RoHS

MESSRS:

APPROVAL NO

296-028

DATE

2014.01.13

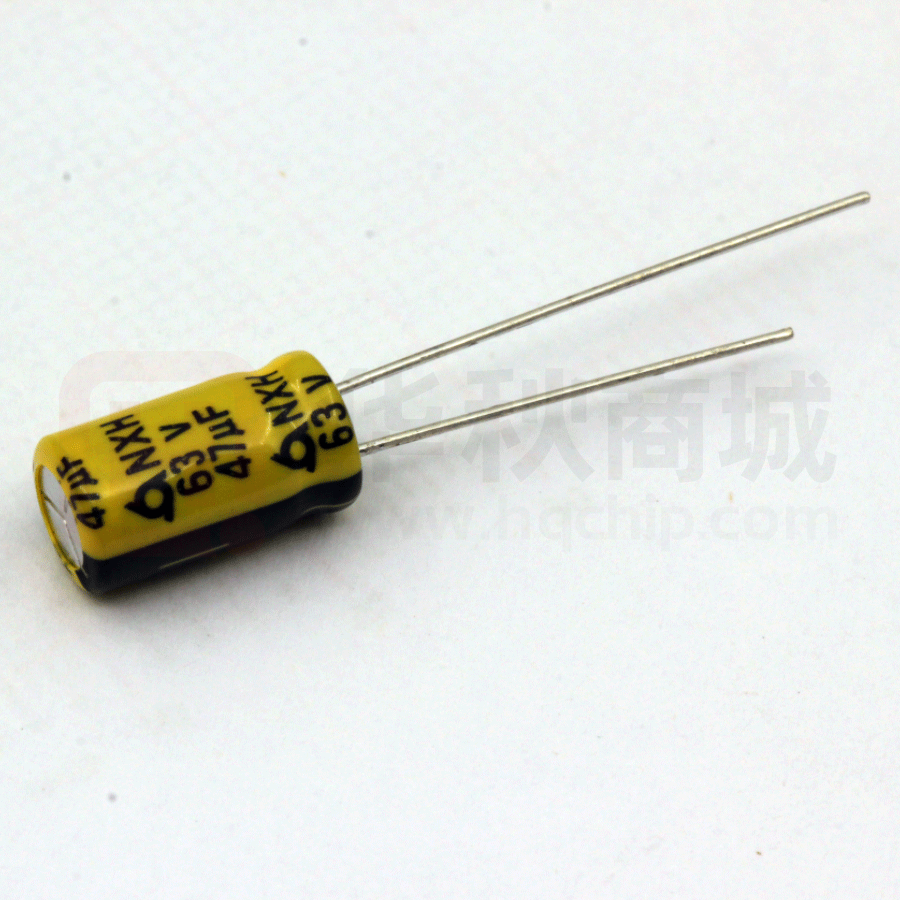

ALUMINUM ELECTROLYTIC

CAPACITOR

APPROVAL SHEET

CATALOG TYPE

NXH

SERIES

USER PART NO.

适 用 机 种

特 记 事 项

Halogen-Free

QINGDAO SAMYOUNG ELECTRONICS CO.,LTD.

MANAGER OF DEVELOPMENT DEPARTMENT

GONG JANG SUG

长孔

硕

USER APPROVAL:

APPROVAL NO.:

SamYoung(Korea) : 146-1,SANGDAEWON-DONG,JOONGWON-GU,SUNGNAM-CITY,KYUNGKI-DO,KOREA

SamYoung(China) : No.5 CHANGJIANG ROAD,PINGDU-CITY,SHANDONG-PROVINCE,CHINA

A4 (210×297)

样式:H-1001-011

SamYoung Electronics Co., Ltd.

�APPROVAL NO.

ALUMINUM ELECTROLYTIC CAPACITOR

296-028

PAGE:

1 OF

6

DATE:

2014.01.13

Specifications of NXH Series

Item

Characteristics

Rated Voltage Range

6.3 ~ 50 VDC

Operating Temperature Range

- 40 ~ + 105 ℃

Capacitance Tolerance

±20%

(at 20℃ ,120Hz)

Leakage Current

After 2 minutes: 0.01CV ( μA ) or 3 μA,whichever is greater

( at 20 ℃ )

Where,C =Nominal capacitance(μF )

V =Rated Voltage(VDC)

Dissipation Factor

Rated voltage(VDC)

6.3

10

16

25

35

50

( TANδ)

TANδ(Max)

0.22

0.19

0.16

0.14

0.12

0.10

( at 20℃,120Hz )

※ When the Capacitance exceeds 1,000μF, 0.02 shall be added every 1,000μF increase.

Temperature Characteristics

Z(-25 ℃) / Z(20℃)

2

(Max.Impedance ratio)

Z(-40 ℃) / Z(20℃)

3

(at 120Hz)

The following specifications shall be satisfied when the capacitors are restored to 20℃ after the rated

voltage is applied with the rated ripple current at 105℃ for the following test time.

Load Life

Capacitance change :≤± 30% the of initial Value (6.3 ~ 10VDC)

Capacitance change :≤± 25% the of initial Value(16 ~ 50VDC)

TANδ

:≤200% of the initial specified value

Leakage current

:≤ The initial specified value

Case Size (ΦD)

Φ5, 6.3

Φ8

Φ10 ~

Life Time

6,000 hours

8,000 hours

10,000 hours

The following specifications shall be satisfied when the capacitors are restored to 20℃ after exposing

them for 1000 hours at 105℃ without voltage applied.The rated voltage shall be applied to the capacitor

for a minimum of 30 minutes,at least 24 hours and not more than 48 hours before the measurements.

Shelf Life

Capacitance change :≤± 30% of the initial Value(6.3 ~ 10VDC)

Capacitance change :≤± 25% of the initial Value(16 ~ 50VDC)

Others

TANδ

:≤200% of the initial specified value

Leakage current

:≤The initial specified value

Satisfies characteristic W of KS C 6421

A.DIAGRAM OF DIMENSION

B.MARKING:WITH YELLOW SLEEVE, BLACK INK

4MIN

F±0.5

15MIN

ΦD

-

NXH

+

VINYL SLEEVE

SAFETY VENT(≥6.3φ)

Φd

≤10

105℃

25V 1500μF

≥12.5

FRONT VIEW OF CAPACITOR

LOT NO.

ΦD'

L'

L

BACK VIEW OF CAPACITOR

When ΦD≤8,ΦD'≤ΦD+0.5,and L'≤L+1.5

When ΦD>8,ΦD'≤ΦD+0.5,and L'≤L+2.0

ΦD

Φd

F

5

0.5

2.0

6.3

0.5

2.5

8

0.6

3.5

10

0.6

5.0

12.5

0.6

5.0

16

0.8

7.5

18

0.8

7.5

←

李波

←

←

立范

波

SamYoung Electronics Co., Ltd.

阿吕

勇

�PAGE

ALUMINUM ELECTROLYTIC CAPACITOR

2 OF 6

APPROVAL NO:

296-028

RATINGS OF NXH Series

6.3

VDC

10

16

CAP.(μF)

IMP.

RIPPLE

CAP.(μF)

IMP.

RIPPLE

CAP.(μF)

IMP.

RIPPLE

5×11

220

0.22

345

150

0.22

345

100

0.22

345

5×15

470

0.13

480

330

0.13

480

220

0.13

480

6.3×11

470

0.094

540

330

0.094

540

220

0.094

540

6.3×15

560

0.084

620

470

0.084

620

330

0.084

620

8×11.5

820

0.056

945

680

0.056

945

470

0.056

945

8×15

1200

0.045

1250

1000

0.045

1250

680

0.045

1250

ΦD×L

8×20

1500

0.029

1500

1500

0.029

1500

1000

0.029

1500

10×12.5

1200

0.039

1330

1000

0.039

1330

680

0.039

1330

10×16

1800

0.028

1760

1500

0.028

1760

1000

0.028

1760

10×20

2200

0.020

1960

1800

0.020

1960

1500

0.020

1960

10×25

2700

0.018

2250

2200

0.018

2250

1800

0.018

2250

10×33

3300

0.015

2550

2700

0.015

2550

2200

0.015

2550

12.5×20

3900

0.017

2480

3300

0.017

2480

2200

0.017

2480

12.5×25

4700

0.015

2900

3900

0.015

2900

2700

0.015

2900

12.5×30

5600

0.013

3450

4700

0.013

3450

3300

0.013

3450

12.5×35

6800

0.012

3570

5600

0.012

3570

3900

0.012

3570

16×20

6800

0.015

3250

4700

0.015

3250

3300

0.015

3250

16×25

8200

0.013

3630

6800

0.013

3630

4700

0.013

3630

18×25

10000

0.012

3650

8200

0.012

3650

5600

0.012

3650

CAP.(μF)

IMP.

RIPPLE

CAP.(μF)

IMP.

RIPPLE

CAP.(μF)

IMP.

RIPPLE

33

0.3

250

2.2

2.5

120

4.7

2.5

120

10

1.0

145

22

0.40

195

27

0.34

238

0.16

350

ΦD×L

5×11

35

25

VDC

68

0.22

345

47

0.22

50

345

5×15

150

0.13

480

100

0.13

480

56

33

0.20

320

6.3×11

100

0.094

540

100

0.094

540

47

0.14

450

150

0.094

540

56

0.14

450

6.3×15

220

0.084

620

150

0.084

620

100

0.12

586

68

0.10

646

330

0.056

945

220

0.056

945

100

0.074

724

390

0.045

1250

270

0.045

1250

120

0.061

950

470

0.045

1330

390

0.029

1500

560

0.029

1500

470

0.029

1600

180

0.046

1190

470

0.039

1330

330

0.039

1330

150

0.061

979

680

0.028

1760

470

0.028

1760

220

0.042

1370

330

0.042

1370

820

0.020

1960

560

0.020

1960

270

0.030

1580

8×11.5

8×15

8×20

10×12.5

10×16

10×20

1000

0.020

1960

680

0.025

1850

10×25

1000

0.018

2250

680

0.018

2250

330

0.028

1870

10×33

1200

0.015

2550

1000

0.015

2550

470

0.025

2110

1000

0.018

2500

1000

0.017

2480

470

0.027

2050

1500

0.017

2550

12.5×25

1800

0.015

2900

1200

0.015

2900

560

0.023

2410

12.5×30

2200

0.013

3450

1500

0.013

3450

680

0.021

2860

12.5×35

2700

0.012

3570

1800

0.012

3570

820

0.019

2960

2200

0.015

3250

1500

0.015

3250

820

0.023

2730

2700

0.015

3250

1000

0.023

2730

16×25

3300

0.013

3630

18×25

3900

0.012

3650

12.5×20

16×20

2200

0.013

3630

1000

0.021

3010

2700

0.012

3650

1500

0.019

3290

Permissible Ripple Current (mArms / 105℃,100KHz)

Immpedance (Ω max. / 20℃, 100KHz)

Nominal Capacitance (μF)

SamYoung Electronics Co., Ltd.

�PAGE:

3 OF 6

APPROVAL NO.

ALUMINUM ELECTROLYTIC CAPACITORS

296-028

STRUCTURE AND MATERIALS

LEAD WIRE

PACKING PAD

LEAD WIRE

AL LEAD

AL FOIL ( - )

AL LEAD

AL FOIL ( + )

SLEEVE

AL CASE

ADHESIVE TAPE

ELEMENT

SEPARATOR

CE04 TYPE

*MINIATURE SIZED TYPE CAPACITORS COMPONENT

PART NAME

LEAD WIRE

AL LEAD

MATERIALS

TINNED COPPER - PLY WIRE(Pb-FREE)

ALUMINUM 99.92 % OVER

VENDER

KISTRON

JIANG SU HONG YANG

(CHINA)

NAN TONG HUI FENG

(CHINA)

JIANG SU HONG YANG

(CHINA)

SUNG NAM

SYNTHETIC RUBBER OR BAKE PAD

(CHINA)

KANG WON AUTO FITTING

KISTRON

PACKING PAD

(KOREA)

ZHE JIANG TIAN TAI

(KOREA)

(KOREA/CHINA)

(CHINA)

ZHE JIANG TIAN HUA

SLEEVE

P.E.T(Poly Ethlylene Terephthalate Resin)

MOO DEUNG

YUN LIN PLASTIC

ZHANG JIA GANG LIAN YI

AL CASE

ALUMINUM 99.0 % OVER

LIN AN AO XING

D.N TECH

AL FOIL

AL FOIL

SEPARATOR

FORMED ALUMINUM 99.9 % OVER

ETCHED ALUMINUM 98.0 % OVER

INSULATION PAPER

ADHESIVE TAPE POLY PROPYLENE FILM

(KOREA/CHINA)

(CHINA)

(CHINA)

(CHINA)

(KOREA/CHINA)

K.D.K

(JAPAN)

SAM YOUNG

(KOREA)

HUAFENG / HISTAR / HAIYI

(CHINA)

K-JCC

(KOREA)

WU JIANG FEILO

(CHINA)

K.D.K

(JAPAN)

ELECON

(CHINA)

KAN

(CHINA)

N.K.K

(JAPAN)

DAI IL

(KOREA)

SamYoung Electronics Co., Ltd.

�PAGE : 4 OF 6

ALUMINNUM ELECTROLYTIC CAPACITOR

APPROVAL NO.

296-028

Taping Dimensions:5.0mm T/P (8.0Φ*11.5L)

P

P2

Δh

ΦD

A

H1

Adhesive Tape

Base Tape

F

1.0Max

W0

W

L

W1

W2

H0

Φd

H

P1

t

D0

P0

Items

ΦD

A

Φd

P

P0

Dimensions

8

13.0 Max

0.6

12.7

12.7

Tolerance

±0.5

±0.05

±1.0

±0.2

Cumulative pitch error : 1mm/20pitch

P1

3.85

±0.7

To be measured at bottom of clinch

P2

6.35

±1.0

F

5.0

+0.8

-0.2

△h

W

W0

0

18.0

±2.0

±0.5

10Min

-

W1

9.0

±0.5

W2

H

H0

H1

1.5 Max

18.5

16.0

±0.75

±0.5

H+A

-

D0

t

L

4.0

0.7

11.0Max

±0.2

±0.2

-

Remarks

Not to protrude over base tape

check insertion machine specs

SamYoung Electronics Co., Ltd.

�PAGE

5 OF 6

When using aluminum electrolytic capacitors,pay strict attention to the following:

1. Electrolytic capacitors for DC application require polarization.

Confirm the polarity.If used in reversed polarity,the circuit life may be shortened or the capacitor may be damaged.For

use on circuits whose polarity is occasionally reversed,or whose polarity is unknown,use bi-polarized capacitors (BPseries).Also,note that the electrolytic capacitor cannot be used for AC application.

2. Do not apply a voltage exceeding the capacitor`s voltage rating.

If a voltage execeeding the capacitor`s voltage rating is applied,the capacitor may be damaged as leakage current increases. When using the capacitor with AC voltage superimposed on DC voltage,care must be exercised that the peak

value of AC voltage does not exceed the rated voltage.

3. Do not allow excessive ripple current to pass.

Use the electrolytic capacitor at current values within the permissible ripple range.If the ripple current exceeds the specified value,request capacitors for high ripple current applications.

4. Ascertain the operating temperature range.

Use the electrolytic capacitors according to the specified operating temperature range.Usage at room temperature will

ensure longer life.

5. The electrolytic capacitor is not suitable for circuits in which charge and discharge are frequently repeated.

If used in circuits in which charge and discharge are frequently repeated,the capacitance value may drop,or the capacitor may be damaged.Please consult our engineering department for assistance in these applications.

6. Apply voltage treatment to the electrolytic capacitor which has been allowed to stand for a long time.

If the electrolytic capacitor is allowed to stand for a long time,its withstand voltage is liable to drop,resulting in increased leakage current.If the rated voltage is applied to such a product,a large leakage current occurs and this generates

internal heat,which damaged the capacitor.If the electrolytic capacitor is allowed to stand for a long time,therefore,use

it after giving voltage treatment (Note 1).(However,no voltage treatment is required if the electrolytic capacitor is allowed to stand for less than 2 or 3 years at normal temperature.)

7. Be careful of temperature and time when soldering.

When soldering a printed circuit board with various,components,care must be taken that the soldering temperature is

not too high and that the dipping time is not too long.Otherwise,there will be adverse effects on the electrical characteristics and insulation sleeve of electrolytic capacitors in the case of small-sized electrolytic capacitors,nothing abnormal will occur if dipping is performed at less than 260℃ for less than 10 seconds.

8. Do not place a soldering iron on the body of the capacitor.

The electrolytic capacitor is covered with a vinyl sleeve.If the soldering iron comes in contact with the electrolytic capacitor body during wiring,damage to the vinyl sleeve and/or case may result in defective insulation,or improper protection of the capacitor element.

9. Cleaning circuit boards after soldering.

Some solvents have adverse effects on capacitors.

Please refer to the next page.

10.Do not apply excessive force to the lead wires or terminals.

If excessive force is applied to the lead wires and terminals,they may be broken or their connections with the internal

elements may be affectde.(For strength of terminals,refer to KS C6035 KS C6421(JIS C5102,JIS C5141)

11.Care should be used in selecting a storage area.

If electrolytic capacitors are exposed to high temperatures caused by such things as direct sunlight,the life of the capacitor may be adversely affected.Storage in a high humidity atmosphere may affect the solderability of lead wires and

terminals.

12.Surge voltage.

The surge voltage rating is the maximum DC over-voltage to which the capacitor may be subjected for short periods not exceeding approximately 30 seconds at infrequent intervals of not more than six minutes.According to KS C6421,the test shall be conducted 1000 cycles at room temperature for the capacitors of characteristic W of KS C6421 or at the maximum operating temperature for the capacitors of characteristics B and C of KS C6421 with voltage applied through a series resistance of 1000 ohms without discharge.The electrical characteristics of the capacitor after the test

are specified in KS C6421.Unless otherwise specified,the rated surge voltage are as follows:

Rated Voltage(V)

2

4 6.3 10 16 25 35 50 63 80 100 160 200 250 315 350 400 450 500

Rated Surge Voltage(V) 2.5 5

8

13 20 32 44 63 79 100 125 200 250 300 365 400 450 500 550

Note 1 Voltage treatment … Voltage treatment shall be performed by increasing voltage up to the capacitor`s voltage rating gradually while lowering the leakage current.In this case,the impressed voltage shall be in the range where the leakage current of the electrolytic capacitor is less than specified value.Meanwhile,the voltage treatment time

may be effectively shortened if the ambient temperature is increased (within the operating temperature range).

Note 2 For methods of testing, refer to KS C 6035, KS C 6421,(JIS C 5102,JIS C 5141)

SamYoung Electronics Co., Ltd.

�PAGE 6 OF 6

CLEANING CONDITIONS

Aluminum electrolytic capacitors that have been exposed to halogenated hydrocarbon cleaning and defluxing solvents

are susceptible to attack by these solvents.This exposure can result in solvent penetration into the capacitors, leading

to internal corrosion and potential failure. Therefore, for ordinary capacitors, the cleaning materials of alcohol system

had to be used. However, the solvent proof type capacitors of Samyoung Elec. Can withstand cleaning by some

halogenated solvents shown:

(rated voltage≤100 VDC only)

* FREON TE R OR TES R

Cleaning method: One of immersion, ultrasonic or vap or cleaning.

Maximum cleaning time: 5 minutes(where, KRE,SRM is 2 minutes)

* 1,1,1-Trichlorethane

Cleaning method: immersion cleaning at the normal temperature

Maximum cleaning time: 5 minutes(where, KRE,SRM is not assured)

— Caution —

* When the lead space of the capacitor is different from the hole space of the PC board to be mounted ,

use the lead forming type capacitor to prevent stress on seal.

* Consult for flux to be used and other cleaning conditions.

(Freon TE and TES are registered trademarks of Dupont,Inc.)

* lnfluence of cleaning solvent for aluminum electrolytic capacitor.

Aluminum electrolytic capacitors are easily affeceted by halogen ions,particularly by chloride ions.

Excessive amounts of halogen ions,if happened to enter the inside of the capacitors, will give corrosion

accidents-rapid capacitance drop and vent open. The extent of corrosion accidents varies with kinds of

electrolytes and seal-materials. Therefore, the prevention of halogen ion contamination is the most

improtant check point for quality control in our procuction lines. At present, halogenated hydrocarboncontained organic solvents such as Trichloroethylene, 1,1,1-Trichloroethane, and Freon are used to

remove flux from circuit boards. However, if general types of aluminum electroytic capacitors,whose

seal constructions are not solvent-proof, are cleaned with such solvents, the solvents may gradually

penetrate the seal portion and erode. The inside of the capacitors.

The mechanism of corrosion of aluminum electrolytic capacitors by halogen ions can be explained

as follows:

Halides(RX) are absorbed and diffused into the seal portion. The halides then enter the inside of the

capacitors and contact with the electrolyte of the capacitors. Where by halogen ions are made free by

a hydrolysis with water in the electrolyte:

+

RX + H2O → ROH + H + X

-

The halogen ions (X ) react with the dielectric substance(Al 2O3) of aluminum electrolytic capacitors:

AI2O3 + 6H+ + 6X- →2ALX3 + 3H2O

AIX3 is dissociated with water:

+

ALX3 + 3H2O → AL(OH)3 + 3H + 3X

SamYoung Electronics Co., Ltd.

�