V1.27 Manual (Rev. 1.04 / 2013-SEP-02)

3.

Connect In/Out connector (optional)

If you like to work with the GPIOs or switches, use the In/Out connector.

Label

Pin

4.

1

OUT_0

2

OUT_1

3

IN_0

4

IN_1

5

STOP_L

6

STOP_R

7

HOME

8

GND

Label

GND

+5V

ENC_A

ENC_B

ENC_N

Description

Module ground (system and signal ground)

+5V supply output for external encoder circuit (100 mA max.)

Encoder a channel input (internal pull-up)

Encoder b channel input (internal pull-up)

Optional encoder n / index channel input (internal pull-up)

Connect the motor

Pin

1

2

3

4

6.

Description

General purpose output, open drain (max. 1A)

Integrated freewheeling diode connected to +VLogic

General purpose output, open drain (max. 1A)

Integrated freewheeling diode connected to +VLogic

General purpose input (analog and digital), +24V compatible

Resolution when used as analog input: 12bit (0..4095)

General purpose input (analog and digital), +24V compatible

Resolution when used as analog input: 12bit (0..4095)

Left stop switch input (digital input), +24V compatible, programmable internal

pull-up to +5V

Right stop switch input (digital input), +24V compatible, programmable

internal pull-up to +5V

Home switch input (digital input), +24V compatible, programmable internal

pull-up to +5V

Module ground (system and signal ground)

Connect the encoder (optional)

If you like to work with encoder, use the encoder connector.

Pin

1

2

3

4

5

5.

8

Label

OA1

OA2

OB1

OB2

Description

Motor coil A

Motor coil A

Motor coil B

Motor coil B

Switch ON the power supply

Turn power ON. The green LED for power lights up and the motor is powered but in standstill

now.

If this does not occur, switch power OFF and check your connections as well as the power

supply!

www.trinamic.com

�TMCM-1160 TMCL Firmware V1.27 Manual (Rev. 1.04 / 2013-SEP-02)

2.1.1

Start the TMCL-IDE Software Development Environment

The TMCL-IDE is available on www.trinamic.com.

Installing the TMCL-IDE:

Make sure the COM port you intend to use is not blocked by another program.

Open TMCL-IDE by clicking TMCL.exe.

Choose Setup and Options and thereafter the Connection tab.

Choose COM port and type with the parameters shown in

Figure 2.2 (baud rate 9600). Click OK.

USB interface

If the file TMCM-1160.inf is installed correctly, the module will be identified automatically.

Figure 2.2 Setup dialogue and connection tab of the TMCL-IDE.

Please refer to the TMCL-IDE User Manual for more information (see www.TRINAMIC.com).

www.trinamic.com

9

�TMCM-1160 TMCL Firmware V1.27 Manual (Rev. 1.04 / 2013-SEP-02)

10

2.2 Using TMCL Direct Mode

1.

Start TMCL Direct Mode.

Direct Mode

2.

If the communication is established the TMCM-1160 is automatically detected.

If the module is not detected, please check all points above (cables, interface, power supply,

COM port, baud rate).

3.

Issue a command by choosing Instruction, Type (if necessary), Motor, and Value and click

Execute to send it to the module.

Examples:

- ROR rotate right, motor 0, value 500

- MST motor stop, motor 0

-> Click Execute. The motor is rotating now.

-> Click Execute. The motor stops now.

Top right of the TMCL Direct Mode window is the button Copy to editor. Click here to copy the chosen

command and create your own TMCL program. The command will be shown immediately on the editor.

Note:

Chapter 4 of this manual (axis parameters) includes a diagram which points out the coolStep related axis

parameters and their functions.

www.trinamic.com

�TMCM-1160 TMCL Firmware V1.27 Manual (Rev. 1.04 / 2013-SEP-02)

2.2.1

11

Important Motor Settings

There are some axis parameters which have to be adjusted right in the beginning after installing your

module. Please set the upper limiting values for the speed (axis parameter 4), the acceleration (axis

parameter 5), and the current (axis parameter 6). Further set the standby current (axis parameter 7) and

choose your microstep resolution with axis parameter 140. Please use the SAP (Set Axis Parameter)

command for adjusting these values. The SAP command is described in paragraph 3.6.5. You can use the

TMCL-IDE direct mode for easily configuring your module.

Attention:

The most important motor setting is the absolute maximum motor current setting, since too high values

might cause motor damage!

IMPORTANT AXIS PARAMETERS FOR MOTOR SETTING

Number

4

Axis Parameter

Maximum

positioning

speed

5

Maximum

acceleration

6

Absolute max.

current

(CS / Current

Scale)

Description

Should not exceed the physically highest possible

value. Adjust the pulse divisor (axis parameter 154), if

the speed value is very low (