1. 物料型号:SMD2018系列,包括SMD2018-030、SMD2018-050、SMD2018-100、SMD2018-100-33V、SMD2018-150和SMD2018-200。

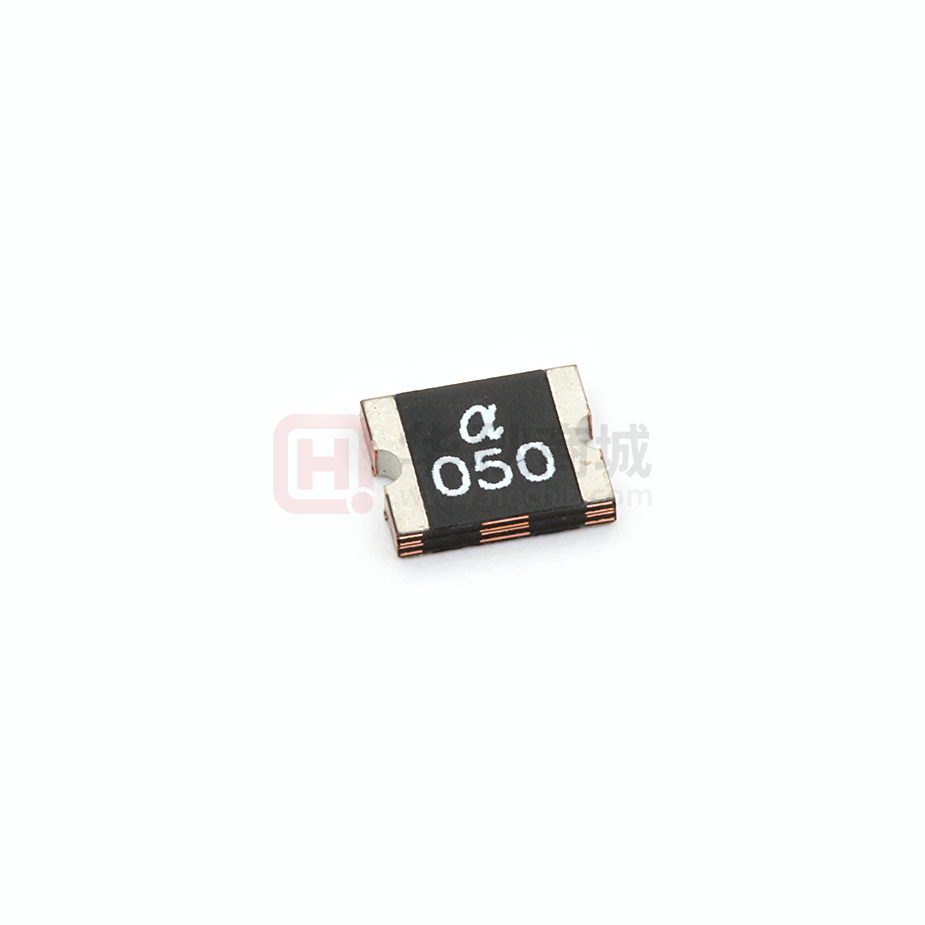

2. 器件简介:SMD2018系列是表面贴装设备,尺寸为5.04.5mm,无铅设备,适用于自动化组装。

3. 引脚分配:文档中未明确提供引脚分配图,但提到了表面贴装封装。

4. 参数特性:包括最大工作电压(Vmax)、最大故障电流(Imax)、保持电流(Ihold)、触发电流(Itrip)、功耗(Pd)、最大电阻变化(Rimin/max)等。

5. 功能详解:SMD2018系列主要用于低电压电源保护,适用于计算机主板、调制解调器、电信设备等。

6. 应用信息:适用于高达60V的低电压电源和需要保护的负载。

7. 封装信息:提供了详细的尺寸和标记信息,包括推荐焊盘布局和端子垫特性。

8. 环境规格:包括被动老化、湿度老化、热冲击、耐溶剂性、振动等测试条件和电阻变化。

9. 机构认证:UL待定,符合RoHS、2002/95/EC、EN14582等标准。

10. 温度与保持电流关系:提供了不同型号在不同环境温度下的保持电流变化。

11. 结构和尺寸:提供了详细的构造和尺寸图。

12. 推荐焊接条件:包括预热、焊接、冷却的推荐条件。

13. 胶带和卷轴规格:提供了EIA胶带组件尺寸和卷轴尺寸。

14. 存储和处理:提供了存储条件和订单信息。

15. 标签信息:提供了标签上需要包含的信息。