Dimensions: [mm]

Recommended Land Pattern: [mm]

Absolute Maximum Ratings (Ambient Temperature 25°C):

Properties

0,45 ±0,1

2

Unit

140

mW

700

mA

IF

70

mA

VREV

5

V

VESD HBM

2000

V

Peak Forward Current

IF Peak

Reverse Voltage

ESD Threshold/ Human Body

Model

1,0

0,7 ±0,1

Value

PDiss

Continuous Forward Current

1

1

2

Test conditions

Power Dissipation

0,45 ±0,1

duty/ 10 @ 10 kHz

Optical Properties:

0,65

0,5

0,65

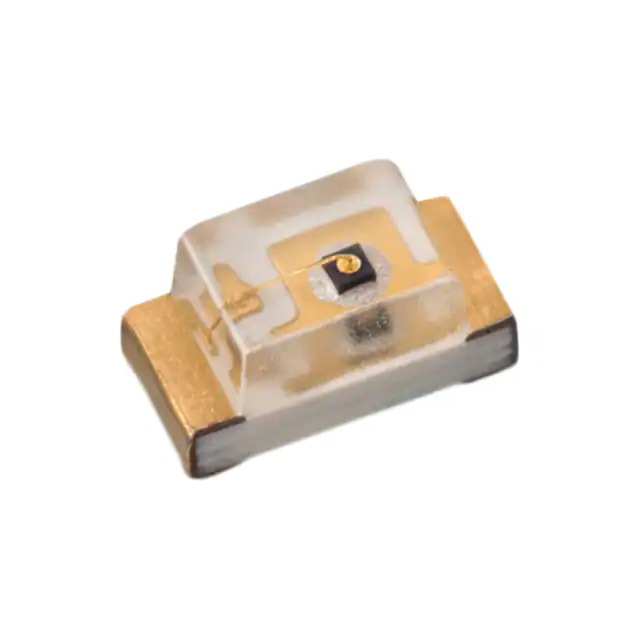

Chip Technology

1,6 ±0,1

AlGaAs

Infrared

Lens Type

0,6 ±0,1

0,32 ±0,1

Emitting Color

Waterclear

Scale - 20:1

General Information:

Schematic:

Operating Temperature

-40 up to +85 °C

Storage Conditions (in original

packaging)

Polarity Mark

(Anode)

< 40 °C ; < 90 % RH

Moisture Sensitivity Level (MSL)

3

1

2

+

1

IR

LEDs emit high intensity IR light.

not look directly into the LED during operation.

This can be harmful to your eyes.

Wear protective eyewear.

Please follow safety precautions given in

�

IEC 60825-1 and IEC 62471.

Keep out of reach of children.

Avoid direct eye and skin exposure to LED!

CAUTION – IR

2

0,8 ±0,1

1,0 ±0,1

Scale - 20:1

Do

CHECKED

REVISION

DATE (YYYY-MM-DD)

GENERAL TOLERANCE

ZAn

001.004

2022-07-05

DIN ISO 2768-1m

PROJECTION

METHOD

DESCRIPTION

Würth Elektronik eiSos GmbH & Co. KG

EMC & Inductive Solutions

Max-Eyth-Str. 1

74638 Waldenburg

Germany

Tel. +49 (0) 79 42 945 - 0

www.we-online.com

eiSos@we-online.com

WL-SICW SMT Infrared Chip LED

Waterclear

ORDER CODE

15406085BA300

SIZE/TYPE

BUSINESS UNIT

STATUS

PAGE

0603

eiPal

Valid

1/9

This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH

& Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety

must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

�Electrical & Optical Properties:

Properties

Viewing Angle:

Test conditions

Value

min.

typ.

max.

Unit

λPeak

20 mA

λCentroid

20 mA

Radiant Intensity

Ie

20 mA

Forward Voltage

VF

20 mA

1.4

Spectral Bandwidth

Δλ

20 mA

30

nm

Reverse Current

IREV

5V

10

µA

20 mA

130

°

Peak Wavelength

Centroid Wavelength

Viewing Angle Phi 0°

2θ50%

850

1

nm

845

nm

2

mW/sr

2

V

0°

-65°

10°

100

Certification:

Compliant [2011/65/EU&2015/863]

REACh Approval

Conform or declared [(EC)1907/2006]

Halogen Free

Photobiological Safety

Conform [JEDEC JS709B]

Conform [IEC 61249-2-21]

IEC-62471 [ Exempt Group 0 ]

Relative Luminous Intensity (%)

RoHS Approval

Halogen Free

20°

30°

90

40°

80

45°

70

50°

60

50

60°

65°

40

70°

30

20

80°

10

90°

-90

-45

0

10

20

30

40

CHECKED

REVISION

DATE (YYYY-MM-DD)

GENERAL TOLERANCE

ZAn

001.004

2022-07-05

DIN ISO 2768-1m

50

60

70

80

90

100

PROJECTION

METHOD

DESCRIPTION

Würth Elektronik eiSos GmbH & Co. KG

EMC & Inductive Solutions

Max-Eyth-Str. 1

74638 Waldenburg

Germany

Tel. +49 (0) 79 42 945 - 0

www.we-online.com

eiSos@we-online.com

WL-SICW SMT Infrared Chip LED

Waterclear

ORDER CODE

15406085BA300

SIZE/TYPE

BUSINESS UNIT

STATUS

PAGE

0603

eiPal

Valid

2/9

This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH

& Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety

must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

�Spectral:

Forward Current vs. Forward Voltage:

250

200

Forward Current [mA]

100

Relative Intensity [%]

80

60

40

150

100

20

0

400

500

600

700

800

900

1000

1100

50

Wavelength [nm]

0

0.0

0.5

1.0

1.5

2.0

Forward Voltage [V]

CHECKED

REVISION

DATE (YYYY-MM-DD)

GENERAL TOLERANCE

ZAn

001.004

2022-07-05

DIN ISO 2768-1m

2.5

3.0

PROJECTION

METHOD

DESCRIPTION

Würth Elektronik eiSos GmbH & Co. KG

EMC & Inductive Solutions

Max-Eyth-Str. 1

74638 Waldenburg

Germany

Tel. +49 (0) 79 42 945 - 0

www.we-online.com

eiSos@we-online.com

WL-SICW SMT Infrared Chip LED

Waterclear

ORDER CODE

15406085BA300

SIZE/TYPE

BUSINESS UNIT

STATUS

PAGE

0603

eiPal

Valid

3/9

This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH

& Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety

must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

�Relative Radiant Intensity vs. Forward Current:

Derating Curve:

12.00

90

80

10.00

8.00

Forward Currennt (mA)

Relative Radiant Intensity

70

6.00

4.00

60

50

40

30

20

2.00

10

0

0.00

0

50

100

150

Forward Current [mA]

200

250

0

10

20

30

40

50

60

70

Ambient Temperature (℃)

CHECKED

REVISION

DATE (YYYY-MM-DD)

GENERAL TOLERANCE

ZAn

001.004

2022-07-05

DIN ISO 2768-1m

80

90

100

PROJECTION

METHOD

DESCRIPTION

Würth Elektronik eiSos GmbH & Co. KG

EMC & Inductive Solutions

Max-Eyth-Str. 1

74638 Waldenburg

Germany

Tel. +49 (0) 79 42 945 - 0

www.we-online.com

eiSos@we-online.com

WL-SICW SMT Infrared Chip LED

Waterclear

ORDER CODE

15406085BA300

SIZE/TYPE

BUSINESS UNIT

STATUS

PAGE

0603

eiPal

Valid

4/9

This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH

& Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety

must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

�Packaging Specification - Tape and Reel: [mm]

Packaging Specification - Reel: [mm]

K0

P0

A

T

P2

W3

E1

D0

W1

close to center

A

E2

B0

C

Top Cover

Tape

D1

A

N

W

F

D

B

P1

W2

T1

A0

T2

End

Feeding direction

Start

Carrier Tape

detail B

Cover Tape

B

Cover Tape

Chip Cavity

Sprocket Hole

No Component

min.160mm

Components

No Component

min.100mm

Polarity Mark

Embossment

Cover Tape

min. 400mm

packaging is reffered to the international standard IEC 60286-3:2013

tolerance

size

15406085xxx

A0 B0 W

typ. typ. +0,3/ -0,1

0,88 1,85 8,0

T

T1 T2 K0 P0 P1 P2

D0

ref. max. typ. typ. ±0,1 ±0,1 ±0,05 +0,1/ -0,0

0,22 0,1 1,25 0,85 4,0 4,0 2,0

1,5

D1 E1 E2 F

Tape Type 2a

min. ±0,1 min. ±0,05

0,3 1,75 6,25 3,5

Polystyrene

VPE / packaging unit

pcs.

4000

165° - 180°

Tolerance

Tape width

8 mm

A

± 2,0

178

B

min.

1.5

C

min.

12.8

D

min.

20.2

N

min.

50

CHECKED

REVISION

DATE (YYYY-MM-DD)

GENERAL TOLERANCE

ZAn

001.004

2022-07-05

DIN ISO 2768-1m

W1

+1,5

8.4

W2

max.

14.4

W3

min.

7.9

W3

max.

10.9

PROJECTION

METHOD

DESCRIPTION

Pull-of force

Tape width

8 mm

0,1 N - 1,0 N

Würth Elektronik eiSos GmbH & Co. KG

EMC & Inductive Solutions

Max-Eyth-Str. 1

74638 Waldenburg

Germany

Tel. +49 (0) 79 42 945 - 0

www.we-online.com

eiSos@we-online.com

WL-SICW SMT Infrared Chip LED

Waterclear

ORDER CODE

15406085BA300

SIZE/TYPE

BUSINESS UNIT

STATUS

PAGE

0603

eiPal

Valid

5/9

This electronic component has been designed and developed for usage in general electronic equipment only. This product is not authorized for use in equipment where a higher safety standard and reliability standard is especially required or where a failure of the product is reasonably expected to cause severe personal injury or death, unless the parties have executed an agreement specifically governing such use. Moreover Würth Elektronik eiSos GmbH

& Co KG products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc.. Würth Elektronik eiSos GmbH & Co KG must be informed about the intent of such usage before the design-in stage. In addition, sufficient reliability evaluation checks for safety

must be performed on every electronic component which is used in electrical circuits that require high safety and reliability functions or performance.

�Classification Reflow Profile for SMT components:

Classification Reflow Soldering Profile:

Profile Feature

Tp

tp

Max. Ramp Up Rate

Max. Ramp Down Rate

TL

Temperature

Ts max

tL

Preheat Area

Ts min

TC –5°C

Value

Preheat Temperature Min

Ts min 150 °C

Preheat Temperature Max

Ts max 200 °C

Preheat Time ts from Ts min to Ts max

ts

Ramp-up Rate (TL to TP)

max. 60 - 120 seconds

3 °C/ second max.

Liquidous Temperature

TL

217 °C

Time tL maintained above TL

tL

max. 60 seconds

Peak package body temperature

Tp

Tp ≤ Tc, see Table below

Time within 5°C of actual peak

temperature

tp

max. 10 seconds

Ramp-down Rate (TP to TL)

6 °C/ second max.

Time 25°C to peak temperature

max. 220 seconds

refer to IPC/ JEDEC J-STD-020E

tS

Package Classification Reflow Temperature (Tc):

Volume mm³

350-2000

Volume mm³

>2000

PB-Free Assembly | Package Thickness 260 °C

< 1.6 mm

260 °C

260 °C

PB-Free Assembly | Package Thickness 260 °C

1.6 mm - 2.5 mm

250 °C

245 °C

PB-Free Assembly | Package Thickness 250 °C

> 2.5 mm

245 °C

245 °C

Properties

25

Time 25°C to Peak

Time

Applied cycles

Volume mm³