page 1 of 7

CRYSTAL SPECIFICATION

华强聚丰

Customer

:

Customer P/N

:

TKD P/N

:

CD05M006000RD1

Product Description

:

49S-6-20-20

Issue Date

:

2018.12.28

CUSTOMER’S APPROVAL

APPROVAL

(PLEASE

CHECKED

CONFORM

RETURN A COPY WITH APPOVAL

Hubei TKD Electronic Technology Co.,LTD

湖北泰晶电子科技股份有限公司

APPROVED

苏婷婷

代 伟

SALE:TEL :0722-3309660

DESIGNER

FAX :0722-3309768

QCD:TEL :0722-3308231

FAX :0722-3309768

FAE:TEL :0755-27328651

FAX :0755-27328001

�page 2 of 7

REV.

Description of Revision History

Date

Designer

Checked By

A

New revision

2018-12-28

Sutingting

DaiWei

�page 3 of 7

CRYSTAL SPECIFICATION

1.

2.

3.

4.

5.

6.

Description:

Quartz Crystal

Nominal Frequency:

6.000000MHz

Oscillation Mode:

Fundamental

Cutting Mode:

AT cut

Measurement Instrument: S&A 250B(Measured FL)

Electrical Characteristics:

[1]Operation Conditions:

Item

Symbol

MIN.

Operating Temperature Range

Topt

Storage Temperature Range

Tstg

MAX.

Unit

-40

85

℃

-55

105

℃

Load Capacitance

CL

Drive Level

DL

0.1

Symbol

MIN.

Tolerance

dF/Fo

Stability Over Temperature

Aging

TYP.

20

Condition

pF

100

uW

MAX.

Unit

Condition

-20

20

ppm

Refer to Center Frequency@25±3℃

dF/F25

-30

30

ppm

Refer to Operating Temperature

@-40~+85℃

dF/F25

-3

3

ppm

Per Year

MAX.

Unit

ESR

80

Ω

Shunt Capacitance

C0

7

pF

Insulation Resistance

IR

[2]Frequency Stability:

Item

TYP.

dF/Fo:Frequency Deviation Refer to Center Frequency

dF/F25:Frequency Deviation Refer to 25℃ Frequency

[3]Electrical Performance:

Item

Equivalent Series Resistance

Symbol

MIN.

500

TYP.

MΩ

Condition

@Series

@DC 100 Volt

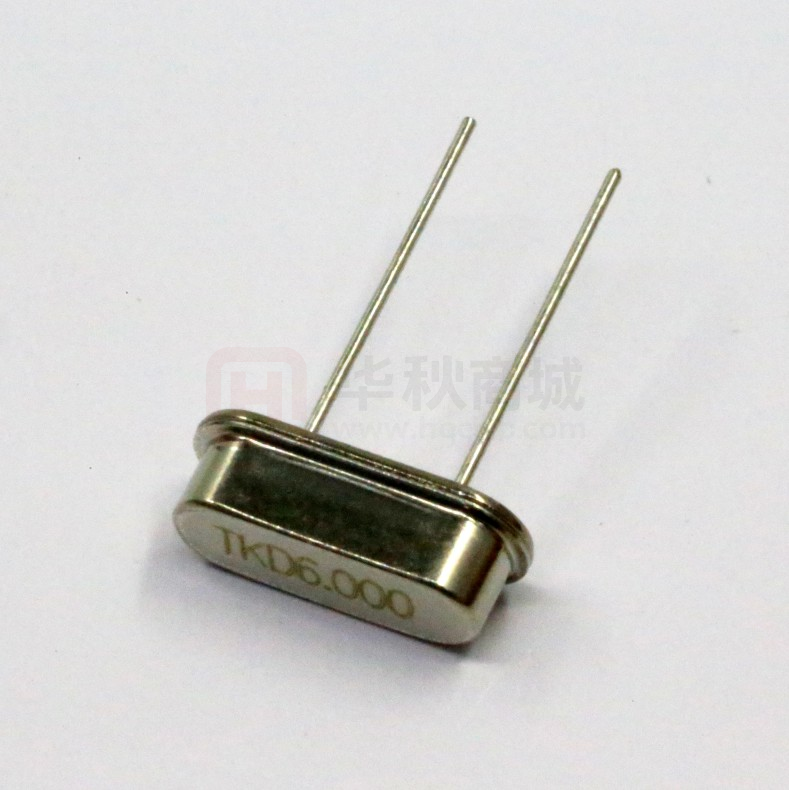

7.

Marking:Laser

TKD :Company Logo

6.000:Nominal Frequency

TKD6.000

�page 4 of 7

8.

Outline drawing (unit:mm)

�page 5 of 7

9.

Reliability Specification

Test Item

Condition of test

Performance

Requirements

Tensile Strength

Termination

The unit’s lead wire should withstand a tensile force applied to the There should be no

termination in the direction of its draw-out axis of up to 1000g abnormalities detected on

maintained as is for 10±2s

the unit

Solder ability

The lead is immersed in a 235±5℃ solder bath within 2±0.5 A new uniform coating of

seconds.

solder shall cover min

mun 95% of the surface

being immersed.

Vibration

Drop

Endurance condition by a frequency sweep shall be made. The

entire frequency range from 10HZ to 50HZ and return to

10HZ,shall be transverseb in 1min. Amplitude(total

excursion):1.5mm this motion shall be applied for a period of 2h

each of 3 mutually perpendicular axes(a total of 6h)

(1).Frequency

Change:±5ppm

(2).Resistance:±15%

Form 70cm height 3 times on 3cm hard wooden floor

(1).Frequency

Change:±5ppm

(2).Resistance:±15%

Shock

Peak acceleration:981m/s2

duration of the pulse :6ms three (1).Frequency

successive shocks shall be applied in both direction of 3 mutually Change:±5ppm

perpendicular axes(a total of 18 shocks)

(2).Resistance:±15%

Damp heat

The unit shall be stored at a temperature of 40±2℃with relative (1).Frequency

humidity of 90%to95% for 48h, then it shall be subjected to Change:±5ppm

standard atmospheric conditions for 1 ~ 2h after which (2).Resistance:±15%

measurement shall be made.

Dry heat

The unit shall be stored at a temperature of 100℃±5℃ for 24h, (1).Frequency

then it shall be subjected to standard atmospheric conditions for Change:±5ppm

1~2h after which measurement shall be made.

(2).Resistance:±15%

Cold

The unit shall be stored at a temperature of-40℃±5℃ for 48h, then (1).Frequency

it shall be subjected to standard atmospheric conditions for 1~2h Change:±5ppm

after which measurement shall be made.

(2).Resistance:±15%

Aging

The unit shall be stored at a temperature of 85℃±5℃ for 7d then it

shall be subjected to standard atmospheric conditions for 1~2h

after which measurement shall be made.

Temperature

cycling

Refer

to

specification

verdict

The unit shall be subjected to 5 successive change of temperature Refer

to

cycles, each as show in table below,then it shall be subjected to specification

standard atmospheric conditions for 1 ~ 2h after which

measurement shall be made

verdict

Temperature

Duration

1

-40℃±3℃

2

Standard atmospheric Within 30s

conditions

3

100℃±3℃

4

Standard atmospheric Within 30s

conditions

30min

30min

�page 6 of 7

Test Item

Sealing

Condition of test

The crystal filter unit shall be immersed in a industry alcohol for

5±0.5 minutes then 25±3℃ 1~2 Hr before testing

Resistance to

soldering heat

Performance

Requirements

Insulation

Resistance>500MΩ

Refer

to

specification

Reflow soldering cure see the chart.

Soldering iron method:

Bit temperature: 350℃±10℃

Application time of soldering iron:5s Max

verdict

�page 7 of 7

�

很抱歉,暂时无法提供与“49S-6-20-20”相匹配的价格&库存,您可以联系我们找货

免费人工找货