ZVS Regulators

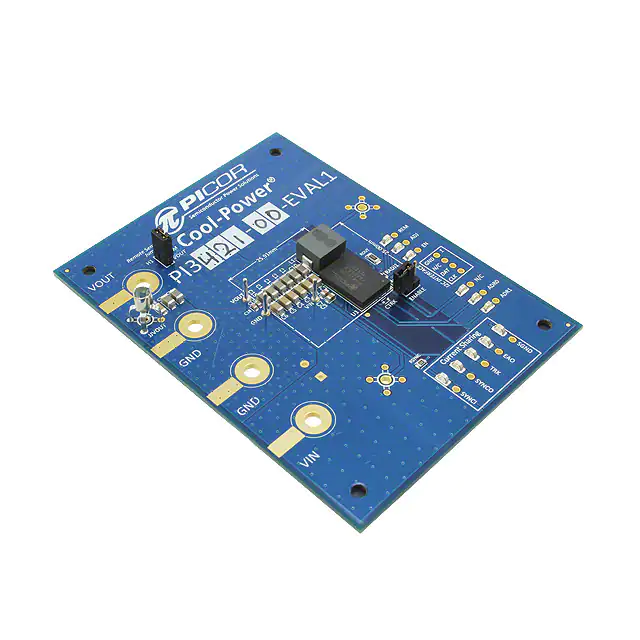

PI34xx-00-LGIZ

8 – 18VIN, 15A ZVS Buck Regulator

Product Description

Features & Benefits

The PI34xx-00 is a family of high‑efficiency DC-DC ZVS Buck

regulators integrating the controller, power switches and support

components within a high-density System-in-Package (SiP).

• High-efficiency ZVS Buck topology

The PI34xx-00 is designed to achieve optimum efficiency at low

input voltage ranges (8 – 18V). The utilization of zero‑current soft

turn-on provided by the high‑performance ZVS topology within the

PI34xx-00 series increases point‑of‑load performance, providing

best in class power efficiency with high throughput power.

• Very fast transient response

The PI34xx-00 requires only an external inductor and minimal

capacitors to form a complete DC-DC switching‑mode

buck regulator.

• Parallel capable with single‑wire current sharing

Device

Output Voltage

• Input voltage range of 8 – 18V

• Power-up into pre-biased load

• High-accuracy pre-trimmed output voltage

• User adjustable soft start & tracking

• Input over/undervoltage lockout (OVLO/UVLO)

• Output overvoltage protection (OVP)

• Overtemperature Protection (OTP)

IOUT Max

Set

Range

PI3423-00-LGIZ

3.3V

2.3 – 4.1V

15A

PI3424-00-LGIZ

5.0V

3.3 – 6.5V

15A

• Fast and slow current limits

• –40 to 125°C operating range (TINT)

The ZVS architecture enables high‑frequency operation while

minimizing switching losses and maximizing efficiency. The

high‑switching‑frequency operation reduces the size of the external

filtering components, improves power density, and enables very

fast dynamic response to line and load transients.

The ZVS architecture enables operation up to 750kHz while

minimizing switching losses and the use of variable frequency

extends high efficiency over a very wide dynamic range. The

PI34xx-00 series has a minimum on time of 20ns which enables

large step‑down conversion ratios.

Applications

• High-Efficiency Systems

• Computing, Communications, Industrial,

Automotive Equipment

Package Information

• 10 x 14 x 2.6mm LGA SiP

Note: Product images may not highlight current product markings.

ZVS Regulators

Page 1 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

Contents

Order Information

3

Application Description

15

Thermal, Storage and Handling Information

3

Output Voltage Trim

15

Absolute Maximum Ratings

3

Soft-Start Adjust and Tracking

16

Functional Block Diagram

4

Inductor Pairing

17

Pin Description

5

Thermal De-Rating

17

Package Pinout

6

Filter Considerations

17

PI3423-00-LGIZ (3.3VOUT ) Electrical Characteristics

7

PI3424-00-LGIZ (5.0VOUT ) Electrical Characteristics

Layout Guidelines

18

10

Recommended PCB Footprint and Stencil

19

Thermal De-Rating Curves

13

Package Drawings

20

Functional Description

14

Product Warranty

22

Enable (EN)

14

Remote Sensing

14

Switching Frequency Synchronization

14

Output Voltage Trim

14

Output Current Limit Protection

14

Input Undervoltage Lockout

14

Input Overvoltage Lockout

14

Output Overvoltage Protection

15

Overtemperature Protection

15

Parallel Operation

15

Pulse Skip Mode (PSM)

15

Variable-Frequency Operation

15

ZVS Regulators

Page 2 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

Order Information

Product

Output Range

IOUT Max

Package

Transport Media

2.3 – 4.1V

15A

10 x 14mm 123-pin LGA

TRAY

3.3 – 6.5V

15A

10 x 14mm 123-pin LGA

TRAY

Set

Range

PI3423-00-LGIZ

3.3V

PI3424-00-LGIZ

5.0V

Thermal, Storage and Handling Information

Name

Rating

Storage Temperature

–65 to 150°C

Internal Operating Temperature

–40 to 125°C

Soldering Temperature for 20 seconds

245°C

MSL Rating

3

ESD Rating

2kV HBM; 1.0kV CDM

Absolute Maximum Ratings

Name

Rating

VIN

–0.7 to 22V

VS1

–0.7 to 22V, 25V for 5ns, –4V for 5ns

VOUT, REM

See relevant product section

SGND

100mA

PWRGD, SYNCO, SYNCI, EN, EAO, ADJ, TRK, ADR1, ADR2, SCL, SDA, VDR

–0.3 to 5.5V / 5mA

Notes: At 25°C ambient temperature. Stresses beyond these limits may cause permanent damage to the device. Operation at these conditions or conditions

beyond those listed in the Electrical Characteristics is not guaranteed. All voltage nodes are referenced to PGND unless otherwise noted. Test conditions are

per the specifications within the individual product Electrical Characteristics.

ZVS Regulators

Page 3 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

Functional Block Diagram

VIN

VS1

VIN

Q2

Q1

VOUT

R4

REM

Power

Control

R1

VCC

+

ZVS Control

SYNCO

SYNCI

PWRGD

EN

PGND

Memory

Interface

EAO

ADJ

1V R2

TRK

0Ω

ADR1

SDA

ADR0

SCL

SGND

Simplified block diagram (I2C™ pins SCL, SDA, ADR0, and ADR1 are for factory use only. Not for use in application.)

ZVS Regulators

Page 4 of 22

Rev 2.2

01/2022

VOUT

�PI34xx-00-LGIZ

Pin Description

Name

Location

I/O

Description

SGND

Block 1

I/O

Signal Ground: Internal logic ground for EA, TRK, SYNCI, SYNCO and ADJ.

SGND and PGND are star‑connected within the regulator package.

PGND

Block 2

Power

Power Ground: VIN and VOUT power returns.

VIN

Block 3

Power

Input Voltage: and sense for UVLO, OVLO and feed‑forward ramp.

VOUT

Block 5

Power

Output Voltage: and sense for power switches and feed-forward ramp.

VS1

Block 4

Power

Switching Node: and ZVS sense for power switches.

PWRGD

A1

O

Power Good: High-impedance when regulator is operating and output voltage is within

approximately 80% of regulation set point; also can be used for parallel timing manangement

intended for lead regulator.

EAO

A2

O

Error Amp Output: External connection for additional compensation and current sharing.

EN

A3

I/O

Enable Input: Regulator enable control.

Asserted high or left floating: regulator enabled. Asserted low: regulator output disabled.

REM

A5

I

Remote Sense: High‑side connection. Connect to output regulation point.

ADJ

B1

I

Adjust Input: An external resistor may be connected between ADJ pin and SGND or VOUT to trim

the output voltage up or down.

TRK

C1

I/O

Soft-Start and Track Input: An external capacitor may be connected between TRK pin and SGND

to decrease the rate of rise during soft start.

NC

A4

Open

SYNCO

K4

O

Synchronization Output: Outputs a high signal for ½ of the minimum period for synchronization

of other regulators.

VDR

K3

O

Internally generated 5.1V for internal use. May be used externally provided it is impedance‑limited

to prevent current in excess of 2mA under any circumstances.

SYNCI

K5

I

Synchronization Input: Synchronize to the falling edge of external clock frequency. SYNCI is a

high‑impedance digital input node and should always be connected to SGND when not in use.

SDA

D1

I/O

Data Line: Connect to SGND. Factory use only. Not for use in application.

SCL

E1

I/O

Clock Line: Connect to SGND. Factory use only. Not for use in application.

ADR1

H1

I

Tri-State Address: No connect. Factory use only. Not for use in application.

ADR0

G1

I

Tri-State Address: No connect. Factory use only. Not for use in application.

ZVS Regulators

Page 5 of 22

No Connect: Leave pins floating.

Rev 2.2

01/2022

�PI34xx-00-LGIZ

Package Pinout

A

D

E

G

K

PGD/

PWRGD

ADJ

TRK

SDA

SCL

SGND

ADR0

ADR1

SGND

SGND

EAO

SGND

SGND

SGND

SGND

SGND

SGND

SGND

SGND

SGND

EN

SGND

SGND

SGND

SGND

SGND

SGND

SGND

SGND

VDR

NC

SGND

SGND

PGND

PGND

PGND

PGND

PGND

SYNCO

PGND

PGND

PGND

PGND

PGND

SYNCI

REM

VOUT

VOUT

VOUT

VOUT

PGND

PGND

PGND

PGND

PGND

PGND

VOUT

VOUT

VOUT

VOUT

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

VS1

VS1

VS1

VS1

VS1

VIN

VIN

VIN

VIN

VS1

VS1

VS1

VS1

VS1

VIN

VIN

VIN

VIN

VS1

VS1

VS1

VS1

VS1

VIN

VIN

VIN

VIN

PI34xx-00

Pin Block Name

Group of pins

SGND

B2-4, C2-4, D2-3, E2-3, F1-3, G2-3, H2-3, J1-3, K1-2

PGND

A8-10, B8-10, C8-10, D8-10, E4-10, F4-10, G4-10, H4-10, J4-10, K6-10

VIN

G12-14, H12-14, J12-14, K12-14

VS1

A12-14, B12-14, C12-14, D12-14, E12-14

VOUT

A6-7, B6-7, C6-7, D6-7

ZVS Regulators

Page 6 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

PI3423-00-LGIZ (3.3VOUT) Electrical Characteristics

Specifications apply for –40°C < TINT < 125°C, VIN = 12V, L1 = 150nH [a] unless other conditions are noted.

Parameter

Symbol

Conditions

Min

Typ

Max

Unit

8

12

18

V

Input Specifications

Input Voltage

VIN_DC

[f]

Input Current

IIN_DC

VIN = 12V, TC = 25°C, IOUT = 15A

Input Current at Output Short

(Fault-Condition Duty Cycle)

IIN_Short

4.43

[b]

A

10

Disabled

2.6

Input Quiescent Current

IQ_VIN

Input Voltage Slew Rate

VIN_SR

[b]

VOUT_DC

[b]

3.24

VOUT_DC

[c]

2.3

Enabled (no load)

mA

mA

4

1

V/µs

3.30

3.36

V

3.3

4.1

V

Output Specifications

Output Voltage Total Regulation

Output Voltage Trim Range

Line Regulation

∆VOUT(∆VIN)

Load Regulation

∆VOUT(∆IOUT)

At 25°C, 8V < VIN < 18V

0.10

At 25°C, 0.5A < IOUT < 15A

0.10

%

17

mVP-P

Output Voltage Ripple

VOUT_AC

IOUT = 7.5A, COUT = 8 x 100μF, 20MHz BW [d]

Continuous Output Current Range

IOUT_DC

Refer to load current vs. ambient temperature curves

Current Limit

IOUT_CL

%

15

18

A

A

Protection

UVLO Start Threshold

VUVLO_START

UVLO Stop Hysteresis

VUVLO_HYS

OVLO Stop Threshold

VOVLO

OVLO Start Hysteresis

VOVLO_HYS

7.10

7.60

8.00

0.36

19.0

20.75

V

V

21.78

V

0.37

V

Number of the switching-frequency cycles

128

Cycles

tf

+1% overdrive

500

ns

Output Overvoltage Protection

VOVP

Above set VOUT

20

%

Overtemperature Fault Threshold

TOTP

UVLO/OVLO Fault Delay Time

UVLO/OVLO Response Time

Overtemperature Restart Hysteresis

tf_DLY

130

TOTP_HYS

135

30

[a]

140

ºC

ºC

All parameters reflect regulator and inductor system performance. Measurements were made using a standard PI34xx-00 evaluation board with 3 x 4in

dimensions and 4 layer, 2oz copper. Refer to inductor pairing table within Application Description section for specific inductor manufacturer and value.

[b] Regulator is assured to meet performance specifications by design, test correlation, characterization, and/or statistical process control.

[c] Output current capability may be limited and other performance may vary from noted electrical characteristics when switching frequency or

VOUT is modified.

[d] Refer to output ripple plots.

[e] Refer to switching frequency vs. load current curves.

[f] Minimum 5V between V – V

IN

OUT must be maintained or a minimum load of 1mA required.

ZVS Regulators

Page 7 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

PI3423-00-LGIZ (3.3VOUT) Electrical Characteristics (Cont.)

Specifications apply for –40°C < TINT < 125°C, VIN = 12V, L1 = 150nH [a] unless other conditions are noted.

Parameter

Symbol

Conditions

Min

Typ

Max

Unit

Timing

Switching Frequency

Fault Restart Delay

fS

[e]

tFR_DLY

700

kHz

30

ms

Sync In (SYNCI)

Synchronization Frequency Range

∆fSYNCI

SYNCI Threshold

VSYNCI

2.5

V

SYNCI Input Impedance

ZSYNCI

100

kΩ

Relative to set switching frequency [c]

50

110

%

Sync Out (SYNCO)

SYNCO High

VSYNCO_HI

Source 1mA

SYNCO Low

VSYNCO_LO

Sink 1mA

SYNCO Rise Time

tSYNCO_RT

20pF load

10

ns

SYNCO Fall Time

tSYNCO_FT

20pF load

10

ns

4.5

V

0.5

V

Soft Start and Tracking

TRK Active Input Range

VTRK

Internal reference tracking range

0

1.2

V

TRK Max Output Voltage

VTRK_MAX

TRK Enable Threshold

VTRK_OV

20

40

62

mV

ITRK

–70

–50

–25

µA

Charge Current (Soft–Start)

Discharge Current (Fault)

Soft-Start Time

1.2

ITRK_DIS

tSS

CTRK = 0µF

TRK to EAIN Offset

V

6.8

mA

2.2

ms

34

100

mV

Enable

High Threshold

VEN_HI

0.9

1

1.1

V

Low Threshold

VEN_LO

0.7

0.8

0.9

V

Threshold Hysteresis

VEN_HYS

100

200

300

mV

Enable Pull-Up Voltage

(Floating, Unfaulted)

VEN_PU

With positive-logic EN polarity

2

V

Enable Pull-Down Voltage

(Floating, Faulted)

VEN_PD

With negative-logic EN polarity

0

V

Source Current

IEN_SO

With positive-logic EN polarity

–50

µA

Sink Current

IEN_SK

With negative-logic EN polarity

50

µA

[a]

All parameters reflect regulator and inductor system performance. Measurements were made using a standard PI34xx-00 evaluation board with 3 x 4in

dimensions and 4 layer, 2oz copper. Refer to inductor pairing table within Application Description section for specific inductor manufacturer and value.

[b] Regulator is assured to meet performance specifications by design, test correlation, characterization, and/or statistical process control.

[c] Output current capability may be limited and other performance may vary from noted electrical characteristics when switching frequency or

VOUT is modified.

[d] Refer to output ripple plots.

[e] Refer to switching frequency vs. load current curves.

[f] Minimum 5V between V – V

IN

OUT must be maintained or a minimum load of 1mA required.

ZVS Regulators

Page 8 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

PI3423-00-LGIZ (3.3VOUT) Electrical Characteristics (Cont.)

100

95

Efficiency (%)

90

85

80

75

70

65

60

55

50

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15

Output Current (A)

VIN:

8V

12V

18V

Figure 1 — Efficiency at 25ºC

Figure 4 — Transient response: 7.5 – 15A, at 5A/µs

Figure 2 — Short circuit test

Figure 5 — Output ripple 12VIN 3.3VOUT at 15A; COUT = 8 x 100µF

Switching Frequency (kHz)

800

700

600

500

400

300

200

100

0

1

2

3

4

5

6

7

8

9

10

11 12 13 14 15

Output Current (A)

VIN:

8V

12V

Figure 3 — Switching frequency vs. load current

ZVS Regulators

Page 9 of 22

18V

Figure 6 — Output ripple 12VIN 3.3VOUT at 7.0A;

COUT = 8 x 100µF

Rev 2.2

01/2022

�PI34xx-00-LGIZ

PI3424-00-LGIZ (5.0VOUT) Electrical Characteristics

Specifications apply for –40°C < TINT < 125°C, VIN = 12V, L1 = 150nH [a] unless other conditions are noted.

Parameter

Symbol

Conditions

Min

Typ

Max

Unit

8

12

18

V

Input Specifications

Input Voltage

VIN_DC

[f]

Input Current

IIN_DC

VIN = 12V, TC = 25°C, IOUT = 15A

Input Current at Output Short

(Fault-Condition Duty Cycle)

IIN_Short

6.57

[b]

A

10

Disabled

2.6

Input Quiescent Current

IQ_VIN

Input Voltage Slew Rate

VIN_SR

[b]

VOUT_DC

[b]

4.93

VOUT_DC

[c]

3.3

Enabled (no load)

mA

mA

4

1

V/µs

5.07

V

6.5

V

Output Specifications

Output Voltage Total Regulation

Output Voltage Trim Range

Line Regulation

∆VOUT(∆VIN)

Load Regulation

∆VOUT(∆IOUT)

At 25°C, 8V < VIN < 18V

5

0.10

%

At 25°C, 0.5A < IOUT < 15A

0.10

%

Output Voltage Ripple

VOUT_AC

IOUT = 7.5A, COUT = 8 x 100μF, 20MHz BW [d]

20.8

mVP-P

Continuous Output Current Range

IOUT_DC

Refer to load current vs. ambient temperature curves

Current Limit

IOUT_CL

15

18

A

A

Protection

UVLO Start Threshold

VUVLO_START

UVLO Stop Hysteresis

VUVLO_HYS

OVLO Stop Threshold

VOVLO

OVLO Start Hysteresis

VOVLO_HYS

7.10

7.60

8.00

0.36

19.0

20.75

V

V

21.78

V

0.37

V

Number of the switching-frequency cycles

128

Cycles

tf

+1% overdrive

500

ns

Output Overvoltage Protection

VOVP

Above set VOUT

20

%

Overtemperature Fault Threshold

TOTP

UVLO/OVLO Fault Delay Time

UVLO/OVLO Response Time

Overtemperature Restart Hysteresis

tf_DLY

130

TOTP_HYS

135

30

[a]

140

ºC

ºC

All parameters reflect regulator and inductor system performance. Measurements were made using a standard PI34xx-00 evaluation board with 3 x 4in

dimensions and 4 layer, 2oz copper. Refer to inductor pairing table within Application Description section for specific inductor manufacturer and value.

[b] Regulator is assured to meet performance specifications by design, test correlation, characterization, and/or statistical process control.

[c] Output current capability may be limited and other performance may vary from noted electrical characteristics when switching frequency or

VOUT is modified.

[d] Refer to output ripple plots.

[e] Refer to switching frequency vs. load current curves.

[f] Minimum 5V between V – V

IN

OUT must be maintained or a minimum load of 1mA required.

ZVS Regulators

Page 10 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

PI3424-00-LGIZ (5.0VOUT) Electrical Characteristics (Cont.)

Specifications apply for –40°C < TINT < 125°C, VIN = 12V, L1 = 150nH [a] unless other conditions are noted.

Parameter

Symbol

Conditions

Min

Typ

Max

Unit

Timing

Switching Frequency

Fault Restart Delay

fS

[e]

tFR_DLY

750

kHz

30

ms

Sync In (SYNCI)

Synchronization Frequency Range

∆fSYNCI

SYNCI Threshold

VSYNCI

2.5

V

SYNCI Input Impedance

ZSYNCI

100

kΩ

Relative to set switching frequency [c]

50

110

%

Sync Out (SYNCO)

SYNCO High

VSYNCO_HI

Source 1mA

SYNCO Low

VSYNCO_LO

Sink 1mA

SYNCO Rise Time

tSYNCO_RT

20pF load

10

ns

SYNCO Fall Time

tSYNCO_FT

20pF load

10

ns

4.5

V

0.5

V

Soft Start and Tracking

TRK Active Input Range

VTRK

Internal reference tracking range

0

1.2

V

TRK Max Output Voltage

VTRK_MAX

TRK Enable Threshold

VTRK_OV

20

40

62

mV

ITRK

–70

–50

–25

µA

Charge Current (Soft–Start)

Discharge Current (Fault)

Soft-Start Time

1.2

ITRK_DIS

tSS

CTRK = 0µF

TRK to EAIN Offset

V

6.8

mA

2.2

ms

34

100

mV

Enable

High Threshold

VEN_HI

0.9

1

1.1

V

Low Threshold

VEN_LO

0.7

0.8

0.9

V

Threshold Hysteresis

VEN_HYS

100

200

300

mV

Enable Pull-Up Voltage

(Floating, Unfaulted)

VEN_PU

With positive-logic EN polarity

2

V

Enable Pull-Down Voltage

(Floating, Faulted)

VEN_PD

With negative-logic EN polarity

0

V

Source Current

IEN_SO

With positive-logic EN polarity

–50

µA

Sink Current

IEN_SK

With negative-logic EN polarity

50

µA

[a]

All parameters reflect regulator and inductor system performance. Measurements were made using a standard PI34xx-00 evaluation board with 3 x 4in

dimensions and 4 layer, 2oz copper. Refer to inductor pairing table within Application Description section for specific inductor manufacturer and value.

[b] Regulator is assured to meet performance specifications by design, test correlation, characterization, and/or statistical process control.

[c] Output current capability may be limited and other performance may vary from noted electrical characteristics when switching frequency or

VOUT is modified.

[d] Refer to output ripple plots.

[e] Refer to switching frequency vs. load current curves.

[f] Minimum 5V between V – V

IN

OUT must be maintained or a minimum load of 1mA required.

ZVS Regulators

Page 11 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

PI3424-00-LGIZ (5.0VOUT) Electrical Characteristics (Cont.)

100

95

Efficiency (%)

90

85

80

75

70

65

60

55

50

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15

Output Current (A)

VIN:

8V

12V

18V

Figure 7 — Efficiency at 25ºC

Figure 10 — Transient response: 7.5 – 15A, at 5A/µs

Figure 8 — Short circuit test

Figure 11 — Output ripple 12VIN 5.0VOUT at 15A; COUT = 8 x 47µF

Switching Frequency (kHz)

800

700

600

500

400

300

200

100

0

1

2

3

4

5

6

7

8

9

10

11 12 13 14 15

Output Current (A)

VIN:

8V

12V

Figure 9 — Switching frequency vs. load current

ZVS Regulators

Page 12 of 22

18V

Figure 12 — Output ripple 12VIN 5.0VOUT at 7.0A; COUT = 8 x 47µF

Rev 2.2

01/2022

�PI34xx-00-LGIZ

16

16

14

14

12

12

Load Current (A)

Load Current (A)

Thermal De-Rating Curves

10

8

6

4

2

10

8

6

4

2

0

0

25

35

45

55

65

75

85

95

105

25

115

35

Ambient Temperature (ºC)

VIN:

8V

12V

55

65

75

85

95

105

115

Ambient Temperature (ºC)

18V

VIN:

Figure 13 — PI3423 – load current vs. ambient temperature, 0LFM

ZVS Regulators

Page 13 of 22

45

8V

12V

18V

Figure 14 — PI3424 – load current vs. ambient temperature, 0LFM

Rev 2.2

01/2022

�PI34xx-00-LGIZ

Functional Description

Soft-Start

The PI34xx-00 is a family of highly integrated ZVS Buck regulators.

The PI34xx-00 has a set output voltage that is trimmable within

a prescribed range shown in Table 1. Performance and maximum

output current are characterized with a specific external power

inductor (see Table 4).

The PI34xx-00 includes an internal soft-start capacitor to ramp the

output voltage in 2ms from 0V to full output voltage. Connecting

an external capacitor from the TRK pin to SGND will increase the

start-up ramp period. See, “Soft Start Adjustment and Track,” in

the Applications Description section for more details.

Output Voltage Trim

The PI34xx-00 output voltage can be trimmed up from the preset

output by connecting a resistor from ADJ pin to SGND and can be

trimmed down by connecting a resistor from ADJ pin to VOUT. The

Table 1 defines the voltage ranges for the PI34xx-00 family.

L1

VIN

VIN

CIN

PGND

VS1

PI34xx

VOUT

VOUT

COUT

REM

TRK

SYNCO

ADJ

EN

EAO

SGND

SYNCI

Device

For basic operation, Figure 15 shows the connections and

components required. No additional design or settings are required.

Enable (EN)

EN is the enable pin of the regulator. The EN Pin is referenced to

SGND and permits the user to turn the regulator on or off. The EN

polarity is a positive logic assertion. If the EN pin is left floating or

asserted high, the regulator output is enabled. Pulling EN pin below

0.8VDC with respect to SGND will disable the regulator output.

Remote Sensing

An internal 100Ω resistor is connected between REM pin and

VOUT pin to provide regulation when the REM connection is

broken. Referring to Figure 15, it is important to note that L1 and

COUT are the output filter and the local sense point for the power

supply output. As such, the REM pin should be connected at COUT

as the default local sense connection unless remote sensing to

compensate additional distribution losses in the system. The REM

pin should not be left floating.

Switching Frequency Synchronization

The SYNCI input allows the user to synchronize the controller

switching frequency by an external clock referenced to SGND. The

external clock can synchronize the unit between 50 and 110% of

the preset switching frequency (fS).

ZVS Regulators

Page 14 of 22

Set

Range

PI3423-00-LGIZ

3.3V

2.3 – 4.1V

PI3424-00-LGIZ

5.0V

3.3 – 6.5V

Table 1 — PI34xx-00 family output voltage ranges

Figure 15 — ZVS Buck with required components

The PI34xx-00 syncs to the falling edge of the applied clock

providing 180° phase shift from SYNCO. This allows for the

paralleling of two PI34xx-00 devices. When using the internal

oscillator, the SYNCO pin provides a 5V clock that can be used

to sync other regulators. Therefore, one PI34xx-00 can act as the

lead regulator and have additional PI34xx-00s running in parallel

and interleaved.

Output Voltage

Output Current Limit Protection

PI34xx-00 has two methods implemented to protect from output

short or overcurrent condition.

Slow Current Limit protection: prevents the output load from

sourcing current higher than the regulator’s maximum rated

current. If the output current exceeds the Current Limit (IOUT_CL) for

1024µs, a slow current limit fault is initiated and the regulator is

shut down which eliminates output current flow. After Fault Restart

Delay (tFR_DLY ), a soft-start cycle is initiated. This restart cycle will be

repeated indefinitely until the excessive load is removed.

Fast Current Limit protection: PI34xx-00 monitors the regulator

inductor current pulse-by-pulse to prevent the output from

supplying very high current due to sudden low impedance short

(50A typical). If the regulator senses a high inductor current pulse,

it will initiate a fault and stop switching until Fault Restart Delay

ends and then initiate a soft-start cycle.

Input Undervoltage Lockout

If VIN falls below the input Undervoltage Lockout (UVLO) threshold,

the regulator will enter a low‑power state and initiate a fault. The

system will restart once the input voltage is reestablished and after

the Fault Restart Delay.

Input Overvoltage Lockout

If VIN exceeds the input Overvoltage Lockout (OVLO) threshold

(VOVLO), while the regulator is running, the PI34xx-00 will complete

the current cycle and stop switching. The system will resume

operation after the Fault Restart Delay.

Rev 2.2

01/2022

�PI34xx-00-LGIZ

Output Overvoltage Protection

The PI34xx-00 family is equipped with output Overvoltage

Protection (OVP) to prevent damage to input voltage sensitive

devices. If the output voltage exceeds 20% of its set regulated

value, the regulator will complete the current cycle, stop switching

and issue an OVP fault. The system will resume operation once

the output voltage falls below the OVP threshold and after Fault

Restart Delay.

Overtemperature Protection

The internal package temperature is monitored to prevent

internal components from reaching their thermal maximum. If the

Overtemperature Protection Threshold (OTP) is exceeded (TOTP),

the regulator will complete the current switching cycle, enter a

low‑power mode, set a fault flag, and will soft start when the

internal temperature falls below Overtemperature Restart (TOTP_HYS).

Parallel Operation

Paralleling modules can be used to increase the output current

capability of a single power rail and reduce output voltage ripple.

VIN

VIN

CIN

SYNCO(#2)

R1

SYNCI(#2)

EN(#2)

VS1

PGND

SGND

L1

VS1

PGND

Each PI34xx-00 is preprogrammed to a base operating frequency,

with respect to the power stage inductor (see Table 4), to operate

at peak efficiency across line and load variations. At low‑line

and high‑load applications, the base frequency will decrease to

accommodate these extreme operating ranges. By stretching the

frequency, the ZVS operation is preserved throughout the total

input line voltage range therefore maintaining optimum efficiency.

The PI34xx-00 family of buck regulators provides five common

output voltages: 1.0, 1.8, 2.5, 3.3 and 5.0V. A post-package

trim step is implemented to offset any resistor divider network

errors ensuring maximum output accuracy. With a single resistor

connected from the ADJ pin to SGND or REM, each device’s

output can be varied above or below the nominal set voltage (the

PI3420‑00 can only be adjusted above the set voltage of 1V).

EN

VIN

Variable-Frequency Operation

Output Voltage Trim

SYNCO

TRK

PI34xx-00 features a PSM to achieve high efficiency at light loads.

The regulators are set up to skip pulses if EAO falls below a PSM

threshold. Depending on conditions and component values, this

may result in single pulses or several consecutive pulses followed

by skipped pulses. Skipping cycles significantly reduces gate drive

power and improves light load efficiency. The regulator will leave

PSM once the EAO rises above the Skip Mode threshold.

Application Description

SYNCI

TRK(#2)

Pulse Skip Mode (PSM)

VOUT

COUT

ZVS Buck

(#1) REM

EAO

CIN

VOUT

PWRGD

EAO(#2)

VIN

L1

synchronization. Once the regulators reach regulation, SYNCI is

released and the system is now synchronized in a closed-loop

configuration which allows the system to adjust on the fly, when

any of the individual regulators begin to enter variable frequency

mode in the loop.

VOUT

COUT

ZVS Buck

(#2) REM

PWRGD

SYNCO(#1)

SYNCI(#1)

EN(#1)

SYNCI

Device

SYNCO

Set

Range

PI3423-00-LGIZ

3.3V

2.3 – 4.1V

PI3424-00-LGIZ

5.0V

3.3 – 6.5V

EN

EAO(#1)

EAO

TRK(#1)

TRK

SGND

Output Voltage

Figure 16 — PI34xx-00 parallel operation

Table 2 — PI34xx-00 family output voltage ranges

By connecting the EAO pins and SGND pins of each module

together the units will share the current equally. When the TRK

pins of each unit are connected together, the units will track each

other during soft start and all unit EN pins have to be released to

allow the units to start (See Figure 16). Also, any fault event in any

regulator will disable the other regulators. The two regulators will

be out of phase with each other reducing output ripple (refer to

Switching Frequency Synchronization).

The remote pin (REM) should always be connected to the VOUT pin

to prevent an output voltage offset. Figure 17 shows the internal

feedback voltage‑divider network.

To provide synchronization between regulators over the entire

operational frequency range, the Power Good (PWRGD) pin must

be connected to the lead regulator’s (#1) SYNCI pin and a 2.5kΩ

Resistor, R1, must be placed between SYNCO (#2) return and

the lead regulator’s SYNCI (#1) pin, as shown in Figure 16. In this

configuration, at system soft start, the PWRGD pin pulls SYNCI

low forcing the lead regulator to initialize the open-loop start‑up

ZVS Regulators

Page 15 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

Resistor RHIGH should be connected as shown in Figure 17 to

achieve the desired 4.0V regulator output. No external RLOW

resistor is need in this design example since the trim is above the

regulator set voltage.

VOUT

The PI3420 output voltage can only be trimmed higher than the

factory 1V setting. The following Equation 3 can be used calculate

RHIGH values for the PI3420 regulators.

R4

REM

R1

RLOW

ADJ

-

RHIGH(1V) =

+

RHIGH

R2

1.0VDC

SGND

The TRK pin offers a means to increase the regulator’s soft-start

time or to track with additional regulators. The soft‑start slope is

controlled by an internal capacitor and a fixed charge current to

provide a Soft-Start Time tSS for all for all PI34xx-00 regulators.

By adding an additional external capacitor to the TRK pin, the

soft‑start time can be increased further. The following equation

can be used to calculate the proper capacitor for a desired

soft-start times:

R1, R2, and R4 are all internal 1.0% resistors and RLOW and RHIGH

are external resistors for which the designer can add to modify

VOUT to a desired output. The internal resistor values for each

regulator are listed next in Table 3.

Device

R1

R2

R4

PI3423-00-LGIZ

2.61kΩ

1.13kΩ

100Ω

PI3424-00-LGIZ

4.53kΩ

1.13kΩ

100Ω

CTRK = (tTRK • ITRK) – 100 x 10–9,

where, tTRK is the soft-start time and ITRK is a 50µA internal charge

current (see Electrical Characteristics for limits).

Table 3 — PI34xx-00 internal divider values

There is typically either a proportional or direct tracking method

implemented within a tracking design. For proportional tracking

between several regulators at start up, simply connect all devices

TRK pins together. This type of tracking will force all connected

regulators to start up and reach regulation at the same time (see

Figure 18 (a)).

By choosing an output voltage value within the ranges stated in

Table 2, VOUT can simply be adjusted up or down by selecting the

proper RHIGH or RLOW value, respectively. The following equations

can be used to calculate RHIGH and RLOW values:

RLOW =

1

(VOUT – 1) – 1

R1

R2

1

1

R2(VOUT – 1)

–

For Direct Tracking, choose the regulator with the highest output

voltage as the parent and connect the parent TRK pin to the TRK

pin of the other regulators through a divider (Figure 19) with the

same ratio as the child’s feedback divider (see Table 3 for values).

(1)

( )

1

R1

(2)

VOUT 1

VOUT 2

If, for example, a 4.0V output is needed, the user should choose

the regulator with a trim range covering 4.0V from Table 2. For this

example, the PI3423 is selected (3.3V set voltage). First step would

be to use Equation 1 to calculate RHIGH since the required output

voltage is higher than the regulator set voltage. The resistor-divider

network values for the PI3423 can be found in Table 3 and are

(a)

Parent VOUT

VOUT 2

R1 = 2.61kΩ and R2 = 1.13kΩ. Inserting these values into

Equation 1, RHIGH is calculated as follows:

3.78k =

1

(4.0 – 1)

2.61k

– 1

1.13

(3)

Soft-Start Adjust and Tracking

Figure 17 — Internal resistor divider network

RHIGH =

1

V

( OUT – 1)

R1

(b)

t

Figure 18 — PI34xx-00 tracking methods

All connected regulators’ soft-start slopes will track with this

method. Direct tracking timing is demonstrated in Figure 18 (b).

ZVS Regulators

Page 16 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

Thermal De-Rating

Thermal de-rating curves are provided that are based on

component temperature changes versus load current, input

voltage and air flow. It is recommended to use these curves as a

guideline for proper thermal de-rating. These curves represent the

entire system and are inclusive to both the Vicor regulator and the

external inductor. Maximum thermal operation is limited by either

the MOSFETs or inductor depending upon line and load conditions.

Parent VOUT

R1

PI34xx

TRK

Child

Thermal measurements were made using a standard PI34xx-00

evaluation board which is 3 x 4 inches in area and uses 4-layer,

2oz copper. Thermal measurements were made on the three

main power devices, the two internal MOSFETs and the

external inductor.

R2

SGND

Filter Considerations

Figure 19 — Voltage divider connections for direct tracking

All tracking regulators should have their Enable (EN) pins connected

together to work properly.

Inductor Pairing

The PI34xx-00 utilizes an external inductor from Eaton Corporation.

This inductor has been optimized for maximum efficiency

performance. Table 4 details the specific inductor value and part

number utilized for each PI34xx-00 device.

Data sheets are available at:

www.eaton.com.

Device

Inductor

(nH)

Inductor

Part Number

Manufacturer

PI3423-00

150

FPV1006-150-R

Eaton

PI3424-00

150

FPV1006-150-R

Eaton

Table 4 — PI34xx-00 inductor pairing

Device

VIN

(V)

PI3423

12

PI3424

12

ILOAD

(A)

15

7.5

15

7.5

The PI34xx-00 requires input bulk storage capacitance as well as

low‑impedance ceramic X5R input capacitors to ensure proper

start up and high-frequency decoupling for the power stage. The

PI34xx-00 will draw nearly all of the high‑frequency current from

the low‑impedance ceramic capacitors when the main high‑side

MOSFET is conducting. During the time the high-side MOSFET

is off, they are replenished from the bulk capacitor. If the input

impedance is high at the switching frequency of the regulator,

the bulk capacitor must supply all of the average current into the

regulator, including replenishing the ceramic capacitors. This value

has been chosen to be 100µF so that the PI34xx-00 can start up

into a full resistive load and supply the output capacitive load with

the default minimum soft‑start capacitor when the input source

impedance is 50Ω at 1MHz. The ESR for this capacitor should be

approximately 20mΩ. The RMS ripple current in this capacitor is

small, so it should not be a concern if the input recommended

ceramic capacitors are used. Table 5 shows the recommended

input and output capacitors to be used for the various models

as well as expected transient response, RMS ripple currents per

capacitor, and input and output ripple voltages. Table 6 includes

the recommended input and output ceramic capacitors.

CINPUT

Bulk

Electrolytic

CINPUT

Ceramic

X5R

COUTPUT

Ceramic

X5R

CINPUT

Ripple

Current

(IRMS)

COUTPUT

Ripple

Current

(IRMS)

100µF

50V

6 x 22µF

8 x 100µF

2 x 1µF

1 x 0.1µF

1.20

1.15

100µF

50V

6 x 22µF

8 x 100µF

2 x 1µF

1 x 0.1µF

1.29

1.13

Table 5 — Recommended input and output capacitance

ZVS Regulators

Page 17 of 22

Rev 2.2

01/2022

Input

Ripple

(mVP-P)

Output

Ripple

(mVP-P)

179

26

97

17

209

34

98

24.8

Output

Ripple

(mVPK)

Recovery Load Step

Time

(A)

(µs)

[Slew/µs]

±73

70

7.5

[5A/µs]

±98

60

7.5

[5A/µs]

�PI34xx-00-LGIZ

Murata Part Number

Description

GRM188R71C105KA12D

1µF 16V 0603 X7R

GRM319R71H104KA01D

0.1µF 50V 1206 X7R

GRM31CR60J107ME39L

100µF 6.3V 1206 X5R

GRM31CR61A476ME15L

47µF 10V 1206 X5R

GRM31CR61E226KE15L

22µF 25V 1206 X5R

When Q1 is on and Q2 is off, the majority of CIN’s current is used

to satisfy the output load and to recharge the COUT capacitors.

When Q1 is off and Q2 is on, the load current is supplied by the

inductor and the COUT capacitor as shown in Figure 22. During this

period CIN is also being recharged by the VIN. Minimizing CIN loop

inductance is important to reduce peak voltage excursions when

Q1 turns off. Also, the difference in area between the CIN loop and

COUT loop is vital to minimize switching and GND noise.

Table 5 — Capacitor manufacturer part numbers

Layout Guidelines

To achieve maximum efficiency and low‑noise performance

from a PI34xx-00 design, layout considerations are necessary.

Reducing trace resistance and minimizing high‑current loop

returns along with proper component placement will contribute to

optimal performance.

VIN

A typical buck regulator circuit is shown in Figure 20. The potential

areas of high parasitic inductance and resistance are the circuit

return paths, shown as LR below.

CIN

COUT

Figure 22 — Current flow: Q2 closed

VIN

COUT

CIN

The recommended component placement, shown in Figure 23,

illustrates the tight path between CIN and COUT (and VIN and VOUT )

for the high AC return current. This optimized layout is used on the

PI34xx-00 evaluation board.

VOUT

COUT

Figure 20 — Typical buck regulator

GND

The path between the COUT and CIN capacitors is of particular

importance since the AC currents are flowing through both of

them when Q1 is turned on.

CIN

VIN

Figure 21, schematically, shows the reduced trace length

between input and output capacitors. The shorter path

lessens the effects that copper trace parasitics can have on the

PI34xx-00 performance.

VIN

CIN

GND

Figure 23 — Recommended component placement and

metal routing

COUT

Figure 21 — Current flow: Q1 closed

ZVS Regulators

Page 18 of 22

VSW

Rev 2.2

01/2022

�PI34xx-00-LGIZ

Recommended PCB Footprint and Stencil

L

PI34xx-00

L

Recommended receiving footprint for PI34xx‑00 10 x 14mm package. All pads should have a final copper size of 0.55 x 0.55mm,

whether they are solder-mask defined or copper defined, on a 1 x 1mm grid. All stencil openings are 0.45mm when using either a

5 or 6mil stencil.

ZVS Regulators

Page 19 of 22

Rev 2.2

01/2022

�PI34xx-00-LGIZ

Package Drawings

A

K

G

E D

A

D

B

E

DETAIL A

M

L

DETAIL B

A

SEATING PLANE

METALLIZED

PAD

M

M

A

M

SOLDER MASK

DETAIL A

A

L

D

E

AND POSITION

ZVS Regulators

Page 20 of 22

Rev 2.2

01/2022

A

�PI34xx-00-LGIZ

Revision History

Revision

Date

1.0

02/13

1.1

08/03/15

Description

Last release in old format

n/a

Reformatted in new template

n/a

1.2

09/03/15

Inductor pairing table updates

1.3

12/21/15

Clarifications made in Enable Pin Conditions

02/03/20

Formatting changes

Changed PGD pin name to PWRGD

Removed continuous output current range min

Corrected UVLO stop hysteresis, OVLO stop threshold, OVLO start hysteresis

Updated sink current

Added TRK to EAIN offset spec,

revised soft-start charge current, TRK enable threshold

Updated input quiescent current enabled

Updated output voltage total regulation

Updated mechanical drawings

1.4

1.5

02/26/20

Added CDM ESD rating

1.6

05/14/20

Corrected REM absolute maximum rating

1.7

08/11/20

Updated terminology

1.8

12/31/20

Removed end-of-life part numbers

(for PI3420-00, PI3421-00 and PI3422-00 data, see separate document)

Revised PI3424-00 switching frequency vs. load current plot

1.9

01/04/21

Revised switching frequency typical specification

2.0

02/24/21

Revised UVLO start threshold

Added SYNCI input impedance specification

2.1

09/01/21

Corrected figure 1 plot

01/14/22

Corrections to figures 1, 2, 4, 7, 8, 10

removed irrelevant figures

2.2

6, 7 & 25

7, 8, 11, 14, 17 & 28

All

3, 4, 5,

7

7, 10, 13, 16, 19

8

8, 11, 14, 17, 20

10

10, 16

28, 29

3

3

25, 26

1–3

12

11

7, 10

8, 11

9

Note: page added in Rev 1.4, pages removed in Rev 1.8.

ZVS Regulators

Page 21 of 22

Page Number(s)

Rev 2.2

01/2022

9, 12

13

�PI34xx-00-LGIZ

Vicor’s comprehensive line of power solutions includes high density AC-DC and DC-DC modules and

accessory components, fully configurable AC-DC and DC-DC power supplies, and complete custom

power systems.

Information furnished by Vicor is believed to be accurate and reliable. However, no responsibility is assumed by Vicor for its use. Vicor

makes no representations or warranties with respect to the accuracy or completeness of the contents of this publication. Vicor reserves

the right to make changes to any products, specifications, and product descriptions at any time without notice. Information published by

Vicor has been checked and is believed to be accurate at the time it was printed; however, Vicor assumes no responsibility for inaccuracies.

Testing and other quality controls are used to the extent Vicor deems necessary to support Vicor’s product warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

Specifications are subject to change without notice.

Visit http://www.vicorpower.com/dc-dc-converters-board-mount/cool-power-pi33xx-and-pi34xx for the latest product information.

Vicor’s Standard Terms and Conditions and Product Warranty

All sales are subject to Vicor’s Standard Terms and Conditions of Sale, and Product Warranty which are available on Vicor’s webpage

(http://www.vicorpower.com/termsconditionswarranty) or upon request.

Life Support Policy

VICOR’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE

EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL COUNSEL OF VICOR CORPORATION. As used

herein, life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected to

result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness. Per Vicor Terms

and Conditions of Sale, the user of Vicor products and components in life support applications assumes all risks of such use and indemnifies

Vicor against all liability and damages.

Intellectual Property Notice

Vicor and its subsidiaries own Intellectual Property (including issued U.S. and Foreign Patents and pending patent applications) relating to the

products described in this data sheet. No license, whether express, implied, or arising by estoppel or otherwise, to any intellectual property

rights is granted by this document. Interested parties should contact Vicor’s Intellectual Property Department.

The products described on this data sheet are protected by U.S. Patents. Please see www.vicorpower.com/patents for the latest

patent information.

Contact Us: http://www.vicorpower.com/contact-us

Vicor Corporation

25 Frontage Road

Andover, MA, USA 01810

Tel: 800-735-6200

Fax: 978-475-6715

www.vicorpower.com

email

Customer Service: custserv@vicorpower.com

Technical Support: apps@vicorpower.com

©2018 – 2022 Vicor Corporation. All rights reserved. The Vicor name is a registered trademark of Vicor Corporation.

I2C™ is a trademark of NXP semiconductor.

All other trademarks, product names, logos and brands are property of their respective owners.

ZVS Regulators

Page 22 of 22

Rev 2.2

01/2022

�