NO.

FUZETEC TECHNOLOGY CO., LTD.

PQ11-01ER

Product Specification and Approval Sheet Version A9

Page

1/5

Surface Mountable PTC Resettable Fuse : FSMD2920 Series

1. Summary

(a) RoHS Compliant & Halogen Free

(b) Applications : All high-density boards

(c) Product Features : 2920 Dimension, Surface mountable, Solid state, Faster time to

trip than standard SMD devices.

(d) Operation Current : 0.30A~5.00A

(e) Maximum Voltage : 6V~60VDC

(f) Temperature Range : -40℃ to 85℃

2. Agency Recognition

UL :

C-UL:

TÜ V:

File No. E211981

File No. E211981

File No. R50090556

3. Electrical Characteristics (23℃)

Part

Hold

Trip

Rated

Max

Typical

Max Time to Trip

Current

Current

Voltage

Current

Power

Current

Time

RMIN

R1MAX

IH, A

IT, A

VMAX, VDC

IMAX, A

Pd, W

A

Sec

Ohms

Ohms

0.30

0.50

0.75

0.75

1.10

1.00

1.25

1.50

1.85

2.00

2.00

2.50

2.60

2.60

3.00

3.00

3.00

4.00

5.00

0.60

1.00

1.50

1.50

2.20

2.00

2.50

3.00

3.70

4.00

4.00

5.00

5.20

5.20

5.20

5.20

5.20

8.00

10.00

60

60

33

60

33

60

33

33

33

16

24

16

6

24

6

15

24

16

16

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

100

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

2.5

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

8.0

20.0

20.0

3.0

4.0

0.3

0.3

0.5

0.5

2.0

2.0

2.5

4.5

5.0

16.0

20.0

20.0

25.0

20.0

20.0

4.0

5.0

1.000

0.300

0.180

0.180

0.090

0.090

0.050

0.050

0.040

0.035

0.035

0.025

0.020

0.020

0.010

0.010

0.010

0.010

0.005

4.800

1.400

1.000

1.000

0.410

0.410

0.250

0.230

0.150

0.120

0.120

0.085

0.075

0.075

0.048

0.048

0.048

0.040

0.025

Number

FSMD030-2920-R

FSMD050-2920-R

FSMD075-2920-R

FSMD075-60-2920-R

FSMD100-2920-R

FSMD100-60-2920R

FSMD125-2920-R

FSMD150-2920-R

FSMD185-2920-R

FSMD200-2920-R

FSMD200-24-2920-R

FSMD250-2920-R

FSMD260-2920-R

FSMD260-24-2920R

FSMD300-2920-R

FSMD300-15-2920R

FSMD300-24-2920R

FSMD400-16-2920R

FSMD500-16-2920R

Resistance

IH=Hold current-maximum current at which the device will not trip at 23℃still air.

IT=Trip current-minimum current at which the device will always trip at 23℃ still air.

V MAX=Maximum voltage device can withstand without damage at it rated current.(I MAX)

I MAX= Maximum fault current device can withstand without damage at rated voltage (V MAX).

Pd=Typical power dissipated-type amount of power dissipated by the device when in the tripped state in 23℃ still air environment.

RMIN=Minimum device resistance at 23℃ prior to tripping.

R1MAX=Maximum device resistance at 23℃ measured 1 hour after tripping or reflow soldering of 260℃ for 20 seconds.

Termination pad characteristics

Termination pad materials : Pure Tin

NOTE : Specification subject to change without notice.

2016/11/8

�NO.

FUZETEC TECHNOLOGY CO., LTD.

PQ11-01ER

Product Specification and Approval Sheet Version A9

Page

2/5

4. FSMD Product Dimensions (Millimeters)

Part

Number

FSMD030-2920-R

FSMD050-2920-R

FSMD075-2920-R

FSMD075-60-2920-R

FSMD100-2920-R

FSMD100-60-2920R

FSMD125-2920-R

FSMD150-2920-R

FSMD185-2920-R

FSMD200-2920-R

FSMD200-24-2920-R

FSMD250-2920-R

FSMD260-2920-R

FSMD260-24-2920R

FSMD300-2920-R

FSMD300-15-2920R

FSMD300-24-2920R

FSMD400-16-2920R

FSMD500-16-2920R

A

B

C

D

E

Min

Max

Min

Max

Min

Max

Min

Max

Min

Max

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

6.73

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

7.98

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

4.80

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

5.44

0.60

0.60

0.40

0.60

0.40

0.40

0.40

0.40

0.30

0.30

0.20

0.30

0.30

0.65

0.40

0.40

0.65

0.40

0.40

1.15

1.15

1.15

1.15

1.00

1.70

0.90

0.90

0.90

0.90

0.80

0.90

0.90

1.15

0.90

1.15

1.15

1.50

1.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

1.20

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

0.90

NOTE : Specification subject to change without notice.

2016/11/8

�FUZETEC TECHNOLOGY CO., LTD.

NO.

PQ11-01ER

Product Specification and Approval Sheet Version A9

Page

3/5

5. Thermal Derating Curve

Percent of Rated Hold and Trip Current

FSMD2920 Series

200%

150%

100%

50%

A

A= FSMD125-2920-R ~

B

FSMD500-16-2920R

B= FSMD030-2920 -R~

0%

-40

-20

0

20

40

60

80

FSMD100-2920-R

Ambient Temperature (℃)

6. Typical Time-To-Trip at 23℃

A

B

C D EFGH IJ K

L M

100

10

Time-to-trip (S)

A = FSMD030-2920-R

B = FSMD050-2920-R

C = FSMD075-2920-R /

075-60-2920-R

D = FSMD100-2920-R /

100-60-2920R

E = FSMD125-2920-R

F = FSMD150-2920-R

G = FSMD185-2920-R

H = FSMD200-2920-R /

200-24-2920-R

I = FSMD250-2920-R

J = FSMD260-2920-R /

260-24-2920R

K= FSMD300-2920-R /

300-15-2920R /

300-24-2920R

L = FSMD400-16-2920R

M = FSMD500-16-2920R

1

0.1

0.01

0.001

0.1

1

Fault Current (A)

10

100

NOTE : Specification subject to change without notice.

2016/11/8

�NO.

FUZETEC TECHNOLOGY CO., LTD.

PQ11-01ER

Product Specification and Approval Sheet Version A9

Page

4/5

7. Material Specification

Terminal pad material : Pure Tin

Soldering characteristics: Meets EIA specification RS 186-9E, ANSI/J-std-002 Category 3

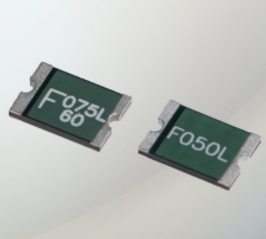

8. Part Numbering and Marking System

Part Numbering System

F S M D □ □ □ – □ □ – 2920 – R

Part Marking System

F

F200L

□ □ □ L

Voltage Rating

Current Rating

Part Identification

Fuzetec Logo

Example

F

075L

60

F

□ □ □ L

□ □

Part Identification

Example

Fuzetec Logo

Warning: -Operation beyond the specified maximum ratings or improper use may result in damage and possible

甲、

electrical arcing and/or flame.

-PPTC device are intended for occasional overcurrent protection. Application for repeated overcurrent

condition and/or prolonged trip are not anticipated.

-Avoid contact of PPTC device with chemical solvent. Prolonged contact will damage the device

performance.

NOTE : Specification subject to change without notice.

2016/11/8

�FUZETEC TECHNOLOGY CO., LTD.

NO.

PQ11-01ER

Product Specification and Approval Sheet Version A9

Page

5/5

9. Pad Layouts、Solder Reflow and Rework Recommendations

The dimension in the table below provide the recommended pad layout for each FSMD2920 device

Pad dimensions (millimeters)

A

B

Device

Nominal

Nominal

All 2920 Series

5.10

2.30

C

Nominal

5.60

Solder reflow

※ Due to “Lead Free” nature, Temperature and

Dwelling time for the soldering zone is higher

Profile Feature

Average Ramp-Up Rate (Tsmax to Tp)

Preheat :

Temperature Min (Tsmin)

Temperature Max (Tsmax)

Time (tsmin to tsmax)

Pb-Free Assembly

3 ℃/second max.

150 ℃

200 ℃

60-180 seconds

Time maintained above:

Temperature(TL)

217 ℃

Time (tL)

60-150 seconds

Peak/Classification Temperature(Tp) : 260 ℃

Time within 5℃ of actual Peak :

20-40 seconds

Temperature (tp)

Ramp-Down Rate :

6 ℃/second max.

8 minutes max.

Time 25 ℃ to Peak Temperature :

Note 1: All temperatures refer to of the package,

measured on the package body surface.

than those for Regular. This may cause

damage to other components.

1. Recommended max past thickness > 0.25mm.

2. Devices can be cleaned using standard

methods and aqueous solvent.

3. Rework use standard industry practices.

4. Storage Envorinment : < 30℃ / 60%RH

Caution:

1. If reflow temperatures exceed the

recommended profile, devices may not meet

the performance requirements.

2. Devices are not designed to be wave soldered

to the bottom side of the board.

Reflow Profile

NOTE : Specification subject to change without notice.

2016/11/8

�

很抱歉,暂时无法提供与“FSMD250-2920-R”相匹配的价格&库存,您可以联系我们找货

免费人工找货- 国内价格

- 5+1.12634

- 50+0.90051

- 150+0.80363

- 国内价格

- 1+0.67500

- 100+0.63000

- 300+0.58500

- 500+0.54000

- 2000+0.51750

- 5000+0.50400